Tech-Clarity’s Addressing the Bottlenecks of FEA Simulation: Enabling Innovation by Getting Even More Value from CAE shares survey results on the simulation process. The analysis identified the top simulation bottlenecks that slow down the process. With a better understanding of these bottlenecks, manufacturers can take steps to minimize them and consequently, get even more value from simulation….

- Executive Overview

- Support Business Goals with the Right Design Tools.

- Examine the Value of Simulation

- Identifying the Top Performers

- Understand the Simulation Process

- Identify Improvement Opportunities during Preprocessing

- Prepare for the Solver

- Streamline Postprocessing

- Look for the Right Qualities in a Simulation Solution

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

As companies seek to improve profitability and competitiveness, investments in the product development process can yield big returns. Empowering teams to make the best design decisions puts them in a great position to bring innovative, high quality, profitable products to market. Simulation can be a powerful tool for supporting better decisions. However, several steps during the simulation process can slow things down and prevent companies from taking full advantage of potential benefits. Understanding simulation challenges can help companies put the right capabilities in place so they may realize even more value from simulation tools. What challenges do companies experience as part of the simulation process? What slows the process down? How do successful companies get the most value from simulation? To answer these questions, Tech-Clarity surveyed over 160 manufacturers about their simulation processes. The results were analyzed to identify the top challenges associated with preprocessing, preparing for the solver, and postprocessing. The research finds that:- Preprocessing is the most time consuming part of the simulation process, taking up 38% of total simulation time

- Top challenges of preprocessing include finding problematic geometry, recreating CAD geometry, and defining assembly contacts

- Top challenges of postprocessing involve the time invested in filtering through vast amounts of data

- Automating many time consuming, tedious tasks associated with preprocessing. They are twice as likely to automate assembly contact definition and 4-times as likely to automate geometry clean up.

- Maintaining flexibility and control so that models are not overly simplified and mesh size is appropriate. They are 52% more likely to have the ability to edit and control the mesh.

- Using visual filtering and sorting tools to more easily review, analyze, and share simulation results. They are 2.2 times more likely than peers to visually filter results, which allows them to interrogate the results and quickly focus on areas of interest.

- Ensuring their simulation solution works for their multi-CAD environment. They are 89% more likely than their peers to look for a simulation solution that has the ability to work with multi-CAD data.

In addition to examining the bottlenecks associated with simulation, this report provides guidance on best practices to address them. These practices will help product development teams get even more value from simulation so that they can make the right product decisions that will lead to more profitable products.

[post_title] => Addressing the Bottlenecks of FEA Simulation (Survey Findings) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => simulation_bottlenecks [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:33 [post_modified_gmt] => 2022-11-15 03:28:33 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=5467 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 1 [filter] => raw ) [1] => WP_Post Object ( [ID] => 5512 [post_author] => 2 [post_date] => 2016-07-18 09:09:33 [post_date_gmt] => 2016-07-18 13:09:33 [post_content] => Autodesk published an infographic sharing our research on why top performing companies - those with better revenue growth, higher margin growth, and greater cost reduction - use Product Lifecycle Management solutions. It also shares some of our findings on the time and cost to implement PLM and Top Performers' use of cloud solutions. We've included a small excerpt here, for visit the Autodesk Fusion Lifecycle site for the full infographic (free of charge, no registration required). [post_title] => Why Do Top Performers Use PLM? (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tp-plm-info

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:07

[post_modified_gmt] => 2022-11-15 03:26:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5512

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 5429

[post_author] => 2572

[post_date] => 2016-07-14 11:45:53

[post_date_gmt] => 2016-07-14 15:45:53

[post_content] => In a guest post titled Successful Products Start with Requirements and Validation on the PTC Integrity blog, Michelle Boucher describes why good requirements management is so critical to product success. Excel and Word tend to be the most common tools used for requirements. They work extremely well for defining requirements, but managing requirements becomes much more difficult. When not properly managed, problems arise. This brings to mind the Seinfeld episode when Jerry reserves a rental car, but then finds there are no more cars. He responds, “You see, you know how to take the reservation, you just don't know how to hold the reservation. And that's really the most important part of the reservation: the holding. Anybody can just take them.” Like holding a reservation, it’s really the management of requirements that’s the most important part.

Read the post on the PTC blog now.

[post_title] => Why Do Top Performers Use PLM? (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tp-plm-info

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:07

[post_modified_gmt] => 2022-11-15 03:26:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5512

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 5429

[post_author] => 2572

[post_date] => 2016-07-14 11:45:53

[post_date_gmt] => 2016-07-14 15:45:53

[post_content] => In a guest post titled Successful Products Start with Requirements and Validation on the PTC Integrity blog, Michelle Boucher describes why good requirements management is so critical to product success. Excel and Word tend to be the most common tools used for requirements. They work extremely well for defining requirements, but managing requirements becomes much more difficult. When not properly managed, problems arise. This brings to mind the Seinfeld episode when Jerry reserves a rental car, but then finds there are no more cars. He responds, “You see, you know how to take the reservation, you just don't know how to hold the reservation. And that's really the most important part of the reservation: the holding. Anybody can just take them.” Like holding a reservation, it’s really the management of requirements that’s the most important part.

Read the post on the PTC blog now.

[post_title] => Successful Products Start with Requirements & Validation - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => successful-products-start-requirements

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:00

[post_modified_gmt] => 2022-11-15 03:26:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5429

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 5485

[post_author] => 2

[post_date] => 2016-07-11 08:33:33

[post_date_gmt] => 2016-07-11 12:33:33

[post_content] => Jim Brown shared his recent research on building versus buying IoT infrastructure in the Top Five Things that Ensure a Successful IoT Implementation: Exploring the Nature of IoT Projects and Build vs. Buy Decisions Industry Week webcast webinar (sponsored by Autodesk). The webcast also featured Autodesk's Head of IoT, Bryan Kester, sharing the value of a smart, connected product strategy.

Watch the replay now, including a very lively Q&A session.

[post_title] => Successful Products Start with Requirements & Validation - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => successful-products-start-requirements

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:00

[post_modified_gmt] => 2022-11-15 03:26:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5429

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 5485

[post_author] => 2

[post_date] => 2016-07-11 08:33:33

[post_date_gmt] => 2016-07-11 12:33:33

[post_content] => Jim Brown shared his recent research on building versus buying IoT infrastructure in the Top Five Things that Ensure a Successful IoT Implementation: Exploring the Nature of IoT Projects and Build vs. Buy Decisions Industry Week webcast webinar (sponsored by Autodesk). The webcast also featured Autodesk's Head of IoT, Bryan Kester, sharing the value of a smart, connected product strategy.

Watch the replay now, including a very lively Q&A session.

[post_title] => Top Five Considerations to Build or Buy IoT Infrastructure (on demand webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => build-buy-iot

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:46

[post_modified_gmt] => 2022-11-15 03:26:46

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5485

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 5342

[post_author] => 2572

[post_date] => 2016-07-01 04:00:33

[post_date_gmt] => 2016-07-01 08:00:33

[post_content] =>

[post_title] => Top Five Considerations to Build or Buy IoT Infrastructure (on demand webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => build-buy-iot

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:46

[post_modified_gmt] => 2022-11-15 03:26:46

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5485

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 5342

[post_author] => 2572

[post_date] => 2016-07-01 04:00:33

[post_date_gmt] => 2016-07-01 08:00:33

[post_content] =>  The Simulation Buyer's Guide for Design Engineers eBook identifies the top 10 buying criteria you should consider when buying a simulation solution for design engineers. You can then use this information as a checklist to select the right solution for you. The eBook includes a list of questions to help you determine your needs for simulation as well as how you can justify the investment for CAE.

Please enjoy the summary below (free of charge, no registration required).

For the full eBook, please visit our sponsor PTC (free of charge, registration required).

The Simulation Buyer's Guide for Design Engineers eBook identifies the top 10 buying criteria you should consider when buying a simulation solution for design engineers. You can then use this information as a checklist to select the right solution for you. The eBook includes a list of questions to help you determine your needs for simulation as well as how you can justify the investment for CAE.

Please enjoy the summary below (free of charge, no registration required).

For the full eBook, please visit our sponsor PTC (free of charge, registration required).

Table of Contents

- Why Do Design Engineers Need a Simulation Solution?

- Determine the Scope of Your Needs

- Identify the Right Solution

- Justify the Investment

- Understand the Value

- Realize Time Savings

- Select the Right Simulation for Your Needs

- About the Author

Why Do Design Engineers Need a Simulation Solution?

How do you know if you should be using simulation? Consider for a moment:- If you could save 7% of your material costs, would it help?

- How would getting to market 14% faster improve your business?

- What would you do with the extra time?

- Would higher quality without adding cost or time make your products more competitive?

Recommendations

- Understand your needs for a simulation solution

- Justify the investment with a focus on how it will empower design engineers to make better decisions that will make products more competitive, lower-cost, and faster to market

- Select a simulation solution that will be easy for design engineers to adopt that will integrate with your existing CAD tool and support existing workflows

- Consider a solution that makes it easy to set up an analysis and includes features such as automated mashing

- Ensure the solution supports design optimization

- Select a solution and vendor that can offer the right training resources to reduce the learning curve

The PLM License and Deployment Flexibility Puts PLM in Reach eBook discusses how new software deployment and licensing approaches including cloud, SaaS, subscription, and others can put PLM in reach for more companies. The eBook reviews the ROI of PLM and dispels the myth that PLM implementations have to be long and expensive. The research reviews the benefits of different licensing and deployment models and highlights key things to look for during procurement, deployment, and operations phases.

Click here for the full eBook, thank you to our sponsor PTC.

The PLM License and Deployment Flexibility Puts PLM in Reach eBook discusses how new software deployment and licensing approaches including cloud, SaaS, subscription, and others can put PLM in reach for more companies. The eBook reviews the ROI of PLM and dispels the myth that PLM implementations have to be long and expensive. The research reviews the benefits of different licensing and deployment models and highlights key things to look for during procurement, deployment, and operations phases.

Click here for the full eBook, thank you to our sponsor PTC.

The Compelling ROI of PLM

Product Lifecycle Management (PLM) has a very attractive ROI. It helps address the inherent complexity of product innovation, product development, and engineering resulting from today’s complex products and product development landscapes. It’s one of the few initiatives that concurrently drives both top-line and bottom-line results. But getting these returns is sometimes considered too big of an investment. PLM initiatives have historically been known for long, expensive implementations. Most manufacturers no longer have the appetite for software projects that don’t show an ROI in the first year or so. So many choose not to get started because they expect high costs, a long payback period, and a significant need for internal IT resources.

Product Lifecycle Management (PLM) has a very attractive ROI. It helps address the inherent complexity of product innovation, product development, and engineering resulting from today’s complex products and product development landscapes. It’s one of the few initiatives that concurrently drives both top-line and bottom-line results. But getting these returns is sometimes considered too big of an investment. PLM initiatives have historically been known for long, expensive implementations. Most manufacturers no longer have the appetite for software projects that don’t show an ROI in the first year or so. So many choose not to get started because they expect high costs, a long payback period, and a significant need for internal IT resources.

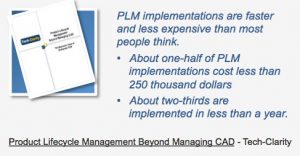

Our research, however, shows that the majority of PLM implementations are faster and less expensive than most think. We believe one of the reasons for so many lower-than-expected implementation efforts is the changing way that companies are buying and deploying PLM. Cloud, SaaS, subscription, and other options are changing the underlying factors that impact implementation investments. Let’s take a look at how things are changing.

Our research, however, shows that the majority of PLM implementations are faster and less expensive than most think. We believe one of the reasons for so many lower-than-expected implementation efforts is the changing way that companies are buying and deploying PLM. Cloud, SaaS, subscription, and other options are changing the underlying factors that impact implementation investments. Let’s take a look at how things are changing.

What’s the Right Path for Your Company?

There’s a lot to consider when looking for a PLM solution. New options reduce barriers to entry and help add flexibility and agility. But it’s important to recognize that the primary goal is to find a solution that meets company needs to combat complexity and improve business performance. Without the capabilities to drive business improvement the rest is pointless. Manufacturers can leverage tools such as Tech-Clarity’s PDM Buyer’s Guide for a framework on how to analyze solutions based on company needs beyond features and functions. While those are important, manufacturers must also know their procurement options, deployment choices, and the impacts those have across the lifecycle of a solution. PLM is more powerful and attainable than ever, which is good news for manufacturers of all sizes. Now is the time to:

PLM is more powerful and attainable than ever, which is good news for manufacturers of all sizes. Now is the time to:

- Understand your needs

- Know your options

- Find the right solution

- Identify the optimal procurement approach for your business

- Determine the most advantageous deployment approach

- Understand the business agility available from new options

- Take advantage of lower barriers to entry for PLM

- Get started with PLM and get a quick ROI

- Extend the benefits over time

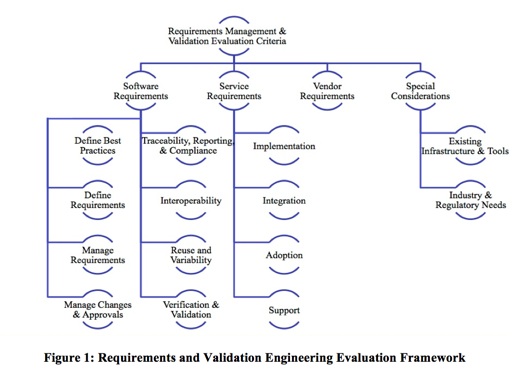

Tech-Clarity's Requirements and Validation Engineering Buyer’s Guide helps manufacturers develop criteria to evaluate software solutions to support requirements management and validation engineering. Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

Tech-Clarity's Requirements and Validation Engineering Buyer’s Guide helps manufacturers develop criteria to evaluate software solutions to support requirements management and validation engineering. Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

- Software capabilities

- Implementation

- User adoption

- Support

- Vendor characteristics / attributes

- Industry or unique business needs

Table of Contents

- Executive Overview

- The Business Value of Requirements Management

- Start with Defining Best Practices

- Define Requirements

- Manage Requirements

- Manage Changes and Approvals

- Enable Traceability, Reporting, and Compliance Management

- Ensure Interoperability

- Support Reuse and Variability

- Verify and Validate Requirements

- Assess Service Requirements

- Consider Vendor Attributes

- Identify Specific Needs for your Company

- Conclusion

- Recommendations

- About the Author

Executive Overview

Fierce global competition means companies have little leeway to bring the wrong product to market. However, today’s products have gotten so complex, it has become increasingly difficult to capture customer and market needs, translate those needs to product requirements, manage them throughout a complex development process involving changes and different configurations, and then make sure the requirements are truly satisfied. A lot of work goes into the initial definition of those requirements, but we do not live in a static world. Changes are inevitable. Tracing all the impacts of those changes, notifying everyone involved, and getting everything updated, including the test case, can be a nightmare. However, with expert requirements and validation engineering practices, combined with the right technology, the process will be far more manageable. This guide consists of four major sections covering requirements management and validation software tool functionality, service requirements, vendor attributes, and special company considerations (Figure 1). Each section includes a checklist with key requirements to investigate when selecting software tools to support requirements and validation processes. To set the foundation for expert requirements and validation engineering practices, companies should focus on the entire lifecycle of requirements, not just the definition. This will enable companies to ensure the product they want to bring to market, is the one they actually do. In addition, it will improve the efficiency of the entire process, with fewer errors, leading to higher product profitability. This guide is not an all-encompassing requirements list. It provides a high level overview for requirements and validation engineering.

[post_title] => Requirements and Validation Buyer’s Guide

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => requirements-buyers-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:53

[post_modified_gmt] => 2022-11-15 03:27:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5275

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 5345

[post_author] => 2

[post_date] => 2016-06-02 13:36:22

[post_date_gmt] => 2016-06-02 17:36:22

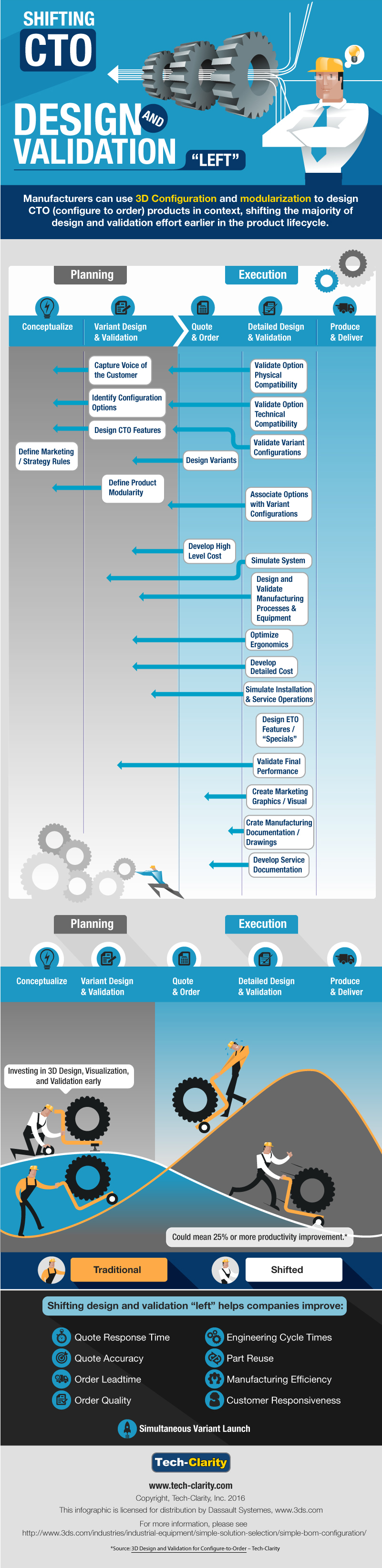

[post_content] => Driving Engineer-to-Order Differentiation and Profitability, Analyzing Trends and Best Practices in Product Configuration

This guide is not an all-encompassing requirements list. It provides a high level overview for requirements and validation engineering.

[post_title] => Requirements and Validation Buyer’s Guide

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => requirements-buyers-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:53

[post_modified_gmt] => 2022-11-15 03:27:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5275

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 5345

[post_author] => 2

[post_date] => 2016-06-02 13:36:22

[post_date_gmt] => 2016-06-02 17:36:22

[post_content] => Driving Engineer-to-Order Differentiation and Profitability, Analyzing Trends and Best Practices in Product Configuration shares survey findings and interviews with leading manufacturers showing how Top Performers achieve higher revenue and profit margin growth through ETO best practice processes and technology. The research shares results of a survey of over 200 manufacturers and analyzes their use of product configurators and automation technology to improve estimation, quote, design, documentation, and manufacturing performance.

Click here for the full report, thank you to our sponsor Siemens PLM.

shares survey findings and interviews with leading manufacturers showing how Top Performers achieve higher revenue and profit margin growth through ETO best practice processes and technology. The research shares results of a survey of over 200 manufacturers and analyzes their use of product configurators and automation technology to improve estimation, quote, design, documentation, and manufacturing performance.

Click here for the full report, thank you to our sponsor Siemens PLM.

Executive Overview

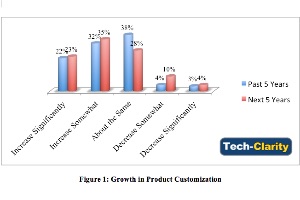

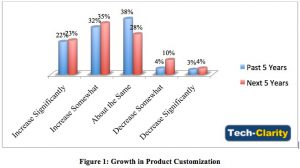

Customized products are more compelling to customers and drive higher profitability. They can also create chaos in sales proposal and order fulfillment processes as engineers scramble to develop cost estimates, customized designs, and detailed manufacturing and sales documentation. This engineer-to-order (ETO) study finds that some companies have found better ways to design custom products, alleviating the engineering bottleneck created in most companies when quotes requests or orders roll in. The manufacturing industry needs to adopt best practices and technology to accommodate the growth in customized products. Researchers for this report surveyed over 200 companies, finding that product customization is growing significantly. Why? For some companies, it helps them differentiate. For others, their industry doesn’t give them a choice. It’s just the nature of the business. Either way, growth in product customization drives increased complexity that leads to late deliveries, recalls / warranty work, and missed financial targets. The cause? Manual processes for custom products make Engineering a bottleneck to getting quotes and orders out of the door. Fortunately Tech-Clarity research1 shows that companies taking more advanced ETO approaches to customize their products end up with better results. This report investigates trends in customization and digs deeper into these best practices. The analysis finds that manufacturers achieving the highest sales and profitability growth, The Top Performers, place more strategic emphasis on rapid quote and order turnaround. They also perform better when executing orders, experiencing significantly fewer errors. Our research shows that Top Performers adopt leading design practices including platform, modular, and rules-based design techniques1. Survey reports show they support these best practices with leading technologies, finding that they are:- More than twice as likely to use technical product configurators

- 53% more likely to have quote automation

- 22% more likely to leverage design automation

Table of Contents

- Executive Overview

- Product Customization is on the Rise

- Understanding Customization Business Drivers

- Creating Differentiation in Customized Products

- Taking A Deeper Look at Customization

- Recognizing Customization Challenges

- Recognizing Potential Negative Impacts of Customization

- Identifying the Top Performers

- Analyzing what Top Performers do Differently

- Evaluating Top Performers’ Process Advantages

- Analyzing the Technical Enablers of Top Performers

- Identifying the Technical Capabilities of Top Performers

- Conclusion

- Recommendations

- About the Author

- About the Research

- Footnote

Conclusion

Product customization is growing and is expected to continue to grow. Customization provides significant business value, but also brings significant challenges. These challenges result in a large percentage of orders with costly and time-consuming mistakes. Top Performers, however, have fewer order errors than others. One of the key differences between their approaches and the Others’ is that they have adopted more engineering automation. ETO automation helps eliminate engineering bottlenecks and manual processes that lead to delays and errors. “If it’s done right, engineering becomes a nonfactor for leadtimes,” explains Price Mechanical’s Rogers.

Some of the key enablers that Top Performers employ more than Others are technical product configurators, design automation, MBOM generation, quote generation, and CAD automation. “The whole idea is to automate a process to allow someone to do something more value-added for the business,” explains Mark Rogers of Price Mechanical. “Automation allows engineers to design new things or cost-down products instead of processing orders.” These technologies help relieve the engineering bottleneck for customized orders and are likely the source of Top Performers enhanced order execution and higher financial performance. Other commonly used technologies including CAD, sales (CPQ) configurators, ERP, and spreadsheets also provide value, but they aren’t correlated with the Top Performers’ better performance.

Product customization is growing and is expected to continue to grow. Customization provides significant business value, but also brings significant challenges. These challenges result in a large percentage of orders with costly and time-consuming mistakes. Top Performers, however, have fewer order errors than others. One of the key differences between their approaches and the Others’ is that they have adopted more engineering automation. ETO automation helps eliminate engineering bottlenecks and manual processes that lead to delays and errors. “If it’s done right, engineering becomes a nonfactor for leadtimes,” explains Price Mechanical’s Rogers.

Some of the key enablers that Top Performers employ more than Others are technical product configurators, design automation, MBOM generation, quote generation, and CAD automation. “The whole idea is to automate a process to allow someone to do something more value-added for the business,” explains Mark Rogers of Price Mechanical. “Automation allows engineers to design new things or cost-down products instead of processing orders.” These technologies help relieve the engineering bottleneck for customized orders and are likely the source of Top Performers enhanced order execution and higher financial performance. Other commonly used technologies including CAD, sales (CPQ) configurators, ERP, and spreadsheets also provide value, but they aren’t correlated with the Top Performers’ better performance.

Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Focus on speed as a differentiator for customized products

- Adopt modular and platform design approaches to streamline customization

- Recognize the different capabilities of Technical Product Configurators and Sales (CPQ) Configurators, using each for their strengths (and possibly in combination)

- Leverage technical product configurators and design automation to remove manual engineering effort that creates bottlenecks and results in errors in sales and order engineering processes

[post_title] => Shifting CTO Design and Validation Left (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cto-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:07

[post_modified_gmt] => 2022-11-15 03:26:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5326

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 5309

[post_author] => 2

[post_date] => 2016-05-02 12:11:10

[post_date_gmt] => 2016-05-02 16:11:10

[post_content] =>

[post_title] => Shifting CTO Design and Validation Left (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cto-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:07

[post_modified_gmt] => 2022-11-15 03:26:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5326

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 5309

[post_author] => 2

[post_date] => 2016-05-02 12:11:10

[post_date_gmt] => 2016-05-02 16:11:10

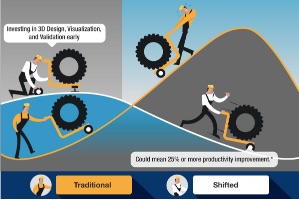

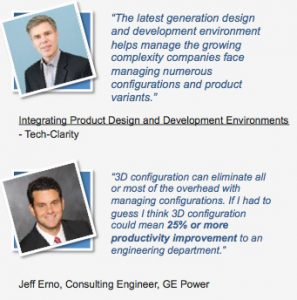

[post_content] =>  This new eBook explains how companies with configure-to-order (CTO) products can improve efficiency and responsiveness through the intelligent use of 3D design and validation techniques. The research shares perspectives from Tech-Clarity's Jim Brown and GE's Jeff Erno on how design and validation can be "shifted left" in time so manufacturers can accurately and rapidly deliver quotes and orders for personalized products.

Please enjoy the excerpt below. For the full report, please visit our sponsor Dassault Systemes (free of charge, registration required).

You also view the related infographic on our site.

This new eBook explains how companies with configure-to-order (CTO) products can improve efficiency and responsiveness through the intelligent use of 3D design and validation techniques. The research shares perspectives from Tech-Clarity's Jim Brown and GE's Jeff Erno on how design and validation can be "shifted left" in time so manufacturers can accurately and rapidly deliver quotes and orders for personalized products.

Please enjoy the excerpt below. For the full report, please visit our sponsor Dassault Systemes (free of charge, registration required).

You also view the related infographic on our site.

The Strategic Value of CTO

Selling configured products can drive significant business benefits including increased differentiation and price margins. An increasing number of manufacturers offer customization as a strategic weapon, while for others it’s a mandatory fact of life to meet customer needs and ensure products fit into customer sites and scenarios. In either scenario, it’s a highly valuable approach. Configuration is also strategic to localizing products to meet global requirements. Many manufacturers are simultaneously launching variants of a single, global product around the world. This takes a little longer to achieve, but maximizes profits across regions and improves operating margins. It can also prevent competitors from copying and launching differentiating features of a product in other parts of the world where it hasn’t been launched yet.

Configuring products to order, however, is inherently complex. Being able to effectively and efficiently design, validate, and sell configure-to-order (CTO) products is a strategic capability that drives profitability. A well-designed CTO process allows companies to define product variants and associate them with customer specifications so they can rapidly respond to customer requests for quote (RFQ) and orders.

Configuration is also strategic to localizing products to meet global requirements. Many manufacturers are simultaneously launching variants of a single, global product around the world. This takes a little longer to achieve, but maximizes profits across regions and improves operating margins. It can also prevent competitors from copying and launching differentiating features of a product in other parts of the world where it hasn’t been launched yet.

Configuring products to order, however, is inherently complex. Being able to effectively and efficiently design, validate, and sell configure-to-order (CTO) products is a strategic capability that drives profitability. A well-designed CTO process allows companies to define product variants and associate them with customer specifications so they can rapidly respond to customer requests for quote (RFQ) and orders.

Conclusion

It’s time for manufacturers to improve CTO performance by leveraging 3D design and validation. With 3D configuration, engineers can develop variants in 3D without generating CAD files for each variant. They can use a max case approach to find errors early using dynamic filters to design in a configured context. “Configured structures change the ball game because you aren’t managing every component in every variant, only the net change,” GE’s Erno explains.

Designing variants in 3D, manufacturers can shift the majority of engineering effort “left” in order to streamline quotes and orders and execute more rapidly and accurately. They can develop more compelling quotes and bids leveraging 3D and high definition renderings, impressing customers and giving them greater confidence in their orders.

Using the right processes and 3D configuration technology, manufacturers can improve efficiency, streamline order processes, reduce errors, and develop accurate quotes much more quickly.

[post_title] => 3D Design and Validation for CTO Products (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cto-3d

[to_ping] =>

[pinged] =>

[post_modified] => 2025-01-31 11:38:54

[post_modified_gmt] => 2025-01-31 16:38:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5309

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 5304

[post_author] => 2

[post_date] => 2016-04-29 16:21:34

[post_date_gmt] => 2016-04-29 20:21:34

[post_content] => Tech-Clarity's Jim Brown will participate in a panel discussion along with a presenter from GE and representatives from Dassault Systemes as a part of the upcoming ENOVIA user meeting. The panel will address customer submitted questions expected to include PLM functionality and the 3DExperience Platform. The theme of the event is "Driving Growth for the Future."

It’s time for manufacturers to improve CTO performance by leveraging 3D design and validation. With 3D configuration, engineers can develop variants in 3D without generating CAD files for each variant. They can use a max case approach to find errors early using dynamic filters to design in a configured context. “Configured structures change the ball game because you aren’t managing every component in every variant, only the net change,” GE’s Erno explains.

Designing variants in 3D, manufacturers can shift the majority of engineering effort “left” in order to streamline quotes and orders and execute more rapidly and accurately. They can develop more compelling quotes and bids leveraging 3D and high definition renderings, impressing customers and giving them greater confidence in their orders.

Using the right processes and 3D configuration technology, manufacturers can improve efficiency, streamline order processes, reduce errors, and develop accurate quotes much more quickly.

[post_title] => 3D Design and Validation for CTO Products (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cto-3d

[to_ping] =>

[pinged] =>

[post_modified] => 2025-01-31 11:38:54

[post_modified_gmt] => 2025-01-31 16:38:54

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5309

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 5304

[post_author] => 2

[post_date] => 2016-04-29 16:21:34

[post_date_gmt] => 2016-04-29 20:21:34

[post_content] => Tech-Clarity's Jim Brown will participate in a panel discussion along with a presenter from GE and representatives from Dassault Systemes as a part of the upcoming ENOVIA user meeting. The panel will address customer submitted questions expected to include PLM functionality and the 3DExperience Platform. The theme of the event is "Driving Growth for the Future." [post_title] => Jim Brown Presents at ENOVIA User Conference

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => jim-brown-presents-enovia-user-conference

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:12

[post_modified_gmt] => 2022-11-15 03:26:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5304

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 5288

[post_author] => 2572

[post_date] => 2016-04-20 21:08:57

[post_date_gmt] => 2016-04-21 01:08:57

[post_content] =>

[post_title] => Jim Brown Presents at ENOVIA User Conference

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => jim-brown-presents-enovia-user-conference

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:12

[post_modified_gmt] => 2022-11-15 03:26:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5304

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 5288

[post_author] => 2572

[post_date] => 2016-04-20 21:08:57

[post_date_gmt] => 2016-04-21 01:08:57

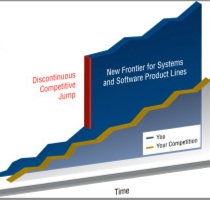

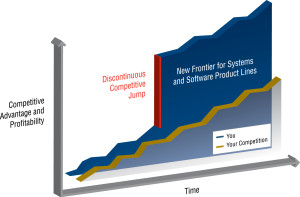

[post_content] =>  During this webinar, Michelle Boucher joins Charles Krueger, CEO of BigLever Software. Together they discuss strategies for handling increasing complexity, meeting varying customer needs, and managing product lines, especially for software-intensive products. The webinar focuses on product line engineering and includes a discussion on:

During this webinar, Michelle Boucher joins Charles Krueger, CEO of BigLever Software. Together they discuss strategies for handling increasing complexity, meeting varying customer needs, and managing product lines, especially for software-intensive products. The webinar focuses on product line engineering and includes a discussion on:

- Successful approaches to product line engineering (PLE) for managing product variation

- How embedded software, combined with the ability to tailor products through PLE approaches, enables organizations to differentiate products, streamline development efforts and boost profitability

- How to leverage the combined strengths of PLE, ALM and PLM to achieve efficiency, cost reduction, time-to-market, product line scalability and quality goals

- Strategies for reducing variant management complexity

- How to facilitate better interoperability across software, electrical and mechanical teams

- Simplify and manage complexity by using a Model Based Enterprise or Systems Engineering approach to ensure systems perform to requirements

- Implement new ways to reduce costs by improving the management of bill of materials(BOM), enterprise data and process optimization

- Minimize business risks and fulfill performance requirements through 3D master development, validation and testing

[post_title] => Supplier Strategies to Win more Business

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => supplier-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:39

[post_modified_gmt] => 2022-11-15 03:26:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5269

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 5252

[post_author] => 2572

[post_date] => 2016-04-12 12:36:58

[post_date_gmt] => 2016-04-12 16:36:58

[post_content] => Michelle Boucher shares six reasons why product development projects fail and they all stem from poor requirements management. The guest post titled 6 Reasons Your Projects Fail: How Requirements Management Can Help on the PTC Integrity blog, explores the impact of these six challenges on project success and discusses various ways poor requirements management can derail a project.

Read the post on the PTC blog now.

[post_title] => Supplier Strategies to Win more Business

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => supplier-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:39

[post_modified_gmt] => 2022-11-15 03:26:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5269

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 5252

[post_author] => 2572

[post_date] => 2016-04-12 12:36:58

[post_date_gmt] => 2016-04-12 16:36:58

[post_content] => Michelle Boucher shares six reasons why product development projects fail and they all stem from poor requirements management. The guest post titled 6 Reasons Your Projects Fail: How Requirements Management Can Help on the PTC Integrity blog, explores the impact of these six challenges on project success and discusses various ways poor requirements management can derail a project.

Read the post on the PTC blog now.

[post_title] => 6 Reasons Your Projects Fail - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => why-projects-fail

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:00

[post_modified_gmt] => 2022-11-15 03:26:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5252

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 5236

[post_author] => 2

[post_date] => 2016-04-06 09:49:45

[post_date_gmt] => 2016-04-06 13:49:45

[post_content] =>

[post_title] => 6 Reasons Your Projects Fail - Guest Post on PTC Blog

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => why-projects-fail

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:00

[post_modified_gmt] => 2022-11-15 03:26:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5252

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 5236

[post_author] => 2

[post_date] => 2016-04-06 09:49:45

[post_date_gmt] => 2016-04-06 13:49:45

[post_content] =>  Our Finding PLM to Fit Midsized Manufacturers eBook explains how smaller companies find themselves stuck between full-featured PLM systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can't afford the errors and inefficiency inherent to informal data and process management, but can't afford a large time, resource, and financial investment to fix their problems. Unfortunately simple solutions, while very attractive, fall short of their real needs, don't help them improve their business the way they want to, and don't leave them room to grow in the future. They need to find the "sweet spot" of a solution that helps them get started quickly with the basics of controlling, managing, and sharing product data but provides the features they need to be successful now and into the future.

Please enjoy the summary below.

For the full eBook, please visit our sponsor Dassault Systèmes (free of charge, registration required).

Our Finding PLM to Fit Midsized Manufacturers eBook explains how smaller companies find themselves stuck between full-featured PLM systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can't afford the errors and inefficiency inherent to informal data and process management, but can't afford a large time, resource, and financial investment to fix their problems. Unfortunately simple solutions, while very attractive, fall short of their real needs, don't help them improve their business the way they want to, and don't leave them room to grow in the future. They need to find the "sweet spot" of a solution that helps them get started quickly with the basics of controlling, managing, and sharing product data but provides the features they need to be successful now and into the future.

Please enjoy the summary below.

For the full eBook, please visit our sponsor Dassault Systèmes (free of charge, registration required).

Midsize Manufacturers Stuck in Between

Midsize manufacturers are poised to grow in today’s vibrant markets. They’re taking advantage of manufacturing revitalization armed with a combination of product innovation and agility. But developing successful products today is complex business. It requires technical knowhow, teamwork, collaboration, and coordination. Midsize companies have to overcome this complexity to compete with larger competitors. They have to connect closely with customers and introduce new products quickly and efficiently to meet their needs. Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may be able to control, access, and share product data with relatively simple Product Data Management (PDM) tools, larger manufacturers rely on full-featured PLM systems that help automate processes and share data across global supply chains.

Midsize companies may find themselves in-between because:

Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may be able to control, access, and share product data with relatively simple Product Data Management (PDM) tools, larger manufacturers rely on full-featured PLM systems that help automate processes and share data across global supply chains.

Midsize companies may find themselves in-between because:

- Product and organizational complexity drive them beyond basic PDM capabilities

- A full-featured PLM implementation may feel out of reach

Get Started with the Right PLM Solution

Core PLM can quickly add value to midsized manufacturers by helping them combat complexity, improve productivity, and stay closer to customers. Recognize the potential value of a fully featured PLM with all of the bells and whistles, but be honest with yourself about whether your company can afford the time and effort to get there (at least right away). Don’t take on too much. Start with the basics and get value quickly, but recognize the shortcomings of simple file sharing solutions that fall short for the complex products and product development environments common to midsize manufacturers. Look for a solution that allows you to design in the context of your products in real time, but also in the context of processes and product development projects. In addition, look for PLM that incorporates automation including automatic CAD and project updates to keep engineers focused on innovation instead of managing files. Finally, make sure to leave your company room to grow as your business dictates, using the initial implementation as a foundation for greater improvements. *This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below. [post_title] => Finding PLM to Fit Midsized Manufacturers eBook [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => midsize-plm [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:09 [post_modified_gmt] => 2022-11-15 03:28:09 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=5236 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [15] => WP_Post Object ( [ID] => 5226 [post_author] => 2572 [post_date] => 2016-04-04 12:07:30 [post_date_gmt] => 2016-04-04 16:07:30 [post_content] =>- Luis Baldez, Software Strategy Program Manager, 3D Printing, HP

- Prabhjot Singh, Manager, Additive Manufacturing Lab, GE Global Research

- Simon Floyd, Director Strategy, Product Lifecycle Management, Microsoft

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/aHgBhAlt2Dk

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/aHgBhAlt2Dk

Prior Episode: Tech-Clarity's Jim Brown discusses the PLM evolution at Suretank with Barry Woods, Systems Project Manager. Barry shares that Suretank had very traditional goals for PLM, primarily revision management and getting data under control. That was a success, but new management arrived and shifted company focus to World Class Customer Care. Suretank leveraged the flexibility of their PLM system to implement new capabilities aligned with the revised corporate strategy and ended up with huge business benefits. Barry shares they have continued plans to improve performance with PLM.

[post_title] => Swivl's Mike Pierce Explains why Startups Need PLM (PLM411 video)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-14

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:47

[post_modified_gmt] => 2022-11-15 03:28:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5168

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 5193

[post_author] => 2572

[post_date] => 2016-03-22 01:47:56

[post_date_gmt] => 2016-03-22 05:47:56

[post_content] => This survey is now closed. Please check out our Active Research page for additional Tech-Clarity survey opportunities.

Prior Episode: Tech-Clarity's Jim Brown discusses the PLM evolution at Suretank with Barry Woods, Systems Project Manager. Barry shares that Suretank had very traditional goals for PLM, primarily revision management and getting data under control. That was a success, but new management arrived and shifted company focus to World Class Customer Care. Suretank leveraged the flexibility of their PLM system to implement new capabilities aligned with the revised corporate strategy and ended up with huge business benefits. Barry shares they have continued plans to improve performance with PLM.

[post_title] => Swivl's Mike Pierce Explains why Startups Need PLM (PLM411 video)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-14

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:47

[post_modified_gmt] => 2022-11-15 03:28:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=5168

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 5193

[post_author] => 2572

[post_date] => 2016-03-22 01:47:56

[post_date_gmt] => 2016-03-22 05:47:56

[post_content] => This survey is now closed. Please check out our Active Research page for additional Tech-Clarity survey opportunities.

How do leading companies empower design engineers with simulation?

Please share your experience. We are conducting new research on simulation and exploring questions such as how does simulation help design engineers? What are the best ways to help design engineers adopt simulation tools? What should you look for in a simulation solution for design engineers?

Please share your experience. We are conducting new research on simulation and exploring questions such as how does simulation help design engineers? What are the best ways to help design engineers adopt simulation tools? What should you look for in a simulation solution for design engineers?

- If you already completed the survey –> please share with a colleague by emailing a link to this page or select the “Share/Save” button above, which also includes social media options.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

In addition, 25 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes or less to complete. Individual responses will be kept confidential.

Thank you for your help and support!

In addition, 25 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes or less to complete. Individual responses will be kept confidential.

Thank you for your help and support!

Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => Simulation Study: Empowering Innovation [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => design-simulation-survey [to_ping] => [pinged] => [post_modified] => 2024-01-20 00:53:02 [post_modified_gmt] => 2024-01-20 05:53:02 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=5193 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 4 [filter] => raw ) [18] => WP_Post Object ( [ID] => 5182 [post_author] => 2572 [post_date] => 2016-03-21 12:10:51 [post_date_gmt] => 2016-03-21 16:10:51 [post_content] => How to Empower R&D and Engineering Teams to Innovate with New Materials: Secrets to Growing Revenue and Increasing Profit Margins identifies six lessons to help companies innovate to secure future revenue streams, while managing risk. The study examines how new materials can help companies innovate and how more successful companies take advantage of the latest developments in materials.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report please visit our sponsor, Elsevier (free of charge, registration required).

How to Empower R&D and Engineering Teams to Innovate with New Materials: Secrets to Growing Revenue and Increasing Profit Margins identifies six lessons to help companies innovate to secure future revenue streams, while managing risk. The study examines how new materials can help companies innovate and how more successful companies take advantage of the latest developments in materials.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report please visit our sponsor, Elsevier (free of charge, registration required).

Table of Contents

- Executive Overview

- Business Drivers for Innovation

- Identifying the Top Performers

- Lesson #1: Understand the Opportunities in New Materials

- Lesson #2: Consider How To Balance Different Levels Of Innovation

- Lesson #3: Implement the Right Innovation Strategies

- Lesson #4: Prioritize Resources and Processes That Help Accelerate Discovery and Commercialization

- Lesson #5: Successfully Transition From Concept to Manufacture at Scale By Looking at the Entire System

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

Optimizing the Bidding Process: How Industrial Equipment Manufacturers Can Win More Business focuses on the importance of getting the bidding process right. Bids require a quick response, yet must be competitively priced, without sacrificing margins. Getting this right is a challenge for many companies, but is especially difficult for businesses such as industrial equipment manufacturers offering Engineer-to-Order products. This report identifies best practices for quickly delivering an accurate, yet competitive bid.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For for more information on bidding for Engineer-to-Order products, please visit our sponsor, Autodesk.

Optimizing the Bidding Process: How Industrial Equipment Manufacturers Can Win More Business focuses on the importance of getting the bidding process right. Bids require a quick response, yet must be competitively priced, without sacrificing margins. Getting this right is a challenge for many companies, but is especially difficult for businesses such as industrial equipment manufacturers offering Engineer-to-Order products. This report identifies best practices for quickly delivering an accurate, yet competitive bid.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For for more information on bidding for Engineer-to-Order products, please visit our sponsor, Autodesk.

Table of Contents

- Executive Overview

- Review your Bidding Process

- Win More Business

- Win Customer Loyalty

- Prepare for the Future

- Extend Bid Automation to Engineering

- Enable Collaboration

- Select the Right Vendor

- Conclusion

- Recommendations

- About the Author

Executive Overview

- Grown revenue 2.2 times more than their lesser performing competitors

- Increased profit margins 2.4 times more than average performing companies

Tech-Clarity's Addressing the Bottlenecks of FEA Simulation: Enabling Innovation by Getting Even More Value from CAE shares survey results on the simulation process. The analysis identified the top simulation bottlenecks that slow down the process. With a better understanding of these bottlenecks, manufacturers can take steps to minimize them and consequently, get even more value from simulation.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, Siemens, here (free of charge, registration required).

Tech-Clarity's Addressing the Bottlenecks of FEA Simulation: Enabling Innovation by Getting Even More Value from CAE shares survey results on the simulation process. The analysis identified the top simulation bottlenecks that slow down the process. With a better understanding of these bottlenecks, manufacturers can take steps to minimize them and consequently, get even more value from simulation.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, Siemens, here (free of charge, registration required).

Table of Contents

- Executive Overview

- Support Business Goals with the Right Design Tools.

- Examine the Value of Simulation

- Identifying the Top Performers

- Understand the Simulation Process

- Identify Improvement Opportunities during Preprocessing

- Prepare for the Solver

- Streamline Postprocessing

- Look for the Right Qualities in a Simulation Solution

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

As companies seek to improve profitability and competitiveness, investments in the product development process can yield big returns. Empowering teams to make the best design decisions puts them in a great position to bring innovative, high quality, profitable products to market. Simulation can be a powerful tool for supporting better decisions. However, several steps during the simulation process can slow things down and prevent companies from taking full advantage of potential benefits. Understanding simulation challenges can help companies put the right capabilities in place so they may realize even more value from simulation tools. What challenges do companies experience as part of the simulation process? What slows the process down? How do successful companies get the most value from simulation? To answer these questions, Tech-Clarity surveyed over 160 manufacturers about their simulation processes. The results were analyzed to identify the top challenges associated with preprocessing, preparing for the solver, and postprocessing. The research finds that:- Preprocessing is the most time consuming part of the simulation process, taking up 38% of total simulation time

- Top challenges of preprocessing include finding problematic geometry, recreating CAD geometry, and defining assembly contacts

- Top challenges of postprocessing involve the time invested in filtering through vast amounts of data

- Automating many time consuming, tedious tasks associated with preprocessing. They are twice as likely to automate assembly contact definition and 4-times as likely to automate geometry clean up.

- Maintaining flexibility and control so that models are not overly simplified and mesh size is appropriate. They are 52% more likely to have the ability to edit and control the mesh.

- Using visual filtering and sorting tools to more easily review, analyze, and share simulation results. They are 2.2 times more likely than peers to visually filter results, which allows them to interrogate the results and quickly focus on areas of interest.

- Ensuring their simulation solution works for their multi-CAD environment. They are 89% more likely than their peers to look for a simulation solution that has the ability to work with multi-CAD data.

In addition to examining the bottlenecks associated with simulation, this report provides guidance on best practices to address them. These practices will help product development teams get even more value from simulation so that they can make the right product decisions that will lead to more profitable products.

[post_title] => Addressing the Bottlenecks of FEA Simulation (Survey Findings) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => simulation_bottlenecks [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:33 [post_modified_gmt] => 2022-11-15 03:28:33 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=5467 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 1 [filter] => raw ) [comment_count] => 0 [current_comment] => -1 [found_posts] => 876 [max_num_pages] => 44 [max_num_comment_pages] => 0 [is_single] => [is_preview] => [is_page] => [is_archive] => [is_date] => [is_year] => [is_month] => [is_day] => [is_time] => [is_author] => [is_category] => [is_tag] => [is_tax] => [is_search] => [is_feed] => [is_comment_feed] => [is_trackback] => [is_home] => 1 [is_privacy_policy] => [is_404] => [is_embed] => [is_paged] => [is_admin] => [is_attachment] => [is_singular] => [is_robots] => [is_favicon] => [is_posts_page] => [is_post_type_archive] => [query_vars_hash:WP_Query:private] => f6cab794204422e33216495d96b40862 [query_vars_changed:WP_Query:private] => 1 [thumbnails_cached] => [allow_query_attachment_by_filename:protected] => [stopwords:WP_Query:private] => [compat_fields:WP_Query:private] => Array ( [0] => query_vars_hash [1] => query_vars_changed ) [compat_methods:WP_Query:private] => Array ( [0] => init_query_flags [1] => parse_tax_query ) [query_cache_key:WP_Query:private] => wp_query:18a8ef5c8afc4eaf5388c67aa47ead5a:0.15513500 17690502590.16454300 1769050259 )All Results for "All"

Why Do Top Performers Use PLM? (infographic)

Autodesk published an infographic sharing our research on why top performing companies – those with better revenue growth, higher margin growth, and greater cost reduction – use Product Lifecycle Management solutions. It also shares some of our findings on the time and cost to implement PLM and Top Performers’ use of cloud solutions. We’ve included…

Successful Products Start with Requirements & Validation – Guest Post on PTC Blog

In a guest post titled Successful Products Start with Requirements and Validation on the PTC Integrity blog, Michelle Boucher describes why good requirements management is so critical to product success. Excel and Word tend to be the most common tools used for requirements. They work extremely well for defining requirements, but managing requirements becomes much more difficult. When not properly…

Top Five Considerations to Build or Buy IoT Infrastructure (on demand webcast)

Jim Brown shared his recent research on building versus buying IoT infrastructure in the Top Five Things that Ensure a Successful IoT Implementation: Exploring the Nature of IoT Projects and Build vs. Buy Decisions Industry Week webcast webinar (sponsored by Autodesk). The webcast also featured Autodesk’s Head of IoT, Bryan Kester, sharing the value of a smart,…

Simulation Buyer’s Guide for Design Engineers

The Simulation Buyer’s Guide for Design Engineers eBook identifies the top 10 buying criteria you should consider when buying a simulation solution for design engineers. You can then use this information as a checklist to select the right solution for you. The eBook includes a list of questions to help you determine your needs for…

PLM License and Deployment Flexibility Puts PLM in Reach (eBook)

The PLM License and Deployment Flexibility Puts PLM in Reach eBook discusses how new software deployment and licensing approaches including cloud, SaaS, subscription, and others can put PLM in reach for more companies. The eBook reviews the ROI of PLM and dispels the myth that PLM implementations have to be long and expensive. The research reviews the benefits of…

Requirements and Validation Buyer’s Guide

Tech-Clarity’s Requirements and Validation Engineering Buyer’s Guide helps manufacturers develop criteria to evaluate software solutions to support requirements management and validation engineering. Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including: Software capabilities Implementation User adoption Support Vendor characteristics / attributes Industry or unique business…

Driving Engineer-to-Order Differentiation and Profitability (survey findings)

Driving Engineer-to-Order Differentiation and Profitability, Analyzing Trends and Best Practices in Product Configuration shares survey findings and interviews with leading manufacturers showing how Top Performers achieve higher revenue and profit margin growth through ETO best practice processes and technology. The research shares results of a survey of over 200 manufacturers and analyzes their use of…

Shifting CTO Design and Validation Left (infographic)

This infographic explains how manufacturers can improve configure-to-order (CTO) profitability by shifting design and validation “left,” earlier in the product lifecycle, to rapidly respond to requests with accurate quotes and quality products. For more information on 3D Design and Validation, download the related eBook from our sponsor Dassault Systemes (free of charge, registration required). You can also see…

3D Design and Validation for CTO Products (eBook)

This new eBook explains how companies with configure-to-order (CTO) products can improve efficiency and responsiveness through the intelligent use of 3D design and validation techniques. The research shares perspectives from Tech-Clarity’s Jim Brown and GE’s Jeff Erno on how design and validation can be “shifted left” in time so manufacturers can accurately and rapidly deliver quotes…

Jim Brown Presents at ENOVIA User Conference

Tech-Clarity’s Jim Brown will participate in a panel discussion along with a presenter from GE and representatives from Dassault Systemes as a part of the upcoming ENOVIA user meeting. The panel will address customer submitted questions expected to include PLM functionality and the 3DExperience Platform. The theme of the event is “Driving Growth for the…

Webinar: Product Line Engineering – Increasing Competitive Advantage by Reducing Complexity Across the Lifecycle

During this webinar, Michelle Boucher joins Charles Krueger, CEO of BigLever Software. Together they discuss strategies for handling increasing complexity, meeting varying customer needs, and managing product lines, especially for software-intensive products. The webinar focuses on product line engineering and includes a discussion on: Successful approaches to product line engineering (PLE) for managing product variation How embedded software, combined with the…

Supplier Strategies to Win more Business

Jim Brown presents on this Industry Week and Aviation Week webcast sharing insights into the new levers of competition for suppliers to the automotive and aerospace industries. He presents with Dassault Systemes Director of Automotive/Transportation Industry Michael Lalande and Aerospace and Defense Business Consultant Paul Granada who share deeper perspectives on their respective industries. Together they share practical ways that suppliers…

6 Reasons Your Projects Fail – Guest Post on PTC Blog

Michelle Boucher shares six reasons why product development projects fail and they all stem from poor requirements management. The guest post titled 6 Reasons Your Projects Fail: How Requirements Management Can Help on the PTC Integrity blog, explores the impact of these six challenges on project success and discusses various ways poor requirements management can derail a project. Read the post on…

Finding PLM to Fit Midsized Manufacturers eBook

Our Finding PLM to Fit Midsized Manufacturers eBook explains how smaller companies find themselves stuck between full-featured PLM systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can’t afford the errors and inefficiency inherent to informal data and process management, but can’t…

3D Printing Panel Discussion at Microsoft Envision

At Microsoft Envision, Tech-Clarity’s Michelle Boucher will chair a panel that includes: Luis Baldez, Software Strategy Program Manager, 3D Printing, HP Prabhjot Singh, Manager, Additive Manufacturing Lab, GE Global Research Simon Floyd, Director Strategy, Product Lifecycle Management, Microsoft Microsoft Envision takes place in New Orleans to April 4 – April 6. The panel discussion will explore…

Swivl’s Mike Pierce Explains why Startups Need PLM (PLM411 video)

In this episode of PLM411, Tech-Clarity’s Jim Brown interviews Mike Pierce to understand how PLM helps Swivl save tens of thousands of dollars by eliminating mistakes. Mike shares his experience that most companies have to “experience something awful” before they realize they need PLM, and then find out how fast PLM makes life easier for them. Mike tells…

Simulation Study: Empowering Innovation