What challenges do manufacturers encounter when working with contract manufacturers? What should they do to reduce the frustration and streamline the relationship? Jim Brown introduces five questions you may find yourself asking if you’re working with a CMO, CDMO, or other supply chain partners and then offers recommendations based on our experience and research in…

- What to do When You've Outgrown Your PDM

- Introducing the Buyer’s Guide for a More Capable PDM Solution

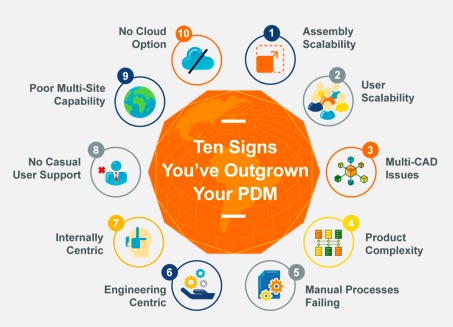

- Top Ten Signs You've Outgrown Your PDM System

- Extending the Control - Access - Share Basics

- Going Beyond PDM Basics

- Extended PDM Requirements

- New Considerations for Service, Vendor, and Special Considerations

- Next Steps

- About the Author

Introducing the PDM Buyer’s Guide

Exceeding the Limits of Basic PDM Although our PDM Buyer’s Guide recommends “considering both current and future needs” when evaluating solutions and “building a foundation to grow on,” there are many valid reasons companies end up outgrowing their system:- Product complexity has increased

- Product development complexity has grown

- Business has expanded

- Business has globalized

Understanding the Buyer’s Guide Structure

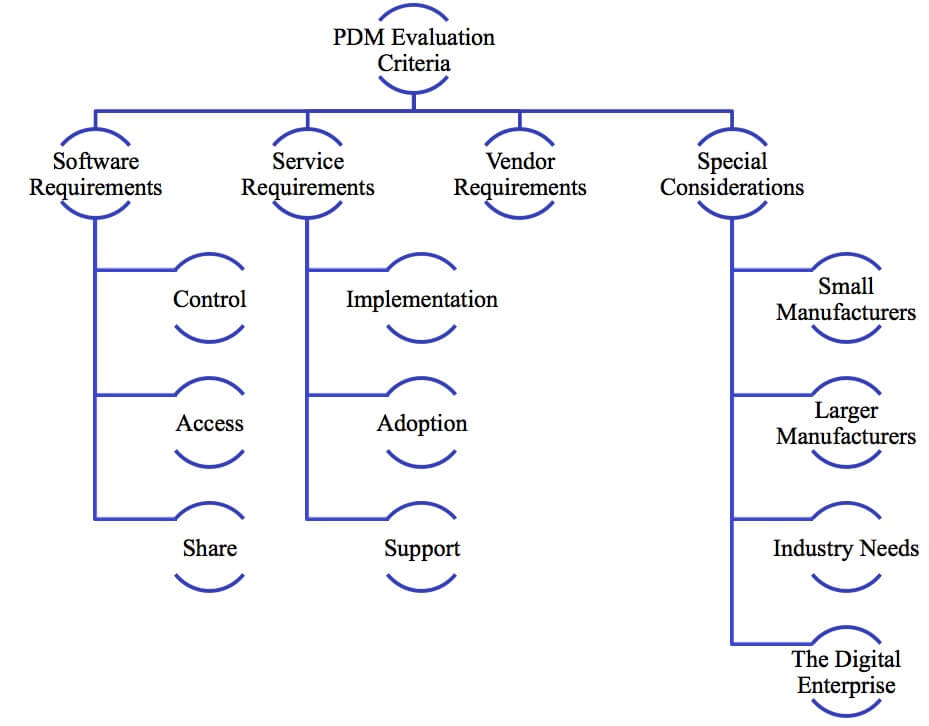

Like our other buyer’s guides, we go beyond functional requirements to address implementation, adoption, vendor partner, and special considerations. We also touch on another recommendation from our PDM guide, specifically how manufacturers can make sure they don’t hit another dead end with their new system as they evolve to become a more digital enterprise.

Understanding the Buyer’s Guide Structure

Like our other buyer’s guides, we go beyond functional requirements to address implementation, adoption, vendor partner, and special considerations. We also touch on another recommendation from our PDM guide, specifically how manufacturers can make sure they don’t hit another dead end with their new system as they evolve to become a more digital enterprise.

Next Steps

Extend Basic PDM Investment to Increase Value Companies that have outgrown their PDM system can leverage their existing investment in organizing CAD files and adopt a new system to take advantage of more mature capabilities. Our research shows the value of the transition. Top Performing companies are more likely to have structured, collaborative systems like a more mature PDM or a PLM system. It’s time to go beyond EDM or basic PDM systems to help unlock innovation and improve product development efficiency. The requirements set forth in this guide can help frame the software selection and decision-making process to find the right system. Companies should start by focusing on the highlighted areas in the Control - Access – Share sections. This is where less capable, “generalist” file management solutions fall short because they lack an intimate understanding of processes for product innovation, product development, engineering, and support. Companies should also consider the requirements in the four new areas discussed in this guide. Create the Foundation for Further Growth As companies adopt a more advanced PDM system, it’s important to give themselves room to expand to more mature capabilities over time. For many companies, that involves adopting advanced PDM capabilities as part of a more comprehensive PLM system to address additional aspects of products, process, departments, and product lifecycles. These are the key areas that expand PDM to PLM, and areas that PLM vendors continue to expand their solution scope. Consider a Platform for the Greatest Potential Value One good option manufacturers should consider to meet extended PDM needs is adopting a Product Innovation Platform (PIP). A PIP offers manufacturers the ability to expand PDM today and create room to grow as they are ready to adopt more, or more mature, processes. A PIP with a modular approach will allow them to scale and add capabilities as they need them. Some common areas that manufacturers extend include:- Requirements Management

- Quality Management

- Product Costing

- Product Compliance and Sustainability

- Manufacturing / Bill of Process

- Service Lifecycle Management

- Systems Engineering

- Program Management

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below. [post_title] => Expanding Beyond Your Outgrown PDM System (Buyer's Guide) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => outgrown-pdm [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:55 [post_modified_gmt] => 2022-11-15 03:27:55 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=7356 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [2] => WP_Post Object ( [ID] => 7325 [post_author] => 2 [post_date] => 2018-11-19 09:10:21 [post_date_gmt] => 2018-11-19 14:10:21 [post_content] => Manufacturing is going through a significant, digital transformation that's disrupting the industry status quo. Companies are investing in digital transformation, smart manufacturing, Industry 4.0, Internet of Things (IoT), and other related initiatives. What are they prioritizing? And, what are they actually taking action on? Tech-Clarity surveyed over 130 manufacturers to find out. The report analyzes companies strategic priorities including Industry 4.0, IoT, IIoT, Digital Twin, Digital Thread, Augmented Reality (AR), and Virtual Reality (VR). It also investigates how they're executing against them as an enterprise including:

Manufacturing is going through a significant, digital transformation that's disrupting the industry status quo. Companies are investing in digital transformation, smart manufacturing, Industry 4.0, Internet of Things (IoT), and other related initiatives. What are they prioritizing? And, what are they actually taking action on? Tech-Clarity surveyed over 130 manufacturers to find out. The report analyzes companies strategic priorities including Industry 4.0, IoT, IIoT, Digital Twin, Digital Thread, Augmented Reality (AR), and Virtual Reality (VR). It also investigates how they're executing against them as an enterprise including:

- If they have executive sponsorship

- Whether they're budgeted

- If a cross-functional team is deployed

- How systems like PLM can help

“Digital” is Viewed as a Significant Business Priority

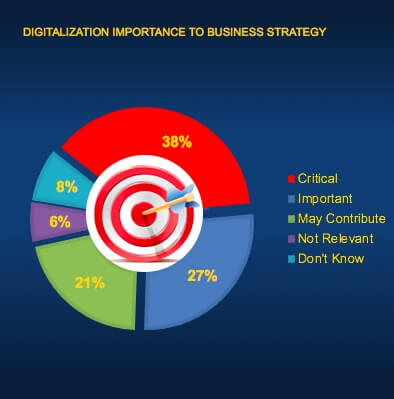

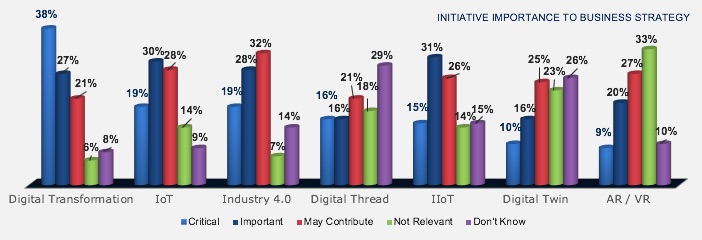

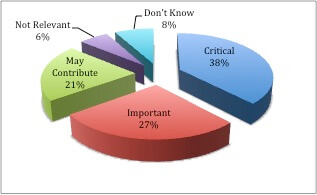

Executive Overview Manufacturers are weighing their options and considering a number of strategic manufacturing initiatives. Many of them are related and all are competing for budget, time, and attention. Which investments are getting the most attention? How are manufacturers addressing the opportunities? How are they leveraging PLM solutions as an enabler? Tech-Clarity conducted a survey of over 130 manufacturers to find out. The program most frequently cited as critical to the business strategy is Digitalization / Digital Enterprise. More than one-half of respondents say that these digital initiatives are “important” if not “critical” to their business strategy. PLM’s Role in Supporting Digital Transformation

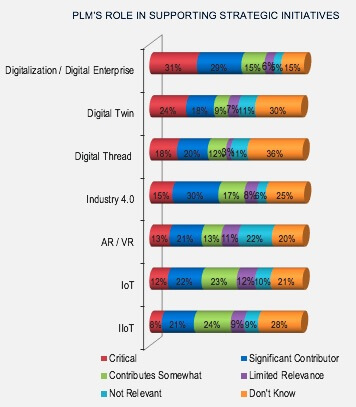

The survey also investigates how Product Lifecycle Management (PLM) supports these strategic manufacturing initiatives. The study finds that PLM not only provides strategic value to existing operations, but also maps well to the manufacturers’ strategic initiatives. This reflects PLM’s importance as the backbone of the digital manufacturing enterprise.

PLM’s Role in Supporting Digital Transformation

The survey also investigates how Product Lifecycle Management (PLM) supports these strategic manufacturing initiatives. The study finds that PLM not only provides strategic value to existing operations, but also maps well to the manufacturers’ strategic initiatives. This reflects PLM’s importance as the backbone of the digital manufacturing enterprise.

A Variety of Digital Initiatives are Deemed Strategic

Digital Transformation is the Leading Priority Surveyed companies report Digital Transformation as the initiative most critical to achieving their business strategy. The second most commonly cited initiative is IoT (Internet of Things). IoT may be a subset of an overall digital transformation initiative. In fact, “Digital Transformation” may serve as a strategic umbrella for many of the initiatives investigated. Industry 4.0 is a High Priority Beyond digitalization, reported on par with IoT initiatives, is Industry 4.0 which was defined as “Industry 4.0 / Smart Manufacturing.” Roughly one-half of companies surveyed say that these initiatives are important or critical to achieving their business strategy. Uncertainty Surrounds Digital Twin and Digital Thread

Manufacturers appear to be unclear about the value of Digital Twin and Digital Thread initiatives. For each, more than one-quarter of respondents claim that they don’t know how important these initiatives are to their business. These are both newer concepts, or at least more prevalently discussed today. Manufacturers should educate themselves on the potential of these important initiatives and explore the value. Lastly, responses to AR / VR value likely reflect that they are more enablers than strategies by themselves.

Uncertainty Surrounds Digital Twin and Digital Thread

Manufacturers appear to be unclear about the value of Digital Twin and Digital Thread initiatives. For each, more than one-quarter of respondents claim that they don’t know how important these initiatives are to their business. These are both newer concepts, or at least more prevalently discussed today. Manufacturers should educate themselves on the potential of these important initiatives and explore the value. Lastly, responses to AR / VR value likely reflect that they are more enablers than strategies by themselves.

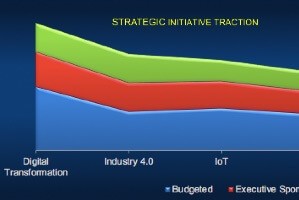

Initiatives Vary in Level of Executional Traction

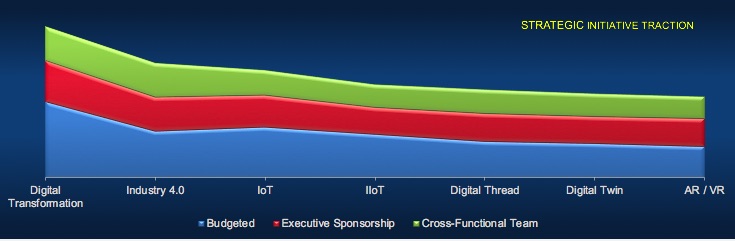

Investigating Initiative Traction The initiatives most frequently reported as critical to the business strategy are Digitalization, IoT, and Industry 4.0. Let’s look beyond what companies say is important to understand what they’re doing about it. Budget

Digital Transformation is more likely than the other initiatives to have a formal budget. Other initiatives with budgets in one-half or more of responding companies include Industry 4.0 and IoT.

Sponsorship

The CEO / Board are more focused on Digitalization than other programs. There is more focus a level down at the VP / C-Level on additional items including Industry 4.0 and IoT. Most initiatives, however, are more likely to be sponsored by mid-level managers / directors.

Execution Responsibility

Digital Transformation and Industry 4.0 are the most likely to be executed by cross-functional teams. Other initiatives are more likely to be executed at a departmental level.

Budget

Digital Transformation is more likely than the other initiatives to have a formal budget. Other initiatives with budgets in one-half or more of responding companies include Industry 4.0 and IoT.

Sponsorship

The CEO / Board are more focused on Digitalization than other programs. There is more focus a level down at the VP / C-Level on additional items including Industry 4.0 and IoT. Most initiatives, however, are more likely to be sponsored by mid-level managers / directors.

Execution Responsibility

Digital Transformation and Industry 4.0 are the most likely to be executed by cross-functional teams. Other initiatives are more likely to be executed at a departmental level.

PLM is Key to Strategic Manufacturing Initiatives

PLM Enables Digital Transformation The survey analyzed how PLM supports the strategic initiatives manufacturers recognize as important to their business strategy. The responses show that PLM plays a critical or significant role in many of the initiatives. This highlights the importance of PLM as the innovation backbone for the digital enterprise. PLM is seen as a major contributor to achieving digital transformation. PLM can provide the digital backbone, providing product context for data. It’s also a contributor to the two less strategically viewed (and understood) initiatives, the Digital Twin and the Digital Thread. PLM can help track product development history, tie data together from step to step, and provide the product details needed to enable a complete digital twin, including revisions and configurations.

PLM Important to Support Industry 4.0

PLM is also a significant contributor to another big priority, Industry 4.0, although it’s identified as more “significant” than “critical.” This is likely because Industry 4.0 requires an ecosystem of solutions including MES (Manufacturing Executing Systems).

IoT and IIoT Leverage PLM as Part of an Ecosystem

IoT and IIoT are very broad initiatives, where PLM can play an important role by providing product information in a much larger context. The data, and experience, shows that IoT requires more than PLM. Supporting these initiatives requires analytics, dashboards, equipment communication, edge computing, ties to other enterprise systems, and more. Many leading PLM vendors have expanded their suites beyond traditional PLM for this reason.

PLM is seen as a major contributor to achieving digital transformation. PLM can provide the digital backbone, providing product context for data. It’s also a contributor to the two less strategically viewed (and understood) initiatives, the Digital Twin and the Digital Thread. PLM can help track product development history, tie data together from step to step, and provide the product details needed to enable a complete digital twin, including revisions and configurations.

PLM Important to Support Industry 4.0

PLM is also a significant contributor to another big priority, Industry 4.0, although it’s identified as more “significant” than “critical.” This is likely because Industry 4.0 requires an ecosystem of solutions including MES (Manufacturing Executing Systems).

IoT and IIoT Leverage PLM as Part of an Ecosystem

IoT and IIoT are very broad initiatives, where PLM can play an important role by providing product information in a much larger context. The data, and experience, shows that IoT requires more than PLM. Supporting these initiatives requires analytics, dashboards, equipment communication, edge computing, ties to other enterprise systems, and more. Many leading PLM vendors have expanded their suites beyond traditional PLM for this reason.

Conclusions and Next Steps

The Manufacturing Industry is in a Revolution The manufacturing industry is changing rapidly and companies have to digitalize or risk losing their market position. Manufacturers are responding, targeting a number of important strategic initiatives related to becoming a digital enterprise. The Digital Transformation Has Begun Digital Transformation is seen as the most critical initiative for the manufacturing industries. Research for this report shows that digital transformation has significant support at the Board level. It’s also a funded initiative that’s more likely to have cross-functional teams executing the program. Industry 4.0 and IoT Initiatives are also frequently viewed as contributors to the corporate business strategy. Although the other initiatives may not have as much executive and enterprise traction, they are also being addressed and play important roles in the overall digital transformation of the company. PLM is a Key Enabler to Support the Digital Revolution PLM plays a key role in supporting digitalization initiatives, serving as the digital innovation backbone. PLM also supports important digital capabilities, including Digital Twin and Digital Thread, which show promise but require some additional education for many companies. PLM is important to the entire Digital Transformation strategy because it provides the product context, history, and details required to support the digital product and manufacturing strategy. Recommended Next Steps Activity level is high, and so are the stakes in terms of impact on business performance. We believe it’s time for manufacturers to review their business strategy, make sure they are educated on these high-level initiatives, and determine how to put these strategies into action. [post_title] => The State of Digitalization in Manufacturing (survey results) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => state-digitalization [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:49 [post_modified_gmt] => 2022-11-15 03:28:49 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=7325 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [3] => WP_Post Object ( [ID] => 7314 [post_author] => 2 [post_date] => 2018-11-12 16:06:31 [post_date_gmt] => 2018-11-12 21:06:31 [post_content] => How can manufacturers extend their PLM investments to gain higher levels of business value? The new 5 Ways to Get More Business Value from Your PLM System offers practical approaches for companies to leverage their existing Product Lifecycle Management investment to improve top-line and bottom-line performance, including tips gained from two leading manufacturers.

Please enjoy the summary below. For the full report, please visit our sponsor Razorleaf (no charge, registration required).

How can manufacturers extend their PLM investments to gain higher levels of business value? The new 5 Ways to Get More Business Value from Your PLM System offers practical approaches for companies to leverage their existing Product Lifecycle Management investment to improve top-line and bottom-line performance, including tips gained from two leading manufacturers.

Please enjoy the summary below. For the full report, please visit our sponsor Razorleaf (no charge, registration required).

Has your PLM Value Stalled?

It’s time to re-energize your PLM solution. Most companies start their PLM implementations with high ambitions for strategic business results. Too often they get through the first implementation, typically supporting core Product Data Management (PDM), and stall. Companies like this are missing a golden opportunity. Once the PLM foundation is in place, there’s a lot more than can be done to leverage it for greater value. Our research shows that companies gain significantly higher levels of ROI from supplemental PLM projects than from their initial implementation. “Expanding capabilities is much easier when you have the foundation in place and a community with PLM skills,” offers the manager of a leading transportation equipment manufacturer.

Even if your company has already gone beyond the basics, it’s likely that changes in your business have opened up opportunities that weren’t considered earlier. Beyond that, the manufacturing industry’s shift to the digital enterprise offers compelling new opportunities that can expand PLM value including IoT, Digital Twin, Augmented Reality (AR), and more. There are proven ways to do it. Let’s explore how your company can leverage what you have to do more.

Expanding Your PLM Value

Most companies have a lot more value to extract from PLM. Even if your company has completed all of your planned phases and met your original goals, it’s very likely they could go beyond what they initially expected. Many companies can get more by simply extending what they have. The digital evolution of the manufacturing industry and PLM’s adoption of platform and cloud architectures have unlocked significant new opportunities for business value for those that want to go further. It’s time for companies to start with the business in mind, make sure they’ve locked in the value available from the basics, and then look to achieve more. “Think of it as an ROI driven investment,” advises the manager of the transportation equipment manufacturer. “Don’t just do it because it’s cool, have a vision for where you want to go and how the tools will get you there. Do the evaluation to make sure it’s worthwhile for the business. Keep improving so you don’t become stagnant.” PLM helps companies manage complexity, improve productivity, and reduce cost. But PLM can do more, enabling top-line growth and margin expansion. It’s also important to recognize that digitalization is changing the market landscape. PLM can provide the foundation to support IoT and other transformational initiatives that may significantly change your company’s value proposition and competitive standing. It’s time to get started. [post_title] => 5 Ways to Get More Business Value from PLM [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => more-from-plm [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:53 [post_modified_gmt] => 2022-11-15 03:27:53 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=7314 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 7303 [post_author] => 2572 [post_date] => 2018-11-01 13:57:03 [post_date_gmt] => 2018-11-01 17:57:03 [post_content] => If you are in the medical device industry, are you prepared for the EU MDR?In this on-demand webcast, Tech-Clarity's Michelle Boucher interviews Caroline Byrd, regulatory expert at Abbott, about the steps Abbott has taken to prepare product data for EU MDR compliance. They discuss:

- Significant changes between the MDD and MDR

- How to prioritize the work required to ensure you have the product data to comply with the EU MDR

- Key roles and responsibilities to define to support the compliance efforts

- The role of technology, including PLM, to create a digital thread that will support complete submissions

[post_title] => EU MDR: How Abbott is Getting Their Digital House In Order (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => eu-mdr-abbott-digital-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:58

[post_modified_gmt] => 2022-11-15 03:26:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7303

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 7279

[post_author] => 2

[post_date] => 2018-10-31 10:20:59

[post_date_gmt] => 2018-10-31 14:20:59

[post_content] =>

[post_title] => EU MDR: How Abbott is Getting Their Digital House In Order (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => eu-mdr-abbott-digital-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:58

[post_modified_gmt] => 2022-11-15 03:26:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7303

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 7279

[post_author] => 2

[post_date] => 2018-10-31 10:20:59

[post_date_gmt] => 2018-10-31 14:20:59

[post_content] =>  How can manufacturers improve OEE with IoT Analytics? How can they leverage IoT and IIoT data to drive higher performance and extend the advantages they've gained from Six Sigma and other productivity improvement programs? Improving Manufacturing Performance with IoT Analytics takes a look at how to improve Operational Equipment Effectiveness through digitalization. Specifically, the report looks at how analytics can help reduce the Six Big Losses of OEE.

Please enjoy the summary below (no charge, no registration required).

For the full report, please visit our sponsor PTC (no charge, registration required).

How can manufacturers improve OEE with IoT Analytics? How can they leverage IoT and IIoT data to drive higher performance and extend the advantages they've gained from Six Sigma and other productivity improvement programs? Improving Manufacturing Performance with IoT Analytics takes a look at how to improve Operational Equipment Effectiveness through digitalization. Specifically, the report looks at how analytics can help reduce the Six Big Losses of OEE.

Please enjoy the summary below (no charge, no registration required).

For the full report, please visit our sponsor PTC (no charge, registration required).

Improving Productivity Through Digitalization

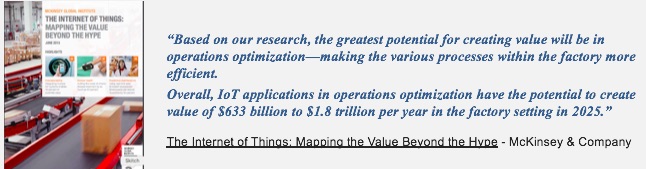

The Strategic Importance of Digitalization Digitalization is changing the landscape in manufacturing as companies adopt Industry 4.0, Smart Manufacturing, and Digital Transformation initiatives. In fact, a recent Tech-Clarity survey shows that over one-half of manufacturers believe that digitalization / digital transformation initiatives are “important” if not “critical” to achieving their business strategy. The Internet of Things (IoT) is a critical component of digitalization in the plant, helping companies connect with production assets to better monitor how they perform. Beyond gathering data, manufacturers can leverage advanced analytics to gain real intelligence about plants and production to improve operations, driver higher performance, and guide continuous improvement.

The Internet of Things (IoT) is a critical component of digitalization in the plant, helping companies connect with production assets to better monitor how they perform. Beyond gathering data, manufacturers can leverage advanced analytics to gain real intelligence about plants and production to improve operations, driver higher performance, and guide continuous improvement.

Justifying IoT Analytics Investments

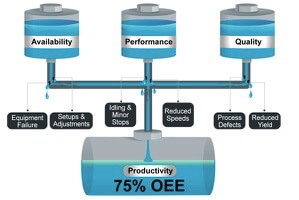

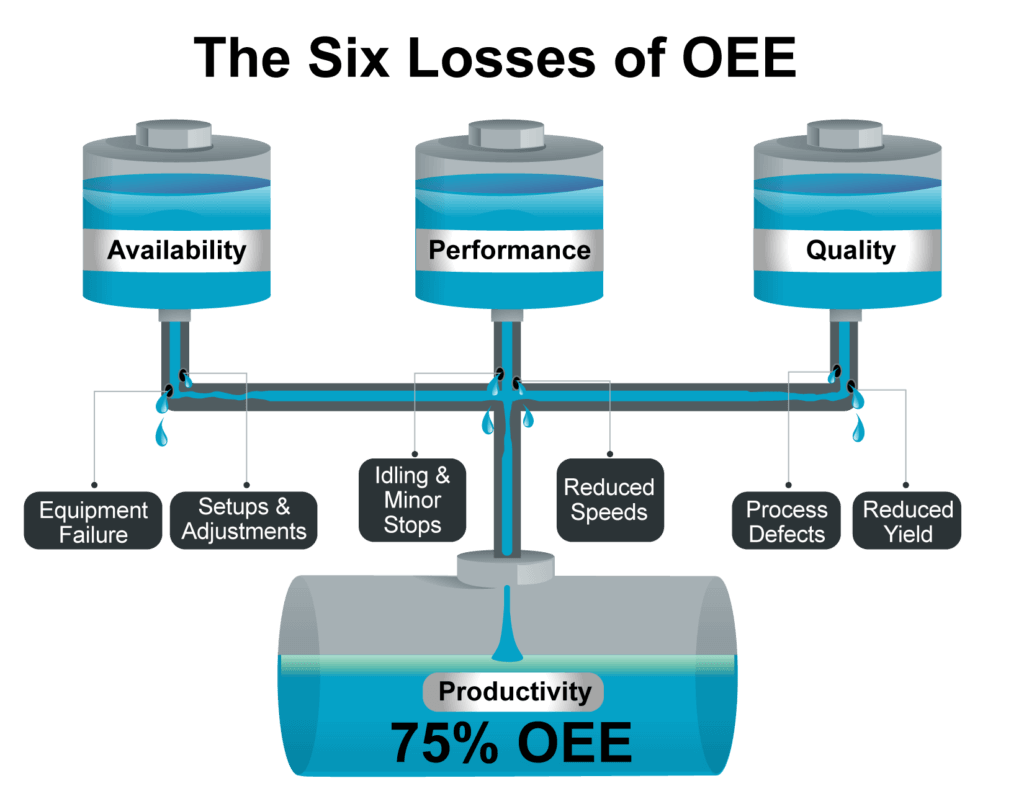

For some companies, leveraging the Industrial IoT (IIoT) is simply a strategic “must do.” For others, they have to cost justify it. This eBook offers a framework to develop an ROI for IoT investments using a common manufacturing metric, Overall Equipment Effectiveness (OEE).

Analyzing improvement potential by OEE allows companies to determine potential savings in the context of the plant. The framework shows how companies can use the IoT and analytics to reduce the “Six Big Losses of OEE” and tangibly improve the three components of OEE – Availability, Performance, and Quality. Manufacturers can compare these improvement opportunities to the investment required to achieve them in order to calculate an ROI.

Justifying IoT Analytics Investments

For some companies, leveraging the Industrial IoT (IIoT) is simply a strategic “must do.” For others, they have to cost justify it. This eBook offers a framework to develop an ROI for IoT investments using a common manufacturing metric, Overall Equipment Effectiveness (OEE).

Analyzing improvement potential by OEE allows companies to determine potential savings in the context of the plant. The framework shows how companies can use the IoT and analytics to reduce the “Six Big Losses of OEE” and tangibly improve the three components of OEE – Availability, Performance, and Quality. Manufacturers can compare these improvement opportunities to the investment required to achieve them in order to calculate an ROI.

Next Steps – Getting Started

Develop Your IoT Analytics ROI Using The OEE Framework Whether you’re trying to grow OEE from the middle of the pack or trying to eek out additional improvements to continuously approach 100%, IoT analytics is a very good option. Companies can use the framework in this eBook to estimate the business value of an IoT analytics initiative based on research and case studies, tailoring the assumptions to fit their business and adding costs to develop an ROI and justify their efforts. Start Small and Expand Of course it’s important that companies recognize that they should start small, gain tangible value, and create a foundation to expand on. Early projects should be valuable and measurable with tangible business results, not just technical proofs of concept. They should identify and prioritize opportunities in the plant based on the ability to improve OEE. For example, they can use IoT analytics reduce equipment downtime for a problem workcell or improve yield for a challenging product. At the same time, they should keep costs low and set the foundation for the future by using a scalable, platform-based approach. Get Started It’s time to improve productivity by reducing the 6 Big Losses of OEE and driving improvements to Availability, Performance, and Quality. Pick a project and scale up the value by extending to new products, production lines, plants, or geographies. It’s time for manufacturing to drive meaningful change with IoT analytics and set the stage for future improvements beyond the plant. Remember, a small improvement to OEE can drive significant bottom line results, and the foundation created by Manufacturing can open up new business models and revenue opportunities across the business. *This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below. [post_title] => Improving Manufacturing Performance with IoT Analytics (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => iot-analytics [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:13 [post_modified_gmt] => 2022-11-15 03:28:13 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=7279 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [6] => WP_Post Object ( [ID] => 7236 [post_author] => 2572 [post_date] => 2018-10-23 15:57:02 [post_date_gmt] => 2018-10-23 19:57:02 [post_content] => How can you strengthen your engineering team with new hires who have the required engineering skills to quickly become productive members of the team? Hear from Tech-Clarity's Michelle Boucher and Dora Smith, Senior Director of Siemens PLM's Global Academic Program, as they discuss the required skills for new engineering graduates to be successful on today's product development teams. This 25 minute interactive discussion reveals research findings such as:

Hear from Tech-Clarity's Michelle Boucher and Dora Smith, Senior Director of Siemens PLM's Global Academic Program, as they discuss the required skills for new engineering graduates to be successful on today's product development teams. This 25 minute interactive discussion reveals research findings such as:

- What skills Top Performing companies look for in new graduates

- The types of experiences that provide engineering students with the right practical skills

- What your company can do to strengthen the pool of engineering graduates

[post_title] => Closing the Engineering Skills Gap (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => engineering_skills_gap

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:58

[post_modified_gmt] => 2022-11-15 03:26:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7236

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 7222

[post_author] => 2

[post_date] => 2018-10-22 12:46:31

[post_date_gmt] => 2018-10-22 16:46:31

[post_content] =>

[post_title] => Closing the Engineering Skills Gap (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => engineering_skills_gap

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:58

[post_modified_gmt] => 2022-11-15 03:26:58

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7236

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 7222

[post_author] => 2

[post_date] => 2018-10-22 12:46:31

[post_date_gmt] => 2018-10-22 16:46:31

[post_content] =>  How can manufacturers expand their PLM implementation to get more value from their Product Lifecycle Management system? Join this webcast to hear Jim Brown shares his perspective and research, including interviews with two manufacturers that have gone beyond their initial PLM footprint.

Implementing PLM successfully is more of a journey than a destination. In a recent study, Tech-Clarity interviewed companies using PLM and found 5 Ways businesses are extracting more value from their PLM investment.

Join us on October 30th at 12PM EDT on a Live Webinar where Jim Brown of Tech-Clarity will reveal his findings: 5 Ways to Get More Business Value from your PLM System.

How can manufacturers expand their PLM implementation to get more value from their Product Lifecycle Management system? Join this webcast to hear Jim Brown shares his perspective and research, including interviews with two manufacturers that have gone beyond their initial PLM footprint.

Implementing PLM successfully is more of a journey than a destination. In a recent study, Tech-Clarity interviewed companies using PLM and found 5 Ways businesses are extracting more value from their PLM investment.

Join us on October 30th at 12PM EDT on a Live Webinar where Jim Brown of Tech-Clarity will reveal his findings: 5 Ways to Get More Business Value from your PLM System.

Learn how to:

Learn how to:

- Reenergize your PLM strategy and implementation plan

- Expand PLM capabilities around product processes

- Identify other functional areas and processes beyond engineering who can benefit from PLM

- Provide better data access and insight for downstream functions

What do leading industry analysts think about Siemens PLM strategy and execution? Industry analyst Allan Behrens of Taxal hosted a discussion about Siemens PLM with two other analysts, Monica Schnitger of Schnitger Corp and Tech-Clarity's Jim Brown. The Disruptive presentation was a unique glimpse at industry watchers (trying not to call ourselves "experts") sharing our key takeaways from an invitation only analyst and press event. It's always a pleasure to speak with Monica and Allan, and it was great to hear that each of us focus on the business value of the technology as opposed to the technology itself. That was a great fit for the conference, which Siemens organized by business initiative instead of their software product lines (a winning approach, in all of our opinions).

So...

What do leading industry analysts think about Siemens PLM strategy and execution? Industry analyst Allan Behrens of Taxal hosted a discussion about Siemens PLM with two other analysts, Monica Schnitger of Schnitger Corp and Tech-Clarity's Jim Brown. The Disruptive presentation was a unique glimpse at industry watchers (trying not to call ourselves "experts") sharing our key takeaways from an invitation only analyst and press event. It's always a pleasure to speak with Monica and Allan, and it was great to hear that each of us focus on the business value of the technology as opposed to the technology itself. That was a great fit for the conference, which Siemens organized by business initiative instead of their software product lines (a winning approach, in all of our opinions).

So...

- What do we think of the Siemens PLM strategy?

- What were our impressions of how Siemens' views the digital twin?

- What are our views on the way that Siemens is incorporating the technology - and the thought leaders - from their significant acquisitions?

- How do we perceive the integration across the Siemens PLM platform?

- What did we observe about the role Siemens PLM plays in the broader Siemens community?

- What else did Allan want us to chat about?

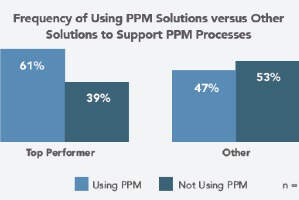

Tech-Clarity was commissioned by Planview to conduct their 6th Annual Product Portfolio Management Benchmark Survey, titled The Business Transformation Required to Innovate in the Digital Era. The survey evaluated trends in managing product portfolios including challenges, processes, and technologies used to make portfolio decisions. Tech-Clarity applied our performance banding methodology to determine what Top Performers do differently than others to achieve better production innovation results. This report also includes a new perspective on the impact of the digital transformation and resulting complexity on portfolio management.

Please see the report on Planview's site (no charge, registration required).

You can also view Tech-Clarity's executive summary with some key findings on our site.

[post_title] => Sixth Annual Product Portfolio Management Benchmark Study

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ppm-benchmark-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:54

[post_modified_gmt] => 2022-11-15 03:25:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7203

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 7190

[post_author] => 2

[post_date] => 2018-10-08 09:32:28

[post_date_gmt] => 2018-10-08 13:32:28

[post_content] =>

Tech-Clarity was commissioned by Planview to conduct their 6th Annual Product Portfolio Management Benchmark Survey, titled The Business Transformation Required to Innovate in the Digital Era. The survey evaluated trends in managing product portfolios including challenges, processes, and technologies used to make portfolio decisions. Tech-Clarity applied our performance banding methodology to determine what Top Performers do differently than others to achieve better production innovation results. This report also includes a new perspective on the impact of the digital transformation and resulting complexity on portfolio management.

Please see the report on Planview's site (no charge, registration required).

You can also view Tech-Clarity's executive summary with some key findings on our site.

[post_title] => Sixth Annual Product Portfolio Management Benchmark Study

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ppm-benchmark-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:54

[post_modified_gmt] => 2022-11-15 03:25:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7203

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 7190

[post_author] => 2

[post_date] => 2018-10-08 09:32:28

[post_date_gmt] => 2018-10-08 13:32:28

[post_content] =>  How can manufacturers survive when they can't consolidate on a single CAD format? Is that even a possibility? Given the unavoidable reality of multi-CAD, let's see if there's a better way to manage the mayhem without spending so much non-value-added time. This eBook shares our perspective on the most practical way to manage designs created by different CAD systems. We also share the experience of two manufacturers, Steelcase and KMP Drivetrains, that successfully address this challenge every day based on the realities of their businesses.

Please enjoy the summary below.

For the full report please visit our sponsor, Autodesk (no charge, registration required).

How can manufacturers survive when they can't consolidate on a single CAD format? Is that even a possibility? Given the unavoidable reality of multi-CAD, let's see if there's a better way to manage the mayhem without spending so much non-value-added time. This eBook shares our perspective on the most practical way to manage designs created by different CAD systems. We also share the experience of two manufacturers, Steelcase and KMP Drivetrains, that successfully address this challenge every day based on the realities of their businesses.

Please enjoy the summary below.

For the full report please visit our sponsor, Autodesk (no charge, registration required).

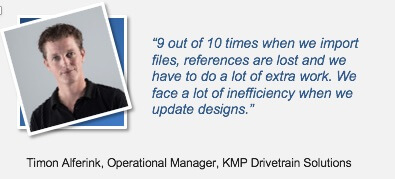

Multi-CAD Mayhem

Does this sound all too familiar?- We spend hours working on suppliers’ designs before we can do any real value-added work

- We waste time re-importing design changes from partners and still have to redo all of our modifications like adding ribs or creating tool paths

- The engineering firm that does our advanced FEA faces the same inefficiencies with our files

- Our industrial designers need features that aren’t supported by our design engineers’ CAD

- We have to rework every design before we send it to the shop floor

- We have years of effort and knowledge in old CAD files so we have to pay for licenses, but we still end up remodeling for the next revision

- We want to move CAD to the cloud, but we’re don’t want to leave our IP behind on the desktop

- We can’t afford to retrain all of the engineers from the company we just acquired and migrate them to our “primary” CAD tool

Multi-CAD leads to significant non-value-added work. Given the unavoidable reality of multi-CAD, there should be a better way to manage the mayhem without wasting so much time. Let’s take a look.

Multi-CAD leads to significant non-value-added work. Given the unavoidable reality of multi-CAD, there should be a better way to manage the mayhem without wasting so much time. Let’s take a look.

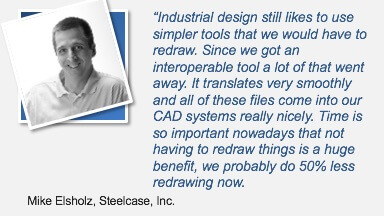

Evaluating Your Survival Options

You may have ended up in a multi-CAD situation due to legacy CAD files, customer mandates, supply chain realities, internal requirements, or all of the above. Regardless of the reason, this is the way it’s going to be. Now, what are you going to do in order to survive? We explore four options:- Option 1: The Status Quo

- Option 2: Standardize on a Common CAD System

- Option 3: Common, Interoperable CAD Data

- Option 4: Incorporating Non-native CAD with Associativity

Next Steps

Pack Interoperability in your Multi-CAD Survival Kit It’s time to adopt non-native CAD with associativity capabilities to take away the multi-CAD productivity penalty. These capabilities are applicable to many different kinds of scenarios and companies. “For a job shop that machines for others if the customer changes a STEP file and changes a face it would they would need to redo 50% for their CAM program because it lost all of the references, but it would be easy with associative CAD interoperability,” explains KMP Drivetrain Solutions’ Alferink. Interoperability and Productivity go Hand-in-Hand The bottom line is that you should demand this kind of interoperability. It exists. Associative interoperability is the new best practice and state of the art to survive the reality of multi-CAD. “In the end, CAD interoperability drives efficiency. Without it, somebody will make a change a part and it will take much longer because you have to redo a lot of work. Associative CAD interoperability will be more efficient for design changes,” concludes KMP Drivetrain Solutions’ Alferink. The Business Value of Native CAD with Associativity

Native CAD with associativity allows companies to develop seamless design workflows regardless of format and adapt quickly to changing designs. It allows companies to embrace collaboration with others regardless of their tool of choice. It can also open up your own ability to embrace new CAD solutions (including cloud options) without worrying about leaving your IP behind.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => The CAD Interoperability Survival Guide (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cad-interoperability

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:12

[post_modified_gmt] => 2022-11-15 03:28:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7190

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 7178

[post_author] => 2

[post_date] => 2018-10-01 13:02:12

[post_date_gmt] => 2018-10-01 17:02:12

[post_content] =>

The Business Value of Native CAD with Associativity

Native CAD with associativity allows companies to develop seamless design workflows regardless of format and adapt quickly to changing designs. It allows companies to embrace collaboration with others regardless of their tool of choice. It can also open up your own ability to embrace new CAD solutions (including cloud options) without worrying about leaving your IP behind.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => The CAD Interoperability Survival Guide (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cad-interoperability

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:12

[post_modified_gmt] => 2022-11-15 03:28:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7190

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 7178

[post_author] => 2

[post_date] => 2018-10-01 13:02:12

[post_date_gmt] => 2018-10-01 17:02:12

[post_content] =>  Tech-Clarity research shows that the majority of manufacturers believe that digitalization is important or critical to achieving their business strategy (see figure). Over one-third say that it’s critical. Digitalization in medical device design and manufacturing has significant promise, but what does it actually mean?

Medical device companies, already struggling with how to address critical initiatives like UDI and the Case for Quality, are inundated with information about “digitalization” accompanied with a host of buzzwords including Digital Twins, Digital Threads, and more. How do they really apply to the design, approval, production, and lifecycle management of medical devices? We’ll try to put it into practical terms.

Tech-Clarity research shows that the majority of manufacturers believe that digitalization is important or critical to achieving their business strategy (see figure). Over one-third say that it’s critical. Digitalization in medical device design and manufacturing has significant promise, but what does it actually mean?

Medical device companies, already struggling with how to address critical initiatives like UDI and the Case for Quality, are inundated with information about “digitalization” accompanied with a host of buzzwords including Digital Twins, Digital Threads, and more. How do they really apply to the design, approval, production, and lifecycle management of medical devices? We’ll try to put it into practical terms.

Digital Thread

Let’s start with the digital thread. That’s probably the most straightforward concept and one that provides tangible value. The digital thread, in its simplest definition, is the collection of information used to define, engineer, and develop a product. Ideally it moves beyond the manufacturer into the in-service part of the equipment lifecycle. It offers a view of the digital continuity of the life of the device. The value for medical device companies, in a nutshell, is end-to-end traceability. It’s the connection between everything from patient needs and early requirements through the patient experience, including post market surveillance requirements required by the EU MDR. It provides a broad base of information that allows medical device companies to analyze and learn from history, for example tracking down root causes for a CAPA. The digital thread also clearly supports regulatory requirements related to these needs including the DHF and UDI, including all of the local variants of the regulations. In addition, the digital thread also provides an integrated source of data that can be used to prepare submission documentation. With the digital thread as the trusted data source, medical device companies can automate much of the process to generate these crucial reports.Digital Twin

One of the key contributors to the digital thread is the Digital Twin. The digital twin has multiple definitions, but it starts at the core as a complete, digital model of the device. It incorporates a holistic view of the design to a level of granularity that companies can accurately simulate and predict device performance and behavior. There is clear overlap with the digital thread in this part of the definition.

The value of the digital model for medical device companies is a cohesive view of the device. It allows people from various disciplines to contribute their part of the design and see it in the context of the whole product. It allows engineers to analyze and optimize performance early in the product lifecycle, catching errors and improving performance in silica before physical prototypes are developed. As regulatory bodies get more comfortable with simulation data, the digital twin may also play a big part in reducing the length and cost of clinical trials. The digital thread also delivers quality management and regulatory value including the development of the DMR.

One of the key contributors to the digital thread is the Digital Twin. The digital twin has multiple definitions, but it starts at the core as a complete, digital model of the device. It incorporates a holistic view of the design to a level of granularity that companies can accurately simulate and predict device performance and behavior. There is clear overlap with the digital thread in this part of the definition.

The value of the digital model for medical device companies is a cohesive view of the device. It allows people from various disciplines to contribute their part of the design and see it in the context of the whole product. It allows engineers to analyze and optimize performance early in the product lifecycle, catching errors and improving performance in silica before physical prototypes are developed. As regulatory bodies get more comfortable with simulation data, the digital twin may also play a big part in reducing the length and cost of clinical trials. The digital thread also delivers quality management and regulatory value including the development of the DMR.

Connected Digital Twin

The value of the digital twin expands dramatically when it goes beyond device production and into usage. Some would say a digital twin without connectivity isn’t a complete twin, but regardless of definitions a digital model is highly valuable. But a connected one adds significantly greater value. The rise of the IoT adds a new dimension to the value available from the digital twin. Companies can collect real-world device performance and associate it back with the intention of the design model. This can help identify issues where devices are not performing as designed, and may provide an early indicator of a potential variance. A second aspect of the digital twin is identifying differences between predicted and actual device performance where the device is operating as designed, but not as intended. In these cases, there are gaps in the simulated performance of the digital model that can be addressed to improve simulations and understanding of how devices perform in the field. Medical device companies gain significant value from the connected digital twin. It rounds out the information in the DMR and supports a more robust data set for UDI. It could also be used early in the lifecycle to help support clinical trials, as well as other regulatory demands throughout the lifecycle.Digital Twin of the Plant

Another aspect of the digital twin is creating digital twins of the equipment used to produces devices. Companies can create fully functioning models of machines, lines, and plants to design, simulate, and optimize production. As with the digital twin of the product, connecting the digital twin provides even greater value. In this case, it may include the IIoT in addition to the IoT. The digital twin of the plant helps medical device companies validate production methodology, SOPs, and set critical control points to improve control, reduce variability, and improve quality. It can also be used to validate process control intent with regulatory bodies. These twins, along with the digital twin of the device (which should be integrated) can also help automate regulatory submissions. Again, we see significant overlap in the use of digital tools in the medical device industry.Analytics

The final piece of the puzzle we’ll discuss today is data analytics. Life sciences companies have been using analytics in multiple aspects of their business for quite some time. The digitalization of the underlying information in the design, engineering, manufacturing, and use of the device dramatically expands the opportunities. Companies now have a much broader data set to analyze and transform into intelligence.

Medical device companies can leverage big data analytics in conjunction with the digital twin and digital thread to identify trends and correlations previously hidden in non-digital or non-integrated data sets. Analytics can be used in multiple phases of the device lifecycle, from identifying process control parameters drifting toward spec limits to analyzing adverse event data in the field. This can make existing processes better, for example being able to more quickly identify root causes for CAPAs. It can also support newer requirements like post market surveillance in the EU and the upcoming shift to focusing on patient outcomes. It can also benefit patients, for example predictive analytics may be able to identify potential failures prior to their occurrence and prevent adverse events. Finally, additional insights may create a new source of innovation that leads to new and better treatment options.

The final piece of the puzzle we’ll discuss today is data analytics. Life sciences companies have been using analytics in multiple aspects of their business for quite some time. The digitalization of the underlying information in the design, engineering, manufacturing, and use of the device dramatically expands the opportunities. Companies now have a much broader data set to analyze and transform into intelligence.

Medical device companies can leverage big data analytics in conjunction with the digital twin and digital thread to identify trends and correlations previously hidden in non-digital or non-integrated data sets. Analytics can be used in multiple phases of the device lifecycle, from identifying process control parameters drifting toward spec limits to analyzing adverse event data in the field. This can make existing processes better, for example being able to more quickly identify root causes for CAPAs. It can also support newer requirements like post market surveillance in the EU and the upcoming shift to focusing on patient outcomes. It can also benefit patients, for example predictive analytics may be able to identify potential failures prior to their occurrence and prevent adverse events. Finally, additional insights may create a new source of innovation that leads to new and better treatment options.

IoT

The last area to discuss is the IoT. We’ve already mentioned it while discussing the earlier digital topics, it’s hard not to given it’s significant potential to change the relationship between medical devices, the manufacturer, healthcare professionals, payers, and the patient. But there is much more to this topic, so we’ll save this for a later post.Our Take

Digitalization of the medical device industry takes the value of new technologies and techniques and extends them to improve both company profitability and patient outcomes. In the end, the buzzwords represent new capabilities with real potential to help medical device companies innovate, drive rapid product design, speed approvals, improve quality, and achieve higher levels of compliance. These are all important for them to continue their mission to improve patient welfare in today’s complex healthcare environment. You can find more information about digitalization for medical devices from our sponsor, Siemens PLM. You can also find more information from Tech-Clarity on digitalization in the medical device industry please see our The Digitalization Opportunity for Medical Device Companies (video) or Digitalization in the Medical Device Industry (animation). [post_title] => Translating Digital Buzzwords to Real Value for Medical Devices (post) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => med-dev-digital-buzz [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:28 [post_modified_gmt] => 2022-11-15 03:28:28 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=7178 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [12] => WP_Post Object ( [ID] => 7171 [post_author] => 2 [post_date] => 2018-09-25 10:20:58 [post_date_gmt] => 2018-09-25 14:20:58 [post_content] => How can manufacturers and service providers drive additional productivity and profitability by developing equipment intelligence by monitoring equipment health? Learn how the IIoT, edge computing, and analytics help companies predict and mitigate equipment issues before they disrupt production. Manufacturers can now identify trends and data relationships that previously went undiscovered by combining data from multiple sources with information from sensored equipment, whether they are monitoring their own facilities or products they service at their customers' sites. Watch the Engineering.com webcast replay, sponsored by Siemens (no charge, registration required). Key takeaways include:

Key takeaways include:

- How manufacturers and service providers are expanding data gathered from equipment, both new and old

- How edge computing and analytics can turn mass volumes of data into actionable intelligence

- How an IIoT platform can help companies more rapidly take advantage of these opportunities

How can companies improve service and gain tangible ROI by remotely monitoring equipment using the IoT? This buyer's guide offers practical advice for companies starting their remote monitoring journey to transform the way they service their equipment whether it's on site, in the field, or at a customer location. At the same time, it offers recommendations to ensure that early projects build a foundation for future machine monitoring and Internet of Things value. As usual, this guide helps companies set functional requirements for their solution, but also addresses implementation, adoption, and partner criteria that help ensure companies get value from their solutions today and well into the future.

Please enjoy the summary below. For the full Buyer's Guide, please visit our sponsor PTC (no charge, registration required).

How can companies improve service and gain tangible ROI by remotely monitoring equipment using the IoT? This buyer's guide offers practical advice for companies starting their remote monitoring journey to transform the way they service their equipment whether it's on site, in the field, or at a customer location. At the same time, it offers recommendations to ensure that early projects build a foundation for future machine monitoring and Internet of Things value. As usual, this guide helps companies set functional requirements for their solution, but also addresses implementation, adoption, and partner criteria that help ensure companies get value from their solutions today and well into the future.

Please enjoy the summary below. For the full Buyer's Guide, please visit our sponsor PTC (no charge, registration required).

Table of Contents

- Improve Service ROI, Build your IoT Foundation for the Future

- Remote Monitoring Drives Service Performance *

- Access Equipment and Equipment Data *

- Communicate with Equipment *

- Leverage the Edge to Pre-Process Communication *

- Share Actionable Service Information *

- Implementation and Adoption *

- Selecting a Strategic Partner *

- Next Steps

- Buyer’s Guide Checklist *

Improve Service ROI, Build your IoT Foundation for the Future

Companies are leveraging the IoT to digitally transform their business and the results are impressive. But many struggle choosing a place to begin. One proven way to get started is by remotely monitoring machines. This initiative allows manufacturers to quickly achieve IoT value while paving the way for even more substantial benefits over time. The most common way that companies gain tangible ROI from IoT is through improved service. The IoT lets companies transform service to generate more – and more profitable – service revenue. They do this by moving from reactive to proactive to predictive service, and leveraging advanced technologies like AI, machine learning, and big data analytics. They can also adopt new service delivery processes like remote service. But the most common first step is reducing cost of service through remote monitoring.

This guide briefly shares the tangible, practical first steps companies can take to improve service through IoT remote equipment monitoring and how IoT Platforms help deliver the value. Then, the majority of the buyer’s guide focuses on the important requirements companies must consider to ensure a successful initiative.

The most common way that companies gain tangible ROI from IoT is through improved service. The IoT lets companies transform service to generate more – and more profitable – service revenue. They do this by moving from reactive to proactive to predictive service, and leveraging advanced technologies like AI, machine learning, and big data analytics. They can also adopt new service delivery processes like remote service. But the most common first step is reducing cost of service through remote monitoring.

This guide briefly shares the tangible, practical first steps companies can take to improve service through IoT remote equipment monitoring and how IoT Platforms help deliver the value. Then, the majority of the buyer’s guide focuses on the important requirements companies must consider to ensure a successful initiative.

Next Steps

Leveraging the IoT can help companies improve service for themselves and their customers by reducing cost and transitioning to proactive and predictive service. Remote monitoring allows companies to identify and resolve issues remotely, providing faster service and increased uptime for the customer while reducing the cost of truck rolls and putting service technicians on site. It can go beyond cost savings to create a new source of revenue from paid upgrades or remotely enhancing equipment capabilities or permissions by “unlocking” enhanced capabilities via a subscription.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Improving Service with IoT Remote Monitoring (Buyer's Guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-monitoring-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:55

[post_modified_gmt] => 2022-11-15 03:27:55

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7154

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 7147

[post_author] => 2

[post_date] => 2018-09-11 12:13:16

[post_date_gmt] => 2018-09-11 16:13:16

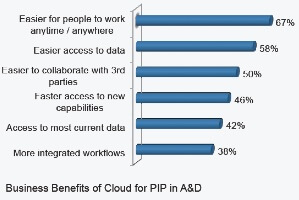

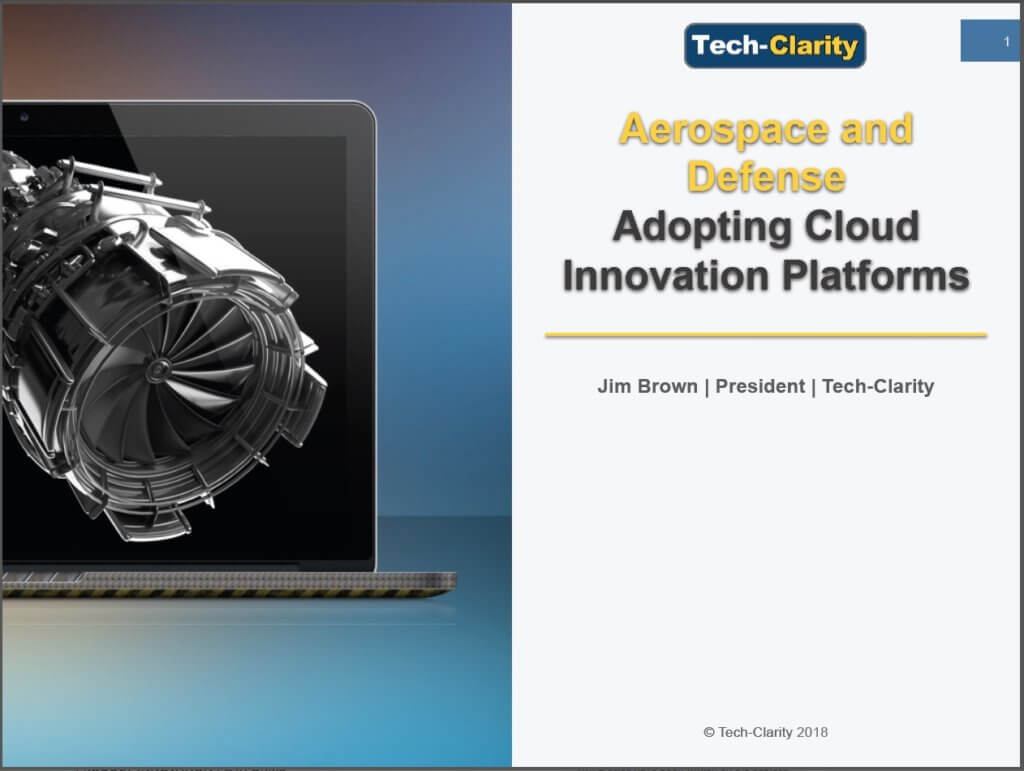

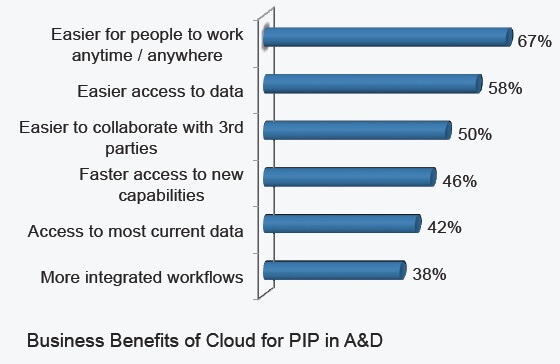

[post_content] => Are Aerospace and Defense companies open to using the cloud? This video shares survey results on cloud adoption from over 250 companies and more detailed analysis of about 70 of those that serve the A&D industries! The survey shows that about one-half of A&D companies are turning to the cloud in order to gain important benefits including faster time to value, reduced cost, less demand on IT, and user scalability. Beyond those benefits, the survey uncovered some more strategic benefits including easier to support global locations, work anytime/anywhere, improve collaboration, easier to access data, access to value-added services.

The survey also looked at whether A&D companies were open to the cloud for product innovation, manufacturing, and service. The survey finds that about one-quarter of A&D companies say they use the cloud for some elements of the Product Innovation Platform (PIP). Of course these companies have concerns and the survey uncovered some interesting statistics about the relationship between security concerns and the use of standards and audits.

For more information on the research you can view a summary of the survey report on our site (free, no registration required).

To download the full research please visit our sponsor Dassault Systèmes (no charge, registration required for full report).

https://youtu.be/RLQwcvhv5Xc

Watch this and more educational videos on the Tech-Clarity YouTube channel.

[post_title] => Aerospace and Defense Opening Up To The Cloud (Video)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aerospace-and-defense-cloud

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:48

[post_modified_gmt] => 2022-11-15 03:28:48

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7147

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 7128

[post_author] => 2

[post_date] => 2018-08-27 09:49:58

[post_date_gmt] => 2018-08-27 13:49:58

[post_content] =>

Leveraging the IoT can help companies improve service for themselves and their customers by reducing cost and transitioning to proactive and predictive service. Remote monitoring allows companies to identify and resolve issues remotely, providing faster service and increased uptime for the customer while reducing the cost of truck rolls and putting service technicians on site. It can go beyond cost savings to create a new source of revenue from paid upgrades or remotely enhancing equipment capabilities or permissions by “unlocking” enhanced capabilities via a subscription.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Improving Service with IoT Remote Monitoring (Buyer's Guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => iot-monitoring-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:55

[post_modified_gmt] => 2022-11-15 03:27:55

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7154

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 7147

[post_author] => 2

[post_date] => 2018-09-11 12:13:16

[post_date_gmt] => 2018-09-11 16:13:16

[post_content] => Are Aerospace and Defense companies open to using the cloud? This video shares survey results on cloud adoption from over 250 companies and more detailed analysis of about 70 of those that serve the A&D industries! The survey shows that about one-half of A&D companies are turning to the cloud in order to gain important benefits including faster time to value, reduced cost, less demand on IT, and user scalability. Beyond those benefits, the survey uncovered some more strategic benefits including easier to support global locations, work anytime/anywhere, improve collaboration, easier to access data, access to value-added services.

The survey also looked at whether A&D companies were open to the cloud for product innovation, manufacturing, and service. The survey finds that about one-quarter of A&D companies say they use the cloud for some elements of the Product Innovation Platform (PIP). Of course these companies have concerns and the survey uncovered some interesting statistics about the relationship between security concerns and the use of standards and audits.

For more information on the research you can view a summary of the survey report on our site (free, no registration required).

To download the full research please visit our sponsor Dassault Systèmes (no charge, registration required for full report).

https://youtu.be/RLQwcvhv5Xc

Watch this and more educational videos on the Tech-Clarity YouTube channel.

[post_title] => Aerospace and Defense Opening Up To The Cloud (Video)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aerospace-and-defense-cloud

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:48

[post_modified_gmt] => 2022-11-15 03:28:48

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7147

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 7128

[post_author] => 2

[post_date] => 2018-08-27 09:49:58

[post_date_gmt] => 2018-08-27 13:49:58

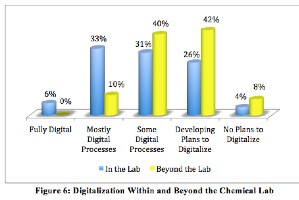

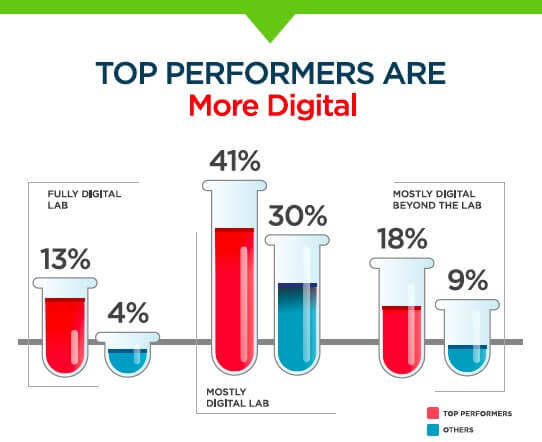

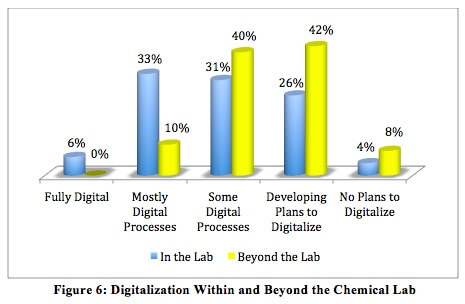

[post_content] =>  How do Top Performers in the chemical industry leverage digitalization in the chemical lab to overcome their innovation struggles? A Tech-Clarity survey shows that chemical companies face a myriad of innovation-related challenges including cost pressure, sustainability, more customer-driven products, and specialized / performance materials. This infographic provides a graphical snapshot of the research sharing that Top Performers are more than three times more likely to have a fully digital lab than their lesser performing competitors. While few have fully digital labs, the benchmarks show that increased digital maturity in the laboratory leads to better innovation and product development performance.

Please enjoy an excerpt of the infographic below, thanks to our sponsor Dassault Systèmes BIOVIA. For more information on the report, you can read a summary of the underlying research report on our site.

For the full infographic and research report and more information, please visit our sponsor Dassault Systèmes BIOVIA and click on the report or infographic in the Resource Center on the right (no charge, no registration required).

How do Top Performers in the chemical industry leverage digitalization in the chemical lab to overcome their innovation struggles? A Tech-Clarity survey shows that chemical companies face a myriad of innovation-related challenges including cost pressure, sustainability, more customer-driven products, and specialized / performance materials. This infographic provides a graphical snapshot of the research sharing that Top Performers are more than three times more likely to have a fully digital lab than their lesser performing competitors. While few have fully digital labs, the benchmarks show that increased digital maturity in the laboratory leads to better innovation and product development performance.

Please enjoy an excerpt of the infographic below, thanks to our sponsor Dassault Systèmes BIOVIA. For more information on the report, you can read a summary of the underlying research report on our site.

For the full infographic and research report and more information, please visit our sponsor Dassault Systèmes BIOVIA and click on the report or infographic in the Resource Center on the right (no charge, no registration required).

*This summary is an abbreviated version of the report and does not contain the full content. Links to download the full infographic and underlying repport are available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => How Digital Chemical Labs Drive Innovation (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-lab-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:08

[post_modified_gmt] => 2022-11-15 03:26:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7128

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 7116

[post_author] => 2

[post_date] => 2018-08-23 10:58:06

[post_date_gmt] => 2018-08-23 14:58:06

[post_content] =>

*This summary is an abbreviated version of the report and does not contain the full content. Links to download the full infographic and underlying repport are available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => How Digital Chemical Labs Drive Innovation (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-lab-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:08

[post_modified_gmt] => 2022-11-15 03:26:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7128

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 7116

[post_author] => 2

[post_date] => 2018-08-23 10:58:06

[post_date_gmt] => 2018-08-23 14:58:06

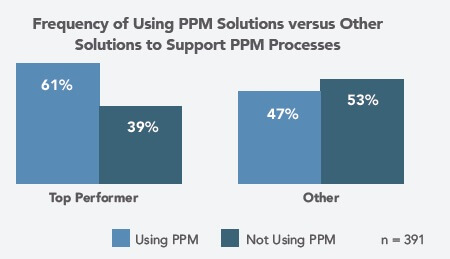

[post_content] =>  How can companies manage their portfolios and product development processes in order to more reliably hit their product innovation and commercialization challenges? How does digital transformation raise the bar on product portfolio management? Tech-Clarity was commissioned by Planview, Inc. to conduct their Sixth Product Portfolio Management Benchmark Study to find out. The research uncovered five best practices that Top Performers follow more frequently than others, resulting in their higher performance in revenue growth, profit margin expansion, and percent of sales from new products than their competitors. The survey also took a hard look at how digitalization impacts product planning and development, and finds that the transition to smarter, more connected products makes current PPM challenges worse.

How can companies manage their portfolios and product development processes in order to more reliably hit their product innovation and commercialization challenges? How does digital transformation raise the bar on product portfolio management? Tech-Clarity was commissioned by Planview, Inc. to conduct their Sixth Product Portfolio Management Benchmark Study to find out. The research uncovered five best practices that Top Performers follow more frequently than others, resulting in their higher performance in revenue growth, profit margin expansion, and percent of sales from new products than their competitors. The survey also took a hard look at how digitalization impacts product planning and development, and finds that the transition to smarter, more connected products makes current PPM challenges worse.

Analyzing Product Innovation Performance