Jim Brown’s recently published eBook research, The Business Value of An Industrial System of Engagement Platform, introduced the concept of the Industrial System of Engagement (SOE). Following the eBook, he penned a guest post for Hexagon summarizing the eBook and how the Industrial SOE provides a platform to extend the value of current enterprise systems…

- Data Centricity

- Integrated Information

- Operationalized Collaboration

- A System for Action

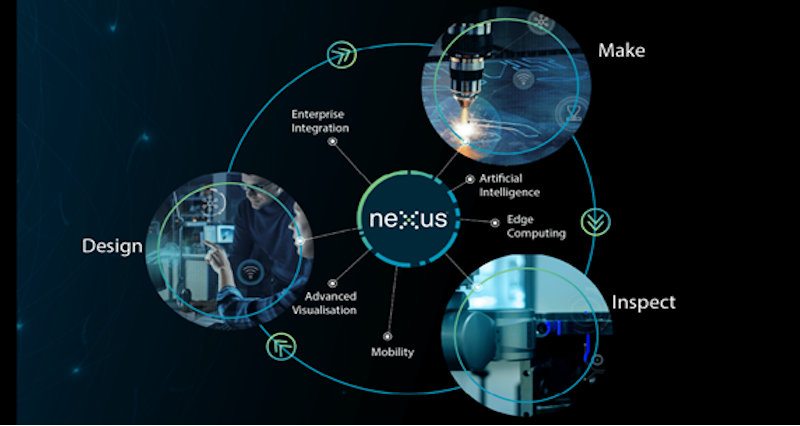

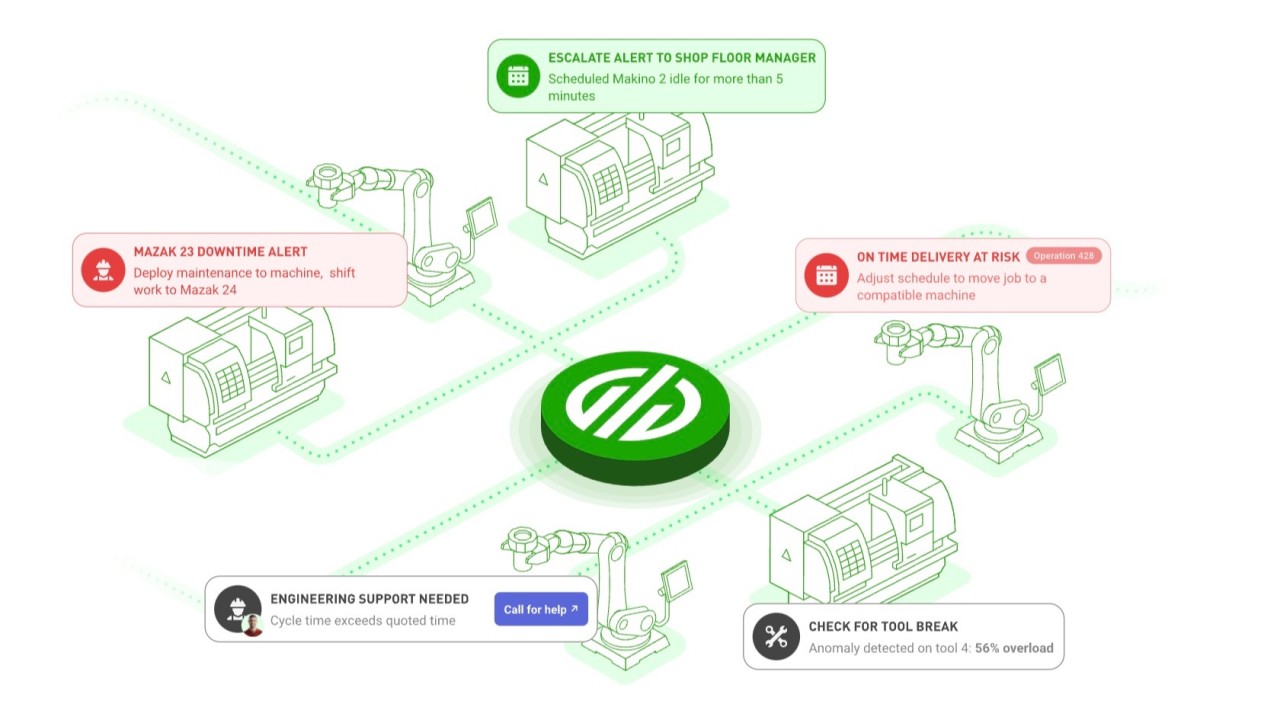

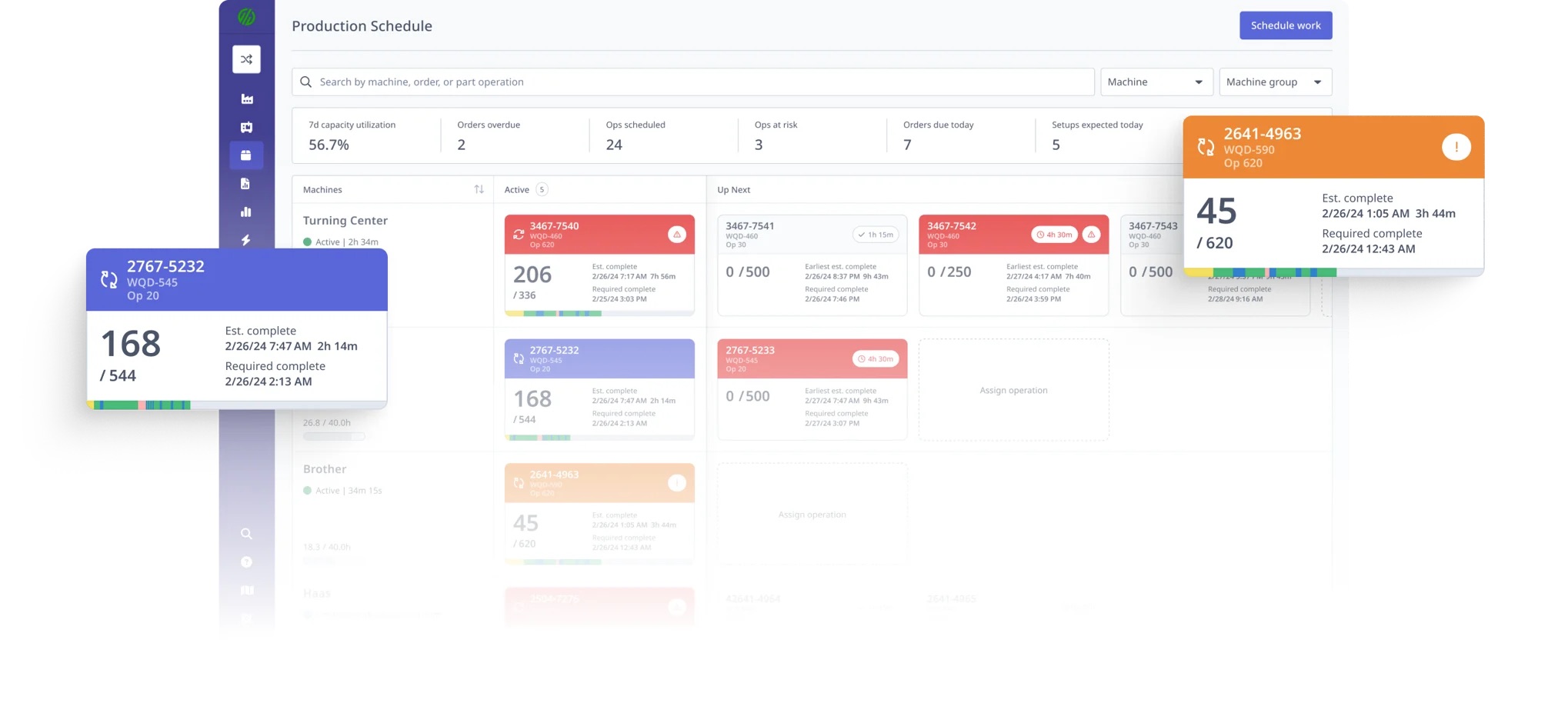

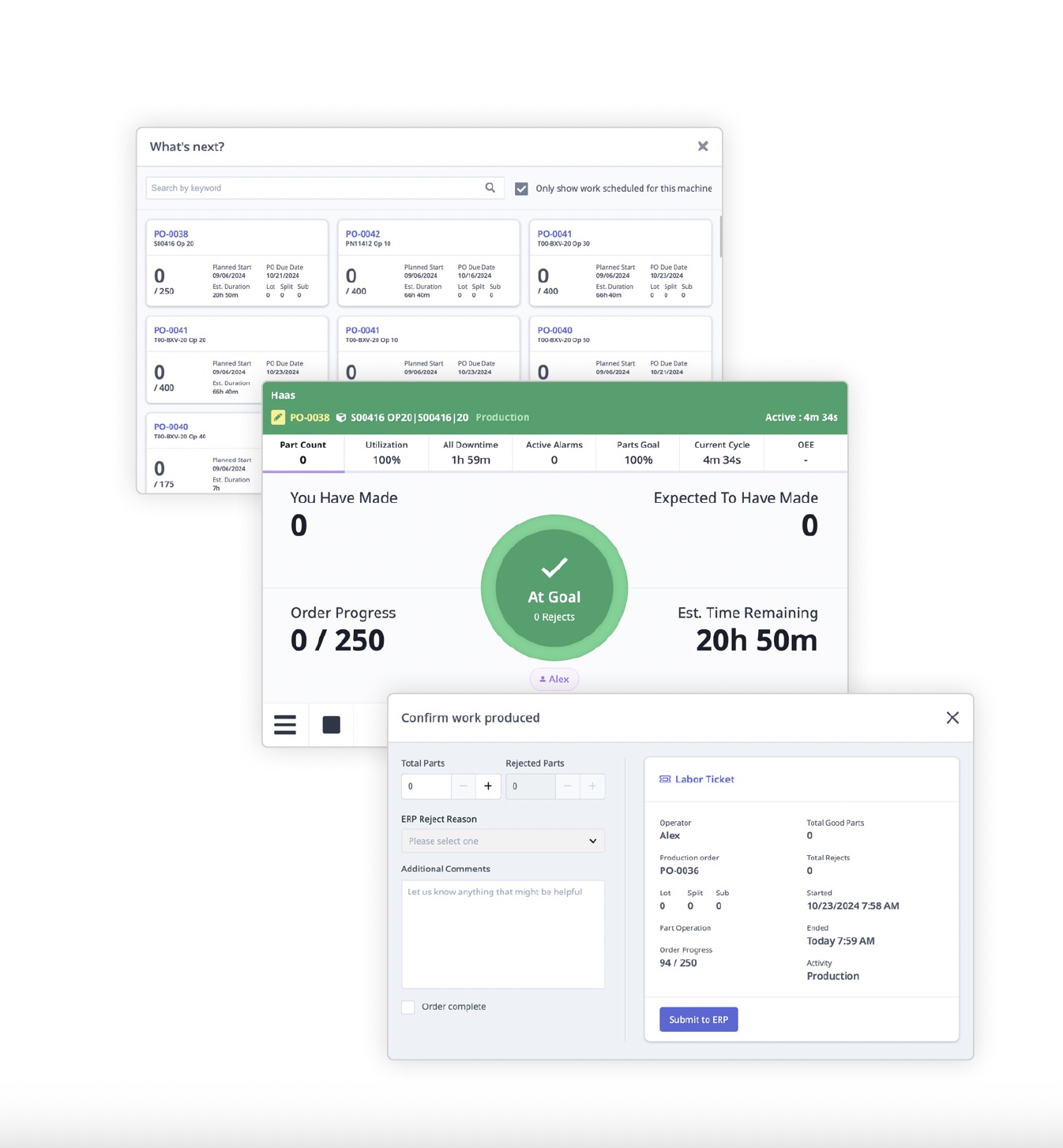

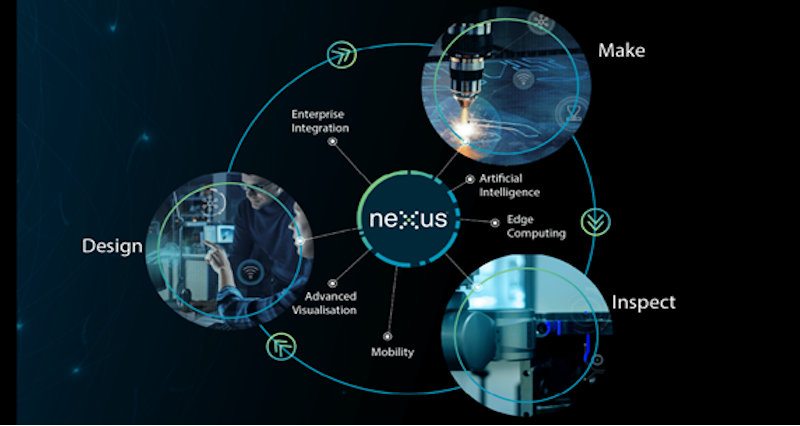

Hexagon’s Nexus Platform

This guest post shares an overview of the Industrial SOE concept based on our research and interviews with two thought leaders, Style Crest Project Engineer Tyler Lucas and Paragon Medical Devices Senior Quality Manager Jeff Livingston. It then discusses how Nexus, Hexagon’s open digital industrial platform for manufacturers built on the Microsoft Azure platform, delivers collaboration value for manufacturers. For more information on the Industrial SOE and Nexus, you can read the full blog post on the Hexagon site. You can also download the full white paper directly from Hexagon.

[post_title] => Hexagon Delivers a New Digital Industrial Platform to Accelerate Innovation

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => industrial-soe

[to_ping] =>

[pinged] =>

[post_modified] => 2025-05-07 14:02:16

[post_modified_gmt] => 2025-05-07 18:02:16

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=21886

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 21911

[post_author] => 2

[post_date] => 2025-05-06 10:00:02

[post_date_gmt] => 2025-05-06 14:00:02

[post_content] =>

For more information on the Industrial SOE and Nexus, you can read the full blog post on the Hexagon site. You can also download the full white paper directly from Hexagon.

[post_title] => Hexagon Delivers a New Digital Industrial Platform to Accelerate Innovation

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => industrial-soe

[to_ping] =>

[pinged] =>

[post_modified] => 2025-05-07 14:02:16

[post_modified_gmt] => 2025-05-07 18:02:16

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=21886

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 21911

[post_author] => 2

[post_date] => 2025-05-06 10:00:02

[post_date_gmt] => 2025-05-06 14:00:02

[post_content] => The Value of AI in Manufacturing is Accelerating

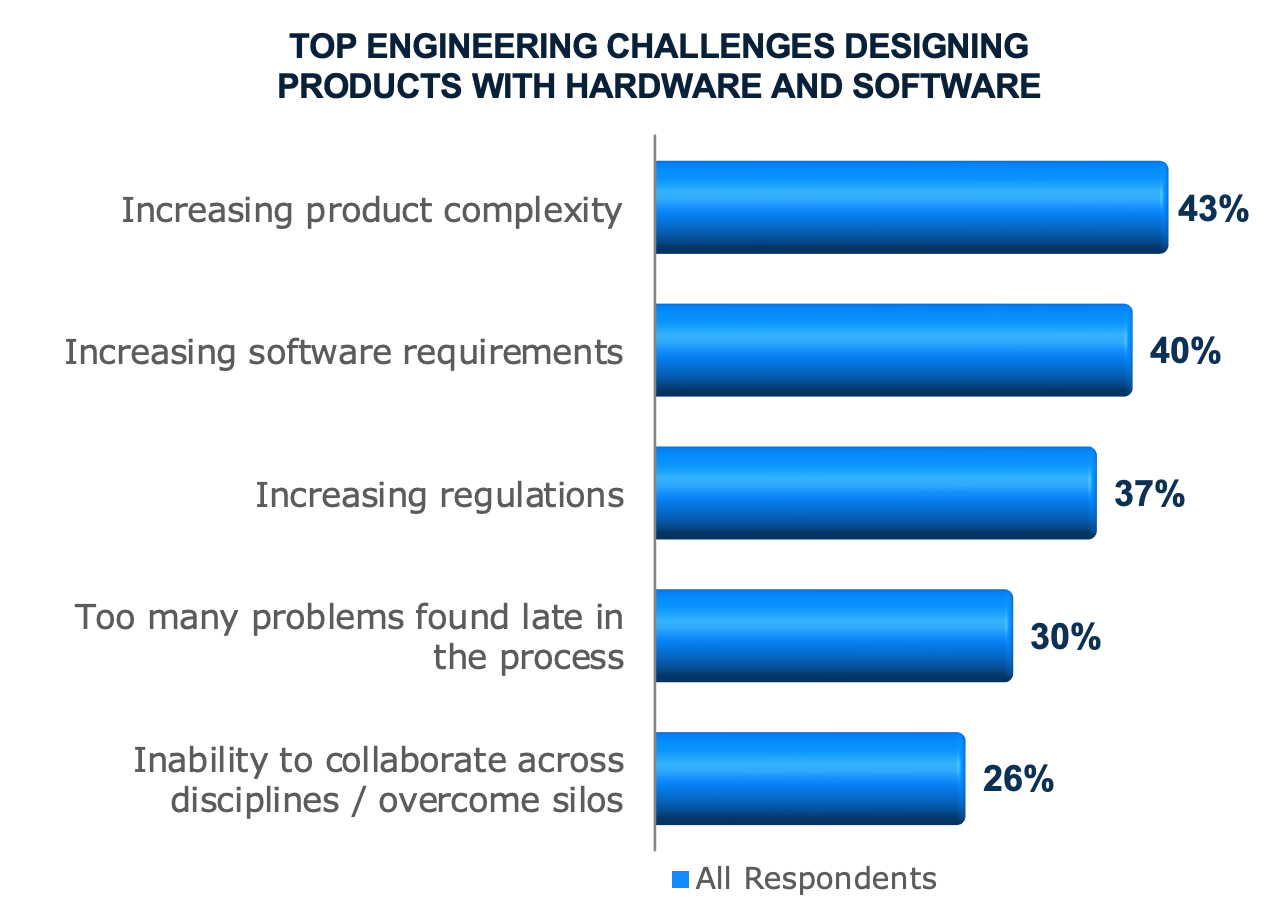

There is a lot of talk about the value of artificial intelligence in manufacturing, and rightfully so. Although AI isn't new, it appears to be reaching a tipping point where companies are more open to exploring its potential and AI techniques are more accessible than ever. Manufacturers are acting on the opportunity. Our recent Making Manufacturing Analytics and AI Matter research, for example, shows that 99% of manufacturers plan to invest in analytics and AI in the next year.

Further, AI has moved from the experimentation phase to the value phase. Our latest executive survey, Executive Strategies for Sustainable Business Success 2024, found that AI / ML (Machine Learning) was the most common application type providing value, with 88% of responding companies reporting they achieved business value from AI / ML. Further, these results can come quickly. The manufacturing analytics and AI study found that companies achieve fast ROI more frequently from advanced analytics / AI than from their other software investments. For example, the data shows that 73% of respondents received benefits from GenAI in less than a year.

Talking about AI Adoption with the Experts

Our research shows that AI / ML can drive value, and companies can achieve that value rapidly. But that value doesn't come from buying software. It comes from applying the right solution to solve a real problem. However, many manufacturers don't know where to start or how to implement these capabilities. To better understand how manufacturers can target and adopt AI, we sat down with two experienced consultants with real-world experience in helping manufacturers improve business value by adopting AI. We sat down with Kalypso: A Rockwell Automation Business's Senior Manager of Data Science and Digital Transformation, Chelsea Barnes and Master Data Consultant William Rosengarten to get their perspective. Let's see what they have to say!

What are Manufacturers Asking For Today?

Jim Brown

Kalypso works with a lot of manufacturing companies. What are manufacturers asking for related to their AI strategy and implementations?

Chelsea Barnes

At one end of the spectrum, some companies are enthusiastic but lack direction. They know they need to do something with AI because it's a buzzword or their CEO says it's important, but they don't know what that looks like. They need help setting a direction. On the other end of the spectrum, some clients have a very specific problem and sometimes possibly even a solution in mind, like needing a machine vision solution to detect malformities or burns on a chip because it's costing them $10 million in scrap every year. They need help validating and implementing a solution. But there's also a middle ground where companies have operational targets in mind and maybe some initial hypotheses about how to improve them but aren't sure where to start.

Regardless of what the starting point looks like, the core of the ask is the same. They want value delivered quickly, at scale, using the best advanced technologies available.

Targeting Business Value versus Technology

Jim Brown

I've known Kalypso for some time and I appreciate that you don't believe in technology for technology's sake but focus on adding business value. How do you get companies started or help them frame their problem?

Chelsea Barnes

We help them discover where their business problems really are and what technology solutions are best suited to those problems. Then, we bring those things together. When we talk to a company, they know their issues far better than we do. For example, the people operating a line will be able to specifically articulate what problems are happening and have a very good hypothesis as to why they’re happening. Then, we bring our business, operational, and technology expertise to those conversations so that they meet in the middle with solutions.

Jim Brown

One of the things I appreciate is that you're not just technologists. You are domain experts who understand operations and the manufacturing industry. For example, in the Consumer Packaged Goods (CPG) industry, when you mentioned "burns on a chip," I knew right away you meant potato chips and not microprocessors. Can you tell me a little bit about why it's important that advisors don’t just approach their clients with AI knowledge, but also bring relevant business expertise to the table?

William Rosengarten

We're not coming in cold because we have a depth of expertise in the industry. We already have a point of view on the end goal. If a client comes to us with a problem, we know what best-in-class in the CPG industry looks like, so we can help them create a plan to achieve it.

Chelsea Barnes

Exactly. We bring together a variety of expertise to make that happen. We're coming in with a really solid set of hypotheses around what the problems typically are. We're familiar with approaches to improve quality yields and deal with issues like variable material inputs that cause problems for food and beverage clients. The specifics come from the client and their own knowledge, but our experience helps us get to a diagnosis more quickly.

Prioritizing the Right Opportunities

Jim Brown

In a recent cross-industry survey, we asked companies about their AI goals. The most common goals identified across industries were product and service innovation, product and service performance, and workforce efficiency. Those are essential in any industry. A survey specific to the manufacturing industry, however, clearly identified cost reduction as the most common investment driver. What are the CPG companies you're working with looking for?

Chelsea Barnes

We’re seeing the same thing on the ground. There are two macro trends that are really squeezing manufacturers right now. The first is inflation, which increases cost pressures. The other is workforce turnover, including a wave of seasoned specialists leaving the workforce, which puts a new sense of urgency on workforce efficiency. To meet those cost reduction and efficiency goals, the top AI use cases we hear are around quality control, process optimization and predictive and prescriptive maintenance.

William Rosengarten

We also see a common pain point in accessing the right data, especially when working with time series data. Five years ago or so, manufacturers felt they needed to capture everything from the plant floor, store it in the cloud, and historize it. So many manufacturers have created a giant haystack of all of their data, and they're struggling to find that needle that will drive specific use cases like the ones Chelsea is describing.

Justifying Projects

Jim Brown

With all of the potential projects you may identify with a client, how do you help them decide on what to focus on? Do you counsel them to focus on the most significant problems, or maybe try to have them find repeatable problems? Or is it purely the project with the largest ROI?

Chelsea Barnes

Manufacturers are absolutely looking at ROI. They need to understand how it will affect the process, the tangible value they will get from the initiative, and how they will measure achievement. It's critical that they know what their quantifiable goal is.

However, when it comes to investments in digital, sometimes the value isn’t as clear-cut as a 12-month payback. In some cases, companies are looking to stay ahead of the competition by operating on the bleeding edge of innovation. This might justify a more long-term investment approach to allow the transformation they’re looking for to take root.

Getting back to determining ROI, we’re big proponents of rapid use case identification and prioritization, where you quickly narrow down your short list of high-potential opportunities before investing too much time rigorously evaluating all options. To do this, you need a good value calculation framework, which we bring to all of our assessment projects. But,you also need the right technologists in the mix to help you quickly vet the solutions and estimate implementation complexity to understand the cost of an initiative.

Choosing the Right Technology

Jim Brown

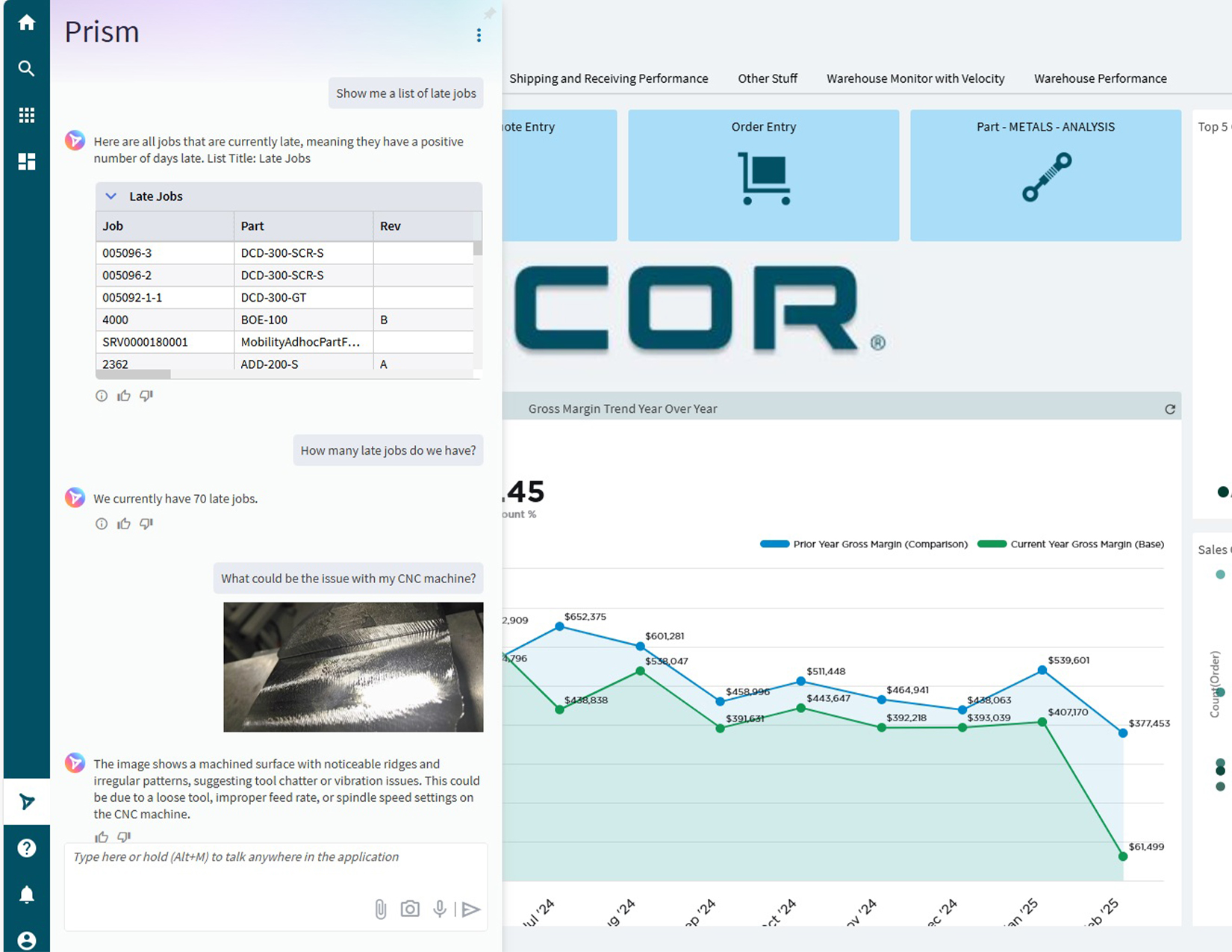

Generative AI is on most peoples' minds and has become popular in conversations because of OpenAI and ChatGPT. However, many other AI and machine learning (ML) techniques are available. AI can be applied at different levels, ranging from companies wanting to retrieve data more effectively to the other end of the spectrum where they are pursuing AI-driven autonomous, real-time decisions to drive equipment behavior on the floor. How do you help your clients decide what technologies to apply for a specific problem?

Chelsea Barnes

We always start by confirming the business needs and what's the problem to solve now. Even if they come to us with a very specific request, like "I need a machine vision solution," we will diagnose the issue together and then confirm that's the right solution. We don't tell our clients to “go GenAI” their business. That wouldn't be good business for them, and it's not good business for us. We have a collection of tools in our toolbox to bring to this equation depending on the problem to solve and the data they have to work with.

William Rosengarten

We make sure to map technologies to business needs. For AI technologies, we consider:

- What data types are we working with?

- Is it structured data?

- Is it time series data?

- Is it natural language data?

- What kind of action or decision are you trying to take?

- What is the risk of error in that decision?

- Is there a human interaction component that would be an essential decision-making factor?

The choice will be different if they just need to organize and retrieve data quickly or if they're looking for insights from the data they have. For example, you shouldn't use copilots for autonomous control, but it's valuable when a human is in the loop for decision-making. These questions help drive considerations about the modeling and architecture that should come into play.

Chelsea Barnes

We always look at what kind of algorithmic approach will be best suited for the scenario. While generative AI is the topic of the day, there are plenty of cases where you should not be using it. For example, a GenAI model will not help make a prediction to autonomously control a production process - think predicting fill by monitoring time series data so you can adjust your filler dosage so it comes exactly at target. It's just not suited to do that. But if you are trying to process something like a year's worth of shift logs to find anomalous patterns in those free text shift logs, that's a situation very well-suited for a large language model.

Two other important decision criteria in regulated scenarios are the risk of error and whether the results are explainable. GenAI models, which are neural networks, are by nature black boxes where you don't know how it arrived at a decision, so having a human operator in the loop is critical to confirm the results.

A Closer Look at Copilots

Jim Brown

AI copilots are gaining a lot of traction to streamline and improve human workflow. When do you find those applicable for your clients?

Chelsea Barnes

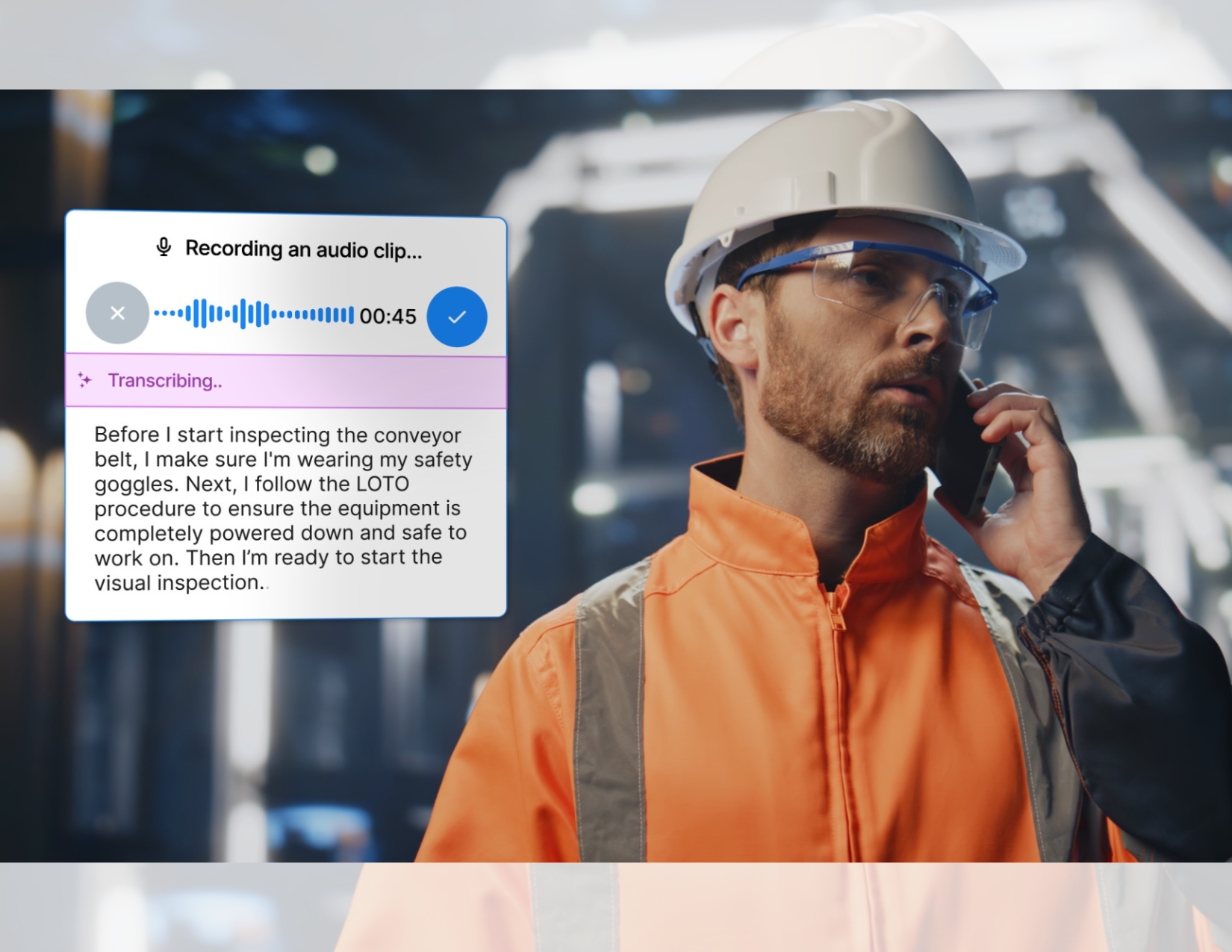

A copilot makes sense when they are trying to augment what a human can do, to make them more efficient in a process, or help them with the decisions that they are making. A good example for an operator would be a troubleshooting copilot. For example, a line is down and a fault code comes up. Instead of looking that up manually, the copilot could take the operator through a decision-making process and walk them through the troubleshooting steps.

Copilots are attractive because the manufacturing industry has not fully rebounded following COVID, and many companies still have jobs left unfilled. Retaining institutional knowledge in manufacturing is even more of an imminent and challenging concern as a substantial percentage of the workforce nears retirement. Many companies would love to get to lights-out manufacturing, but that can be decades away. So the goal is to find the best way to augment and assist the workforce they have. Copilots can help make them more productive and efficient, and equip them with decades of institutional knowledge, even if they haven't worked on the line for 15 years.

William Rosengarten

Agree. Copilot assistants are an excellent solution for capturing and retaining institutional knowledge. For example, they are very good at taking notes. A technician running a troubleshooting process is trying to get the line back up and running and typically doesn't have time to document what they're doing. They are making decisions on what steps to take based on their experience. A copilot could take notes about the decisions they make and the impacts they have on the troubleshooting process. Doing this creates a feedback loop that typically only exists in free text or just in a technician's head and tribal knowledge today. In that way, copilots can help guide troubleshooting and feed information into a knowledge repository to assist in future troubleshooting efforts.

Key Takeaways

You've shared a lot of insights into how manufacturers can identify the right business opportunities and apply AI to solve them. Two of my key takeaways are that it's essential to have industry expertise to help diagnose the problem and that it's critical to have diverse technical knowledge to be able to apply the right AI capabilities to get the job done. This is an exciting topic, and we'll stay in touch about it.

Additional Resources

To learn more from Kalypso, explore the Kalypso website, a Kalypso interview about operational CoPilots, or Kalypso Insights on GenAI.

Thank You

Thank you to Kalypso, a Rockwell Automation Business, and Hadley Bauer for arranging the interview. We learned a lot from the discussion and know manufacturers will, too.

[post_title] => Expert Interview: AI Adoption in Consumer Packaged Goods [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => ai-adoption [to_ping] => [pinged] => [post_modified] => 2025-09-10 15:25:39 [post_modified_gmt] => 2025-09-10 19:25:39 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=21911 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [2] => WP_Post Object ( [ID] => 21810 [post_author] => 2574 [post_date] => 2025-04-17 09:00:51 [post_date_gmt] => 2025-04-17 13:00:51 [post_content] => How can recipe-based producers ensure cost-efficiency and consistent, high-quality products no matter where they are formulated or produced? By implementing enterprise recipe management (ERM) with a manufacturing execution system (MES) to deliver closed-loop data flows in and out of production. Leading Consumer Packaged Goods (CPG), specialty chemical, and other manufacturers are standardizing for ERM. Quite a bit of technology is required to digitalize this recipe transformation process (recipe management, PLM, digital twin. MES), but the value of eliminating inefficiencies, speeding product launches, and cross-disciplinary collaboration creates an excellent payback.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

How can recipe-based producers ensure cost-efficiency and consistent, high-quality products no matter where they are formulated or produced? By implementing enterprise recipe management (ERM) with a manufacturing execution system (MES) to deliver closed-loop data flows in and out of production. Leading Consumer Packaged Goods (CPG), specialty chemical, and other manufacturers are standardizing for ERM. Quite a bit of technology is required to digitalize this recipe transformation process (recipe management, PLM, digital twin. MES), but the value of eliminating inefficiencies, speeding product launches, and cross-disciplinary collaboration creates an excellent payback.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

Table of Contents

- Product Consistency: Key to Brand Success

- Meeting Market Trends and Realities

- Why Enterprise Recipe Management Matters

- The Recipe Management Process

- Changing Recipes and Production

- Multi-Disciplinary Workflows

- Bridging Differences and Disconnects

- Recipe Management Across the Enterprise

- Common Challenges for Enterprisewide Recipe Management

- Technology Challenges to Overcome for Enterprise Recipe Management

- Added Challenges for Enterprise Recipe Management

- ERM Solutions Have Data Management at the Core

- Creating ERM Data Flows

- MES’ Role in ERM

- Top MES Requirements for ERM

- The ERM Digital Thread

- Recipe Management Success

- Acknowledgments

Product Consistency: Key to Brand Success

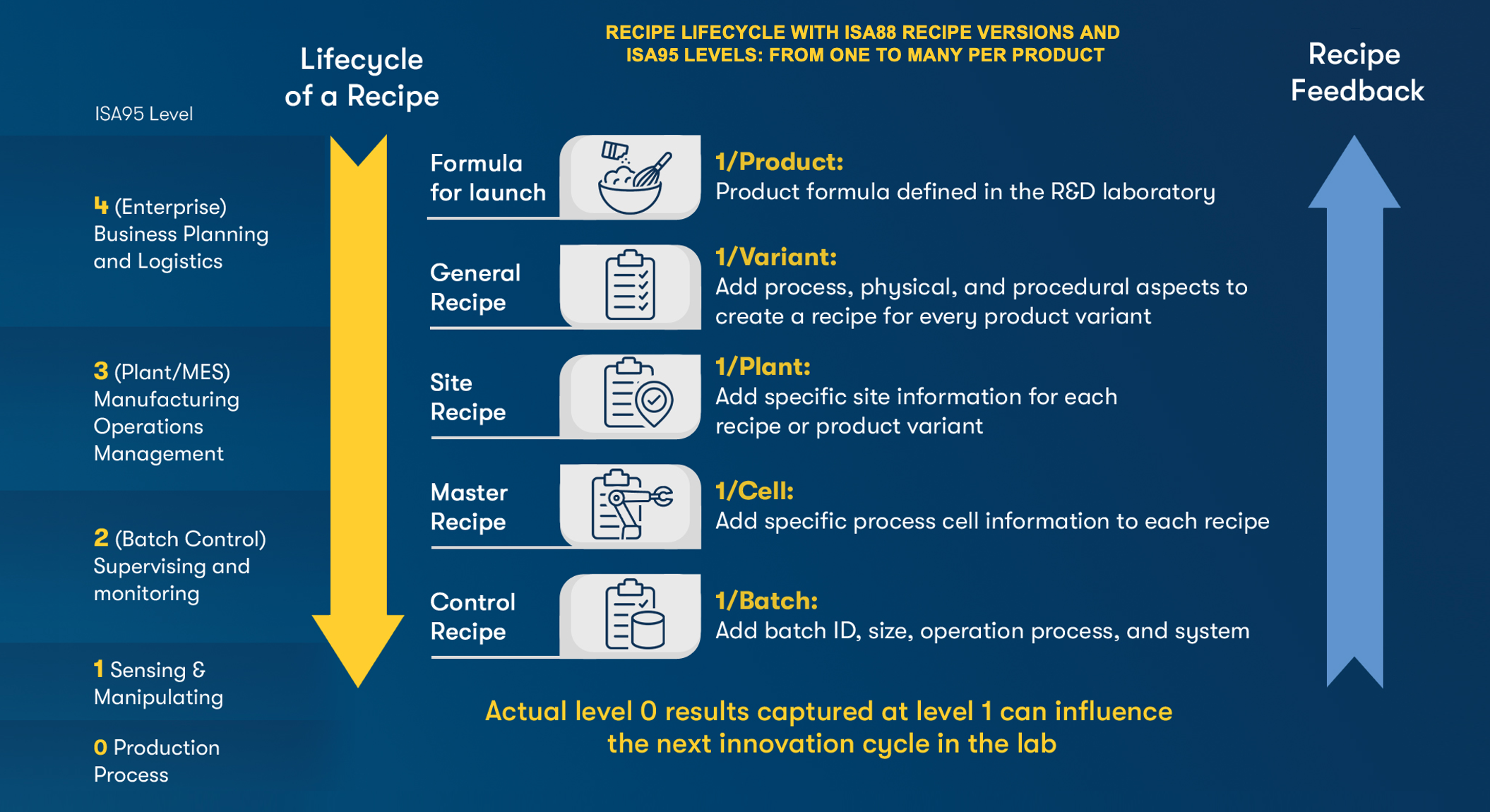

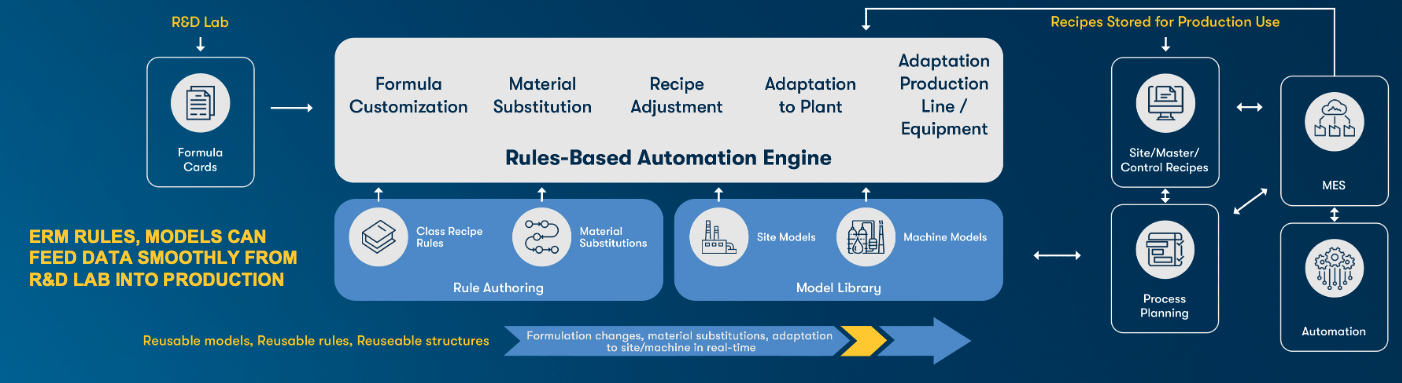

Recipes Matter Managing recipes efficiently and executing them for product consistency on a global scale can be the difference between market leadership and brand disaster for fast-moving consumer packaged goods (CPG or FMCG) and their suppliers. Yet, enterprise recipe management (ERM) is fraught with challenges that can damage margins. Software for Enterprise Recipe Management There are plenty of challenges, but fortunately, some known paths forward. Overlaying current systems with a way to standardize and reuse recipe elements is crucial. ERM needs rules, models, and libraries, as well as data flows among various applications. Do not underestimate the pivotal role a suitable and well-integrated manufacturing execution system (MES) plays in the overall picture of enterprise recipe management. It executes the recipes and can send in-context as-produced data from the actual process back to recipe authors to populate libraries accurately and drive improvement.

Multi-Disciplinary Workflows

The ERM Concept Standardization is at the heart of enterprise success with recipe management. Companies must standardize many interdependent elements for ERM to work. One of the drivers behind the ISA88 standard, Dennis Brandl, explains that the ERM concept is “Standard product descriptions based on standard definitions of manufacturing operations, based on standard quality attribute definitions, based on standard process parameter and process report definitions.” This illustrates the many layers and facets to standardize for ERM.

ERM in Innovation

The NPDI process begins with innovation. This, in itself, is a multi-disciplinary effort, typically including:

Standardization is at the heart of enterprise success with recipe management. Companies must standardize many interdependent elements for ERM to work. One of the drivers behind the ISA88 standard, Dennis Brandl, explains that the ERM concept is “Standard product descriptions based on standard definitions of manufacturing operations, based on standard quality attribute definitions, based on standard process parameter and process report definitions.” This illustrates the many layers and facets to standardize for ERM.

ERM in Innovation

The NPDI process begins with innovation. This, in itself, is a multi-disciplinary effort, typically including:

- R&D with their associated labs and scientists

- Marketing and consumer research

- Product development

- Packaging design and development

- Process and manufacturing engineering

- Operations or production or manufacturing

- Quality

- Food safety & regulatory

- Materials, procurement & supply chain management

- Manufacturing or production IT

- Automation, controls engineering, and operations technology (OT)

Creating ERM Data Flows

Impact Analysis To succeed, ERM must also include impact analysis. For every change in formulation, materials, equipment, or regulation, the system should review whether to update bills of materials and other recipe details, operations, and work packages. Having all the data does not automatically make this impact analysis effective or efficient. Having it centralized does improve the odds of good impact analysis as well as use for other analytics functions or artificial intelligence (AI). Many Systems ERM typically requires integration between MES and PLM, plus PLM or MES and Batch systems, possibly also integration between MES and ERP or PLM and ERP. For ongoing accuracy and best production results, automation and MES are also connected for complete process data sets without overwhelming the enterprise systems. In the ideal scenario, MES, PLM, ERP, and ERM are integrated through a process digital twin that accurately reflects the product and data flows in virtual form. Solutions for ERM A special set of capabilities is needed for a true ERM solution. Data from multiple systems is one aspect, and data management to handle the recipe data volumes, complexities, and contingencies are all key. Handling recipe transformations, testing, and validation will also typically require special software capabilities. These ERM integrated solutions do exist today, butare not yet in common use. With MES, the as-produced data can readily be fed back to ensure the ERM libraries, models, and rules reflect best practices.

Recipe Management Success

ERM for Success Enterprise Recipe Management eliminates inefficiencies and empowers teams to focus on value-added tasks by streamlining processes, reducing manual work, and enabling better resource allocation. Beyond reducing time to market and improving product quality, ERM allows the company to be more agile and adapt to change faster. One measure of success is how many recipes are directly downloaded and executed at top quality with minimal intervention from local operators. Benefits to Expect Creating an ERM digital thread can deliver significant benefits to multi-site, fast-moving consumer goods companies. Benefits that are a hallmark of ERM success span the lifecycle. They start with accelerated innovation, then faster NPDI or speed to market. ERM should also deliver improved product quality assurance and multi-disciplinary collaboration. Better understanding the impact of changes and decisions can lead to increased efficiency, improved product quality, and lower brand risk. Building an ROI Case Calculating potential value from ERM has many facets. Some factors to consider are reduction of labor, time, utilities, other costs based on a consistent source of data, quick recipe conversion, and less test batch engineering time. MESA White Paper #49 includes a basic spreadsheet approach.6 MES Optimizes ERM Every product’s quality relies on the execution of the recipe at a line or cell in a plant; that’s where MES ensures execution matches the recipe's intent. ERM also uses MES's accurate data on plant capacity, production capabilities, and recipe compliance. Finally, MES data on ‘actuals’ from every batch inform everyone of how that recipe is performing, for brand success. *This summary is an abbreviated version of the ebook and does not contain the full content. For the full report, please visit our sponsor Siemens. If you have difficulty obtaining a copy of the research, please contact us. [post_title] => How MES Supports Enterprise Recipe Management [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => enterprise-recipe-management [to_ping] => [pinged] => [post_modified] => 2025-04-17 09:33:42 [post_modified_gmt] => 2025-04-17 13:33:42 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=21810 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [3] => WP_Post Object ( [ID] => 21842 [post_author] => 2 [post_date] => 2025-04-16 10:00:48 [post_date_gmt] => 2025-04-16 14:00:48 [post_content] =>Siemens Support for Service Exceeded Our Expectations

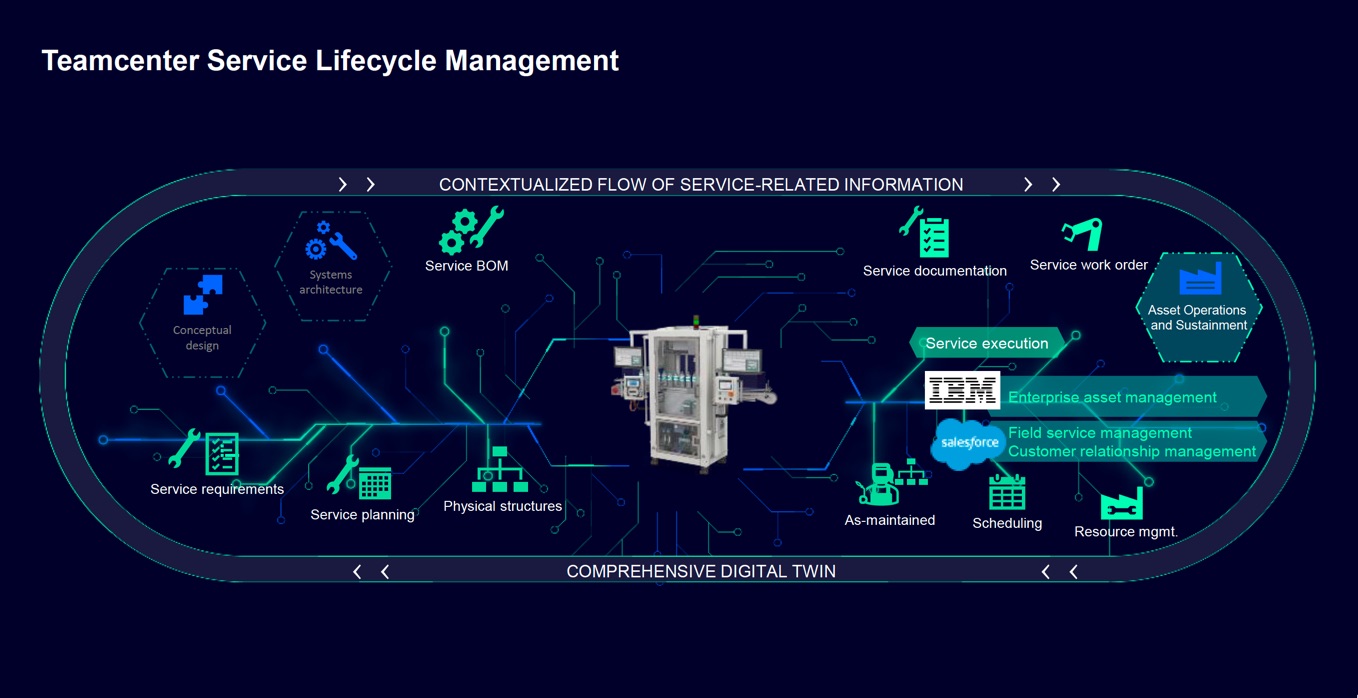

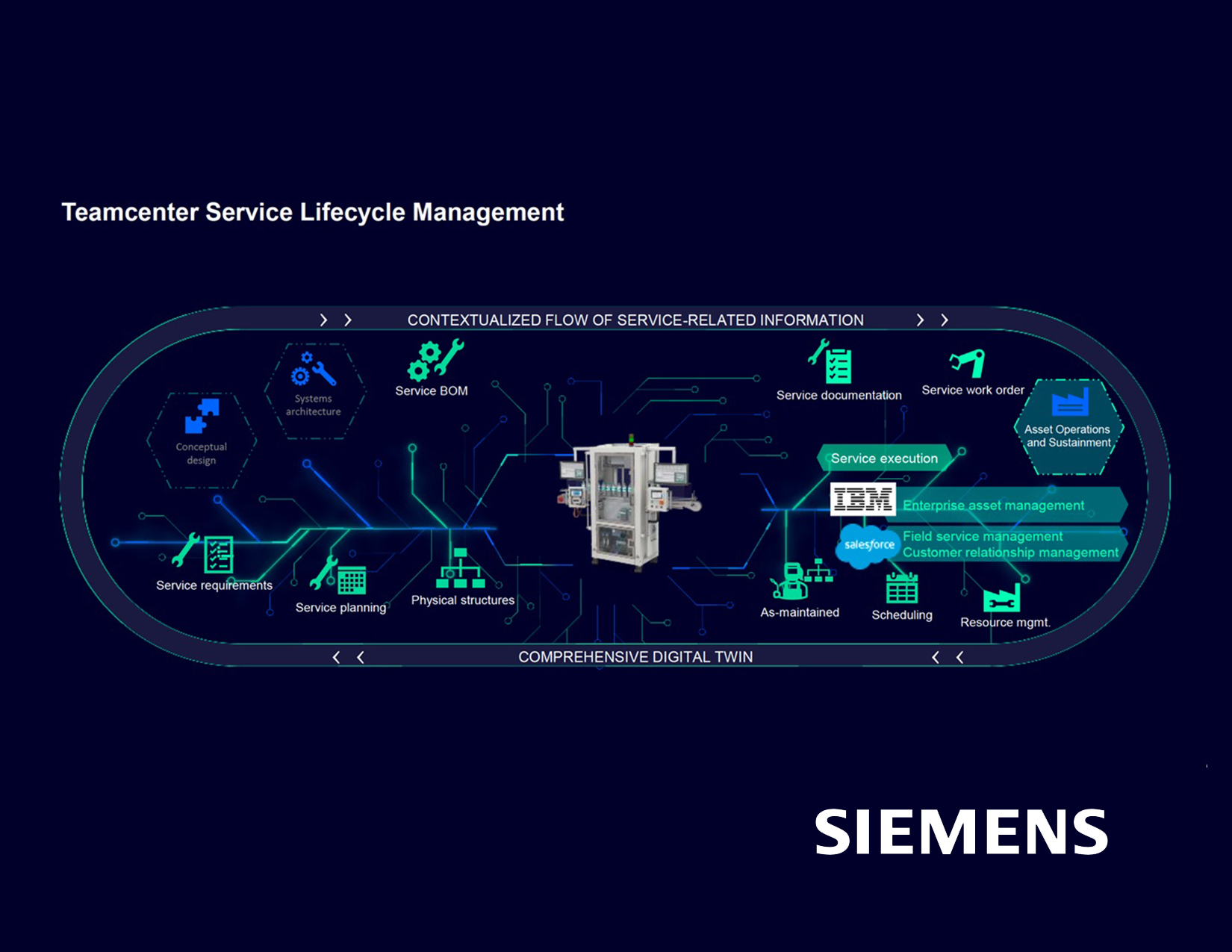

It’s our goal as analysts to stay informed about the software solutions available on the market and how they drive business value for manufacturers. We do this by conducting surveys, speaking with manufacturers, attending events, and taking briefings from solution providers. One of the things that excites us the most is when we learn something new. Recently, we learned that we were underestimating Siemens Digital Industries Software Service Lifecycle Management (SLM) capabilities. We thought it was worth sharing.

Deep Support for Product and Service Data

One of the primary ways that Product Lifecycle Management (PLM) solutions can help add value in a device or equipment's service phase is by providing technical data downstream. Engineering data is highly valuable to service planners, techs, and other support personnel. We were aware of the capabilities Siemens delivers in this area based on prior conversations and briefings. Siemens understands how products are designed, made, and serviced.

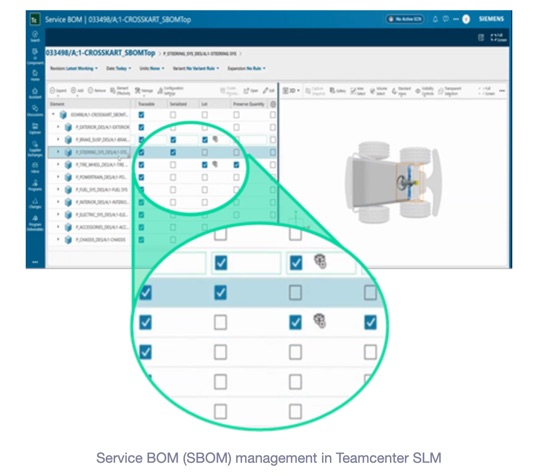

Siemens Teamcenter is a proven PLM solution and Teamcenter SLM has matured nicely over the years. Siemens followed a natural expansion beyond engineering and manufacturing BOMs to support the service BOM. We’ve seen how Teamcenter manages multidisciplinary data across product lifecycles and know it can manage complex configurations for both standard and engineer-to-order (ETO) products. Teamcenter’s ability to manage variants, revisions, and changes for serialized assets creates valuable product intelligence for service-related processes.

Teamcenter’s capabilities in both PLM and SLM also create an opportunity for customers to close the loop from service back to engineering. An integrated view of service and product data allows engineers better visibility downstream so they can better design for service and quality based on real-world feedback.

Supporting the Service Lifecycle

We knew that Teamcenter SLM was a strong source of product- and service-related data and recognized that this underlying information is crucial to effective service. Our research shows the value of extending PLM data into the “in use” phase of the lifecycle. Integrating design and service information provides even greater business value, as shown in our recent infographic on integrated service. The combination of product and service intelligence to support service transformation is compelling. As our Extending Digital Thread to the Customer Experience research shares the value of integrating the digital thread across the development and service lifecycles allows companies to develop a more intimate understanding of the customer and product experience and create new value from increasing profitability with lower costs and higher revenue from spares, suppliers, upgrades, replacements, and cross-selling opportunities.

We knew that Teamcenter SLM was a strong source of product- and service-related data and recognized that this underlying information is crucial to effective service. Our research shows the value of extending PLM data into the “in use” phase of the lifecycle. Integrating design and service information provides even greater business value, as shown in our recent infographic on integrated service. The combination of product and service intelligence to support service transformation is compelling. As our Extending Digital Thread to the Customer Experience research shares the value of integrating the digital thread across the development and service lifecycles allows companies to develop a more intimate understanding of the customer and product experience and create new value from increasing profitability with lower costs and higher revenue from spares, suppliers, upgrades, replacements, and cross-selling opportunities.

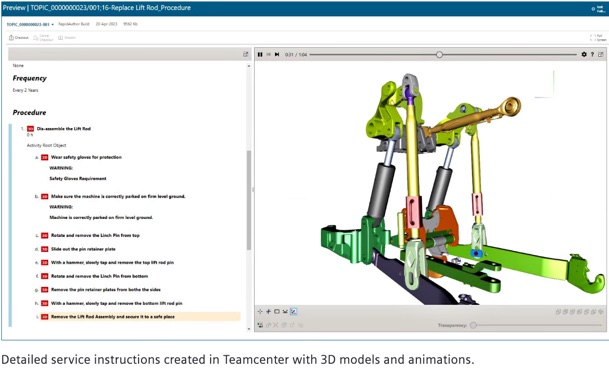

Teamcenter SLM goes further than providing existing data by expanding beyond engineering data to information like service procedures. Not only can the solution manage and share this information, their Tech Pubs/RapidAuthor solution leverages design models and data to develop accurate, 3D technical documentation including visual and animated service instructions.

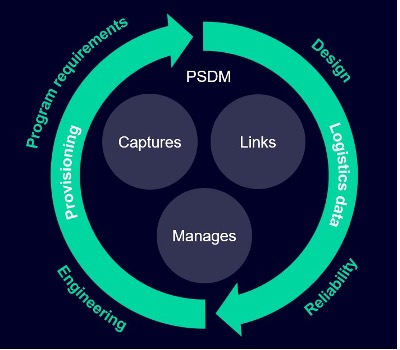

Product Support Data Management (PSDM)

Product Support Data Management (PSDM)

One specific way Siemens drives value is with its Product Support Data Management (#PSDM) solution. PSDM is a standards-based approach to documenting product support requirements tied to specific asset configurations. The solution brings together product lifecycle and logistics support data, leveraging the standard GEIA-STD-0007. The standard originated from the military to support government contracts but is applicable across a variety of industries. Siemens adopted this standard and incorporated it in the Teamcenter data model to support maintenance and logistics related data imports and exports.

Siemens Partners to Support Sales and Service Execution

Beyond sharing information, our research points out the value of strong sales and service execution support. Manufacturing and service companies must improve and optimize the processes supporting sales and service operations to grow their aftermarket business. Sales and service transformation requires convergence across people, processes, data, and systems in the engineering and enterprise systems. Customer interactions, spare parts, service contracts, warranty entitlements, and other service complexities are managed in solutions like CRM, Field Service Management, Enterprise Asset Management (EAM), and even ERP. Siemens’ customers can integrate with these systems, but that doesn’t create a seamless process.

This is where our understanding of Siemens’ capabilities needed to expand. Siemens has been working to bridge the gap between design, service planning, and service execution. They now support the front office, sales teams, customer service, and even equipment operators through strong partnerships. This brings the value of SLM to the front office while keeping it tied into Teamcenter PLM to extend the value of rich digital data beyond the engineering population, in the right context, to enable execution processes. Siemens is not trying to recreate what field service and CRM solutions do, but instead make them more valuable by providing a more complete solution to their customers by connecting with them.

This is where our understanding of Siemens’ capabilities needed to expand. Siemens has been working to bridge the gap between design, service planning, and service execution. They now support the front office, sales teams, customer service, and even equipment operators through strong partnerships. This brings the value of SLM to the front office while keeping it tied into Teamcenter PLM to extend the value of rich digital data beyond the engineering population, in the right context, to enable execution processes. Siemens is not trying to recreate what field service and CRM solutions do, but instead make them more valuable by providing a more complete solution to their customers by connecting with them.

Siemens now supports cohesive processes and a consistent digital thread from engineering through field services and sales. Siemens was able to leverage their open approach and rich APIs in their platform to support a variety of partnerships. These partnerships include IBM Maximo Application Suite for EAM and Salesforce for CRM. In both of these cases, Siemens focuses on the product data and service knowledge, not the customer data and service execution. This is exciting news, and we were happy to hear that Teamcenter SLM for Salesforce has been available on the Salesforce AppExchange for about a year. The Salesforce partnership also opens up Teamcenter’s product and service data to Agentforce, Salesforce’s AI offering, unlocking significant new opportunities to leverage the cohesive digital thread.

Example

Siemens demonstrated an example of how combining an integrated PLM-CRM environment with AI can streamline and improve customer experience, service performance, and profitability. They showed how Agentforce could be deployed on an equipment manufacturer’s website. A customer can visit the site and enter an asset name and serial number, which would be interpreted to create a draft case for review, combining details about the configuration, including product information like 3D visuals, service data like detailed service instructions, and business data such as warranty terms in one place. They went further to show how the combined, AI-enabled solution could identify additional opportunities like a service upgrade based on the combined data. It was a compelling view of an end-to-end integrated process.

Our Take

Siemens has a lot to offer across the product and service lifecycle through the Siemens Xcelerator portfolio and their partnerships. Siemens’ value in SLM goes beyond product data and service knowledge to service execution, enabling an integrated digital thread. The offering extends on Siemens’ deep expertise and strength in PLM and their open platform approach. Together with their partners, they have developed a very compelling offering spanning the product and service lifecycle. If you haven’t seen it in a while, it’s worth a deeper look. We learned quite a bit.

Thank You

Thank you for the briefing Kerri Doyle, Brian Johnsen, Dominique Gilles, Yishai Barak, and Rajvi Vaidya for taking the time for the briefings, we appreciate your time.

[post_title] => Siemens Support for SLM Exceeded Our Expectations [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => siemens-slm [to_ping] => [pinged] => [post_modified] => 2025-05-19 13:47:33 [post_modified_gmt] => 2025-05-19 17:47:33 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=21842 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 21799 [post_author] => 2572 [post_date] => 2025-04-10 10:00:37 [post_date_gmt] => 2025-04-10 14:00:37 [post_content] =>We recently had a chance to catch up with Siemens Digital Industries Software and get an update on NX. We heard about recent developments, the latest strategic direction for #CAD, their efforts to support comprehensive workflows, and progress to enable a Model-Based Enterprise (MBE). Here are a few of the highlights.

NX Innovation and Customer Adoption

The NX team at Siemens has been very busy. They are on a continuous release cycle, with major releases every December and June. The 4200 enhancements and 45 patents reflect the level of innovation investment over the last year. At the same time, they maintain high levels of quality, as 75% of NX customers are on a release from 2024 or 2023. They've also added over 1000 new customer logos, especially in the SMB space. Their cloud offering, NX X, largely drove this. Additionally, they continue to receive awards from peer review sites like G2 and Trust Radius.

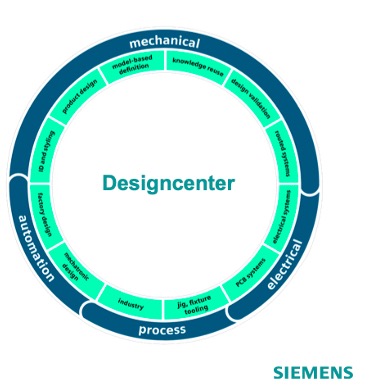

Introducing Designcenter

On January 6, 2025, at the CES trade show in Las Vegas, Siemens introduced Designcenter.

On January 6, 2025, at the CES trade show in Las Vegas, Siemens introduced Designcenter.

Designcenter is a new brand that combines both CAD products, NX and Solid Edge, to provide a single scalable mechanical CAD offering. The intent is to offer comprehensive workflows that integrate with Teamcenter and Simcenter to provide a seamless experience across design, simulation, and manufacturing.

Both NX and Solid Edge are built on the same Parasolid kernel, making it easier to work with Solid Edge models in NX and vice versa. Over the last couple of years, Siemens has invested in evolving the user interfaces to give them a similar look and feel. This is intended to make it easier for users to switch between the products. Designcenter furthers this approach to bring the two brands closer.

Scalable and Comprehensive

To meet customer needs, whether they are a large, medium, or small enterprise, Designcenter offers four options:

- Essentials

- Standard

- Advanced

- Premium

Essentials is the rebranded product that was formerly Zel X. Standard, Advanced, and Premium are tiered offerings so that customers can match the package with their needs, yet have options to scale should their requirements evolve. All three include built-in data management.

Within these packages, NX offers extensive capabilities for typical parts, assemblies, and drawings. However, based on the business, organizational function, industry, project stage, and supply chain role, some users may need more specialized functionality that is available in an optional module. In the past, it was difficult to justify the investment in an optional module, especially if it was for functionality that wasn't needed regularly. Siemens has addressed this challenge with a value-based licensing model for NX. This concept has worked well in the Simulation/CAE space to give users access to specialized analyses when needed, so it makes sense to apply it to CAD as well.

NX's value-based licensing model uses tokens for optional modules, which allows customers to use and return tokens for different functionalities. The intent is to give customers a cost-effective, flexible way to access specialized functionality when needed. For example, an aerospace company may want to use the token pool to take advantage of optional modules to design machined aerospace components or composite parts.

Enabling a Model-Based Enterprise (MBE)

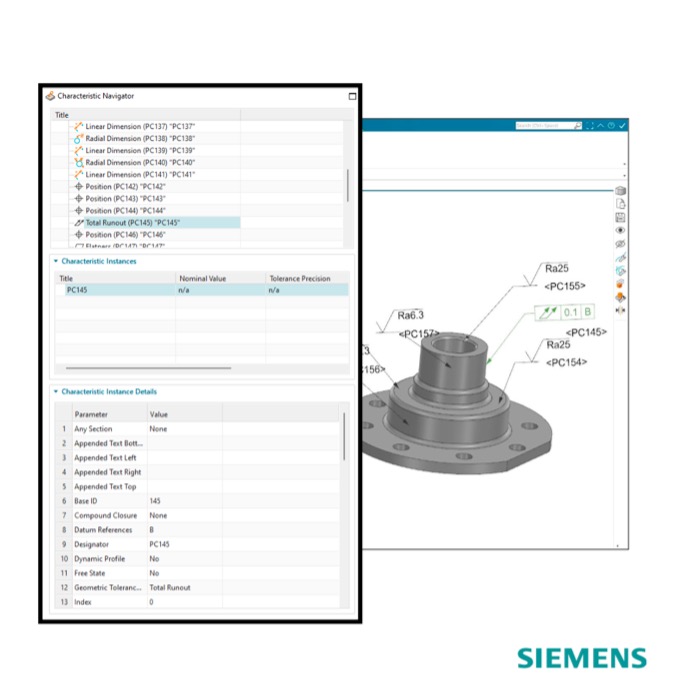

Tech-Clarity’s research has found that while companies who have started the journey to adopt MBE report many benefits, including better traceability, greater agility, and faster time to market, there are still many barriers to adoption. Interestingly, people and culture challenges are even bigger obstacles than either technology or process challenges. To overcome this, the Product and Manufacturing Information (PMI) embedded in the CAD model needs to become more consumable to downstream departments. Siemens is looking to do this with NX Stage Models, which help manufacturing engineers decompose design models into manufacturing stages, and a new NX Inspector, which supports a new standard for model-based characteristics.

In 2024, the DMSC™, an ANSI Accredited Standards Developing Organization and an ISO A-Liaison, released the Model-Based Characteristics Standard (MBC). The new MBC standard defines a common approach for tagging and uniquely identifying product characteristics for quality processes in a way that makes the PMI both human-readable and machine-readable. This is a giant step toward making PMI more usable, which should encourage MBE initiatives. By supporting this new standard, NX Inspector provides a mechanism for automating inspection plans based on the PMI in the CAD model.

Our Take

It is nice to see all the effort into making NX more accessible, especially to smaller and medium-sized enterprises. Solid Edge customers should also have an easier path to scale up to more advanced capabilities as they need them. The token-based licensing model is also a nice way to make advanced, productivity-improving capabilities available to more users.

What's really exciting to us is the MBE capabilities. The MBE capabilities should be particularly interesting to the Aerospace and Defense industry, which has shown the most interest in MBE.

The vision to move away from 2D drawings has been around for well over 20 years now. However, manufacturing still largely follows a 2D-driven process. Capabilities that leverage semantic PMI to automate downstream processes should go a long way to finally realize that vision. The functionality offered by NX Inspector that supports an opportunity to automate inspection plans based on the 3D model is a big step forward. It should save significant time and reduce the risk of errors introduced with traditional, manual processes that leverage a 2D drawing. This should lead to efficiency gains, which will be a huge motivator for adopting an MBE approach. We look forward to seeing how this evolves, especially as Siemens works towards integrating metrology within its digital industries.

Thank You

Thank you George Rendell, Tod Parrella, Jennifer Piper, and Shaun Ennis for sharing this update.

[post_title] => A Siemens NX Update: Extending Access and MBE [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => siemens-nx [to_ping] => [pinged] => [post_modified] => 2025-07-18 00:20:36 [post_modified_gmt] => 2025-07-18 04:20:36 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=21799 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [5] => WP_Post Object ( [ID] => 21746 [post_author] => 2574 [post_date] => 2025-04-08 09:00:15 [post_date_gmt] => 2025-04-08 13:00:15 [post_content] => Where’s the best place to start in improving supply chain resilience? Our research shows it’s inside the company. Many companies will need to start new initiatives and make additional investments to ensure their data is flowing for supply chain internal value. Data sharing and collaboration are crucial within supply chain disciplines, but also throughout the company between supply chain and engineering, manufacturing engineering, and the plant floor.

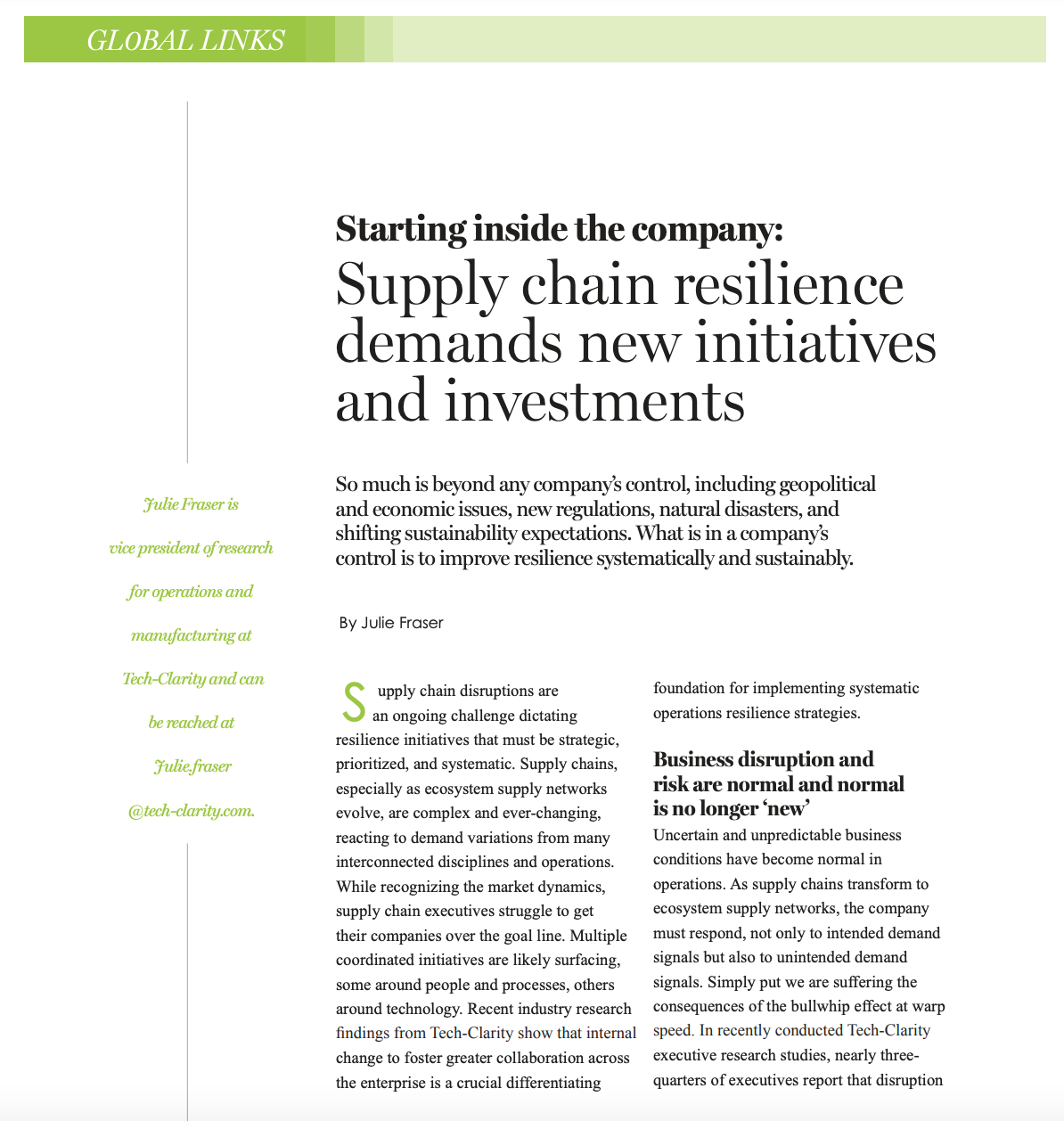

Supply chain and business disruptions are normal and often have severe negative impacts. Some of those factors are outside a company’s control, so most companies are investing in supply chain resilience (70%). Supply chain leaders must invest to tackle the #1 supply chain issue for executives: risk. Most companies need to do more to manage effectively and stay agile in the face of uncertainty, volatility, and ever-changing issues.

So, what to do? Change suppliers? Move production? Pull more production in-house and away from external suppliers? Improve design for supply? All of those might have good results.

Supply Chain resilience inside is the key. Gaining visibility into the product development and manufacturing or “make” areas of the company are crucial differentiators for those companies doing well. How would it be to see changes to products or production capabilities within an hour? Companies that can do that are performing better. Our research suggests that strong data flows across the company are a foundation for supply chain resilience.

Yet for many companies, this will require setting up new initiatives and investing at an enterprise level. Some of the changes might be in employee metrics and incentives to foster collaboration. Another idea is to invest in software that might have agentic AI, improved integration, or multi-tier planning and response capabilities.

Read Julie Fraser’s article in the Global Links section of Supply Chain Management Review that went live in March 2025. The above is a summary, and the full PDF of the article is linked here.

Thanks to Richard Sherman and Supply Chain Management Review for the opportunity to share our views.

[post_title] => Starting Inside the Company: Supply Chain Resilience Requires New Initiatives and Investments

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => supply-chain-resilience-inside

[to_ping] =>

[pinged] =>

[post_modified] => 2025-04-08 09:05:44

[post_modified_gmt] => 2025-04-08 13:05:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=21746

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 21722

[post_author] => 2574

[post_date] => 2025-04-02 10:00:30

[post_date_gmt] => 2025-04-02 14:00:30

[post_content] =>

Where’s the best place to start in improving supply chain resilience? Our research shows it’s inside the company. Many companies will need to start new initiatives and make additional investments to ensure their data is flowing for supply chain internal value. Data sharing and collaboration are crucial within supply chain disciplines, but also throughout the company between supply chain and engineering, manufacturing engineering, and the plant floor.

Supply chain and business disruptions are normal and often have severe negative impacts. Some of those factors are outside a company’s control, so most companies are investing in supply chain resilience (70%). Supply chain leaders must invest to tackle the #1 supply chain issue for executives: risk. Most companies need to do more to manage effectively and stay agile in the face of uncertainty, volatility, and ever-changing issues.

So, what to do? Change suppliers? Move production? Pull more production in-house and away from external suppliers? Improve design for supply? All of those might have good results.

Supply Chain resilience inside is the key. Gaining visibility into the product development and manufacturing or “make” areas of the company are crucial differentiators for those companies doing well. How would it be to see changes to products or production capabilities within an hour? Companies that can do that are performing better. Our research suggests that strong data flows across the company are a foundation for supply chain resilience.

Yet for many companies, this will require setting up new initiatives and investing at an enterprise level. Some of the changes might be in employee metrics and incentives to foster collaboration. Another idea is to invest in software that might have agentic AI, improved integration, or multi-tier planning and response capabilities.

Read Julie Fraser’s article in the Global Links section of Supply Chain Management Review that went live in March 2025. The above is a summary, and the full PDF of the article is linked here.

Thanks to Richard Sherman and Supply Chain Management Review for the opportunity to share our views.

[post_title] => Starting Inside the Company: Supply Chain Resilience Requires New Initiatives and Investments

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => supply-chain-resilience-inside

[to_ping] =>

[pinged] =>

[post_modified] => 2025-04-08 09:05:44

[post_modified_gmt] => 2025-04-08 13:05:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=21746

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 21722

[post_author] => 2574

[post_date] => 2025-04-02 10:00:30

[post_date_gmt] => 2025-04-02 14:00:30

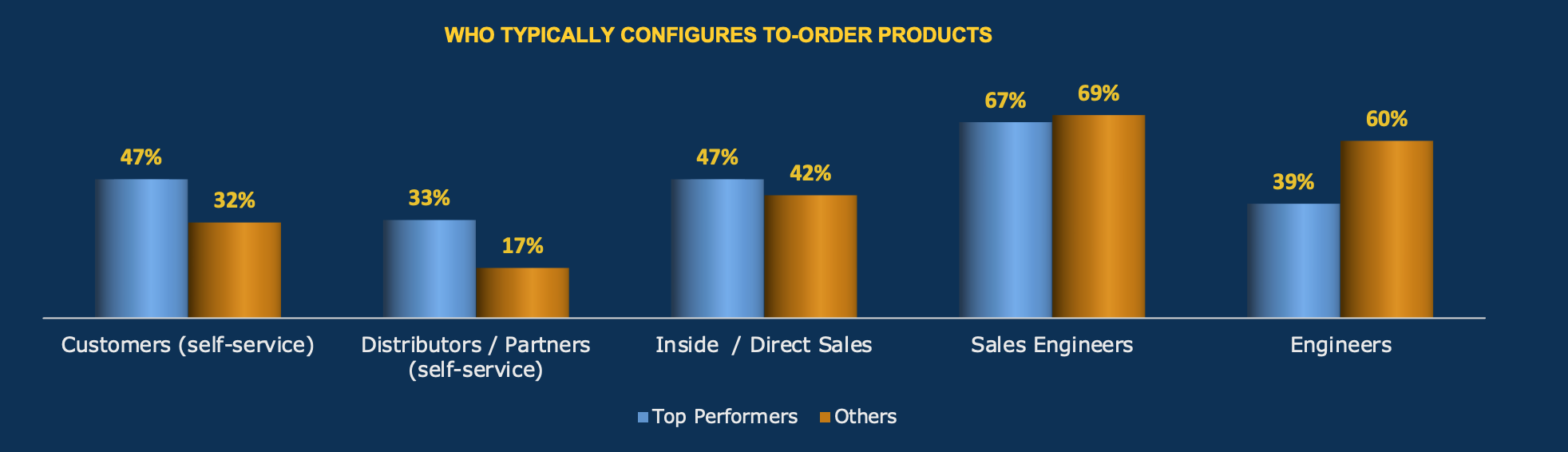

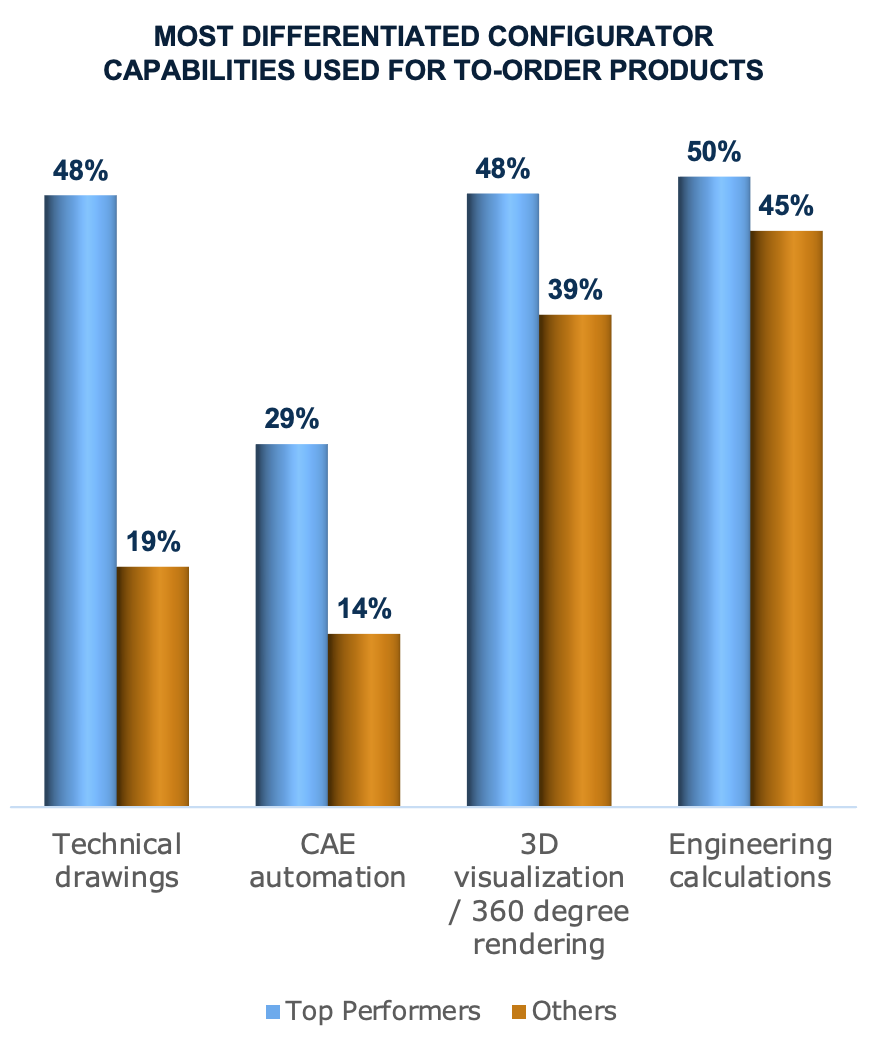

[post_content] =>  How can companies be sure to gain value from manufacturing analytics and AI projects? It turns out benefits are ubiquitous for those who have invested. Yet the Top Performers in our new survey of over 400 manufacturing respondents indicates some key differences that improve their results.

Please enjoy the summary* below. For the full research, please visit our sponsor MESA International (registration required).

How can companies be sure to gain value from manufacturing analytics and AI projects? It turns out benefits are ubiquitous for those who have invested. Yet the Top Performers in our new survey of over 400 manufacturing respondents indicates some key differences that improve their results.

Please enjoy the summary* below. For the full research, please visit our sponsor MESA International (registration required).

Table of Contents

- It's Time to Invest in Analytics and AI

- Why Invest in Manufacturing Operations and Analytics

- Business Challenges

- Smart Manufacturing Journey

- Smart Manufacturing Progress

- Investment Outcomes

- Analytics May Pay Off Faster Than Other Software

- Analytics and AI Deliver Benefits that Matter

- Top Performers Are Role Models

- Smarter Manufacturing

- Descriptive Analytics

- Predictive Analytics

- Predictive Analytics Hurdles

- Overcoming the Challenges

- Predictive Analytics Benefits

- Generative AI and Analytics to Support and Guide

- GenAI Hurdles

- GenAI Benefits

- Rapid Benefits from GenAI

- Manufacturing DataOps Needs Improvement

- Industry-Specific AI

- Key Takeaways

- Recommendations

- About the Research

- Acknowledgments

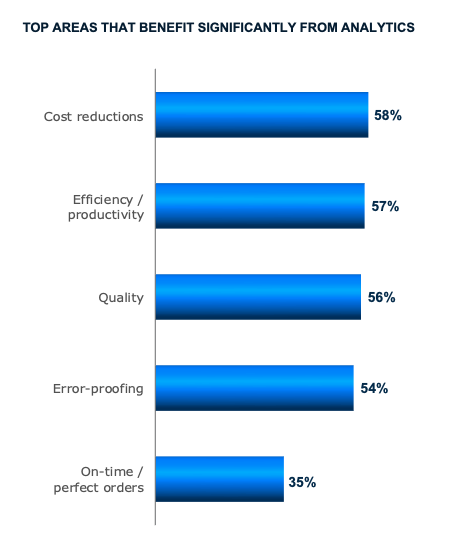

It’s Time to Invest in Analytics and AI

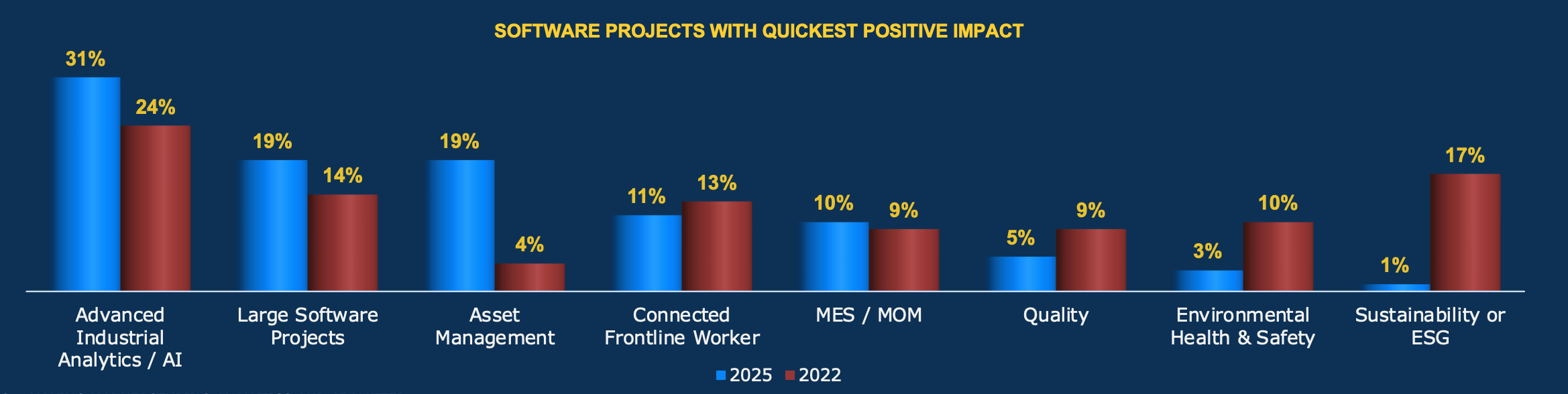

Analytics and AI Deliver Value to Manufacturing Analytics and artificial intelligence (AI) are hot topics in manufacturing operations today. This research explores what companies are doing, why, and how. The data from 423 responses from companies that manufacture or produce worldwide is conclusive. Those investing in Analytics and AI are gaining substantial benefits. The benefits matter, as they are in the areas that match their objectives: cost, efficiency/productivity, quality, and error-proofing most commonly. 100% of these respondents are facing significant challenges, and 99% are investing in manufacturing operations, analytics, and AI to address them. Those using analytics and AI longer tend to see benefits in more areas. Top Performers doing better on operations metrics are also outperforming Others on business metrics. What are they doing differently? More of them are using dashboards, analytics, and AI. They also prioritize use cases based on business value.Analytics May Pay Off Faster Than Other Software

Quick Positive Impact Investments are always made to yield a return or positive impact. Just as the previous time MESA partnered to conduct this research2, advanced analytics was the top application for rapidly delivering ROI. Nearly a third of the respondents gained the value of analytics and AI relatively rapidly. Changes Over Time We suspect many of the changes between 2022 and 2025 are due to the different sets of respondents. Other possible reasons for the significant changes: The big new drive to AI in the past couple of years is likely a factor in its more prominent showing. Maintenance and asset management have been a focus of predictive analytics. In contrast, sustainability has moved into the realm of legal and regulatory requirements, which may be slowing the benefits. Critical Data Each use case will require a specific set of data. New technologies make it easier to identify and extract essential data from existing sources. Data Foundation Most of these projects require modeling and data-cleansing efforts to deliver benefits. Companies gaining rapid benefits from analytics and AI will likely already have a good data foundation. Paving the Path to Value Companies may get a solid data foundation by implementing some of the other systems on this list, such as ERP, Asset Management, and Manufacturing Execution Systems (MES) or Manufacturing Operations Management (MOM).

Analytics and AI Deliver Benefits That Matter

100% Gaining Benefits

Analytics projects are delivering significant benefits that support top drivers and help meet challenges. Every one of these respondents (100%) reports gaining benefits from analytics programs, which is excellent news for our industries.

Cost

Cost reduction is the #1 driver (p. 4) and actual benefit. Most companies know they could lower costs, but analytics and AI can help to pinpoint where to focus efforts. Predictive and preventive analytics can avoid an array of unnecessary expenses due to waste.

Efficiency & Quality

Efficiency contributes to cost and indicates people are effective, even in the face of a skilled workforce shortage. Error-proofing is necessary for less skilled staff, and even more experienced staff can benefit from error-proofing when change is rapid, the product mix through the plant is high, or specifications change frequently.

What Customers Need

On-time perfect orders make the company a reliable supplier, leading to revenue opportunities and being viewed as trustworthy in these uncertain times. Customers also seek quality; internally that lowers costs, increases revenue opportunity, improves supply chain resilience, and enhances sustainability.

And More

Other areas where respondents report significant benefits from analytics programs include:

100% Gaining Benefits

Analytics projects are delivering significant benefits that support top drivers and help meet challenges. Every one of these respondents (100%) reports gaining benefits from analytics programs, which is excellent news for our industries.

Cost

Cost reduction is the #1 driver (p. 4) and actual benefit. Most companies know they could lower costs, but analytics and AI can help to pinpoint where to focus efforts. Predictive and preventive analytics can avoid an array of unnecessary expenses due to waste.

Efficiency & Quality

Efficiency contributes to cost and indicates people are effective, even in the face of a skilled workforce shortage. Error-proofing is necessary for less skilled staff, and even more experienced staff can benefit from error-proofing when change is rapid, the product mix through the plant is high, or specifications change frequently.

What Customers Need

On-time perfect orders make the company a reliable supplier, leading to revenue opportunities and being viewed as trustworthy in these uncertain times. Customers also seek quality; internally that lowers costs, increases revenue opportunity, improves supply chain resilience, and enhances sustainability.

And More

Other areas where respondents report significant benefits from analytics programs include:

- Office visibility into performance (22%), which is crucial to executives and other disciplines since manufacturing is at the center of the company.

- Planning and scheduling at 21% is heavily dependent on insights and is inherently an analytical process.

- Customer satisfaction and collaboration (20%) based on analyzed data and sharing insights can drive revenue.

- Some get benefits in waste/scrap/energy, asset performance and uptime, comparability among lines or sites, employee satisfaction, supplier issues, and returns or warranty costs.

Key Takeaways

Progress: Manufacturers are moving along the Smart Manufacturing path. Many have multiple projects underway or are already seeing results.

Progress: Manufacturers are moving along the Smart Manufacturing path. Many have multiple projects underway or are already seeing results.- Seeking Data Outcomes: Manufacturers are seeking some fundamental data management outcomes from their investments, such as easy access to high-quality, timely, complete plant data for plant employees and integration of equipment, plant, and enterprise data.

- Interested in New Technologies: Many are also focused on advanced analytics and IIoT.

- Varied Drivers: What matters most to manufacturers right now varies, but cost reduction, supply chain resilience, sustainability, workforce skills, and revenue opportunity top the list.

- AI Delivering Benefits: Fortunately, AI in all its forms is delivering benefits in desired areas. Benefits come relatively quickly, with expected payback often in less than a year.

- Supporting Operations: AI can help fill the knowledge gap in today’s workforce, driving efficiency and guiding people.

- Key Differences: Top Performers are more likely to have organizational structures, capabilities, and technologies to support their success.

- Room for Improvement: Nearly all manufacturers we surveyed could improve their data management, governance, accessibility, and operations. We are growing as an industry in this area.

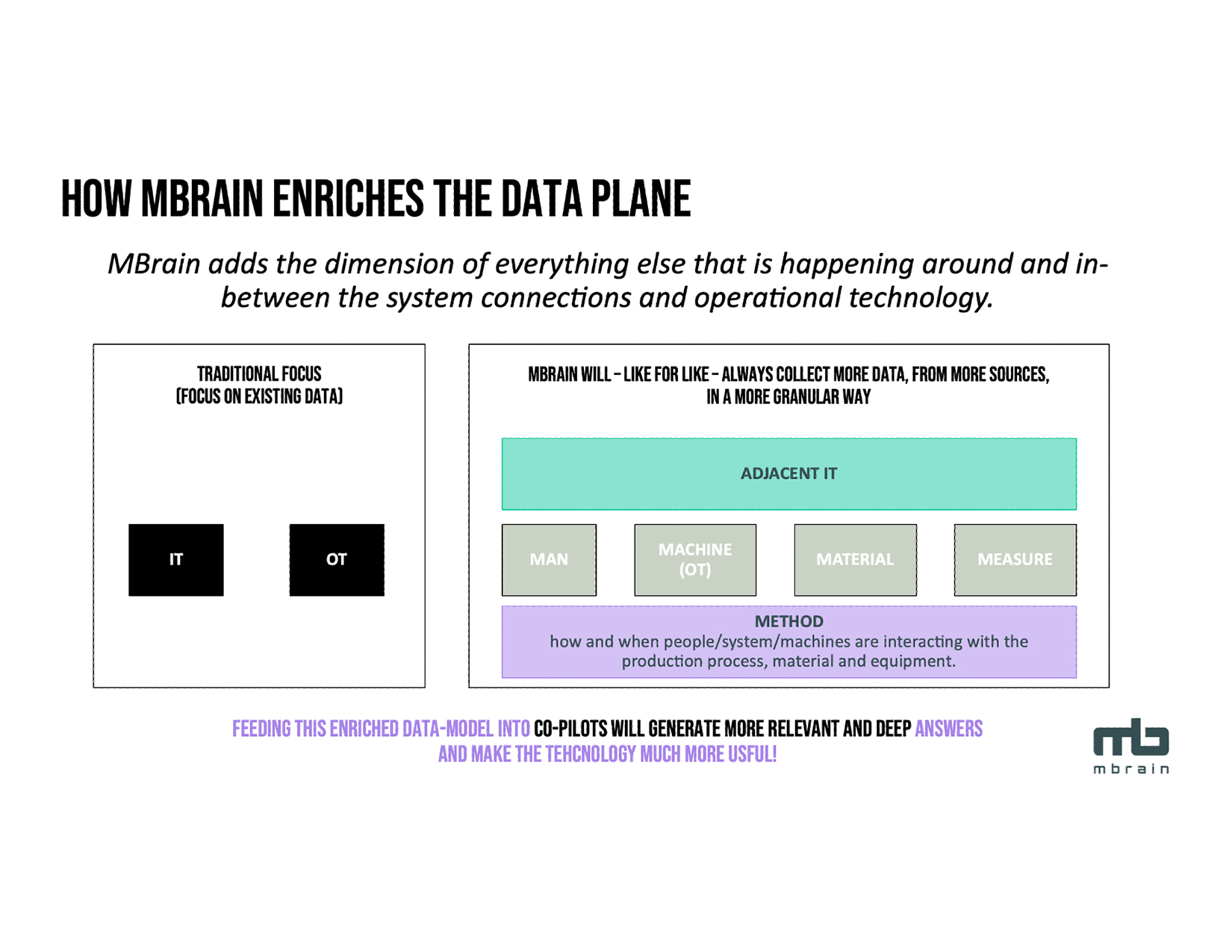

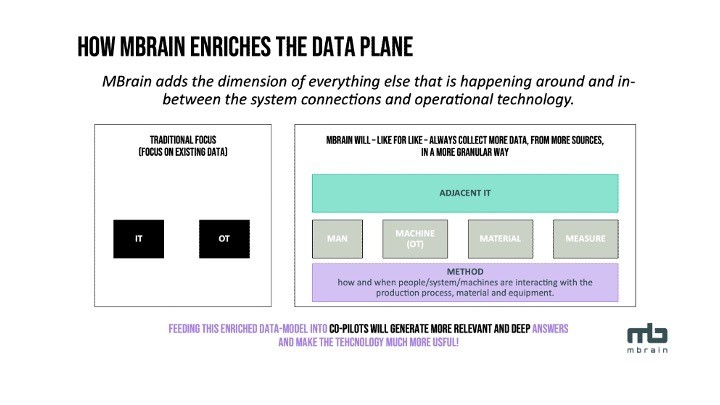

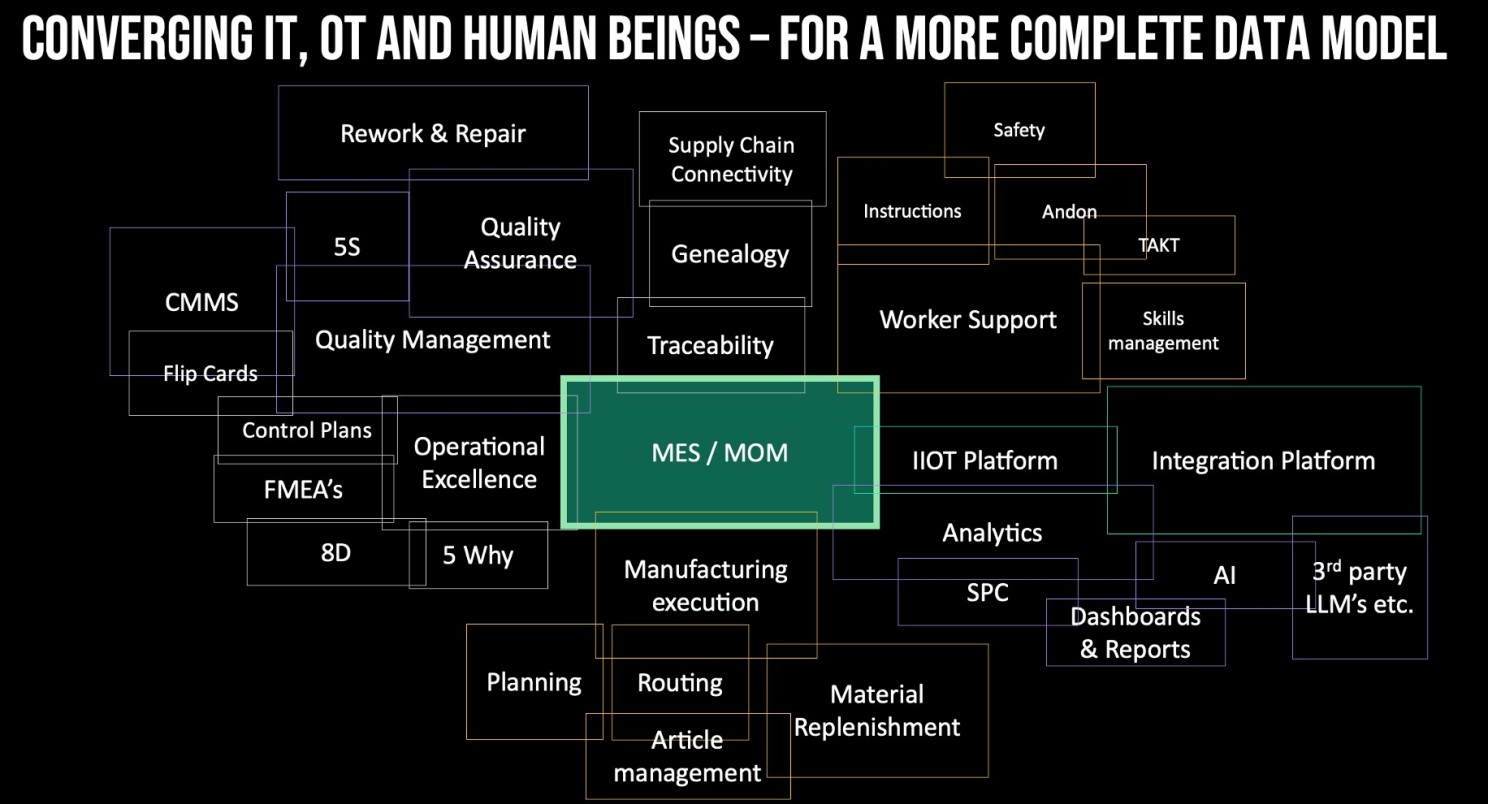

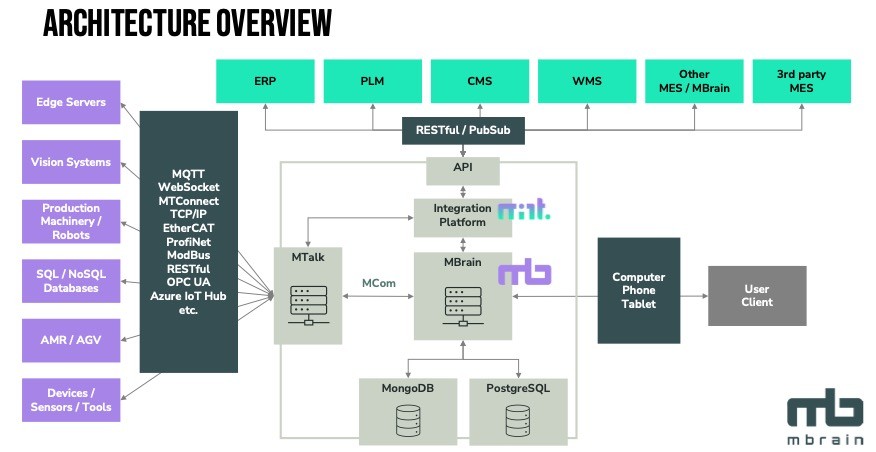

What does it take to digitalize assembly, an area where people must participate? Quite a lot, especially with complex configured products. Over time, MTEK Industry AB has consistently focused on developing software to support complex discrete assembly operations. They keep adding functionality in MOM and beyond to the MBrain digital production system. Integrating to equipment, informing people, and improving are core. They recently added a no-code IT integration platform, Mint, for enterprise data flow. They are delivering value in weeks.

Assembly Focus

For several years, MTEK has focused on creating no-code software that supports manufacturers with complex discrete manufacturing operations typically characterized by configured products, takted or untakted assembly flows, and a high reliance on manual operations. This market has largely been underserved, partly because it’s very complex and changes frequently, often for every configured product (“batch-size one”). Most of these companies have some equipment and automation, but many operations also rely on people since variation is generally the enemy of automation. MTEK started in 2002 as a manufacturing excellence consulting company, so its roots are deep in these industries.

Broad Functionality

Not constrained by what is traditionally included in MES, they have built many functions. MTEK calls it a Digital Production System. MBrain has core functions focused on delivering visibility, a large variety of “make” functions, and a suite of “improve” functions to make lean best practices digital. These functions support specific assembly challenges such as planning, andon, configuration QA, line tolerance, and user competences.

Traditionally, this scope might require four or five specialized systems besides MES. Because it’s no-code, once a customer gets proficient, they can – and typically do – expand it further to meet their specific needs.

Start Where You Are

Anyone who has worked in an assembly operation, particularly a takted one, knows how critical the processes are to keeping products flowing through the plant. MBrain includes a Process, or Method Builder, which is the core tool for constructing a digital replica of the logic of your production and the heart of why MBrain sets out to be a Digital Production System.

They encourage customers to start by mapping their current methods and keep working as they have. Given the no-code design, manufacturers can use the system to identify areas for improvement and then implement them. With more rigid system architectures, clients typically need to identify the “to-be” state before implementation. MTEK challenges that logic and way of working with a more flexible tool.

They can use or later add elements such as getting product data from PLM, reporting materials consumption to ERP, pushing a recipe to a machine, or printing a label. The great news is that customers can view the method or workflow in production, maintenance, quality, etc., at any level of granularity. This supports both skilled and less skilled workers at just the level they need.

Mid-Size Operations Typically

While manufacturers are all different, the MTEK team realized these complex assembly operations have a typical profile. Whether the plant is part of a larger group or the company's entire operations, the facilities are typically 100-250 people, with around $100M in output (+/- 50%). They are often in smaller towns, which limits how large operations can be. Typically, even larger companies are also built by acquiring many smaller operations – meaning there are geographical and historical reasons for the size of a typical plant in discrete manufacturing and assembly. Focusing on this scope of operation, they knew a traditional multi-million dollar, multi-year MES implementation was not the best approach. MTEK’s no-code approach enables MBrain to be both affordable and configurable to the specific operating needs of each customer.

Microsoft Azure IoT Operations Partner

In November 2024, Microsoft’s Azure IoT Operations included MTEK as a launch partner. This is a prestigious position in the Microsoft Adaptive Cloud approach for cloud-to-edge connectivity in manufacturing. Using the Mint and MTalk elements of MTEK’s digital production system, data from equipment, sensors, IoT devices, and adjacent IT systems can feed not only MBrain but also cloud-based analytics. MTEK is strong on its own, but the Microsoft partnership illustrates the advanced nature of their software architecture to enable scaling.

No-Code Mint for IT Integration

The new addition to the MTEK product family is a no-code integration platform, Mint. This innovation from MTEK was originally designed to remove the barrier to growth created by the monetary cost and delay caused by traditional integration work.

As the platform has been deployed with clients, however, MTEK has noticed that the bulk of the value comes from creating a much more integrated systems architecture and event-driven IT/OT stack. Gaining data flows among IT systems can be a powerful and transformative step for manufacturers. The goal is not just to integrate IT systems but to integrate and automate business processes seamlessly. This patent-pending approach to integration can serve MBrain customers and others.

Customer Success

Much of the breadth of functionality has come from customer needs. Since 2020, MTEK has had success with complex discrete assembly customers, including many larger companies whose names you recognize. In one larger company, Accenture was the service partner and saw the value of MBrain. With this no-code approach, many customers report seeing results in a couple of weeks after starting to deploy MBrain. This is not possible with traditional full-code manufacturing software. With the improved IT integration of Mint, the value of these deployments could continue to grow even beyond the MBrain functional footprint.

Solid Combination

No-code, but with built-out functionality out of the box as a starting point, is a strong starting point. Adding so much functionality beyond traditional MES allows MTEK to lay claim to a larger footprint and deliver more value. Integrating the lean tools natively gives continuous improvement a leg up. Integration to automation with MTalk supports automated aspects of the operation. Adding the Mint integration platform addresses one of the most troubling issues in manufacturing digital transformation, helping data flow among systems across the company.

Assembling for the Future

We are convinced that assembly-based manufacturers should explore the MTEK Digital Production System. It seems to have both industry-specific functions that are ready to use and extreme configurability with the no-code approach. Thank you, Tord Johnson and Oscar Wallner, for updating me.

[post_title] => MTEK’s Digital Production System Delivers Value for Complex Assembly in Weeks [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => digital-production-system [to_ping] => [pinged] => [post_modified] => 2025-07-23 09:38:33 [post_modified_gmt] => 2025-07-23 13:38:33 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=21790 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 21705 [post_author] => 2 [post_date] => 2025-03-25 09:00:46 [post_date_gmt] => 2025-03-25 13:00:46 [post_content] => How does expanding PLM beyond engineering to support the digital thread from requirements through commercialization help manufacturers launch quality products that meet regulatory demands and customer expectations? How can companies take an end-to-end PLM approach to drive better new product success?

Join the Meet the Pros: New Solutions & Expert Advice To Help You Achieve Product Success webinar to hear Jim Brown share Tech-Clarity’s research on how Top Performers get the most out of PLM to drive better, more profitable products. Jim will join Propel experts who will share their perspectives on a more valuable approach to PLM and directly share some announcements and answer questions about their offerings.

How does expanding PLM beyond engineering to support the digital thread from requirements through commercialization help manufacturers launch quality products that meet regulatory demands and customer expectations? How can companies take an end-to-end PLM approach to drive better new product success?

Join the Meet the Pros: New Solutions & Expert Advice To Help You Achieve Product Success webinar to hear Jim Brown share Tech-Clarity’s research on how Top Performers get the most out of PLM to drive better, more profitable products. Jim will join Propel experts who will share their perspectives on a more valuable approach to PLM and directly share some announcements and answer questions about their offerings.

[post_title] => How an End-to-End PLM Approach Drives Product Success

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => product-success

[to_ping] =>

[pinged] =>

[post_modified] => 2025-03-25 09:24:44

[post_modified_gmt] => 2025-03-25 13:24:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=21705

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 22260

[post_author] => 2574

[post_date] => 2025-03-18 10:00:30

[post_date_gmt] => 2025-03-18 14:00:30

[post_content] =>

[post_title] => How an End-to-End PLM Approach Drives Product Success

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => product-success

[to_ping] =>

[pinged] =>

[post_modified] => 2025-03-25 09:24:44

[post_modified_gmt] => 2025-03-25 13:24:44

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=21705

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 22260

[post_author] => 2574

[post_date] => 2025-03-18 10:00:30

[post_date_gmt] => 2025-03-18 14:00:30

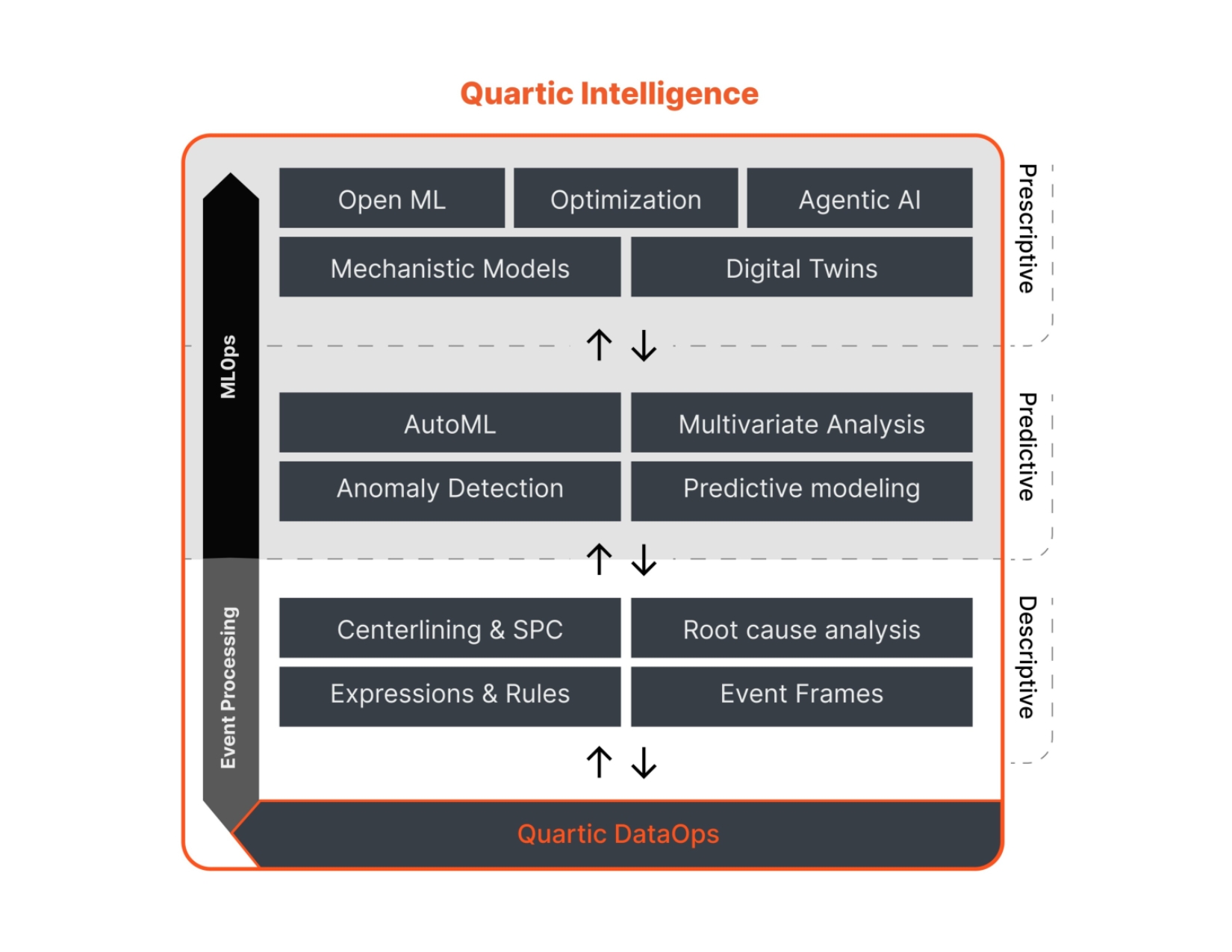

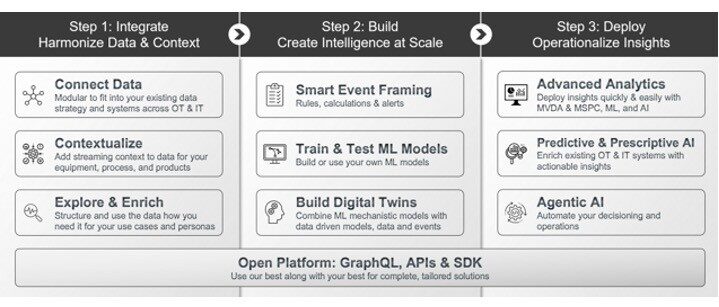

[post_content] =>  Why would batch process manufacturers want more than their MES to manage operations? To gain real-time intelligence with AI-based optimization at scale. Quartic.ai’s industrial DataOps platform is open to handle data from and serve intelligence to nearly any plant floor or enterprise application. It focuses on confident, timely decisions, complementing MES, LIMS, EAM, and other operations software that focuses on execution.

Why would batch process manufacturers want more than their MES to manage operations? To gain real-time intelligence with AI-based optimization at scale. Quartic.ai’s industrial DataOps platform is open to handle data from and serve intelligence to nearly any plant floor or enterprise application. It focuses on confident, timely decisions, complementing MES, LIMS, EAM, and other operations software that focuses on execution.

Closing the Gaps

Manufacturers have long had challenges closing the gap between MES and ERP. This integration may suffer for various reasons, but Quartic plays a role in ensuring the data from all systems is available for operations intelligence. Like older automation or OT systems, some batch process MES and LIMS systems are not entirely open to sharing data. Quartic can again manage that data and put it into analytics data streams.

Industry-Focused Digital Platform

Quartic has spent years refining a comprehensive, enterprise-capable platform for digital DataOps, MLOps, and intelligence delivery for batch process industries. It has successes in pharmaceutical and life sciences, CPG, food and beverage, specialty chemicals, and metals and mining. This means they are ready to handle time-series and relational data, spectral data, real-time and historical data, and events. This company understands batch issues, phases, and challenges. The variability and interdependencies of these industries that make them difficult for others are the starting point for Quartic. The team has expertise in process manufacturing and reliability, data science and AI, and enterprise software development.

Comprehensive Platform

The Quartic Intelligent MOM Platform has three main components: DataOps, Intelligence, and Applications. This is an unusually broad set of capabilities for manufacturing operations, and Quartic is working to ensure that each component is complete.

Full-Stack DataOps

Manufacturers have been discovering in their Smart Manufacturing and AI-based initiatives that getting data ready to use is more complicated than first meets the eye. Quartic’s platform includes OT and IT data connectors and ingestion from many sources, with the capability to put it all in context through a data fabric. This might also be called a unified namespace (UNS). The full stack DataOps with enriched data serves as the enterprise broker that can feed many analytical models, use cases, and feed source systems for wider distribution.

AI Platform

For Quartic, AI is a founding focus, not a new addition. Beyond DataOps, this platform includes MLOps and a full array of industrial AI capabilities. Whether you want an assistant for your people making decisions, a predictive engine to drive forward-looking insights and enable preparatory or preventive action, or a fully autonomous AI agent, these are proven in the platform. While agentic AI has become a hot buzzword in the last year, Quartic has taken this approach for about 5 years.

Applications

Quartic has also had applications available for batch manufacturers for years. The applications may be native or offered with a partner. There are dozens of them, mainly developed at a customer request and developed into a reusable application. Categories of applications include:

- Product performance analysis (all native)

- Enhanced quality

- Maintenance management

- Material tracking

- Energy Optimization

- Production scheduling (with partners)

Flexible for Fit and Future

Quartic has been building this extensive and robust functionality for many years, working with customers to expand in areas of greatest need. Their goal is to create a flexible and robust system that’s also quick to deploy. Flexibility matters to fit companies at different stages of maturity in data integration. It also matters to keep up with future needs as they evolve.

Thanks, Rajiv Anand, Vinodh Rodrigues, and Bryan Pope, for getting us back up to speed! We look forward to following Quartic’s progress in the market.

[post_title] => Quartic.ai Moves to Make MOM Intelligent with a Powerful Open AI Platform [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => dataops-ai-platform [to_ping] => [pinged] => [post_modified] => 2025-07-16 20:54:02 [post_modified_gmt] => 2025-07-17 00:54:02 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=22260 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [10] => WP_Post Object ( [ID] => 21775 [post_author] => 2580 [post_date] => 2025-03-17 10:00:13 [post_date_gmt] => 2025-03-17 14:00:13 [post_content] =>The Case for Boosting Digital Transformation with Low-Code

Why should Siemens Xcelerator customers embrace low-code capabilities from Mendix, a Siemens Digital Industries Software Business, to accelerate their #digitaltransformation journey?

In today’s fast-paced manufacturing environment, using data from various sources to make informed decisions is crucial for operating profitably. This dynamic data often resides in systems like ERP, CRM, PLM, and MES. However, most manufacturers lack the resources to rapidly develop and deploy software applications integrating data from these systems. IT teams struggle to meet these needs, often too company-specific for solution providers like Siemens to address directly.

Our research, Filling Digital Transformation Gaps with Applications, found that digital transformation increases the speed of change, demands more agility, and creates the need for more (and faster) software development. The survey also found, however, that manufacturers using low-code development are better able to fill their digital transformation gaps to meet their evolving needs.

To stay competitive, manufacturers must repurpose existing solutions, connect them, and augment them with new capabilities. Mendix, Siemens’ low-code platform, enables this adaptability. A recent Mendix briefing to Tech-Clarity analysts shed light on their strategy for helping manufacturers efficiently extend and enhance their core systems.

Adapt and Extend Siemens Xcelerator with Mendix

Mendix makes low-code available for any industry, but Siemens has invested in making Mendix more valuable for industrial customers using Siemens’ existing solutions. There are two ways Siemens customers can use Mendix to extend their product development and manufacturing data:

- Use the Mendix platform to build applications: Manufacturers can use the Mendix platform to easily build and manage applications. Its low-code capabilities empower teams to develop, deploy, and maintain applications more efficiently, which is helpful to get the most out of limited IT resources. Mendix enables application developers to integrate data from Siemens solutions like Teamcenter (PLM) and Opcenter (MES) and make it available to more users. Additionally, it supports external data sources such as ERP, allowing manufacturers to create comprehensive, composite applications that unify multiple systems. By centralizing data and providing access to stakeholders, Mendix helps manufacturers make informed business decisions.

- Use Mendix capabilities embedded in Siemens Xcelerator products: Siemens has strategically embedded Mendix low-code technology within its core Xcelerator portfolio, driving greater flexibility and accessibility. Key Mendix functionalities are already integrated into Opcenter (see our earlier Insight on Mendix Lowcode for Industrial Applications), enabling users to personalize, extend, and enhance the way they use Opcenter in their factories. Siemens is set to embed Mendix into Teamcenter Active Workspace, extending Teamcenter’s existing configurable user experience and empowering product development teams to seamlessly connect and enrich their data with Mendix-powered solutions. This will further the ability of Teamcenter, providing additional capabilities beyond what is available today. This deep integration ensures manufacturers can rapidly adapt to evolving business needs and unlock new levels of efficiency.

Do More with AI, Integrate New Technologies