How can aerospace and defense engineers improve productivity? The aerospace and defense industry continues to develop some of the world’s most complex products while adhering to stringent regulations and rigorous certification standards. Moreover, technological advancements have created exciting opportunities for innovation, such as greater sustainability and automation. However, this also drives requirements for even more…

- Executive Summary

- Product Development is Critical to Business Strategies

- The Time Wasters

- Implications of Time Wasters to the Business

- A Solution to Avoid Time Wasters

- Business Value from PLM

- Extending PLM Use Results in Greater Satisfaction

- How Companies Implement PLM

- Additional Values Due to the Cloud

- Conclusions

- Recommendations

- About the Research

- Acknowledgments

Executive Summary

Engineers Impact Business Success

Success at aerospace and defense companies relies on exceptional engineering. Engineers are crucial to ensuring integrated systems function as intended and will pass certification. Their design decisions directly impact sustainability goals, cost targets, and regulatory and safety requirements. Therefore, empowering engineers is key to the successful execution of business strategies.

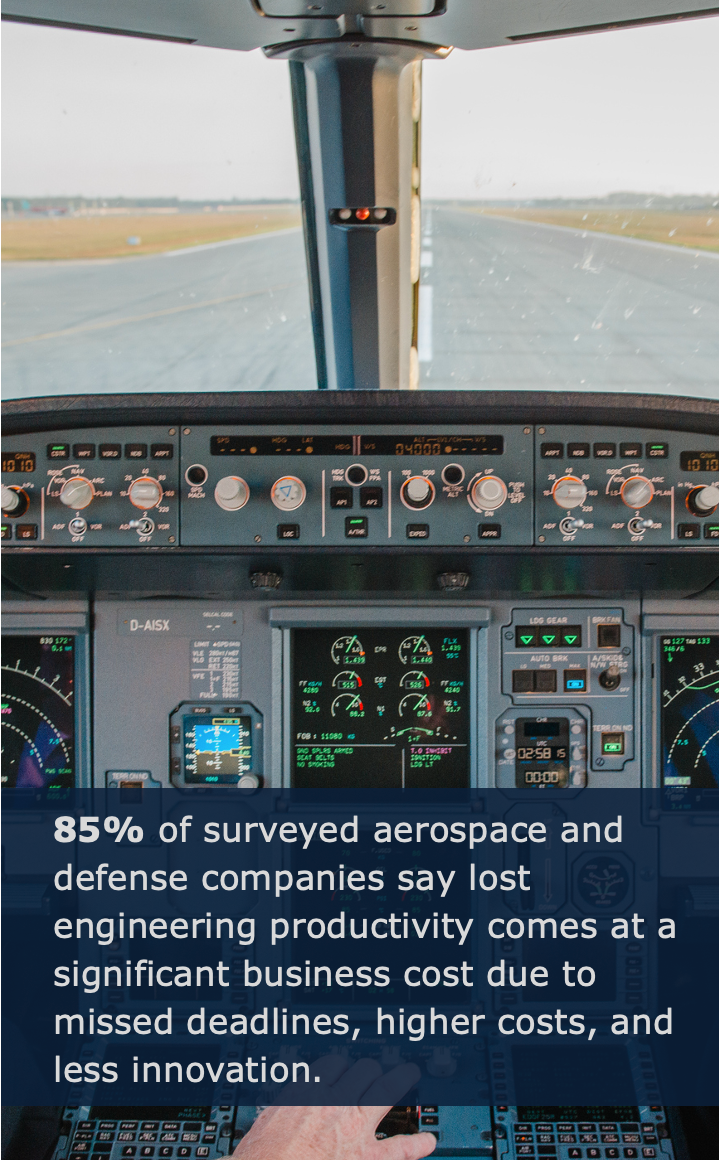

Too Many Time Wasters

Unfortunately, engineers report spending too much time on non-value-added work with too many interruptions, taking them away from critical innovation work. Furthermore, 85% of surveyed aerospace and defense companies say this loss in engineering productivity comes at a significant business cost due to missed deadlines, higher costs, less innovation, and poor quality. One way to overcome productivity losses is to manage product data better and make it accessible to those who need it, when they need it.

Reclaiming Wasted Time

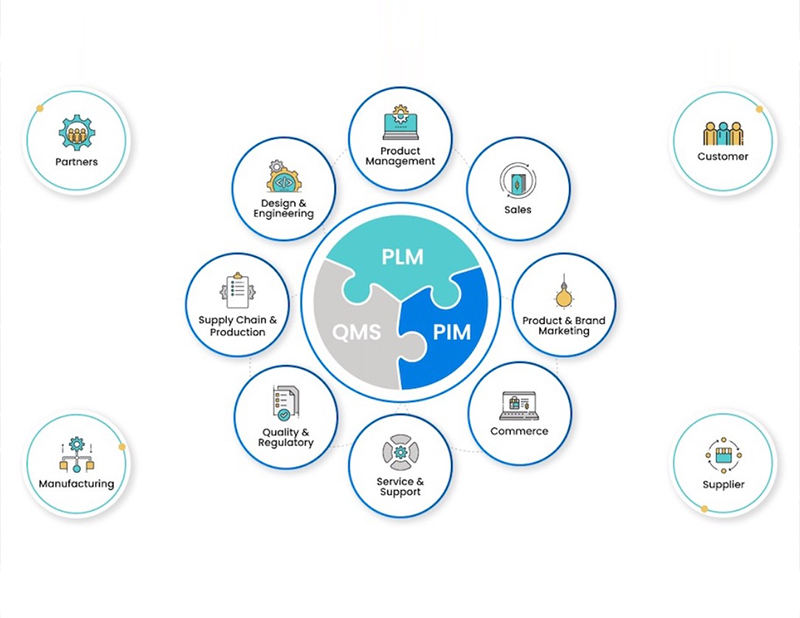

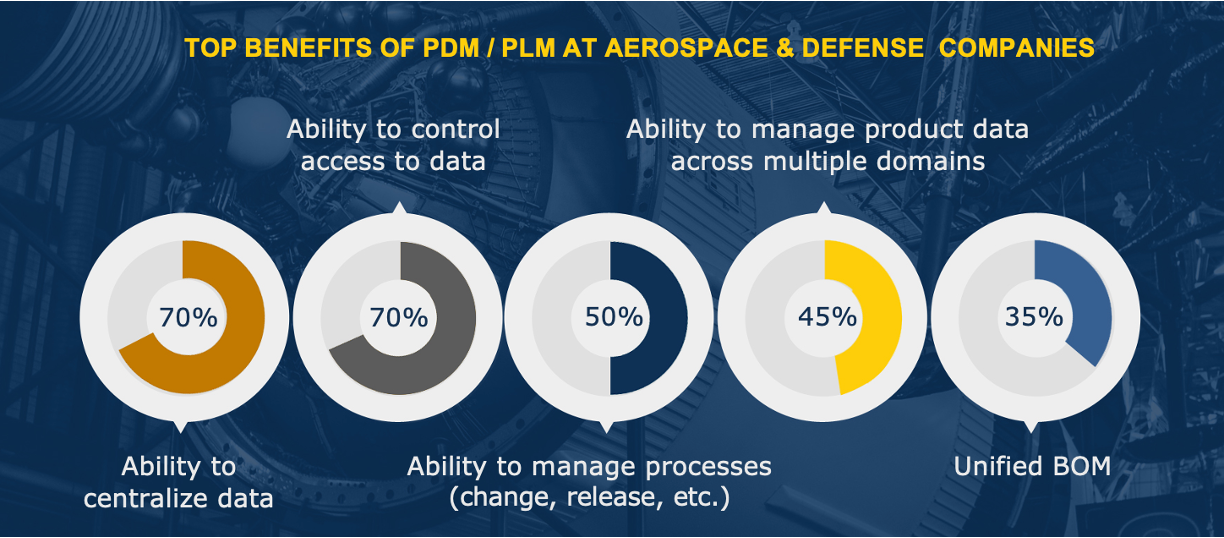

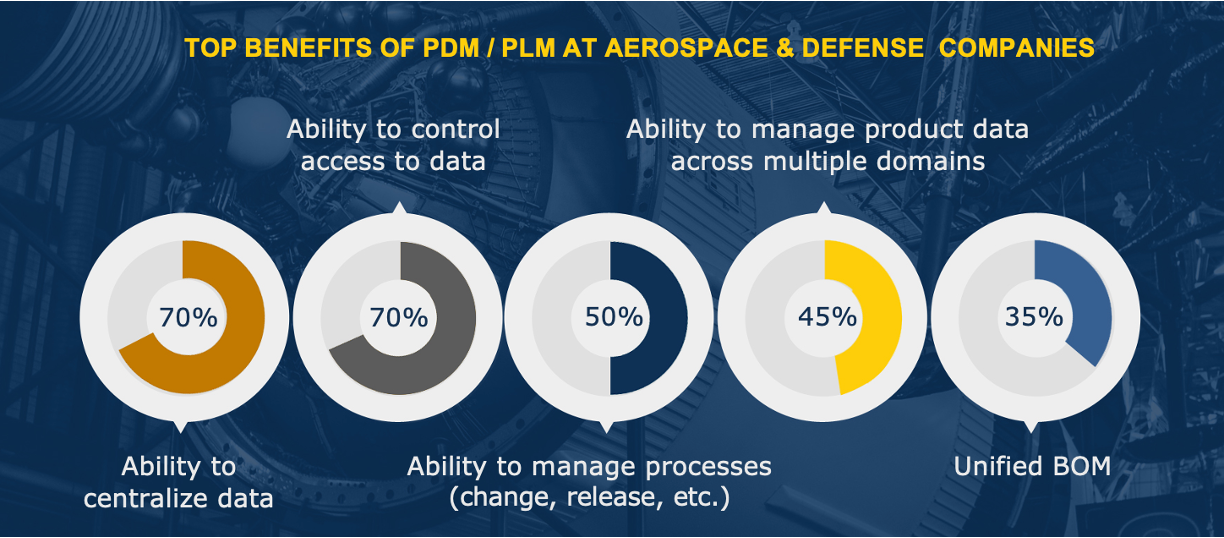

This report identifies substantial engineering time wasters in the aerospace and defense industry. It explores how companies of all sizes, including OEMs and suppliers, reclaim lost time by examining the use and value of PLM (Product Lifecycle Management) solutions to centralize data across multiple domains, manage processes, and collaborate better. Incidentally, PLM users reported fewer changes due to outdated information and errors, significantly reducing non-value-added work and shortening development times. This report also examines how companies select and use PLM solutions, including cloud-based implementations.

Engineers Impact Business Success

Success at aerospace and defense companies relies on exceptional engineering. Engineers are crucial to ensuring integrated systems function as intended and will pass certification. Their design decisions directly impact sustainability goals, cost targets, and regulatory and safety requirements. Therefore, empowering engineers is key to the successful execution of business strategies.

Too Many Time Wasters

Unfortunately, engineers report spending too much time on non-value-added work with too many interruptions, taking them away from critical innovation work. Furthermore, 85% of surveyed aerospace and defense companies say this loss in engineering productivity comes at a significant business cost due to missed deadlines, higher costs, less innovation, and poor quality. One way to overcome productivity losses is to manage product data better and make it accessible to those who need it, when they need it.

Reclaiming Wasted Time

This report identifies substantial engineering time wasters in the aerospace and defense industry. It explores how companies of all sizes, including OEMs and suppliers, reclaim lost time by examining the use and value of PLM (Product Lifecycle Management) solutions to centralize data across multiple domains, manage processes, and collaborate better. Incidentally, PLM users reported fewer changes due to outdated information and errors, significantly reducing non-value-added work and shortening development times. This report also examines how companies select and use PLM solutions, including cloud-based implementations.

The Time Wasters

What Slows Engineers Down? The graph identifies the top engineering time wasters aerospace and defense companies face. The findings highlight how much they waste on non-value-added work. Consequently, they need better ways to automate tedious tasks, especially those associated with compliance documentation, so they can focus more energy on adding value. Another top-ranking time waster, too many manual processes/ bottlenecks, emphasizes this further. Interruptions Similarly, constant interruptions to answer questions, share data, and provide updates also slow engineers down. These interruptions break an engineer's train of thought and distract them from their work. Yet, engineers still need convenient ways to easily exchange data with suppliers, OEMs, and engineers across domains to prevent working with outdated data. Limited Reuse Interconnected systems of mechanical components, electronics, and software are incredibly complex. If engineers can leverage compliant, proven, and tested subsystems and components, they will save time, reduce the risk of errors, and spend less effort on new certifications. However, the number of components across multiple engineering domains and suppliers makes it very difficult to find needed data, and searching for it wastes valuable time. To avoid these issues, engineers need suitable methods for finding what they need. Lack of Traceability Changes to complex, interconnected systems can require significant effort without easy methods for identifying the change's impacts. Traceability makes this possible. Traceability also makes compliance management significantly easier. It makes it possible to determine what's been verified and tested to meet regulatory and safety requirements. Then when tests fail, you can quickly identify what's impacted by the failure. Consequently, traceability can significantly reduce the manual burden of certification. Unfortunately, the manual document-driven processes common at aerospace and defense companies substantially limit traceability. Conclusions

Conclusions

Reclaiming Lost Time

Aerospace and defense companies prioritize their future growth and sustained success on winning in the marketplace with better, differentiated offerings. To support this, they can significantly boost their product development capabilities by eliminating time wasters that consume engineers' valuable time.

Aerospace and defense manufacturers find that PLM can empower their engineers to innovate by significantly reducing engineers' time on non-value-added tasks. As a result, they can enjoy a competitive advantage. In addition, technological advances, such as cloud-based offerings, can reduce implementation time, cost, and difficulty, making PLM more accessible.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Siemens (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Aerospace & Defense: Reducing Engineering Time Wasters

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aerospace-and-defense

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-13 11:39:57

[post_modified_gmt] => 2024-03-13 15:39:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=19954

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 19930

[post_author] => 2574

[post_date] => 2024-03-06 09:00:30

[post_date_gmt] => 2024-03-06 14:00:30

[post_content] =>  How can heavily regulated pharmaceutical and biotechnology manufacturers keep up with changes? By being flexible and paperless. Yet that’s not as easy as it may sound. Finding the appropriate manufacturing execution systems (MES) is a foundation for success.

This eBook outlines why being flexible and paperless are now imperative. It goes on to point out the challenges of doing either of those. It explains MES, and why it’s crucial in supporting pharmaceutical companies’ journey to being flexible and paperless. Finally, it points to some specific advanced capabilities that this industry requires from MES for success today and in the future.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

For related research, read our insight to find out if the next steps of IT/OT convergence are at hand, hear how life sciences manufacturers can accelerate their innovation in this recorded webinar, and read our eBook to find out what manufacturers need in MES to be competitive today and in the future.

How can heavily regulated pharmaceutical and biotechnology manufacturers keep up with changes? By being flexible and paperless. Yet that’s not as easy as it may sound. Finding the appropriate manufacturing execution systems (MES) is a foundation for success.

This eBook outlines why being flexible and paperless are now imperative. It goes on to point out the challenges of doing either of those. It explains MES, and why it’s crucial in supporting pharmaceutical companies’ journey to being flexible and paperless. Finally, it points to some specific advanced capabilities that this industry requires from MES for success today and in the future.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

For related research, read our insight to find out if the next steps of IT/OT convergence are at hand, hear how life sciences manufacturers can accelerate their innovation in this recorded webinar, and read our eBook to find out what manufacturers need in MES to be competitive today and in the future.

Table of Contents

- A Changing Life Sciences World

- Extreme Pressure on Production Operation

- The Flexibility Imperative

- Flexibility Challenges

- The Paperless Imperative

- Graphic: Paperless Benefits and Capabilities

- Challenges of Going Paperless

- MES or Manufacturing Operations Software

- MES Definition and Role

- How MES Addresses Flexibility Challenges

- How MES Enables Paperless

- Advanced MES Capabilities

- A Healthy BioPharma Future

The Need to be Flexible and Paperless

MES to Meet Pressures and Imperatives

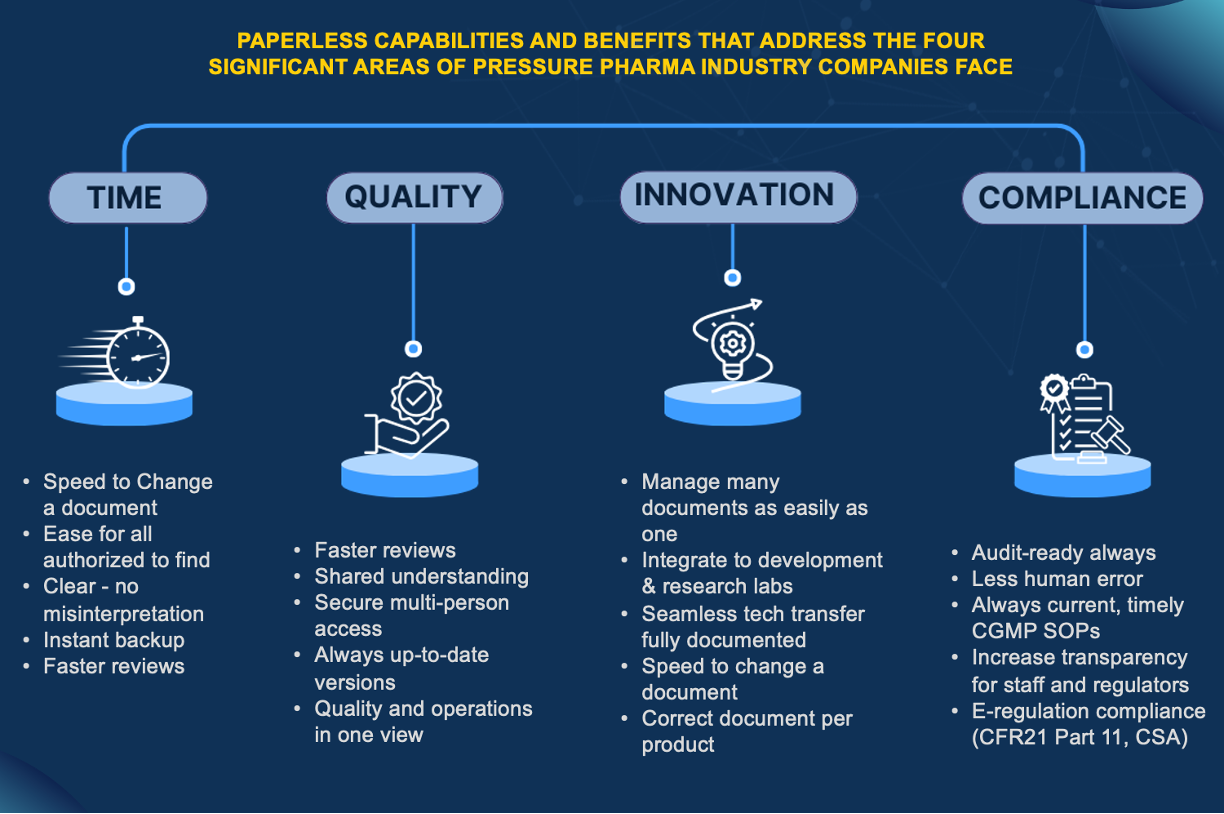

All companies in the pharmaceutical industry are under pressure for time, quality, compliance, and innovation. These pressures create imperatives to be both paperless and flexible to protect profitability. The stresses and imperatives apply to small-molecule pharmaceuticals, active ingredients (API), contract drug manufacturers (CDMOs), large-molecule biotechnology, and gene and cell therapy makers.

Fortunately, a manufacturing execution system (MES) proven in these pharmaceutical segments can support many aspects of these imperatives. By choosing MES wisely, such a system can support success now and into the future.

MES to Meet Pressures and Imperatives

All companies in the pharmaceutical industry are under pressure for time, quality, compliance, and innovation. These pressures create imperatives to be both paperless and flexible to protect profitability. The stresses and imperatives apply to small-molecule pharmaceuticals, active ingredients (API), contract drug manufacturers (CDMOs), large-molecule biotechnology, and gene and cell therapy makers.

Fortunately, a manufacturing execution system (MES) proven in these pharmaceutical segments can support many aspects of these imperatives. By choosing MES wisely, such a system can support success now and into the future.

Extreme Pressure on Production Operations

Pressures Mount The pharmaceutical industry was once high-margin and relatively safe and consistent. However, more competition and new situations mean challenges from many angles. Four pressures are at the forefront: time, quality, compliance, and innovation. Time Time pressure is a multifaceted pressure—Time-to-market for new or smaller population therapies and time-to-deliver existing products to customers and patients who need them. Quality Patient safety and efficacy depend on end-to-end quality. This is not new, but the number of sites and companies involved often is. Compliance Regulators expect more from pharmaceutical manufacturers every year. Now, these expectations include digital approaches to speed the process and minimize chances for error. Innovation To succeed, companies are building a broad portfolio of products for multiple markets with specific regulations and needs. The innovation is often in related therapeutic areas to build strength in revenues and reputation. Beyond Tradeoffs Companies must seek no longer only tradeoffs between time, quality, compliance, and innovation. Pharmaceutical companies that pursue becoming flexible and paperless are on a path to enable all four simultaneously.“We have a program for digital transformation in manufacturing particularly, also in Quality and other areas. The key is implementation of eBR.” Nina Mikadze, Digital Transformation Leader, PHARMA INDUSTRY

How MES Addresses Flexibility Challenges

MES with eBR Design eBR design capabilities can ensure any need is pre-designed for operations. Having designs that support a variety of possibilities means that the MES workflow can handle a higher mix rapidly and confidently. This up-front, behind-the-scenes work streamlines activities for those in production. People can handle the increased mix of flexible manufacturing much more confidently and with higher assurance. Multi-product Design Space Regulators want more therapies to reach patients who need them, so they have created guidelines for validated processes to handle more than a single process or product in a process design space. Using MES, companies can seamlessly leverage the specs and recipes or bills of process for a wide variety of products. This risk-based approach and the new CSA guidance will help ensure that validated processes can be flexible. Auto-Document MES automatically documents everything that occurs. It can also error-proof processes for each specific product. So, no matter how many products are in play in a given shift, MES can ensure they are processed correctly and document the details of each unit’s processing, including CFR21 Part 11 compliant e-signatures. Assurance In pharma, implementing MES is a matter of setting it up for every product. This means pivoting to process correctly, document thoroughly, and ensure quality. As a result, you can be assured that human error is minimized. This also makes the process easy to audit. With MES, all this happens during the process; after-the-fact assurance efforts vanish. Accurate data is a given with MES. A Healthy BioPharma Future

A Healthy BioPharma Future

Imperatives to Change

Pharmaceutical companies of every stripe urgently need to modernize and move to paperless, flexible operations. Time, quality, compliance, and innovation pressures apply to pharmaceutical, biotech, cell and gene therapy, API, and other suppliers to the industry. Those who don’t yet have a commercial, modern MES to address them are likely to suffer in the face of competition that does.

Key Take-Aways

- In today’s world, all eight aspects of industrial competitiveness matter:7 agile, innovative, resilient, engaging, responsive, insightful, sustainable, and improving.

- MES is a foundation for flexible and paperless operations and quality.

- Ensure you get modern and pharma-experienced MES to provide eBR and beyond.

- Evaluate your business strategy and match your focus for production software to meet both short-term and long-term needs for flexibility.

- Educate everyone on the value of paper-free documentation and provide training and systems that make it natural.

- Ensure the MES has advanced capabilities and works with newer technologies that can deliver value. According to Deloitte research, most pharma companies have used the cloud, wearables, and AR/VR already.8

- Make the move to MES positive for the workers using it – by selecting the right software, educating them up front, and setting it up to support and empower them.

- Set a strategy to digitalize your company and ecosystem and keep at it.

How can manufacturers meet growing sustainability demands without compromising manufacturing performance, quality, and availability? How does a data-driven, systematic approach leveraging the digital thread in PLM allow them to operationalize sustainability to meet ESG demands?

Please enjoy the summary* below. For the full research, please visit our sponsor Aras (registration required).

How can manufacturers meet growing sustainability demands without compromising manufacturing performance, quality, and availability? How does a data-driven, systematic approach leveraging the digital thread in PLM allow them to operationalize sustainability to meet ESG demands?

Please enjoy the summary* below. For the full research, please visit our sponsor Aras (registration required).

Table of Contents

- Take a Systemic Approach

- 1) Develop Sustainability Requirements

- 2) Focus on Product Sustainability

- 3) Focus on Manufacturing Sustainability

- 4) Focus on Service and Operational Sustainability

- 5) Monitor, Track, and Report Sustainability Progress

- Conclusions / Call to Action

- Acknowledgments

It's Time to Operationalize Sustainability

Sustainability Dominates Business Strategies Sustainability is experiencing increased urgency in corporate strategies. Driven by regulation and customer demand, among other drivers, it is rapidly moving from a topic of discussion to a business imperative for manufacturers. Our 2022 survey on executive strategies saw the biggest inflection toward environmental, sustainability, and governance (ESG) action that we’ve seen. The percentage of companies that view environmental sustainability and corporate social responsibility as critical to long-term business success has grown by double digits.Take a Systemic Approach

Put Sustainability Strategy into Action Strategy without action doesn’t create results, however, and putting sustainability goals into action is a big challenge for manufacturers today. Manufacturers have difficulty approaching it because the problem is multi-faceted and they struggle to define their priorities. Should they focus on their own sustainability? Their suppliers’ ESG performance? The contents of their products? Or the impact their products have in use by customers? Then where should they start? Beyond defining goals, how will they support and measure the progress of their initiatives? Manufacturers need to address these questions in a systematic way and make hard tradeoffs to improve their sustainability – and their business. They need to take a systematic, data-driven approach to achieve their goals, leveraging and extending the data in the digital thread to operationalize sustainability. Focus Sustainability Efforts Sustainability is a complex topic. For example, greenhouse gas (GHG) emissions alone are typically broken down into three different “scopes” based on their source. And that’s only one aspect of sustainability.“CO2 is one thing, but not the only thing. We have a push for more circularity, how we get raw materials from the supply chain, and how to ensure the steel we get is sustainable.” – Technical Director, Fluid Transfer Systems Manufacturer.

In a similar way to the GHG scopes, there are many different facets to how manufacturers can improve their sustainability. They could focus on one or a combination of:

In a similar way to the GHG scopes, there are many different facets to how manufacturers can improve their sustainability. They could focus on one or a combination of:

- Their direct business (buildings, vehicles, etc.)

- The makeup / contents of their products including materials and the impact of their supply chain

- Their production, including energy, water, waste, consumables

- The impact of customers / users / operators using the product and how it affects their ESG goals

Jeff Stroh, Sr. Director Digital & Information Systems Management for McDermott International, explained the rationale for his business. “We are in a very carbon-intensive industry. We did a study of a liquid natural gas (LNG) facility on scopes 1,2, and 3. We found that the biggest impact we can have, even though we can do a lot different things, is in the first year our customer operates the plant.”That gives them a focus area to improve that will make a tangible difference. Take a Systems View First, manufacturers need to instill a company culture that rewards sustainability. Then, it can take a systems view to navigate the complexity, interrelationships, and tradeoffs required to make meaningful sustainability improvements. They must take into account all of the demands they face, both internal and external, and identify where they can couple doing the right thing with tangible business benefits like cost reduction. At that point, they can set requirements and goals for each. With that, they can take a holistic view to understand how potential actions will impact the targets and other implications they may have across the business so they can evaluate tradeoffs. Then, companies must monitor and track the plans across the business to fulfill the requirements and achieve their sustainability goals. This eBook shares five different ways manufacturers can improve ESG by taking a systems engineering approach.

Conclusions / Call to Action

Get Started Sustainability is being driven by customers and regulations and is quickly becoming a high priority in corporate agendas. And, it is just good business.According to Jeff Stroh of McDermott, “ESG is increasingly becoming a pre-requisite for bid eligibility, with more customers screening contractors such as McDermott for ESG criteria.”Manufacturers need to develop a culture that values sustainability across the enterprise. Then, they should take a holistic, systems approach, setting specific sustainability goals, breaking their strategic plans down into achievable systems requirements, and defining associated measurements and responsibilities. Support the Effort Driving sustainability improvements requires a systems-level approach. It requires manufacturers to move from a document-driven to a data-driven approach, leveraging robust digital threads and digital twins that incorporate data from a variety of sources. The data gathering, collaboration, and decision-making tools to drive new levels of sustainability – whether they focus on products, manufacturing, or operations – must be both comprehensive and agile. There is no “killer app” for sustainability, it requires an integrated ecosystem of collaborators, internal data, external databases, enterprise solutions, and tools throughout the product lifecycle. For example, solutions like LCA can be helpful, but they are often employed too late. Leverage PLM for Sustainability

Data is the primary foundation for sustainability. Data must be digital, accessible, unified, and centralized. Manufacturers must know their business goals and their product, including cohesive, trusted digital threads and digital twins by variant and configuration. This information must be put into the hands of designers and other decision-makers early to provide decision support, support simulation, and manage tradeoffs so designers can understand the impacts of their decisions at local and holistic levels.

It’s time to take a systematic, data-driven approach and operationalize sustainability to drive strategic ESG improvements. Although there is no single solution for sustainability, the right PLM solution is essential to support this approach. PLM provides crucial product data and integration with design tools where decisions are made. It allows companies to optimize, validate, implement, and trace sustainability decisions using core systems engineering, requirements management, lifecycle management, change control, supplier collaboration, and configuration management capabilities. The PLM solution will need to be open and flexible, however, to go beyond these core capabilities to manage new sustainability data and ESG-related processes and reporting. An open, flexible PLM solution, along with the right company culture and strategy, can help manufacturers reach their sustainability objectives and build a foundation for future improvements.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Aras (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Operationalize Sustainability with the Digital Thread

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => operationalize-sustainability-2

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-05 14:19:13

[post_modified_gmt] => 2024-03-05 19:19:13

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=19901

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 19856

[post_author] => 2574

[post_date] => 2024-02-13 11:51:27

[post_date_gmt] => 2024-02-13 16:51:27

[post_content] =>

Data is the primary foundation for sustainability. Data must be digital, accessible, unified, and centralized. Manufacturers must know their business goals and their product, including cohesive, trusted digital threads and digital twins by variant and configuration. This information must be put into the hands of designers and other decision-makers early to provide decision support, support simulation, and manage tradeoffs so designers can understand the impacts of their decisions at local and holistic levels.

It’s time to take a systematic, data-driven approach and operationalize sustainability to drive strategic ESG improvements. Although there is no single solution for sustainability, the right PLM solution is essential to support this approach. PLM provides crucial product data and integration with design tools where decisions are made. It allows companies to optimize, validate, implement, and trace sustainability decisions using core systems engineering, requirements management, lifecycle management, change control, supplier collaboration, and configuration management capabilities. The PLM solution will need to be open and flexible, however, to go beyond these core capabilities to manage new sustainability data and ESG-related processes and reporting. An open, flexible PLM solution, along with the right company culture and strategy, can help manufacturers reach their sustainability objectives and build a foundation for future improvements.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Aras (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Operationalize Sustainability with the Digital Thread

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => operationalize-sustainability-2

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-05 14:19:13

[post_modified_gmt] => 2024-03-05 19:19:13

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=19901

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 19856

[post_author] => 2574

[post_date] => 2024-02-13 11:51:27

[post_date_gmt] => 2024-02-13 16:51:27

[post_content] =>  In this time of uncertainty and new technologies, is it time to re-evaluate how we explore and fine-tune our supply chain forecasts, schedules, and plans? For decades, optimization and what-if planning have been in place in manufacturing supply chains. We’ll discuss new possible approaches and what we have seen working.

In this time of uncertainty and new technologies, is it time to re-evaluate how we explore and fine-tune our supply chain forecasts, schedules, and plans? For decades, optimization and what-if planning have been in place in manufacturing supply chains. We’ll discuss new possible approaches and what we have seen working.

- Are traditional algorithmic and simulation approaches to optimization still working with the current volatility and uncertainty?

- Have you used digital twins for your supply chain? How is that working?

- Are you optimizing at all levels: strategic, tactical, and operational? Are some more effective than others? Are there barriers?

- Are machine learning and related advanced analytics helping with optimization?

- Do you see a role for Generative AI or other new approaches?

- Beyond technologies, are there new processes, and mindsets needed for optimization and scenario planning?

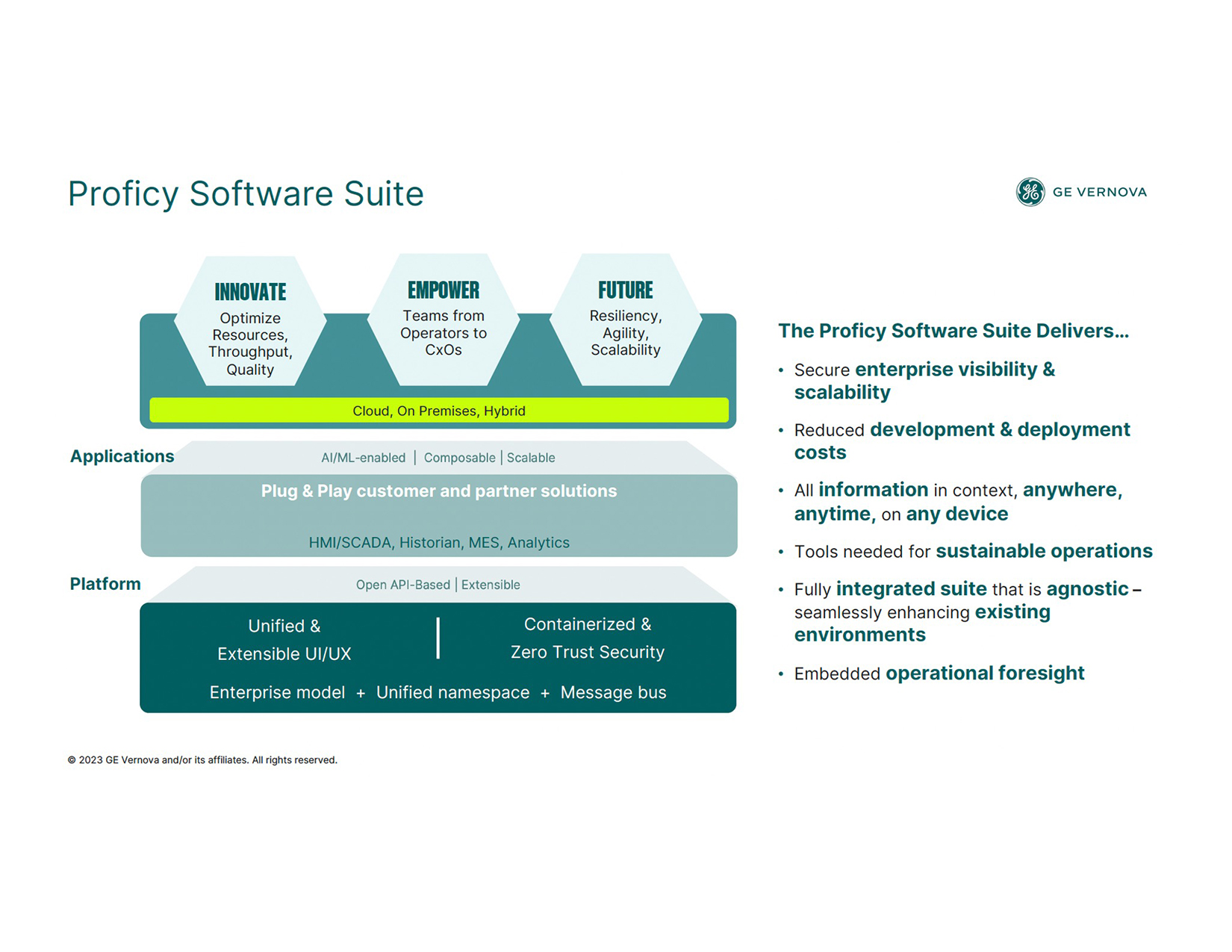

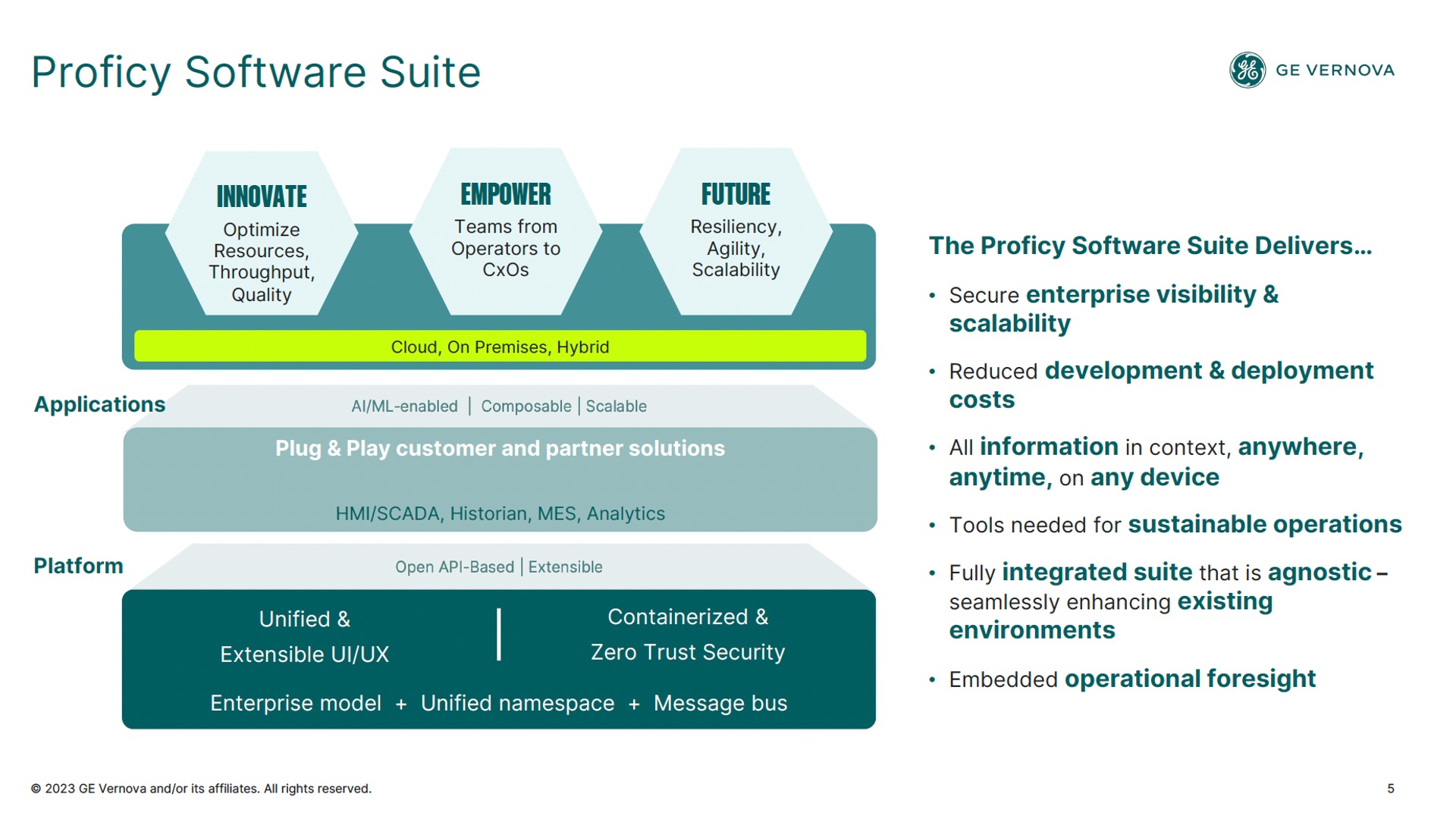

Making plant floor software more straightforward to use, rollout, maintain, and sustain is a worthy endeavor. The fourth annual release of the GE Digital Proficy portfolio as an integrated release was packed! Updates range from expanding industry fit to architecture for enterprise rollout, cloud everywhere, composability, consistency for connected workers, sustainability functionality, and pre-built analytics for common needs.

Jim Brown and Julie Fraser had a chance to catch up with the GE Digital product management team for a preview of the Proficy 2024 unified launch. Unified is a relatively new capability for Proficy, with cloud or hybrid hosting, a common user experience (UX), and common administration. That’s rare, since this suite includes not only comprehensive MES and plant applications, but also historian, automation software and Sustainability software.

Some of the highlights are:

Coherent, flexible architecture: Historian and MES are entirely rewritten to be containerized on the same unified namespace (UNS). Other components of this model are a data model, support for a range of databusses including MQTT, OPS-UA and more, and a directory service. We see this as a solid approach for the software to stay useful at enterprise scale over the long term.

Connected worker consistency: IT are not the only ones with new capabilities. Operations Hub supports operators, supervisors, technicians, and other connected workers. It lets the customers compose applications as they wish behind a single UI. Applications from HMI, dashboards, engineering analytics, and MES all use containers and Operations Hub to appear in a consistent way. It aims to work even beyond the Proficy suite.

Enterprise scale: Cloud, on-prem, or hybrid hosting is working into most of this suite. Customers can now pipe data into data lakes and an array of analytics tools. The file storage approach means sending even millions of data points per second from OT tags across multiple plants is possible. Configuration Hub is central to the ability of a center of expertise (CoE) to manage all of these applications seamlessly. GE reports that one automotive customer is automatically building tag databases for their many plants retooling for EV production, and it’s taking only weeks to build HMI/SCADA databases. Licensing by tags also enables customer flexibility to deploy as needed.

Expanded discrete industry support: GE Digital is working with GE Aviation to support complex low-volume discrete industries such as A&D (Proficy has long had a strong base in automotive). This industry has only a few successful MES who offer what they need in engineering change and dispatching, so this market entry is welcome.

Expanded analytics: More of the applications now have embedded issue-specific analytics already included. The suite also offers customers the ability to build their own analytics models. Sustainability is one such area, based on Vernova’s focus. PID loop health is another. Alarm management in the automation suite has been upgraded to reduce distribution during alarm floors, and new capabilities for troubleshooting alarms are included also.

All of these new capabilities are in a coherent yet open suite of products. Customers can benefit across OT, IT, sustainability, and plant operations. We see how this would put GE Digital in a strong position as the spin-off of GE Vernova approaches.

Thank you, Steve Pavlovsky, Prasad Pai, Joe Gerstl, and Ben Whiteman, for an excellent overview of the new possibilities in Proficy. Thanks, Carter Conway and Spenser Murray, for setting up the briefing for us. We will look forward to more news as Proficy continues to leverage technology advances and meet market shifts.

For related content, read our previous insights on how GE Aims to Operationalize Sustainability and how they plan to Enhance MES for TCO and Flexibility.

[post_title] => GE Proficy 2024: Expanding on IT, OT, Sustainability, and Operations Scale and Ease

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ge-proficy-2024-unified-release

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-09 12:38:41

[post_modified_gmt] => 2024-02-09 17:38:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=19841

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 19826

[post_author] => 2

[post_date] => 2024-02-07 10:00:56

[post_date_gmt] => 2024-02-07 15:00:56

[post_content] => [caption id="attachment_19828" align="aligncenter" width="770"]

Making plant floor software more straightforward to use, rollout, maintain, and sustain is a worthy endeavor. The fourth annual release of the GE Digital Proficy portfolio as an integrated release was packed! Updates range from expanding industry fit to architecture for enterprise rollout, cloud everywhere, composability, consistency for connected workers, sustainability functionality, and pre-built analytics for common needs.

Jim Brown and Julie Fraser had a chance to catch up with the GE Digital product management team for a preview of the Proficy 2024 unified launch. Unified is a relatively new capability for Proficy, with cloud or hybrid hosting, a common user experience (UX), and common administration. That’s rare, since this suite includes not only comprehensive MES and plant applications, but also historian, automation software and Sustainability software.

Some of the highlights are:

Coherent, flexible architecture: Historian and MES are entirely rewritten to be containerized on the same unified namespace (UNS). Other components of this model are a data model, support for a range of databusses including MQTT, OPS-UA and more, and a directory service. We see this as a solid approach for the software to stay useful at enterprise scale over the long term.

Connected worker consistency: IT are not the only ones with new capabilities. Operations Hub supports operators, supervisors, technicians, and other connected workers. It lets the customers compose applications as they wish behind a single UI. Applications from HMI, dashboards, engineering analytics, and MES all use containers and Operations Hub to appear in a consistent way. It aims to work even beyond the Proficy suite.

Enterprise scale: Cloud, on-prem, or hybrid hosting is working into most of this suite. Customers can now pipe data into data lakes and an array of analytics tools. The file storage approach means sending even millions of data points per second from OT tags across multiple plants is possible. Configuration Hub is central to the ability of a center of expertise (CoE) to manage all of these applications seamlessly. GE reports that one automotive customer is automatically building tag databases for their many plants retooling for EV production, and it’s taking only weeks to build HMI/SCADA databases. Licensing by tags also enables customer flexibility to deploy as needed.

Expanded discrete industry support: GE Digital is working with GE Aviation to support complex low-volume discrete industries such as A&D (Proficy has long had a strong base in automotive). This industry has only a few successful MES who offer what they need in engineering change and dispatching, so this market entry is welcome.

Expanded analytics: More of the applications now have embedded issue-specific analytics already included. The suite also offers customers the ability to build their own analytics models. Sustainability is one such area, based on Vernova’s focus. PID loop health is another. Alarm management in the automation suite has been upgraded to reduce distribution during alarm floors, and new capabilities for troubleshooting alarms are included also.

All of these new capabilities are in a coherent yet open suite of products. Customers can benefit across OT, IT, sustainability, and plant operations. We see how this would put GE Digital in a strong position as the spin-off of GE Vernova approaches.

Thank you, Steve Pavlovsky, Prasad Pai, Joe Gerstl, and Ben Whiteman, for an excellent overview of the new possibilities in Proficy. Thanks, Carter Conway and Spenser Murray, for setting up the briefing for us. We will look forward to more news as Proficy continues to leverage technology advances and meet market shifts.

For related content, read our previous insights on how GE Aims to Operationalize Sustainability and how they plan to Enhance MES for TCO and Flexibility.

[post_title] => GE Proficy 2024: Expanding on IT, OT, Sustainability, and Operations Scale and Ease

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ge-proficy-2024-unified-release

[to_ping] =>

[pinged] =>

[post_modified] => 2024-02-09 12:38:41

[post_modified_gmt] => 2024-02-09 17:38:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=19841

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 19826

[post_author] => 2

[post_date] => 2024-02-07 10:00:56

[post_date_gmt] => 2024-02-07 15:00:56

[post_content] => [caption id="attachment_19828" align="aligncenter" width="770"] Denodo Data Virtualization Capabilities[/caption]

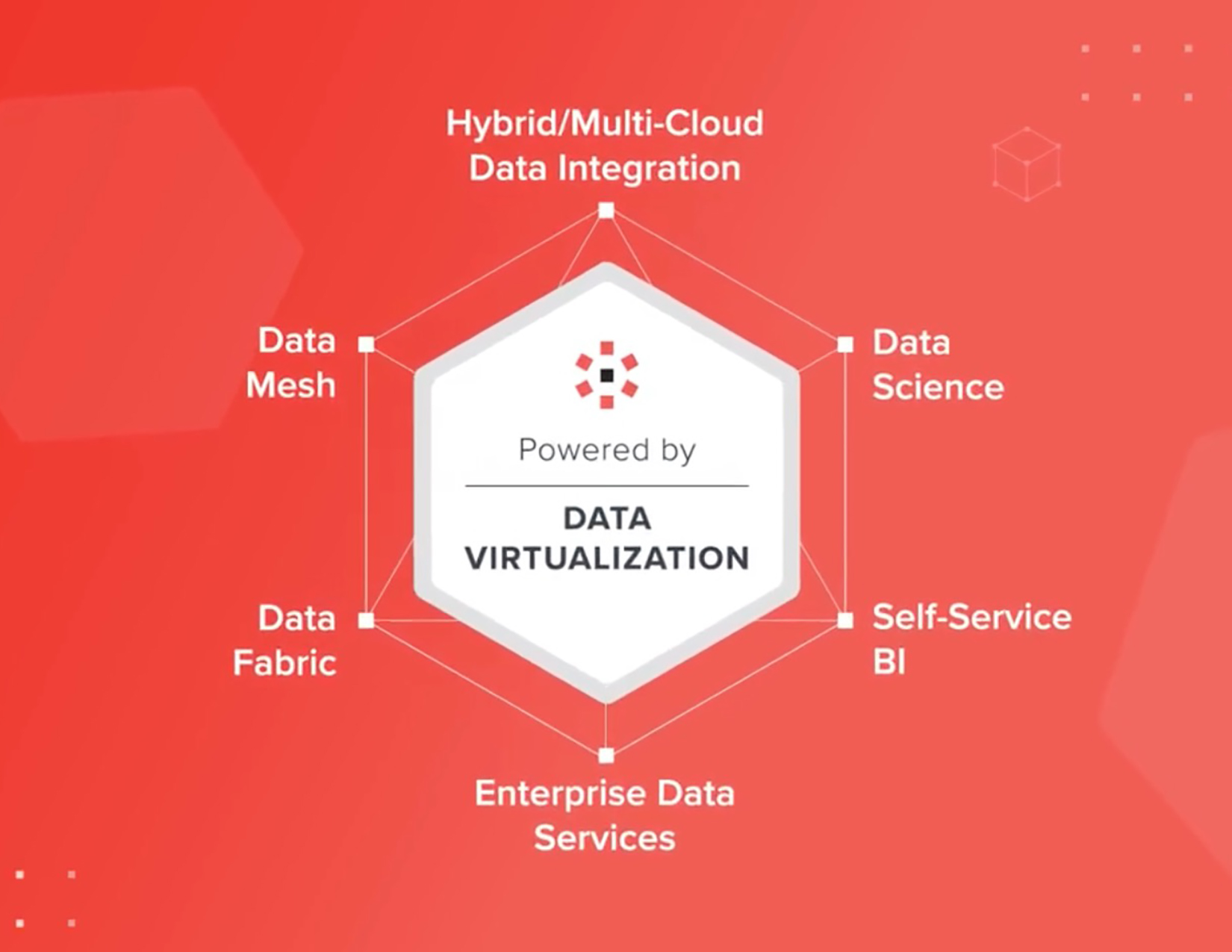

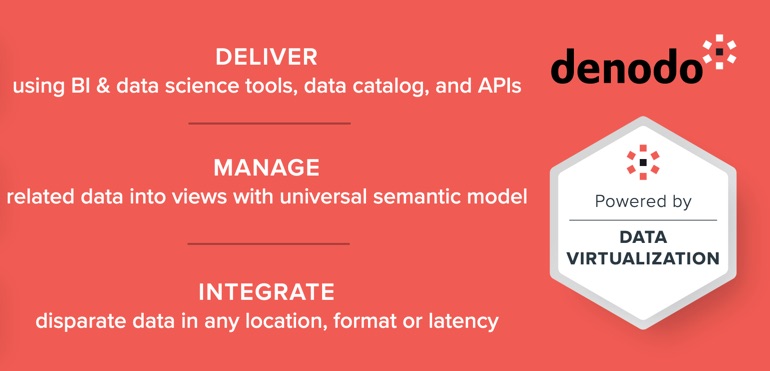

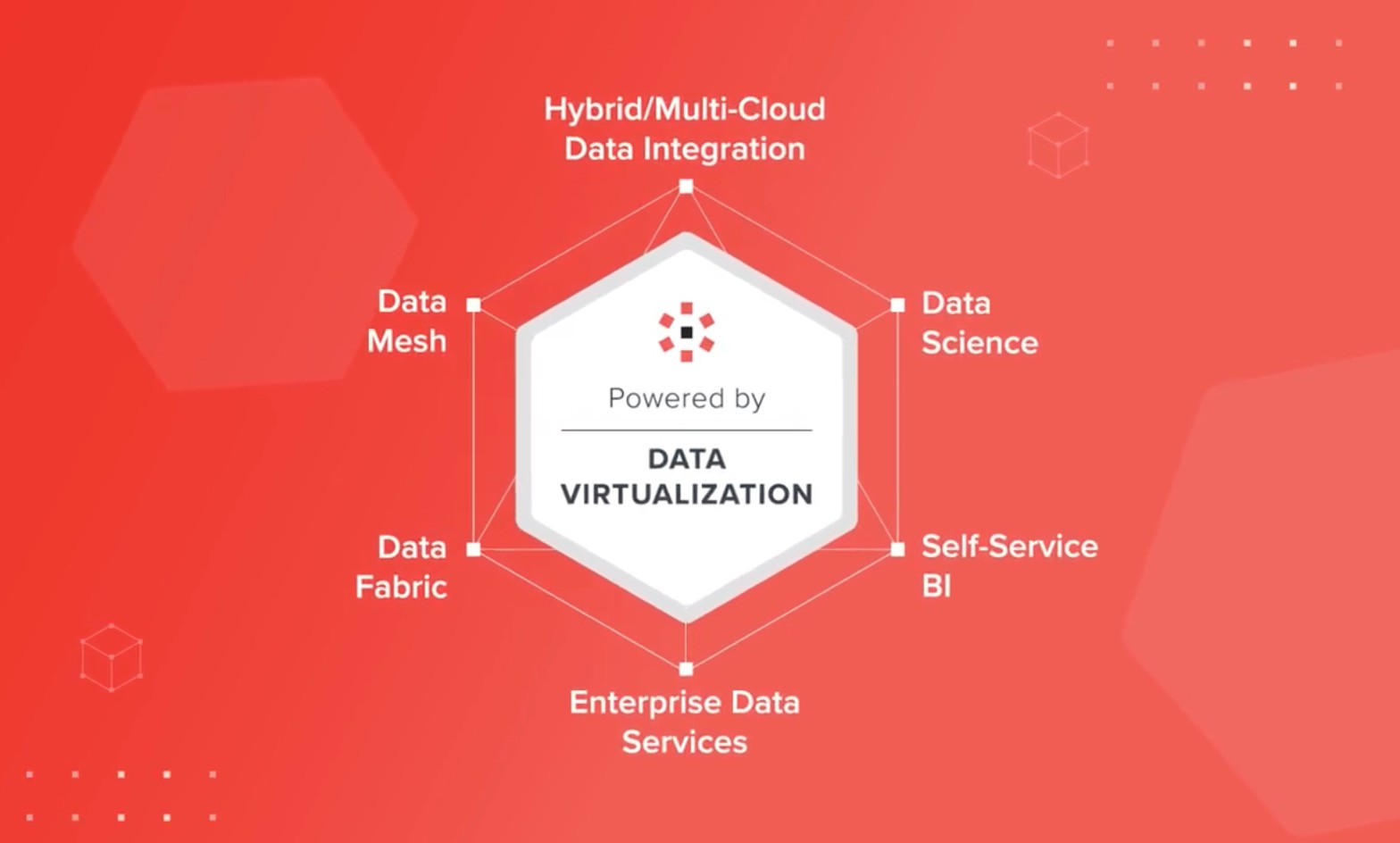

Julie Fraser and I were introduced to Denodo through a connection made in the Manufacturing Enterprise Solutions Association (MESA) International Smart Manufacturing Community. Denodo is a large, fast-growing data management company with capabilities supporting enterprise data fabric and data integration. We spent some time with the Denodo team, learning about their solution for data virtualization to create “integration without integration.”

Denodo Data Virtualization Capabilities[/caption]

Julie Fraser and I were introduced to Denodo through a connection made in the Manufacturing Enterprise Solutions Association (MESA) International Smart Manufacturing Community. Denodo is a large, fast-growing data management company with capabilities supporting enterprise data fabric and data integration. We spent some time with the Denodo team, learning about their solution for data virtualization to create “integration without integration.”

Denodo helps companies create a single view of distributed data to drive analytics. As one would expect, the offering provides data integration, management, quality, and governance. But Denodo’s solution does not aggregate and replicate large volumes of data, instead creating a form of data mesh by sourcing and storing metadata while leaving data in place, but accessible. They then use the metadata to create a data catalog that allows self-service data discovery and data preparation on a logical abstraction of a variety of data stores. Although Denodo takes a “logical first” approach, leading with virtualization, they can also support ETL, ESBs, or APIs with over 200 adapters for complete data management and delivery.

Our research shows that manufacturers typically invest significant time and effort in creating and maintaining integrated data to drive decisions and support AI. In particular, they struggle to put IT and OT data in context. Denodo’s abstraction layer and services could play a significant role in simplifying this and deliver significant benefits.

[caption id="attachment_19829" align="aligncenter" width="824"] Denodo Platform Functionality[/caption]

Denodo Platform Functionality[/caption]

The real value comes by putting the data into action. Denodo provides connectivity to data analysis tools like Tableau or PowerBI to turn that data into actionable insights. In this way, their data virtualization approach can help create intelligence from fragmented and proliferated data in real time without waiting for traditional extract, transformation, and load (ETL) processes.

We’ve seen some case studies and we’re impressed, but we also have more to learn. We believe that Denodo can offer significant value to support manufacturing and supply chain analytics and AI with their data fabric approach. Thank you, Dave Nixon, for making the connection, and Saptarshi Sengupta and Deborah Wiltshire for introducing us to Denodo’s capabilities. We look forward to continuing our learning and watching their progress in manufacturing industries.

[post_title] => Denodo Delivers Data Fabric Value via Data Virtualization [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => data-virtualization [to_ping] => [pinged] => [post_modified] => 2024-02-08 11:13:42 [post_modified_gmt] => 2024-02-08 16:13:42 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=19826 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [6] => WP_Post Object ( [ID] => 19772 [post_author] => 2 [post_date] => 2024-01-30 11:54:42 [post_date_gmt] => 2024-01-30 16:54:42 [post_content] =>

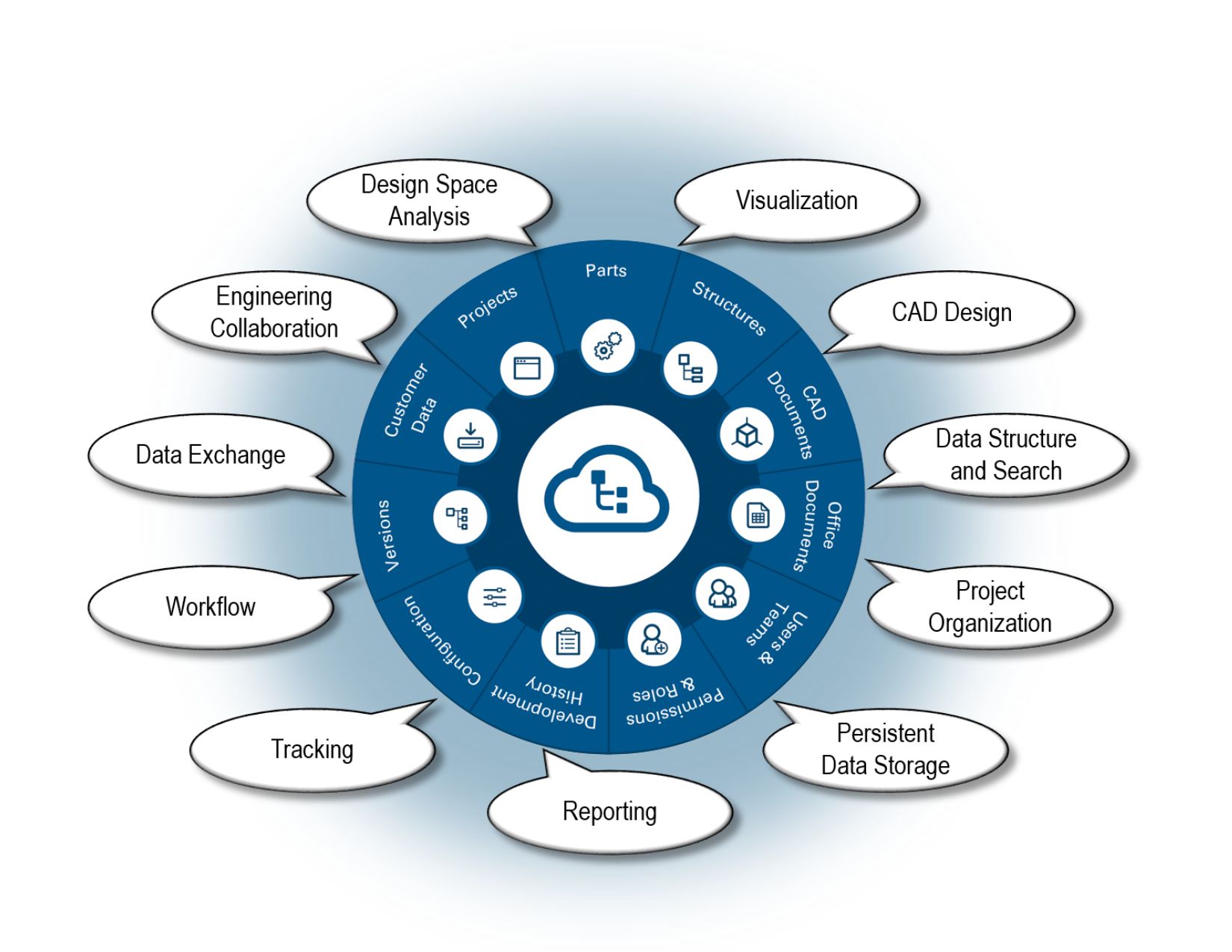

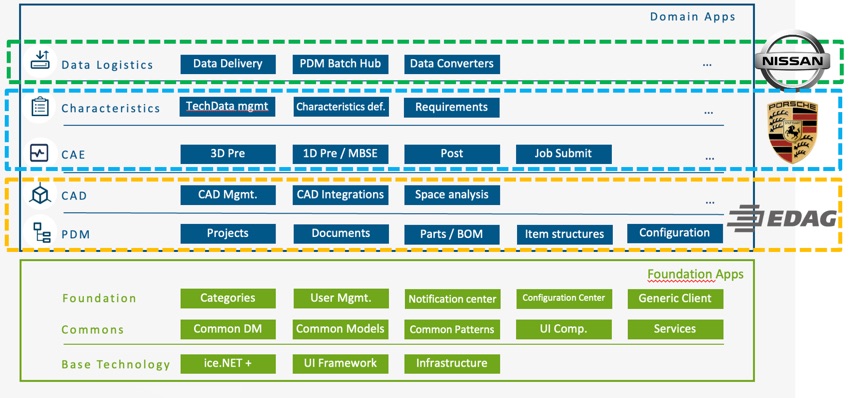

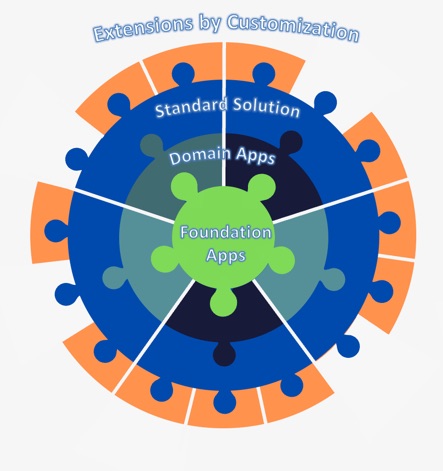

I caught up with an old friend who has an exciting new role as Executive Board Member and Co-Owner of PDTec, a company that I am excited to get to know better. The company offers a series of composable apps based on their data management platform, ice. NET. I love their tagline “innovation through integration” and their focus spanning data, process, and systems integration. Their solutions, based on a scalable component architecture, are designed to help engineers be more effective and efficient in product development, including:

- Simulation and systems engineering data management - SimData Manager

- PDM / PLM - CAD Portal

- Data exchange for tasks like supplier integration and collaboration - PDMconnect

In addition to these preconfigured standard offerings, PDTec can leverage their component-based platform to develop unique solutions on a consultative basis driven by their deep industry expertise.

PDTec is not a flashy software company, instead focusing on serving their customers who include majorlinke complex, discrete manufacturers with significant adoption in the automotive industry. In fact, they publicly list many German automotive OEMs as their customers, including Porsche AG, AUDI AG, Volkswagen, Mercedes-Benz AG, and Daimler Truck. Their customers also include tier 1 automotive suppliers such as Brose Group, Japanese automotive OEMs Mitsubishi Corporation and Nissan Motor Corporation.

PDTec is not a flashy software company, instead focusing on serving their customers who include majorlinke complex, discrete manufacturers with significant adoption in the automotive industry. In fact, they publicly list many German automotive OEMs as their customers, including Porsche AG, AUDI AG, Volkswagen, Mercedes-Benz AG, and Daimler Truck. Their customers also include tier 1 automotive suppliers such as Brose Group, Japanese automotive OEMs Mitsubishi Corporation and Nissan Motor Corporation.

PDTec is a company I look forward to learning more about. Thank you Michael Murgai for the overview.

[post_title] => PDTec offers Manufacturers Innovation through Integration [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => pdtec-composable-architecture [to_ping] => [pinged] => [post_modified] => 2024-01-30 12:02:27 [post_modified_gmt] => 2024-01-30 17:02:27 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=19772 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [7] => WP_Post Object ( [ID] => 19614 [post_author] => 2 [post_date] => 2024-01-16 10:00:11 [post_date_gmt] => 2024-01-16 15:00:11 [post_content] => [caption id="attachment_19627" align="aligncenter" width="904"] Tech-Clarity Analysts Jim Brown and Michelle Boucher at Autodesk University[/caption]

2023 is in the rearview mirror and I’m reflecting on a few things that Michelle Boucher and I learned and what they mean for our industry. Here are some takeaways from Autodesk University 2023, including AI and PLM strategy updates, that will have a big impact on the industry. This is only a small portion of what we learned from multiple presentations and conversations, it’s always hard to decide what to report on from these large conferences!

Tech-Clarity Analysts Jim Brown and Michelle Boucher at Autodesk University[/caption]

2023 is in the rearview mirror and I’m reflecting on a few things that Michelle Boucher and I learned and what they mean for our industry. Here are some takeaways from Autodesk University 2023, including AI and PLM strategy updates, that will have a big impact on the industry. This is only a small portion of what we learned from multiple presentations and conversations, it’s always hard to decide what to report on from these large conferences!

Artificial Intelligence

Not surprisingly, one of the biggest takeaways from AU2023 was related to the increased attention being placed on artificial intelligence (AI). AI was a central conference theme and it’s clear that Autodesk believes in its potential. Autodesk CEO Andrew Anagnost dedicated a portion of his keynote highlighting the ability for AI to change the way people work. Although a lot of the attention in the market today is about generative AI, thanks to the increased attention created by ChatGPT, Andrew also pointed out how AI can automate away non-value-added (NVA) work. A tangible example of automating repetitive, NVA tasks with AI is creating drawings and documentation with Fusion automated drawings. Autodesk shared other examples across the industries they serve. It's important to point out that Autodesk is not new to AI. We’ve been in conversations with Autodesk about AI for a long time. Autodesk was one of the first large engineering software vendors to focus heavily in generative design and has been at it for some time. They are continuing their investment in generative AI to augment human innovation, for example they announced an acquisition of Blank.AI to rapidly develop design concepts for the automotive industry.

Autodesk has invested a lot of brainpower into how AI can make a difference for their customers. They’ve also invested a lot of expensive computing power to develop AI models from the vast amount of data they have access to. They have learned a lot and we expect to see continued AI capabilities rolled out at all levels of Autodesk products. To support this, Autodesk announced Autodesk AI to provide intelligent assistance and generative capabilities across their software portfolio as a part of the Autodesk Platform.

Autodesk VP Vikram Dutt further shared their vision for AI, “The cloud has connected our customers’ data, and it's enabling AI to unlock new ways of working. We really believe we're on the cusp of a new era, one where AI will fundamentally change the way our customers do business, unleashing both their agility as well as creativity. And we believe our customers really need an entirely new way of working.” It’s a bold objective that offers significant potential. We’re keeping our eyes on the progress.

It's important to point out that Autodesk is not new to AI. We’ve been in conversations with Autodesk about AI for a long time. Autodesk was one of the first large engineering software vendors to focus heavily in generative design and has been at it for some time. They are continuing their investment in generative AI to augment human innovation, for example they announced an acquisition of Blank.AI to rapidly develop design concepts for the automotive industry.

Autodesk has invested a lot of brainpower into how AI can make a difference for their customers. They’ve also invested a lot of expensive computing power to develop AI models from the vast amount of data they have access to. They have learned a lot and we expect to see continued AI capabilities rolled out at all levels of Autodesk products. To support this, Autodesk announced Autodesk AI to provide intelligent assistance and generative capabilities across their software portfolio as a part of the Autodesk Platform.

Autodesk VP Vikram Dutt further shared their vision for AI, “The cloud has connected our customers’ data, and it's enabling AI to unlock new ways of working. We really believe we're on the cusp of a new era, one where AI will fundamentally change the way our customers do business, unleashing both their agility as well as creativity. And we believe our customers really need an entirely new way of working.” It’s a bold objective that offers significant potential. We’re keeping our eyes on the progress.

Design & Manufacturing - PLM

We were also excited to get an update on the solutions for the manufacturing industries. Given that one of the biggest challenges with AI initiatives is having trusted, organized data we’ll start with data management. We were excited to see Autodesk integrate a “PLM Summit” into AU. The summit was a dedicated track for PLM customers to learn how to get business value from PLM. It was a well-organized, well-attended, collaborative event that primarily focused on Fusion 360 Manage and allowed users to openly share tips and techniques and what they’ve accomplished with the system. [caption id="attachment_19629" align="aligncenter" width="935"] Autodesk University PLM Summit[/caption]

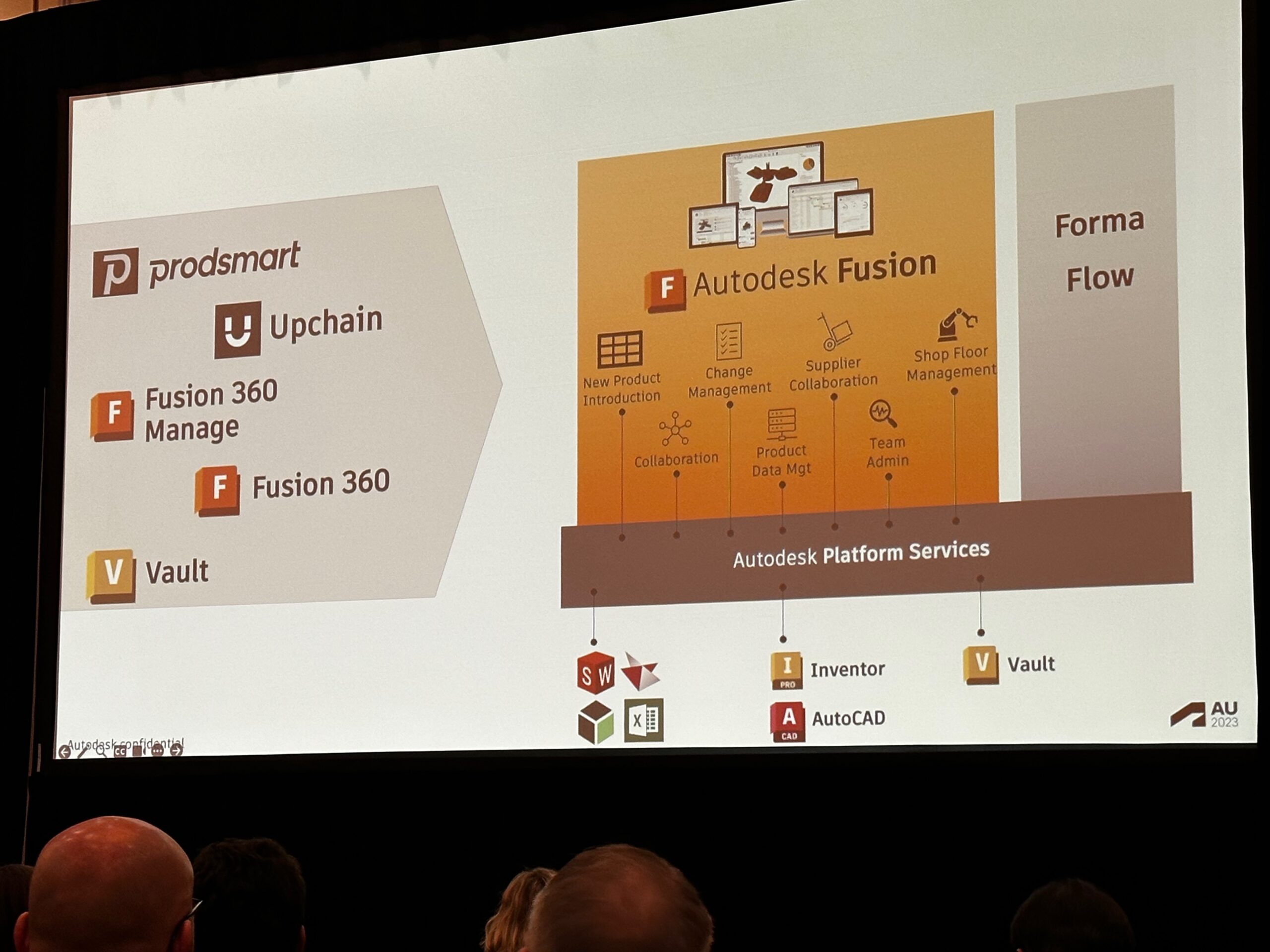

Fusion 360 Manage is a flexible, workflow-oriented system. Fusion 360 Manage complements Autodesk’s extended PDM solution, Vault. They also offer their still relatively newly acquired Upchain solution that supports what they described as “fully cloud PDM with some PLM capabilities,” which is well suited for design-centric, multi-CAD environments.

Although there is some overlap in the offerings, Autodesk is investing in integrating all of these solutions with Fusion, their industry cloud for manufacturing. In a presentation on Autodesk Fusion Data Management, Jeremy Lambert explained that their goal is a single, unified industry cloud with capabilities from Prodsmart, Fusion 360 Manage, Fusion 360, Vault, and Upchain.

[caption id="attachment_19628" align="aligncenter" width="961"]

Autodesk University PLM Summit[/caption]

Fusion 360 Manage is a flexible, workflow-oriented system. Fusion 360 Manage complements Autodesk’s extended PDM solution, Vault. They also offer their still relatively newly acquired Upchain solution that supports what they described as “fully cloud PDM with some PLM capabilities,” which is well suited for design-centric, multi-CAD environments.

Although there is some overlap in the offerings, Autodesk is investing in integrating all of these solutions with Fusion, their industry cloud for manufacturing. In a presentation on Autodesk Fusion Data Management, Jeremy Lambert explained that their goal is a single, unified industry cloud with capabilities from Prodsmart, Fusion 360 Manage, Fusion 360, Vault, and Upchain.

[caption id="attachment_19628" align="aligncenter" width="961"] Autodesk Fusion Data Management[/caption]

Fusion is clearly Autodesk’s long-term strategy for the manufacturing industry. Fusion is a pure platform built from the ground up and goes well beyond PLM. As described by VP Cloud Data and PLM Derrek Cooper, Fusion is CAD, CAM, PLM, and MES data in a graph database, decoupled from logic, run through APIs. It leverages a common data model across applications, which is the target for integrating Autodesk’s PDM and PLM offerings.

Autodesk Fusion Data Management[/caption]

Fusion is clearly Autodesk’s long-term strategy for the manufacturing industry. Fusion is a pure platform built from the ground up and goes well beyond PLM. As described by VP Cloud Data and PLM Derrek Cooper, Fusion is CAD, CAM, PLM, and MES data in a graph database, decoupled from logic, run through APIs. It leverages a common data model across applications, which is the target for integrating Autodesk’s PDM and PLM offerings.

Design & Manufacturing - General

As the vision for Fusion shows, Autodesk design and manufacturing goes beyond PLM. AU gave us the opportunity to hear from EVP Design & Manufacturing Jeff Kinder and others about how they support the industry. Jeff shared a number of updates and customer stories, including how Rivian uses Fusion to develop more / faster prototypes, create real-time rendering, ensure design and manufacturability, and manufacture using CAM / CNC to machine prototype parts. Rivian spoke as well, explaining how Fusion enables them to work on a common data model to understand if a design is manufacturable, and if not change it in the design tab and move back to the manufacturing tab. They also shared how they leverage VR / AR to eliminate early physical models using VRED. This is a great example of how Fusion is intended to work across functions. In fact, Rivian shared how Autodesk can help a manufacturer with everything from AEC for the plant to line planning and factory layout, all in the same data model. As Jeff Hammoud, Rivian Chief Design Officer, shares, Fusion provides “seamless data sharing across the organization.” This helps them rethink not just their product, but their manufacturing processes. There is so much more to share, including a new partnership with Cadence and well-received enhancements to existing products like Vault with numerous user-driven enhancements and Inventor adding IFC in Inventor for industrialized construction and sheet metal tools. There isn’t room to share it all.Design & Manufacturing – Supporting The Factory

One last area I want to focus on is the factory. Autodesk is the “design and make” company. Their strategy goes beyond engineering to the plant. They’ve extended their factory planning and manufacturing portfolio by partnering with CloudNC for AI toolpaths and acquiring a factory simulation solution to extend their ability to help manufacturing engineers understand factory flow and bottlenecks. Beyond that, it will be very interesting to see what they do with Prodsmart and how they evolve to support plant operations. I asked Steve Hooper, VP Product Development, about future for manufacturing planning and execution. He mentioned that they already have capabilities for manufacturing engineers / process planners, from the plant / facility design, 1D planning, factory design, CAM, and CNC. He explained that he does see going deeper to support others who are left out of factory technology and need a digital thread solution that extends to lines, workcells, and workers. We’ll be watching this space. [caption id="attachment_19625" align="aligncenter" width="889"] AU Design & Manufacturing Executive Panel[/caption]

AU Design & Manufacturing Executive Panel[/caption]

Architecture, Engineering, Design, and Construction (AEC)

We also heard from Amy Bunszel, EVP of AEC Design and Jim Lynch Senior VP, GM of Autodesk Construction Solutions. In a similar way to manufacturing, supporting AEC is all about the data. Autodesk continues to invest in BIM, with industry-leading Revit solution moving to Forma, their industry cloud for AEC. As Amy explains, “Forma is AI-powered design.” Autodesk shared some great examples of using AI in AEC to test different concepts, showing the impact of designs on sunlight, noise, and solar array positioning, and shared that these kinds of capabilities will eventually cover the entire BIM process. [caption id="attachment_19620" align="aligncenter" width="957"] Autodesk University AEC Panel[/caption]

Autodesk has a leading position in AEC and there is much more to share, but I’m going to limit my commentary to one more exciting update related to the the intersection of D&M and AEC, industrialized construction. There was a very interesting presentation and exhibit from Factory OS sharing how they use Forma for sustainable modular construction, working collaboratively in the cloud , around a common language and drawings. The parallels with Fusion are noticeable, and both supported by Autodesk Platform.

Autodesk University AEC Panel[/caption]

Autodesk has a leading position in AEC and there is much more to share, but I’m going to limit my commentary to one more exciting update related to the the intersection of D&M and AEC, industrialized construction. There was a very interesting presentation and exhibit from Factory OS sharing how they use Forma for sustainable modular construction, working collaboratively in the cloud , around a common language and drawings. The parallels with Fusion are noticeable, and both supported by Autodesk Platform.

Autodesk Platform Services

Sitting behind the industry solutions for manufacturing, AEC, and media & entertainment is the Autodesk Platform. As announced at AU last year, The Forge platform is now Autodesk Platform Services (APS). APS is a significant investment in the future, shared across all industries. They’ve taken a data-centric approach with a granular data model, interoperable apps, and APIs on the cloud. Autodesk took this approach early and started from the ground up with the fundamentals. Autodesk shared some updates including continued investment in APIs and Autodesk Docs, offering cloud document management and a common data environment (CDE). Autodesk is extending what is already one of the most advanced platform strategies. Again, this is a space to watch as the Autodesk Platform continues to mature and offer comparable capabilities on a cloud platform.Summary

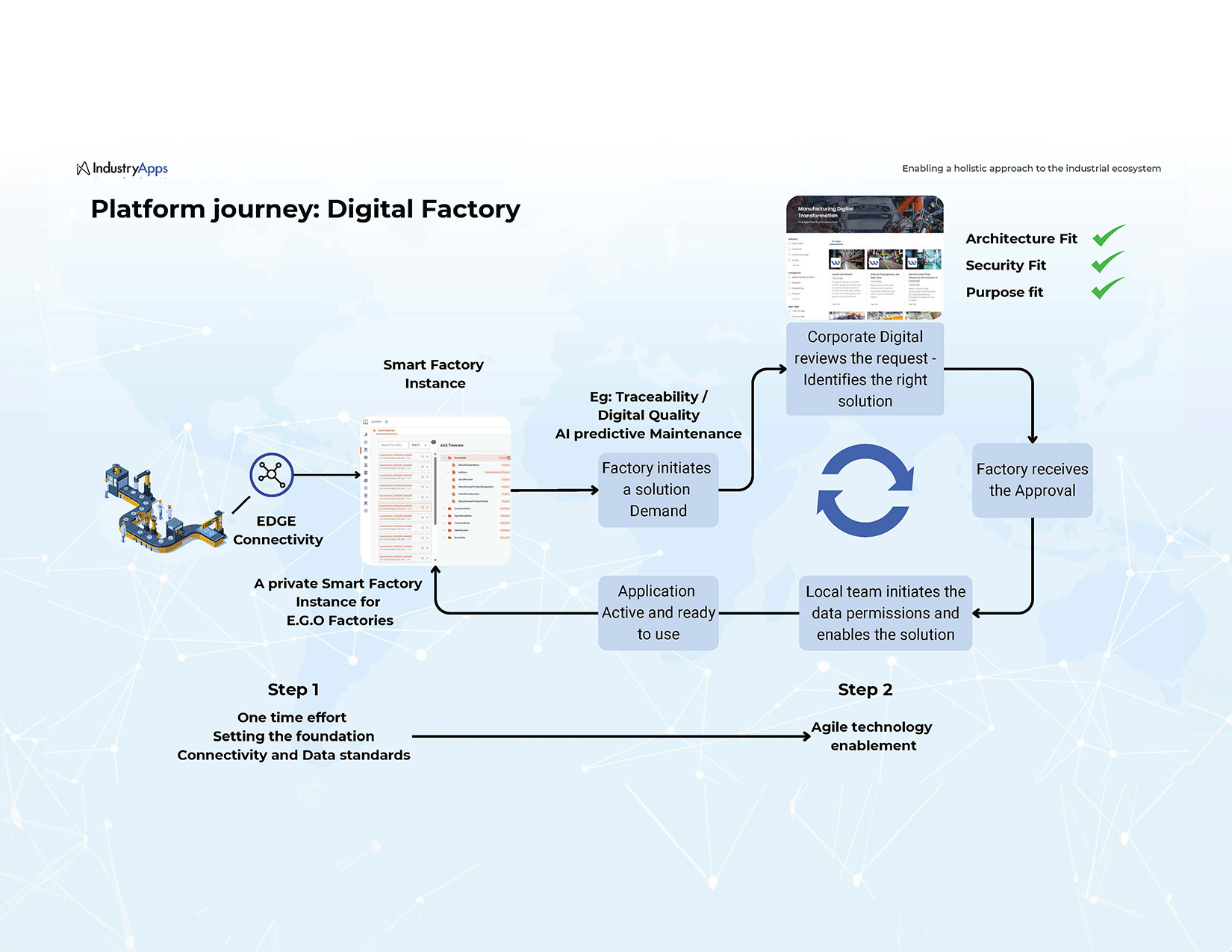

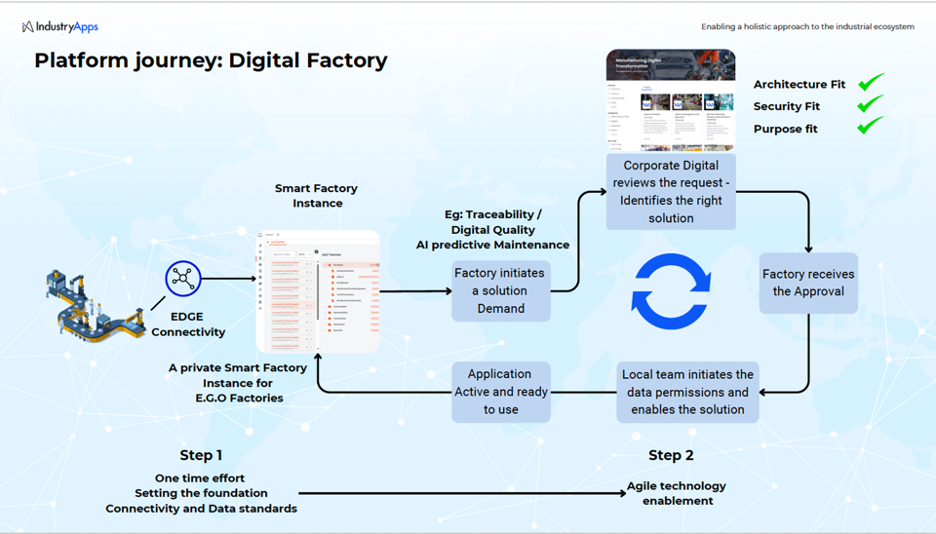

There is a lot that I’ve left out, but I hope this gives you an idea of what we took away from the event. Thank you to Jason Love, Christa Prokos, and the entire Autodesk University team for coordinating our AU2023 experience and putting together such great learning opportunities. [post_title] => Reflections on AI, PLM, and more from Autodesk University [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => autodesk-ai [to_ping] => [pinged] => [post_modified] => 2024-01-30 12:22:56 [post_modified_gmt] => 2024-01-30 17:22:56 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=19614 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 19638 [post_author] => 2574 [post_date] => 2024-01-16 09:00:39 [post_date_gmt] => 2024-01-16 14:00:39 [post_content] => What is holding companies back from Industry 4.0 project and initiative success? A few things: integration for data flows, speed to deploy software consistently to multiple sites for scalability, disconnects between corporate IT mandates and in-the-plant needs, and projects that don’t fit the budget of smaller plants and companies. Recently, Jim Brown and Julie Fraser learned how IndustryApps aims to alleviate those issues and democratize access to best-in-class Industry 4.0 approaches.

How? By building an industrial dataspace using industry standards, and inviting software application providers to use this platform to expand their reach and speed time-to-value for their projects. Manufacturers subscribe to the apps they need at any time. The OpEx approach lowers the barrier to entry and the cloud-based hosting speeds implementation.

What is holding companies back from Industry 4.0 project and initiative success? A few things: integration for data flows, speed to deploy software consistently to multiple sites for scalability, disconnects between corporate IT mandates and in-the-plant needs, and projects that don’t fit the budget of smaller plants and companies. Recently, Jim Brown and Julie Fraser learned how IndustryApps aims to alleviate those issues and democratize access to best-in-class Industry 4.0 approaches.

How? By building an industrial dataspace using industry standards, and inviting software application providers to use this platform to expand their reach and speed time-to-value for their projects. Manufacturers subscribe to the apps they need at any time. The OpEx approach lowers the barrier to entry and the cloud-based hosting speeds implementation.

Aiming to Democratize Industry 4.0

IndustryApps’ stated mission is to make Industry 4.0 simple for all industrial businesses. They envision their single platform as a foundation for digital transformation. The platform is based on digital twin standards. With this platform, manufacturers can create digital twins for machines and products. The platform is a secured, private application enablement environment. Beyond the platform, the AppStore of proven solutions across the broad array of functional needs creates new opportunities for manufacturers of all sizes and industries.Ecosystem

Creating an ecosystem for other software companies has the potential to accelerate growth for IndustryApps – and rapidly expand value for manufacturers who use it. There are already 80 solution providers with software in the AppStore. All of these applications use the standard data exchange approach IndustryApps has built into its platform. Solution providers are interested in participating for several reasons. They get a new channel to market, covering geographies or industries that are hard for them to reach, that provides first-line support. Participating is a driver to adopt the many industry standards at the core of the IndustryApps Platform. These include RAMI 4.0, Asset Administration Shell (AAS) Consortium, ISO/ECLASS for semantics, Open Industry 4.0 Alliance architectures, GAIA-X distributed sovereign data rules, and ISA 95. Many software companies are already adopting these standards to provide customers with more flexibility and better integration. Although it takes a strong commitment from vendors, adopting standards is a path to more complete digital threads and industrial dataspaces.Industry Origins

The founders began to develop this platform approach while working at Henkel. When Sandeep Sreekumar’s scope expanded to 140 plants, he realized he needed a way to scale and roll out rapidly, plus allow flexible deployment at sites. Developing a platform enabled the bottom-up approach to digitalizing factories. Some of these Henkel factories became lighthouses in the World Economic Forum Industry 4.0 program. Extend Manufacturers continually seek to extend their company's capabilities by leveraging software. New applications from solution providers make up one aspect of the extensibility of IndustryApps. Now, the platform is open for manufacturers to onboard their internally-developed solutions. Manufacturers can subscribe to new apps for a monthly fee and get up and going with minimal training or delay. The connectivity is provided or open to using their own data connectivity layer.Cybersecurity

Another crucial aspect of Industry 4.0 software is cybersecurity and data protection. With manufacturers increasingly being a target for cyberattacks, this is crucial. Also, when the data may need to flow among multiple companies or departments, the ability to dictate and update access control for each person is vital. Further, the manufacturers always own their own data on the IndustryApps platform and ecosystem. Thank you, Sandeep Sreekumar, for spending time to update us on your vision and status. We look forward to following IndustryApps’ progress in the market. [post_title] => IndustryApps Industrial Dataspace and Ecosystem Aims to Democratize Industry 4.0 [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => industrial-dataspace [to_ping] => [pinged] => [post_modified] => 2024-01-26 13:56:31 [post_modified_gmt] => 2024-01-26 18:56:31 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=19638 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [9] => WP_Post Object ( [ID] => 19484 [post_author] => 2 [post_date] => 2024-01-10 10:00:12 [post_date_gmt] => 2024-01-10 15:00:12 [post_content] =>Introduction

I had the opportunity to join two industry experts, Stephen Birtsas and Leo Moran of Kalypso, in an interactive panel discussion about the manufacturing digital twin. Our goal was to examine the business value of manufacturing digital twins in the consumer packaged goods (CPG) industry and review some tangible examples of successful implementations. There's a lot of confusion about digital twins in the market, including competing definitions and requirements. The panel cut through the hype and shared real-world experience about using digital twins in manufacturing to solve practical problems and unlock new value. I hope you find this summary informative.What is a Digital Twin Anyway?

We've all heard the term, maybe more than we wanted to. There's a lot of marketing hype, and the term "digital twin" itself has become a bit of a buzzword. Part of that is because people are trying to attach themselves to a valuable concept, even if they are just rebadging an existing capability to do so. Fortunately, we had the experts on the webinar to set the record straight on what it is and its real potential. I'll share some of their most insightful commentary here, but please watch the recorded panel discussion to get the complete picture, including how to get started. Stephen described the manufacturing digital twin as a visual representation, in silico, that simulates a production process. That process, he shares, could be anything from an entire facility to a line to a particular operation or cell. The representation allows engineers to evaluate production at a high level all the way down to the control logic that will control a manufacturing line and its equipment. He explains that doing this in a digital environment allows manufacturers to simulate production flow down to how PLC code impacts the physical world in a virtual simulation. Leo Moran further explained that digital twins are a discipline and capability they use to improve their clients' operations on their factory floors, warehouses, and distribution centers. They do this by determining the data needed to build a model and simulating equipment and operations to create analyses of an area to improve in the factory.What's the Value of a Digital Twin in CPG?

With the understanding of what a digital twin is, we turned to the obvious question of why they are valuable. We all agreed that the objective isn't to develop a model or digital twin, it's to solve a real business problem like optimizing plant efficiency. It's a strategic business capability, and our research shows that about two-thirds of manufacturers see the digital twin not just as a technology but as an important or critical capability to achieve their business strategy. Leo described the versatility and scope of the digital twin. He shared that Kalypso helps their clients across the lifecycle of a factory. It can start as they first design a factory to validate the design and ensure that it will meet requirements. Following that, it can go into a phase where they have to install and commission a great deal of complex equipment and then ultimately into operations to help optimize and manage production. He explained that there's a tremendous amount of time and cost savings available from simulation technology with the digital twin in all of these phases. Stephen shared a bit more detail, describing how clients look to solve real-world problems by applying a digital twin in one of those three areas:- In the design phase, to predict how a design would work, for example, doing a throughput or feasibility analysis, and adjust the design to deliver on requirements and create a very high level of confidence that the operation is going to work effectively

- In the commissioning phase, by virtually testing controls and systems integration to find bugs and optimize designs early to commission and get up to your target OEE rates much faster

- In the operations phase, for example, for troubleshooting and testing a hypothesis on a potential solution to quickly implement improvements

Learning from Real Case Studies

Stephen and Leo shared a number of projects they've completed with their clients. I'll provide a summary of the benefits here, but I encourage you to watch the webinar to learn more about how they achieve these significant benefits from the manufacturing digital twin.- Design

- A medical device company simulated factories to understand real production flow, identify where bottlenecks occur, rightsize their warehouses, and improve supply chain planning, allowing them to meet a huge increase in demand as they release new products

- A solar panel manufacturer used both simulation and emulation to identify and eliminate over 157 design flaws in their material handling process design, leading to a significant improvement in the overall capacity of the factory

- Commissioning

- A major CPG company built a digital twin for both design and emulation of all of their control systems, leading to incredible savings in commissioning time for new lines

- A global retailer simulated and virtually commissioned half a dozen automated storage and retrieval systems, delivering 30% savings in commissioning time and a massive reduction in downtime

- Operations

- A tire manufacturer built a more analytical model of tire splicing that enabled them to reduce downtime, resulting in an annual production increase of about half a million tires per year

- A beverage manufacturer developed a digital twin to simulate and replicate line stoppages and was able to test potential solutions ten times faster, solving the problem which resulted in a 52% downtime reduction and 14% improvement in OEE

Final Thoughts

The conversation confirmed that the manufacturing digital twin can drive a lot of business value. The case studies show that digital twins are more than hype, they're a path to improve how manufacturers design, commission, and operate their plants, lines, equipment, and processes. Thank you to Stephen, Leo, and host Hadley Bauer for including me in the discussion. To learn more about how Kalypso helps manufacturers gain tangible value from the digital twin, you can watch the webinar replay (no registration required) and find additional information about digital twins for consumer and retail companies on the Kalypso site. For related content, read the State of PLM in CPG find out what top performers are doing with their PLM systems. [post_title] => The Value of the Manufacturing Digital Twin in CPG [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => manufacturing-digital-twin-2 [to_ping] => [pinged] => [post_modified] => 2024-02-20 12:33:14 [post_modified_gmt] => 2024-02-20 17:33:14 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=19484 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [10] => WP_Post Object ( [ID] => 19366 [post_author] => 2574 [post_date] => 2024-01-04 09:00:24 [post_date_gmt] => 2024-01-04 14:00:24 [post_content] => How can you get on the journey to a model-based enterprise? What are we learning that you can put into action today? Mark your calendars for January 17th at 11AM PT/2PM ET to join us for an engaging webinar covering topics such as:

How can you get on the journey to a model-based enterprise? What are we learning that you can put into action today? Mark your calendars for January 17th at 11AM PT/2PM ET to join us for an engaging webinar covering topics such as:

- Why transform? What are the biggest benefits as a manufacturer moves toward MBE? (For example, traceability, agility, time to market, quality, efficiency, new customer requirements, etc.)

- What do aerospace and complex manufacturers need to do now to prepare and embark on the MBE journey?

- Given that program cycles are long, how do we learn and iterate to advance MBE practices within just a few years?

- What software advances are needed in both PLM and MES to enable better PMI and model-based process planning?

- What is metadata, and what is its role in model-based design (MBD)?

- What are solution providers doing to support model-based manufacturing and get usable PMI from engineering to manufacturing?

- What have we already learned about what has worked and has not?

- Ron Squires, who leads Digital Transformation for the Strategic Space Systems Division of Northrop Grumman Space Systems

- Jeff Gleeson, an independent consultant and digital manufacturing leader with decades of experience at Lockheed Martin as both a practitioner and an innovator of production operations business processes and supporting technologies

- Michel Gadbois, Senior Vice President and Chief Enterprise Architect at iBase-t

- Julie Fraser, VP of Research for Operations and Manufacturing at Tech-Clarity and long-time industry analyst, will join and moderate.

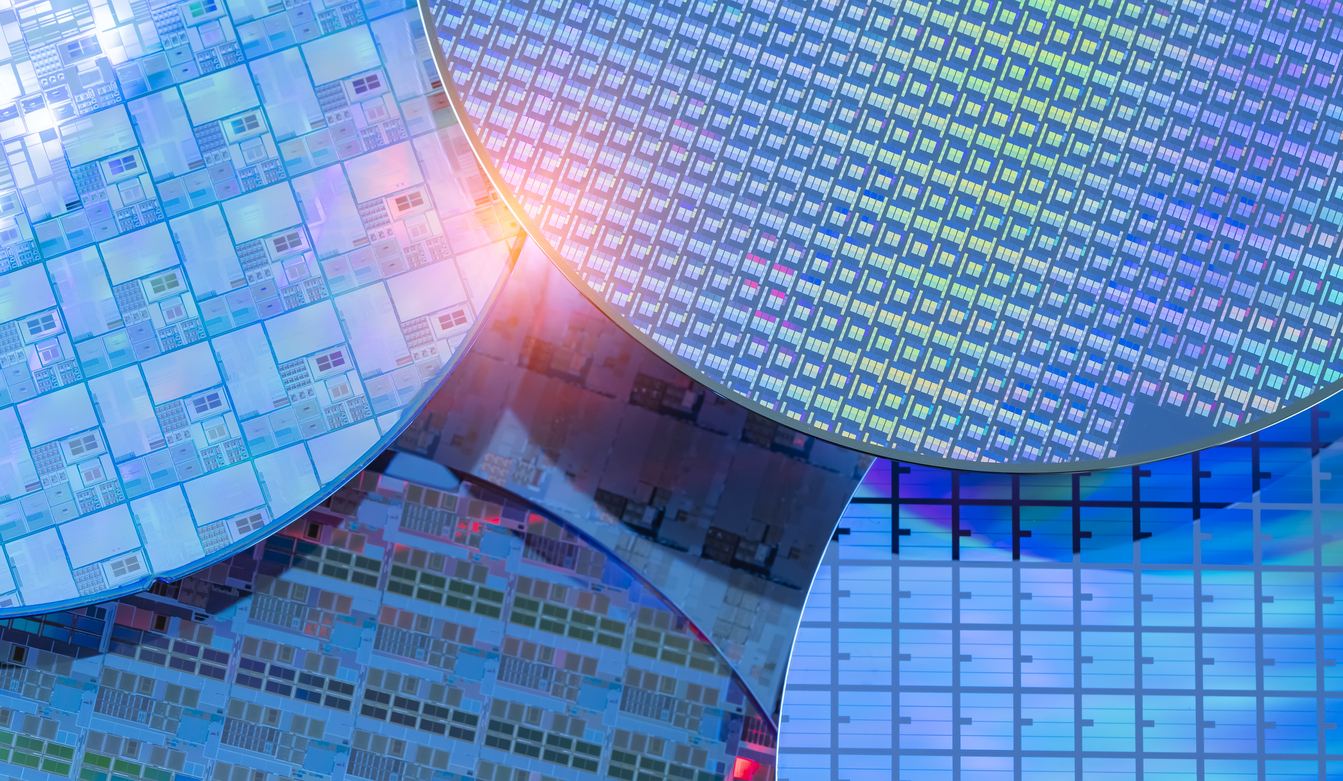

Semiconductor makers must evolve and innovate, so how can MES keep delivering value? Specialty chips can be great niches, but they don’t necessarily improve linearly or predictably. So, semiconductor companies must become more effective innovators rather than only seeking stability or increased product processing speed. Changing products, processes, and customers can boost win rates. No matter what, research and development (R&D) is a crucial foundation for business success.

Yet historically, innovation, changes, and R&D created significant challenges for legacy MES. As a result, these older systems have lost value over time. Semiconductor companies need MES that is reliable and flexible to keep up with innovation and evolving business and production processes.

Meeting new applications that build on the company’s current capabilities is a winning strategy. Specialty chips often work where virtual meets real. The intersection of virtual and real is also where MES models and capabilities meet actual fabrication, assembly, and test of chips.

In the face of constant innovation, the MES must be able to process multiple experiments at the same time as standard runs. The MES should be able to support fabs in running experimental lots with little to no disruption to commercial production. The MES ideally fully records and reports all the runs, small, large, or one-off experiments.

For reliability at the same time as flexibility, it’s ideal to have an MES that includes not only dispatching of special and commercial lots, but also maintenance, quality, materials, and more. The value comes from support for all aspects of change and innovation.

Fortunately, there are semiconductor MES available that have all of that and support greater agility with less manual effort than ever before. These modern systems enable semiconductor companies to set and meet their goals for evolving and innovating into new market opportunities. Choosing the right semiconductor MES to evolve and innovate is crucial.

Read this third in a blog series about semiconductor MES issues by Julie Fraser for a deeper look into what you might need and why. Thank you to Eyelit for supporting our efforts to educate the market to the business value of technology.

For related content, please read the previous senmconductor blog posts by Julie Fraser on Eyelit, including Redefining Semiconductor MES and the Semiconductor Risk Conundrum.

[post_title] => Ongoing Value from MES as a Semiconductor Company Evolves and Innovates

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => semiconductor-mes-evolve-and-innovate

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-19 10:34:31

[post_modified_gmt] => 2023-12-19 15:34:31

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=19276

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 19130

[post_author] => 2574

[post_date] => 2023-12-07 09:00:28

[post_date_gmt] => 2023-12-07 14:00:28

[post_content] =>

Semiconductor makers must evolve and innovate, so how can MES keep delivering value? Specialty chips can be great niches, but they don’t necessarily improve linearly or predictably. So, semiconductor companies must become more effective innovators rather than only seeking stability or increased product processing speed. Changing products, processes, and customers can boost win rates. No matter what, research and development (R&D) is a crucial foundation for business success.