On Tuesday May 9, 2017 Michelle Boucher conducted a live interview with Lisbeth Sivertsen, expert at Novo Nordisk for product quality strategy. They focused on key topics for medical device companies, including the Case for Quality. During the discussion, Michelle shared research on medical device industry trends. She also discussed the implications for the Case for Quality and offered advice to efficiently manage…

- Transitioning from 2D CAD to 3D CAD

- Migrating from 3D CAD to a new 3D CAD

- Adopting model-based definition (MBD)

Why Change to a New 3D CAD Tool?

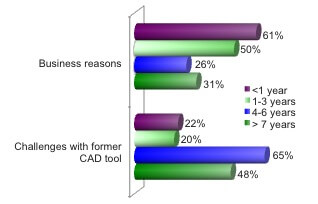

There are several reasons why a company may change from one 3D CAD tool to another. Research from Tech-Clarity's, “Are You Changing CAD Tools? What You Should Know” found that interestingly, those reasons have shifted over the last several years. Problems with the CAD tool used to be the primary drivers. Now, business reasons have become more important. This indicates that CAD tools have become more of a strategic piece of the overall product development solution.

However, changing something as critical as CAD involves multiple aspects. With a good understanding of best practices for adopting a new CAD tool, companies can enjoy the benefits of their new tool even sooner.

There are several reasons why a company may change from one 3D CAD tool to another. Research from Tech-Clarity's, “Are You Changing CAD Tools? What You Should Know” found that interestingly, those reasons have shifted over the last several years. Problems with the CAD tool used to be the primary drivers. Now, business reasons have become more important. This indicates that CAD tools have become more of a strategic piece of the overall product development solution.

However, changing something as critical as CAD involves multiple aspects. With a good understanding of best practices for adopting a new CAD tool, companies can enjoy the benefits of their new tool even sooner.

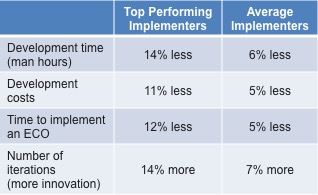

Tech-Clarity analyzed how companies rated their transition process to migrate to a new CAD tool. The experiences of those who were especially happy with how the migration went were compared to the rest. The results of this analysis became the basis for best practices for migrating to a new 3D CAD tool. While both groups reported many benefits after making the transition, Top Performing Implementers reported even greater improvement.

Tech-Clarity analyzed how companies rated their transition process to migrate to a new CAD tool. The experiences of those who were especially happy with how the migration went were compared to the rest. The results of this analysis became the basis for best practices for migrating to a new 3D CAD tool. While both groups reported many benefits after making the transition, Top Performing Implementers reported even greater improvement.

Benefits of a 3D-to-3D Transition

Since implementing their current 3D CAD tool, companies report several improvements. By following best practices to support their transition to a new 3D CAD tool, Top Performing Implementers realize even more benefits. The table shows the respective improvements reported by each group. *This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Adopting a New 3D CAD (survey findings eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => adopting_new_3d_cad

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:34

[post_modified_gmt] => 2022-11-15 03:28:34

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6080

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 6076

[post_author] => 2572

[post_date] => 2017-05-02 02:57:59

[post_date_gmt] => 2017-05-02 06:57:59

[post_content] =>

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Adopting a New 3D CAD (survey findings eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => adopting_new_3d_cad

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:34

[post_modified_gmt] => 2022-11-15 03:28:34

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6080

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 6076

[post_author] => 2572

[post_date] => 2017-05-02 02:57:59

[post_date_gmt] => 2017-05-02 06:57:59

[post_content] =>  Are you making your products smarter? Are you feeling pressure to add software and electronics? Please share your experience, thoughts, and lessons learned in this new survey on transforming product design to develop smart products. The survey explores challenges you should be aware of, the impacts of those challenges, and how to avoid them.

We will explore questions such as:

What strategies should you consider when developing connected products? What challenges should you be aware of when designing the PCB? How do you overcome electrical wiring challenges?

We would like to learn what you find hard and hear your advice. Please share your experience.

Are you making your products smarter? Are you feeling pressure to add software and electronics? Please share your experience, thoughts, and lessons learned in this new survey on transforming product design to develop smart products. The survey explores challenges you should be aware of, the impacts of those challenges, and how to avoid them.

We will explore questions such as:

What strategies should you consider when developing connected products? What challenges should you be aware of when designing the PCB? How do you overcome electrical wiring challenges?

We would like to learn what you find hard and hear your advice. Please share your experience.

- If you already completed the survey –> please share with a colleague or on social media using the “Share/Save” buttons above.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of smart products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

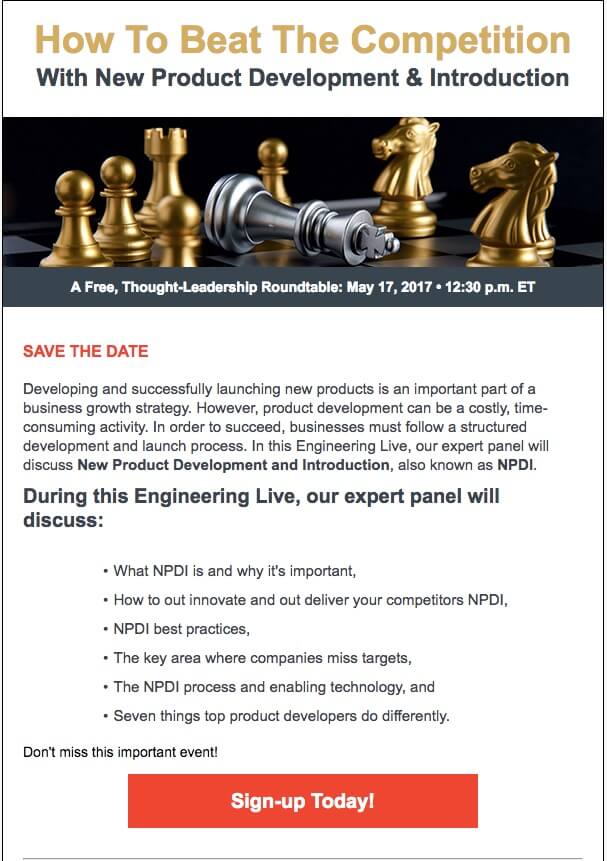

[post_title] => Transforming Product Design for Today’s Smart Products (survey invite) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => smart_products [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:52 [post_modified_gmt] => 2022-11-15 03:27:52 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=6076 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 4 [filter] => raw ) [3] => WP_Post Object ( [ID] => 6063 [post_author] => 2 [post_date] => 2017-04-25 12:37:57 [post_date_gmt] => 2017-04-25 16:37:57 [post_content] => Jim Brown joins Autodesk's Michael Vesperman during this Engineering Live panel discussion moderated by Janine Mooney, Editor in Chief at Advantage Business Media. Jim and Michael share insights from recent survey results and customer experience in an interactive discussion on NPDI. They share NPD best practices and technology including 7 things that Top Performers in NPDI do differently than the rest. Watch the on demand replay now! [post_title] => Beating the Competition with New Product Development and Introduction (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => npdi-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:52

[post_modified_gmt] => 2022-11-15 03:26:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6063

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 6048

[post_author] => 2572

[post_date] => 2017-04-24 12:34:46

[post_date_gmt] => 2017-04-24 16:34:46

[post_content] =>

[post_title] => Beating the Competition with New Product Development and Introduction (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => npdi-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:52

[post_modified_gmt] => 2022-11-15 03:26:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6063

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 6048

[post_author] => 2572

[post_date] => 2017-04-24 12:34:46

[post_date_gmt] => 2017-04-24 16:34:46

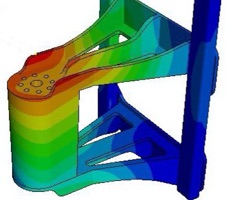

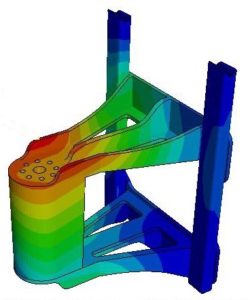

[post_content] =>  Listen to Michelle Boucher share tips to improve the efficiency of simulation preprocessing. During this webinar, Shawn Wasserman, simulation editor at ENGINEERING.com, joined Michelle.

This webinar reveals:

Listen to Michelle Boucher share tips to improve the efficiency of simulation preprocessing. During this webinar, Shawn Wasserman, simulation editor at ENGINEERING.com, joined Michelle.

This webinar reveals:

- The top improvement areas you should focus on to get even more value from simulation

- Common challenges during the preprocessing phase

- Best practices to overcome those preprocessing challenges

- Case studies demonstrating the benefits of efficient preprocessing

[post_title] => Solving the Bottlenecks of Simulation Preprocessing (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => live-webinar-solving-bottlenecks-simulation-preprocessing

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:50

[post_modified_gmt] => 2022-11-15 03:26:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6048

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 6028

[post_author] => 2

[post_date] => 2017-04-19 15:41:01

[post_date_gmt] => 2017-04-19 19:41:01

[post_content] =>

[post_title] => Solving the Bottlenecks of Simulation Preprocessing (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => live-webinar-solving-bottlenecks-simulation-preprocessing

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:50

[post_modified_gmt] => 2022-11-15 03:26:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6048

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 6028

[post_author] => 2

[post_date] => 2017-04-19 15:41:01

[post_date_gmt] => 2017-04-19 19:41:01

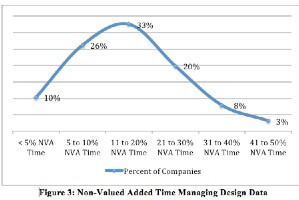

[post_content] =>  The Design Data Management Maturity Improves Profitability, Analyzing Best Practices for Managing Designs report shares fresh survey data and interviews. It updates our design data management research to cover new trends like using cloud file sharing applications to manage data. It also drills down on the topics of complexity and non-value added time spent managing design data, and shares metrics on the business improvements available from design data management best practices and technologies.

The Design Data Management Maturity Improves Profitability, Analyzing Best Practices for Managing Designs report shares fresh survey data and interviews. It updates our design data management research to cover new trends like using cloud file sharing applications to manage data. It also drills down on the topics of complexity and non-value added time spent managing design data, and shares metrics on the business improvements available from design data management best practices and technologies.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required thanks to our sponsor, Siemens PLM).

Executive Overview

Our previous report, Best Practices in Managing Design Data, showed that “Companies with world-class performance are more likely to have very effective data management capabilities.” Now, we’ve extended that earlier research with new survey data to take a fresh look at data management challenges and best practices. We also take a deeper dive into product complexity, explore whether companies still suffer from non-value-added time managing data, and quantify the impact of improving design data management. Survey results indicate that data management is still a big business challenge. Complexity has continued to grow, resulting in poor productivity even for smaller companies. Almost one-third of companies surveyed report their technical resources spend more than 25% of their time on non-value-added data management tasks! The survey also uncovers that data management is evolving, including significant growth in the use of cloud-based file sharing tools. It appears that the adoption of these tools may be making it easier for companies to share their designs, but making it more difficult to effectively control design data. The prior report makes suggestions on how to improve data management and resulting productivity, which still hold true. It shows that some companies are more effective at data management and are “more likely to use structured, collaborative design data management technology, 30% more likely to use PDM or PLM.” It also finds that these companies spend 25% less time on nonproductive data management tasks. This survey furthers the research and finds that companies with the highest product development performance, the Top Performers, have higher data management maturity. They:- Use more collaborative design data management capabilities

- Leverage their design data management solutions for more functions

- Have tighter integration between their design tools / CAD and data management

- Couple data management tightly with cloud file sharing (if they’re using cloud)

Table of Contents

- Executive Overview

- Effective Data Management Improves Productivity, Performance

- Design Data Management Continues to be a Struggle

- Data Management Challenges Continue to Impact Productivity

- Complexity on the Rise

- Identifying Data Management Practices of the Top Performers

- Top Performers have Greater Data Management Usage Maturity

- Top Performers have Greater Collaboration Maturity

- Emergence of Cloud Highlights another Dimension of Maturity

- Quantifying Design Data Management Impact on Profitability

- Design Data Management is a Foundation to Grow On

- Conclusion

- Recommendations

- About the Author

- About the Research

- References and Links

Conclusion

Product and product development complexity are on the rise, bringing with it significant reductions in design productivity for companies small and large. The leaders are combatting this complexity with design data management. Top Performers have been shown to use more structured, collaborative solutions including PDM and PLM. This research shows that even if these tools are not within reach, companies can improve their design data management maturity and achieve a productivity and business performance advantage. Companies can extend their design data management in several ways. The first is to follow more formal data management processes. The second is to use their CAD tool to help manage designs if they are using less formal design data management capabilities like network drivers or cloud file-sharing. “The combination of cloud file sharing with some sort of data control is a great solution for smaller companies,” concludes Bird Technologies’ Winter. “As soon as our vendor made this available it was a no-brainer and we jumped on it right away.” Finally, companies can improve performance by increasing their design usage maturity, leveraging their design data management solution to support more tasks. There is always room to improve. The Top Performers are extending their design data management maturity in multiple ways, and are more able to leverage their design data management foundation to gain higher benefits over time.Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Understand the complexity is a larger driver of design data management issues than company size

- Recognize the impact of increasing product complexity and improve design data management maturity to mitigate the risk

- Use formal data management tools such as PDM or PLM, if accessible

- If formal systems aren’t available and you’re using network or cloud file management, at a minimum improve maturity through better processes

- For greater levels of performance, leverage your CAD tool’s capabilities to help manage complexity

- Extend the usage maturity of design data management to continually improve and raise the bar on productivity and business performance relative to the competition

Tech-Clarity's Medical Devices Manufacturers Software Selection Guide helps manufacturers identify the right buying criteria for software solutions to support developing, producing, and servicing medical devices. This buyer's guide also takes into account unique needs for medical device companies including regulatory compliance and support for the FDA's Case for Quality.

Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

Tech-Clarity's Medical Devices Manufacturers Software Selection Guide helps manufacturers identify the right buying criteria for software solutions to support developing, producing, and servicing medical devices. This buyer's guide also takes into account unique needs for medical device companies including regulatory compliance and support for the FDA's Case for Quality.

Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

- Software capabilities

- Implementation

- User adoption

- Support

- Vendor characteristics / attributes

- Unique business needs

Table of Contents

- Executive Overview

- Identify Your Challenges

- Transition from Document Centric to Product Centric

- Consider the Complete Lifecycle

- Manage the Product

- Manage Requirements (Customer Needs to Regulatory)

- Support Product Development for Hardware

- Support Software Development

- Enable Smart and Connected Products

- Ensure Regulatory Compliance

- Support Quality Management

- Plan for Manufacturing

- Control Suppliers

- Plan for Service

- Assess Implementation Requirements

- Consider Vendor Attributes

- Identify Specific Needs for your Company

- Conclusion

- Recommendations

- About the Author

Executive Overview

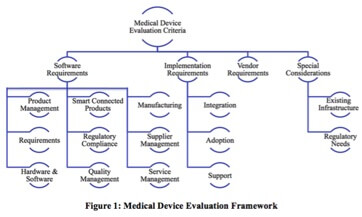

Medical device companies are in the business of making people’s lives better. As Joel Hembrock, Senior Designer and CAD Administrator at Medtronic says, “Our patients are the people who benefit from our products. Restoring life is our main focus. [We want] to be giving people their lives back, restoring their health, allowing them to actually live again and not have their disease or any other ailment keep them from being able to live.” With lives at stake, patient safety is of the upmost importance. As such, the industry faces heavy regulations. Compliance is so critical that if medical device companies do not adhere to FDA, EU and other worldwide standards and regulations, they will not be profitable. However, so much time, effort, and cost goes into compliance documentation, it takes efforts away from innovating and ensuring high quality products. Consequently, it is harder to take advantage of opportunities that will boost profitability. On the other hand, medical device companies who adopt practices focused on high quality devices can expect greater patient satisfaction, improved competitiveness, and higher profits. In fact, McKinsey estimates that companies who adopt quality focused best practices can increase profits by 3% to 4% of revenues. They estimate the revenue increase alone could be a $3.5 billion opportunity for the industry and this doesn’t even factor in profitability improvements by avoiding costly quality issues. To achieve this, companies need to be empowered to shift from a document centric process to one that focuses on high quality, innovative products that meet patient needs. The good news is that with investments in the right technology, this is possible. Technology can reduce manual, time intensive reporting processes to a push of a button. Rather than structuring processes around documentation, technology can allow you to focus on developing the right products and services that will meet patient needs. For these reasons, some medical device manufacturers are integrating quality processes into core product lifecycle management activities. By integrating quality processes throughout the product design and delivery lifecycle, companies can improve efficiency. With this approach, time spent searching for compliance supporting documentation and reporting, can instead be invested in quality and innovation. The result will be greater profitability. Other changes in the medical device industry are coming from recent trends such as the transition to outcome-based healthcare in the US. In some cases, to be compensated, medical professionals must show positive patient outcomes. One way to accomplish this is to take advantage of innovation enabled by the Internet of Things (IoT). This along with requirements for Unique Device Identifiers (UDI’s) can provide new levels of traceability and communication that can demonstrate device effectiveness. However, to take advantage of this and manage it, the right technology must be in place. While many of these issues may require new investments in technology, existing systems that are working well, should be leveraged. Working solutions such as Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) should be considered when selecting a complete solution to manage medical devices. The new solution should use a platform that will leverage and extend the investments made in existing solutions. With so much to consider, how do you know what will be the right technology? This buyer’s guide will serve as guidance to help you select what is right for your company. This guide consists of four major sections covering software tool functionality required for medical device companies, implementation requirements, vendor attributes, and special company considerations (Figure 1). Each section includes a checklist with key requirements to investigate when selecting software tools. This guide is not an all encompassing requirements list. It provides a high level overview.

[post_title] => Medical Devices Manufacturers Software Selection Guide

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical-device-buyers-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:51

[post_modified_gmt] => 2022-11-15 03:27:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5927

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 5947

[post_author] => 2572

[post_date] => 2017-02-21 11:00:41

[post_date_gmt] => 2017-02-21 16:00:41

[post_content] =>

Each section includes a checklist with key requirements to investigate when selecting software tools. This guide is not an all encompassing requirements list. It provides a high level overview.

[post_title] => Medical Devices Manufacturers Software Selection Guide

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical-device-buyers-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:51

[post_modified_gmt] => 2022-11-15 03:27:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5927

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 5947

[post_author] => 2572

[post_date] => 2017-02-21 11:00:41

[post_date_gmt] => 2017-02-21 16:00:41

[post_content] =>  Michelle Boucher participated in a webinar for medical device companies on. In addition, IEEE Spectrum's Dexter Johnson moderated the event.

Michelle Boucher participated in a webinar for medical device companies on. In addition, IEEE Spectrum's Dexter Johnson moderated the event.

During the webinar, Michelle shares medical device industry trends. She will also offers advice to efficiently manage regulatory compliance and discuss the implications for the Case for Quality. She was joined by Mr. Sri Tupil, VP Software Quality Eng. & Program Management, Fresenius Medical Care for an interactive discussion about how Fresenius is responding to these trends to improve their business.

Access this event as well as other healthcare related webcasts and content.

During the webinar, Michelle shares medical device industry trends. She will also offers advice to efficiently manage regulatory compliance and discuss the implications for the Case for Quality. She was joined by Mr. Sri Tupil, VP Software Quality Eng. & Program Management, Fresenius Medical Care for an interactive discussion about how Fresenius is responding to these trends to improve their business.

Access this event as well as other healthcare related webcasts and content.

[post_title] => Medical Devices: Making The Right Choice – Your Case For Quality (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-medical-devices

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:50

[post_modified_gmt] => 2022-11-15 03:26:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5947

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 5874

[post_author] => 2

[post_date] => 2016-12-13 14:50:21

[post_date_gmt] => 2016-12-13 19:50:21

[post_content] =>

[post_title] => Medical Devices: Making The Right Choice – Your Case For Quality (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-medical-devices

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:50

[post_modified_gmt] => 2022-11-15 03:26:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5947

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 5874

[post_author] => 2

[post_date] => 2016-12-13 14:50:21

[post_date_gmt] => 2016-12-13 19:50:21

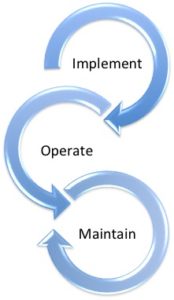

[post_content] =>  How Top Performers Implement, Operate, and Maintain PLM Integration - Best Practices for Integrating Product Lifecycle Management shares survey results detailing how Top Performers implement their PLM systems. The research uncovers integration challenges and best practices across the PLM Integration Lifecycle, recognizing that implementing integration is only the first step in the process.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, Razorleaf (free of charge, registration required).

How Top Performers Implement, Operate, and Maintain PLM Integration - Best Practices for Integrating Product Lifecycle Management shares survey results detailing how Top Performers implement their PLM systems. The research uncovers integration challenges and best practices across the PLM Integration Lifecycle, recognizing that implementing integration is only the first step in the process.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, Razorleaf (free of charge, registration required).

Table of Contents

Executive Overview

Executive Overview- The Business Value of Integrating PLM

- When do Companies Begin Integrating?

- Introducing the PLM Integration Lifecycle

- Implementation Challenges

- Operation Challenges

- Maintenance Challenges

- Business Impacts

- Quantifying the Impact

- Identifying the Top Performers

- Top Performers Experience Fewer Negative Impacts

- Top Performers Integrate More

- Top Performers Integrate with More Advanced Tools

- Top Performers Integrate with More Advanced Enterprise Applications

- Top Performers Integrate More PLM Data

- Top Performers Use More Advanced Integration Techniques

- Focusing on the Future: The Impact of IoT on PLM Integration

- Conclusion

- Recommendations

- About the Author

- About the Research

- Copyright Notice

Executive Overview

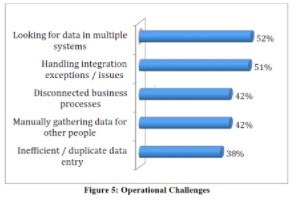

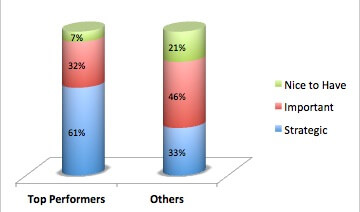

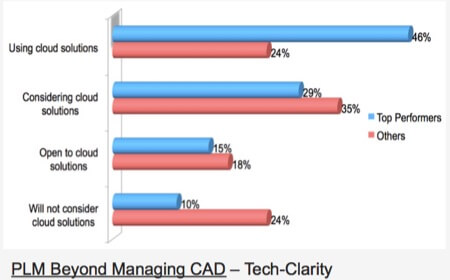

Product Lifecycle Management (PLM) helps manufacturers in many ways ranging from operational efficiencies to top-line financial improvement. It improves business performance in multiple dimensions including increased revenue, reduced product cost, and decreased product development cost. But PLM is just one of many systems in the engineering and enterprise software ecosystems, and provides greater value when it shares data and connects workflows with other software. As reported in Product Lifecycle Management Beyond Managing CAD, “Top Performers are much more likely to integrate PLM with a host of other systems.” We surveyed over 150 companies to understand their PLM integration strategy, processes, and technical enablers in order to understand how proper integration can extend PLM value. The findings indicate that the vast majority of manufacturers view PLM as “Strategic” or “Important.” It also finds that many believe that PLM integration will become even more strategic (and challenging) as IoT initiatives progress. In order to understand how companies get the most business value from PLM integration, we identified manufacturers that were gaining the largest operational benefit from their PLM implementation, the Top Performers. These leaders achieve significantly better than average PLM business benefits. We analyzed what these companies do differently related to PLM integration in order to offer advice to poorer performing companies. The analysis determines that Top Performers in gaining the benefits from PLM: Are more likely to view PLM integration as strategic

Are more likely to view PLM integration as strategic- Integrate PLM to more design tools and more enterprise applications

- Integrate PLM to more advanced tools and applications

- Are more able to implement, operate, and maintain PLM integration in an agile, cost-effective way

- Experience fewer operational issues including:

- Needing to look for data in multiple systems

- Duplicate data entry

- Data inconsistency across systems

Conclusion

PLM helps companies improve product innovation, product development, and engineering efficiency and helps enhance communication across the enterprise and the supply chain. Improving PLM integration helps companies achieve the benefits PLM has to offer, making it a highly strategic investment. The level of importance, along with the level of complexity, will only increase as companies move to smarter, more connected products and the IoT. Top Performers, those that get the most benefits out of their PLM systems, are more likely to view PLM integration as strategic. They integrate more design tools and enterprise applications with PLM, and integrate PLM to more advanced tools and applications. They also integrate more data, including more information that spans the enterprise and the supply chain. The leads us to the conclusion that better PLM integration is simply good business. Top Performers take different approaches to integrating PLM, employing a variety of tools but more likely including adaptable techniques like a hub and spoke approach that provides benefits across the PLM Integration Lifecycle. The result is that these Top Performing companies are more able to implement, operate, and maintain PLM integration in an agile, cost-effective way and experience less need to look for data in multiple systems, perform less duplicate data entry, and find less data inconsistency across systems.Recommendations

Based on our experience and the research for this report, Tech-Clarity offers the following recommendations:- Manufacturers should integrate PLM with a broader number of enterprise applications and design tools

- Companies should integrate with more advanced systems, including those that extend beyond Engineering into the enterprise and the supply chain

- Companies should use a variety of integration techniques depending on the specific solutions and connectivity methods available, leveraging more advanced approaches such as hub and spoke when practical to provide more agility across the PLM Integration Lifecycle

- Manufacturers should consider outside expertise to fill the PLM integration knowledge gap

- Companies should focus integration plans and efforts beyond the initial implementation to optimize across the entire PLM Integration Lifecycle

Register for the December 14 Engineering.com webcast sponsored by Autodesk (free of charge, no registration required).

[post_title] => Five Ways to Beat Product Development Deadlines (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 5-ways-beat-npd

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:49

[post_modified_gmt] => 2022-11-15 03:26:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5895

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 5864

[post_author] => 2

[post_date] => 2016-11-29 09:14:31

[post_date_gmt] => 2016-11-29 14:14:31

[post_content] => Tech-Clarity analyst Jim Brown joins Razorleaf's Director of Integrations and Development Derek Neiding to share the results of a recent study on PLM integration. The webcast will highlight the strategies, processes, and technologies Top Performers use to integrate PLM with design tools and other enterprise systems.

Register now for the December 13 webcast, sponsored by Razorleaf Corporation (free of charge, registration required).

Register for the December 14 Engineering.com webcast sponsored by Autodesk (free of charge, no registration required).

[post_title] => Five Ways to Beat Product Development Deadlines (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 5-ways-beat-npd

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:49

[post_modified_gmt] => 2022-11-15 03:26:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5895

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 5864

[post_author] => 2

[post_date] => 2016-11-29 09:14:31

[post_date_gmt] => 2016-11-29 14:14:31

[post_content] => Tech-Clarity analyst Jim Brown joins Razorleaf's Director of Integrations and Development Derek Neiding to share the results of a recent study on PLM integration. The webcast will highlight the strategies, processes, and technologies Top Performers use to integrate PLM with design tools and other enterprise systems.

Register now for the December 13 webcast, sponsored by Razorleaf Corporation (free of charge, registration required).

[post_title] => Better PLM Integration Drives Better Business Performance (Webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => integ-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:45

[post_modified_gmt] => 2022-11-15 03:26:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5864

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 5837

[post_author] => 2

[post_date] => 2016-10-25 17:53:17

[post_date_gmt] => 2016-10-25 21:53:17

[post_content] => Join an interactive discussion between Tech-Clarity's Jim Brown and Autodesk's Ron Locklin moderated by Advantage Business Media Editor in Chief Janine Mooney as they discuss the history, challenges, benefits, and future of Product Lifecycle Management (PLM). The event will be available on Product Design & Development, Manufacturing.net, and Manufacturing Business Technology.

[post_title] => Better PLM Integration Drives Better Business Performance (Webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => integ-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:45

[post_modified_gmt] => 2022-11-15 03:26:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5864

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 5837

[post_author] => 2

[post_date] => 2016-10-25 17:53:17

[post_date_gmt] => 2016-10-25 21:53:17

[post_content] => Join an interactive discussion between Tech-Clarity's Jim Brown and Autodesk's Ron Locklin moderated by Advantage Business Media Editor in Chief Janine Mooney as they discuss the history, challenges, benefits, and future of Product Lifecycle Management (PLM). The event will be available on Product Design & Development, Manufacturing.net, and Manufacturing Business Technology.

Watch the event live, October 31 at 12:30 PM Eastern. Sign up now (free of charge, registration required).

Sponsored by Autodesk and their Fusion Lifecycle product.

[post_title] => Engineering Live PLM Discussion

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => live-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:39

[post_modified_gmt] => 2022-11-15 03:26:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5837

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 5793

[post_author] => 2

[post_date] => 2016-10-19 09:26:51

[post_date_gmt] => 2016-10-19 13:26:51

[post_content] => This episode of Tech-Clarity TV discusses developing a cloud strategy for product innovation, product development, and engineering software. It reviews the benefits applicable to any cloud software but then highlights some areas where cloud software characteristics can fundamentally improve the way a job is done. The discussion also covers how to decide between options such as hosted, managed service, SaaS, and IaaS taking into account the maturity of your current software vendors' cloud strategy.

https://youtu.be/Wf0nyfJSJ_w

For more information on cloud computing please visit Siemens Offers Business-ready Cloud Solutions on the Siemens site.

Watch this and more educational videos on the Tech-Clarity YouTube channel. http://www.youtube.com/user/techclarity

Watch the event live, October 31 at 12:30 PM Eastern. Sign up now (free of charge, registration required).

Sponsored by Autodesk and their Fusion Lifecycle product.

[post_title] => Engineering Live PLM Discussion

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => live-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:39

[post_modified_gmt] => 2022-11-15 03:26:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5837

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 5793

[post_author] => 2

[post_date] => 2016-10-19 09:26:51

[post_date_gmt] => 2016-10-19 13:26:51

[post_content] => This episode of Tech-Clarity TV discusses developing a cloud strategy for product innovation, product development, and engineering software. It reviews the benefits applicable to any cloud software but then highlights some areas where cloud software characteristics can fundamentally improve the way a job is done. The discussion also covers how to decide between options such as hosted, managed service, SaaS, and IaaS taking into account the maturity of your current software vendors' cloud strategy.

https://youtu.be/Wf0nyfJSJ_w

For more information on cloud computing please visit Siemens Offers Business-ready Cloud Solutions on the Siemens site.

Watch this and more educational videos on the Tech-Clarity YouTube channel. http://www.youtube.com/user/techclarity

You can also view a summary of the Exploring Cloud Options for Product Innovation and Development eBook on our site, or download the full report courtesy of Siemens PLM (free of charge, no registration required).

[post_title] => Cloud Deployment Options for Product Innovation and Development (video)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-choice

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:27

[post_modified_gmt] => 2022-11-15 03:29:27

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5793

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 5809

[post_author] => 2

[post_date] => 2016-10-12 09:05:03

[post_date_gmt] => 2016-10-12 13:05:03

[post_content] =>

You can also view a summary of the Exploring Cloud Options for Product Innovation and Development eBook on our site, or download the full report courtesy of Siemens PLM (free of charge, no registration required).

[post_title] => Cloud Deployment Options for Product Innovation and Development (video)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-choice

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:27

[post_modified_gmt] => 2022-11-15 03:29:27

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5793

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 5809

[post_author] => 2

[post_date] => 2016-10-12 09:05:03

[post_date_gmt] => 2016-10-12 13:05:03

[post_content] =>  Jim Brown contributed insights from his recent research on cloud options for product innovation, product development, and engineering software in a guest post titled Moving Production Innovation and Engineering to the Cloud, What's Your Strategy? on the Siemens PLM Community. The post references findings our recent Exploring Cloud Options for Product Innovation and Development eBook.

For more information on cloud computing please visit Siemens Offers Business-ready Cloud Solutions on the Siemens site.

Jim Brown contributed insights from his recent research on cloud options for product innovation, product development, and engineering software in a guest post titled Moving Production Innovation and Engineering to the Cloud, What's Your Strategy? on the Siemens PLM Community. The post references findings our recent Exploring Cloud Options for Product Innovation and Development eBook.

For more information on cloud computing please visit Siemens Offers Business-ready Cloud Solutions on the Siemens site.

You can also view a summary of the Exploring Cloud Options for Product Innovation and Development eBook on our site, or download the full report courtesy of Siemens PLM (free of charge, no registration required).

[post_title] => Moving Production Innovation and Engineering to the Cloud (guest blog post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-post

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:05

[post_modified_gmt] => 2022-11-15 03:26:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5809

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 5820

[post_author] => 2572

[post_date] => 2016-10-11 18:55:49

[post_date_gmt] => 2016-10-11 22:55:49

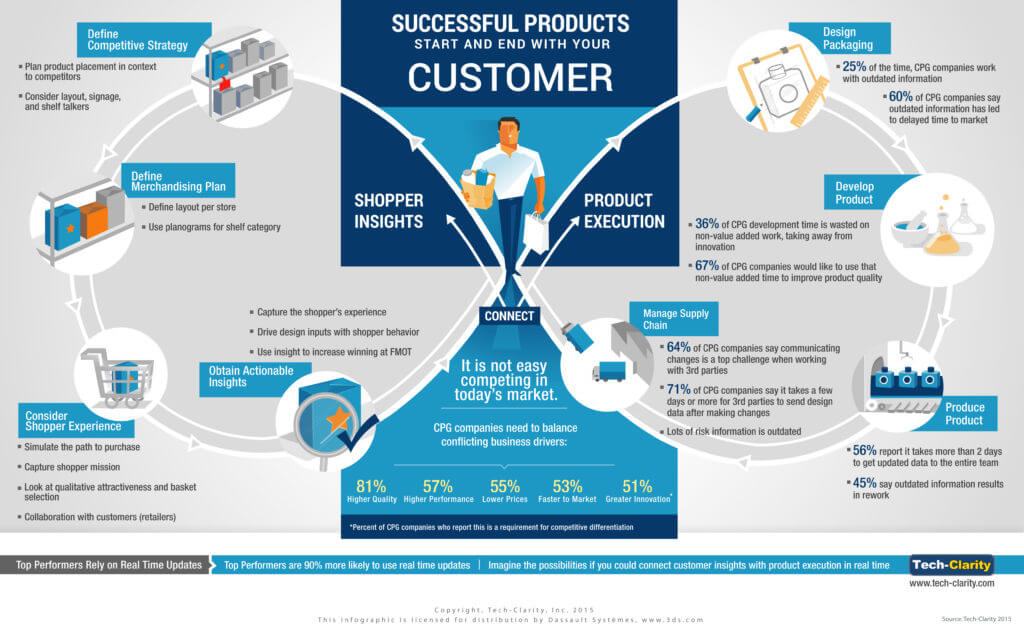

[post_content] => Tech-Clarity's Infographic, Successful Products Start and End with Your Customer provides guidance to CPG companies. By embedding your customer in the middle of your product life cycle, your products will be more successful. The infographic, shows that by capturing insights obtained during the shopping experience, you can drive a move successful approach to product development.

To be successful, companies navigate multiple competing pressures. This isn't easy, but access to real time information can help. When you have real time insights into what your customers are doing in the store, you can make better product decisions for superior product execution. This essentially puts your customer at the center of your product life cycle.

For more information on this and other solutions for Consumer Product companies, please visit our sponsor Dassault Systèmes.

You can also view a summary of the Exploring Cloud Options for Product Innovation and Development eBook on our site, or download the full report courtesy of Siemens PLM (free of charge, no registration required).

[post_title] => Moving Production Innovation and Engineering to the Cloud (guest blog post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-post

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:05

[post_modified_gmt] => 2022-11-15 03:26:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5809

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 5820

[post_author] => 2572

[post_date] => 2016-10-11 18:55:49

[post_date_gmt] => 2016-10-11 22:55:49

[post_content] => Tech-Clarity's Infographic, Successful Products Start and End with Your Customer provides guidance to CPG companies. By embedding your customer in the middle of your product life cycle, your products will be more successful. The infographic, shows that by capturing insights obtained during the shopping experience, you can drive a move successful approach to product development.

To be successful, companies navigate multiple competing pressures. This isn't easy, but access to real time information can help. When you have real time insights into what your customers are doing in the store, you can make better product decisions for superior product execution. This essentially puts your customer at the center of your product life cycle.

For more information on this and other solutions for Consumer Product companies, please visit our sponsor Dassault Systèmes.

The Exploring Cloud Options for Product Innovation and Development eBook shares our thoughts about the cloud software choices available for product innovation, product development, and engineering software including PLM, PDM, CAD, CAE, and more. The eBook details the different software models available and provides considerations for each. It also helps put the various options into context with a sample flowchart on the decision to identify the appropriate deployment platform for a cloud solution, including how to consider your existing vendors' solutions in the process.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required thanks to our sponsor, Siemens PLM).

For more information on cloud computing please visit Siemens Offers Business-ready Cloud Solutions on the Siemens site.

The Exploring Cloud Options for Product Innovation and Development eBook shares our thoughts about the cloud software choices available for product innovation, product development, and engineering software including PLM, PDM, CAD, CAE, and more. The eBook details the different software models available and provides considerations for each. It also helps put the various options into context with a sample flowchart on the decision to identify the appropriate deployment platform for a cloud solution, including how to consider your existing vendors' solutions in the process.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required thanks to our sponsor, Siemens PLM).

For more information on cloud computing please visit Siemens Offers Business-ready Cloud Solutions on the Siemens site.

Table of Contents

- It's Time for a Cloud Strategy

- Understanding the Options *

- Comparing Your Options *

- Assessing Company Readiness *

- Sample Cloud Decision Tree *

- Reviewing Vendor Cloud Maturity *

- Special Cloud Opportunities for Product Innovation and Engineering *

- Weighing the Options, Looking at Timing *

- Next Steps

It’s Time for a Cloud Strategy

The shift toward cloud computing is undeniable. An increasing number of companies are transitioning to cloud solutions in order to take advantage of significant advantages, including:- Cost reduction

- Reduced IT resource needs

- Scalability

- Agility

- Rapid deployment

- Shifting capital investments to expenses

Software for product innovation, product development, and engineering – including PLM, CAD, and CAE – has evolved toward the cloud at a cautious pace. This market is closer to the beginning of the cloud transformation than some others such as CRM and ERP where cloud adoption is already more prevalent. But it’s happening. Initial skepticism is fading away and companies are learning how to effectively manage cloud software.

The market is responding with the entry of new cloud offerings and incumbents evolving to the cloud. For manufacturers planning to implement or replace product-related software, it’s time to develop a strategy that reflects the reality of today’s market. The strategy needs to consider:

Software for product innovation, product development, and engineering – including PLM, CAD, and CAE – has evolved toward the cloud at a cautious pace. This market is closer to the beginning of the cloud transformation than some others such as CRM and ERP where cloud adoption is already more prevalent. But it’s happening. Initial skepticism is fading away and companies are learning how to effectively manage cloud software.

The market is responding with the entry of new cloud offerings and incumbents evolving to the cloud. For manufacturers planning to implement or replace product-related software, it’s time to develop a strategy that reflects the reality of today’s market. The strategy needs to consider:

- Cloud delivery models

- Software capabilities and scope

- Timing and transition

Next Steps

The time is right to take advantage of the cloud, but it’s not a trivial decision or transition for product innovation, product development, and engineering software. The reality of the market maturity requires companies to develop a strategy that jointly considers vendor cloud maturity, company readiness, and the availability of needed capabilities. A considered cloud transition is important to reap the benefits without major disruption. Most companies are taking a very deliberate, methodical approach to leverage the cloud. For most, a staged program with a hybrid mix of solutions will be the most reasonable approach, as few companies can justify wholesale replacement of existing systems.

Fortunately, companies may not have to do it all on their own. They can adopt a pragmatic, staged approach that coordinates with their vendor’s timeline. Many existing vendors have predefined relationships with cloud services companies and trained service providers. These partnerships can provide an IaaS or managed services approach that provides benefits without having to replace existing software. In addition, many vendors offer complementary solutions that provide unique opportunities only realistically available from the cloud. It’s important to understand the potential of these solutions in your transformation strategy.

The transition to the cloud is underway. It’s time for manufacturers to take a closer look and develop a practical strategy and timeline that works for their business.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above thanks to Siemens PLM.

[post_title] => Cloud Options for Product Innovation and Development (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-options

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:12

[post_modified_gmt] => 2022-11-15 03:28:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5777

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 5

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 5766

[post_author] => 2572

[post_date] => 2016-10-04 13:28:02

[post_date_gmt] => 2016-10-04 17:28:02

[post_content] => To help manufacturers prepare for the future of product design, PTC has released a new eBook, 10 Expert Insights : The Future of Product Design in the Age of Smart & Connected Devices. Michelle Boucher's contribution, New Possibilities with IoT, shares her thoughts on the future of product design. In this section, she explains how the Internet of Things will empower product development teams. With IoT, design teams will have access to information about product operation in ways that have never been possible before. As a result, they will have insights they previously could only have dreamed about.

The eBook also shares thoughts from nine other industry experts. While reviewing these perspectives, you will have new ideas to help prepare for the future of product design. You can download the eBook here (free of charge, registration required).

A considered cloud transition is important to reap the benefits without major disruption. Most companies are taking a very deliberate, methodical approach to leverage the cloud. For most, a staged program with a hybrid mix of solutions will be the most reasonable approach, as few companies can justify wholesale replacement of existing systems.

Fortunately, companies may not have to do it all on their own. They can adopt a pragmatic, staged approach that coordinates with their vendor’s timeline. Many existing vendors have predefined relationships with cloud services companies and trained service providers. These partnerships can provide an IaaS or managed services approach that provides benefits without having to replace existing software. In addition, many vendors offer complementary solutions that provide unique opportunities only realistically available from the cloud. It’s important to understand the potential of these solutions in your transformation strategy.

The transition to the cloud is underway. It’s time for manufacturers to take a closer look and develop a practical strategy and timeline that works for their business.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above thanks to Siemens PLM.

[post_title] => Cloud Options for Product Innovation and Development (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-options

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:12

[post_modified_gmt] => 2022-11-15 03:28:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5777

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 5

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 5766

[post_author] => 2572

[post_date] => 2016-10-04 13:28:02

[post_date_gmt] => 2016-10-04 17:28:02

[post_content] => To help manufacturers prepare for the future of product design, PTC has released a new eBook, 10 Expert Insights : The Future of Product Design in the Age of Smart & Connected Devices. Michelle Boucher's contribution, New Possibilities with IoT, shares her thoughts on the future of product design. In this section, she explains how the Internet of Things will empower product development teams. With IoT, design teams will have access to information about product operation in ways that have never been possible before. As a result, they will have insights they previously could only have dreamed about.

The eBook also shares thoughts from nine other industry experts. While reviewing these perspectives, you will have new ideas to help prepare for the future of product design. You can download the eBook here (free of charge, registration required).

[post_title] => New Possibilities with IoT - Contribution to PTC eBook

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => possibilities-with-iot-future_of_design

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:53

[post_modified_gmt] => 2022-11-15 03:25:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5766

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 6090

[post_author] => 2572

[post_date] => 2017-05-04 16:12:14

[post_date_gmt] => 2017-05-04 20:12:14

[post_content] =>

[post_title] => New Possibilities with IoT - Contribution to PTC eBook

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => possibilities-with-iot-future_of_design

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:53

[post_modified_gmt] => 2022-11-15 03:25:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5766

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 6090

[post_author] => 2572

[post_date] => 2017-05-04 16:12:14

[post_date_gmt] => 2017-05-04 20:12:14

[post_content] =>  On Tuesday May 9, 2017 Michelle Boucher conducted a live interview with Lisbeth Sivertsen, expert at Novo Nordisk for product quality strategy. They focused on key topics for medical device companies, including the Case for Quality.

On Tuesday May 9, 2017 Michelle Boucher conducted a live interview with Lisbeth Sivertsen, expert at Novo Nordisk for product quality strategy. They focused on key topics for medical device companies, including the Case for Quality.

During the discussion, Michelle shared research on medical device industry trends. She also discussed the implications for the Case for Quality and offered advice to efficiently manage regulatory compliance. Throughout the discussion, she had an interactive conversation with Lisbeth Sivertsen. Lisbeth revealed how Novo Nordisk addresses their quality initiatives and how they are responding to key trends in the medical device industry.

Access the recorded event and other healthcase related webcasts and content.

[post_title] => Quality The Product Driver At Novo Nordisk (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar_case_for_quality

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:50

[post_modified_gmt] => 2022-11-15 03:26:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6090

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => 1fc4d4591aa84678bf9529aadb45af82

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:3ad55f0a7255bd1f61edb8fbc218a1df:0.96816400 17692672680.97766500 1769267268

)

During the discussion, Michelle shared research on medical device industry trends. She also discussed the implications for the Case for Quality and offered advice to efficiently manage regulatory compliance. Throughout the discussion, she had an interactive conversation with Lisbeth Sivertsen. Lisbeth revealed how Novo Nordisk addresses their quality initiatives and how they are responding to key trends in the medical device industry.

Access the recorded event and other healthcase related webcasts and content.

[post_title] => Quality The Product Driver At Novo Nordisk (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar_case_for_quality

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:50

[post_modified_gmt] => 2022-11-15 03:26:50

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6090

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => 1fc4d4591aa84678bf9529aadb45af82

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:3ad55f0a7255bd1f61edb8fbc218a1df:0.96816400 17692672680.97766500 1769267268

)

All Results for "All"

Adopting a New 3D CAD (survey findings eBook)

The How-to Guide to Adopting a New 3D CAD shares best practices for changing from one 3D CAD tool to another. The guide shares the reasons you should consider making a change, potential benefits of making a change, and advice for selecting a new tool. The guide then goes deeper into the steps you should take…

Transforming Product Design for Today’s Smart Products (survey invite)

Are you making your products smarter? Are you feeling pressure to add software and electronics? Please share your experience, thoughts, and lessons learned in this new survey on transforming product design to develop smart products. The survey explores challenges you should be aware of, the impacts of those challenges, and how to avoid them. We will explore…

Beating the Competition with New Product Development and Introduction (webcast)

Jim Brown joins Autodesk’s Michael Vesperman during this Engineering Live panel discussion moderated by Janine Mooney, Editor in Chief at Advantage Business Media. Jim and Michael share insights from recent survey results and customer experience in an interactive discussion on NPDI. They share NPD best practices and technology including 7 things that Top Performers in NPDI…

Solving the Bottlenecks of Simulation Preprocessing (webcast)

Listen to Michelle Boucher share tips to improve the efficiency of simulation preprocessing. During this webinar, Shawn Wasserman, simulation editor at ENGINEERING.com, joined Michelle. This webinar reveals: The top improvement areas you should focus on to get even more value from simulation Common challenges during the preprocessing phase Best practices to overcome those preprocessing challenges Case studies…

Design Data Management Maturity Improves Profitability (survey report)

The Design Data Management Maturity Improves Profitability, Analyzing Best Practices for Managing Designs report shares fresh survey data and interviews. It updates our design data management research to cover new trends like using cloud file sharing applications to manage data. It also drills down on the topics of complexity and non-value added time spent managing design data,…

Four Ways Medical Device Companies Can Become More Profitable – Guest Post on PTC Blog

In this PTC guest post, Michelle Boucher shares Four Ways Medical Device Companies Can Become More Profitable. As companies plan for 2017, medical device companies should consider these four suggestions to help them improve margins. The post touches on topics such as the cost of compliance, the Case for Quality, and considerations for the impact of IoT….

Tips for Designing IoT Products: Use Model-Driven IoT Code – Guest Post on PTC Blog

Michelle Boucher shares tips for designing IoT products and systems by using model-driven IoT code in this PTC guest post. As a result of reading this post, you will have a better understanding of how this can be a helpful step for those looking to incorporate the Internet of Things (IoT) technology in their products. Many products…

Medical Devices Manufacturers Software Selection Guide

Tech-Clarity’s Medical Devices Manufacturers Software Selection Guide helps manufacturers identify the right buying criteria for software solutions to support developing, producing, and servicing medical devices. This buyer’s guide also takes into account unique needs for medical device companies including regulatory compliance and support for the FDA’s Case for Quality. Tech-Clarity’s Buyer’s Guides go beyond software functionality to…

Medical Devices: Making The Right Choice – Your Case For Quality (webcast)

Michelle Boucher participated in a webinar for medical device companies on. In addition, IEEE Spectrum’s Dexter Johnson moderated the event. During the webinar, Michelle shares medical device industry trends. She will also offers advice to efficiently manage regulatory compliance and discuss the implications for the Case for Quality. She was joined by Mr. Sri Tupil, VP Software Quality Eng….

How Top Performers Implement, Operate, and Maintain PLM Integration (survey findings)

How Top Performers Implement, Operate, and Maintain PLM Integration – Best Practices for Integrating Product Lifecycle Management shares survey results detailing how Top Performers implement their PLM systems. The research uncovers integration challenges and best practices across the PLM Integration Lifecycle, recognizing that implementing integration is only the first step in the process. Please enjoy…

Five Ways to Beat Product Development Deadlines (webcast)

Jim Brown will present findings from his recent study on New Product Development and Introduction (NPDI) to help companies learn from Top Performing product developers. The webcast will share the strategies, approaches, and enablers they use to drive high profits from their new product initiatives. Learn how the leaders will meet (or beat) their new…

Better PLM Integration Drives Better Business Performance (Webcast)

Tech-Clarity analyst Jim Brown joins Razorleaf’s Director of Integrations and Development Derek Neiding to share the results of a recent study on PLM integration. The webcast will highlight the strategies, processes, and technologies Top Performers use to integrate PLM with design tools and other enterprise systems. Register now for the December 13 webcast, sponsored by Razorleaf Corporation (free…

Engineering Live PLM Discussion

Join an interactive discussion between Tech-Clarity’s Jim Brown and Autodesk’s Ron Locklin moderated by Advantage Business Media Editor in Chief Janine Mooney as they discuss the history, challenges, benefits, and future of Product Lifecycle Management (PLM). The event will be available on Product Design & Development, Manufacturing.net, and Manufacturing Business Technology. Watch the event live, October 31 at…

Cloud Deployment Options for Product Innovation and Development (video)

This episode of Tech-Clarity TV discusses developing a cloud strategy for product innovation, product development, and engineering software. It reviews the benefits applicable to any cloud software but then highlights some areas where cloud software characteristics can fundamentally improve the way a job is done. The discussion also covers how to decide between options such as…

Moving Production Innovation and Engineering to the Cloud (guest blog post)

Jim Brown contributed insights from his recent research on cloud options for product innovation, product development, and engineering software in a guest post titled Moving Production Innovation and Engineering to the Cloud, What’s Your Strategy? on the Siemens PLM Community. The post references findings our recent Exploring Cloud Options for Product Innovation and Development eBook. For more information on…

Successful Products Start and End with Your Customer (infographic)

Tech-Clarity’s Infographic, Successful Products Start and End with Your Customer provides guidance to CPG companies. By embedding your customer in the middle of your product life cycle, your products will be more successful. The infographic, shows that by capturing insights obtained during the shopping experience, you can drive a move successful approach to product development. To be…

Cloud Options for Product Innovation and Development (eBook)

The Exploring Cloud Options for Product Innovation and Development eBook shares our thoughts about the cloud software choices available for product innovation, product development, and engineering software including PLM, PDM, CAD, CAE, and more. The eBook details the different software models available and provides considerations for each. It also helps put the various options into context with a…

New Possibilities with IoT – Contribution to PTC eBook

To help manufacturers prepare for the future of product design, PTC has released a new eBook, 10 Expert Insights : The Future of Product Design in the Age of Smart & Connected Devices. Michelle Boucher’s contribution, New Possibilities with IoT, shares her thoughts on the future of product design. In this section, she explains how the Internet of Things will empower product…