Cloud Security Discussion with Siemens EVP Bob Jones (Video)

How have manufacturers’ perspectives on cloud security changed, and what can they do to mitigate cloud risk? This episode digs into the cloud security issue for product innovation and engineering software. Tech-Clarity’s Jim Brown and Siemens’ Digital Industries Software EVP Global Sales & Customer Sucess Bob Jones discuss the evolving view of security for cloud…

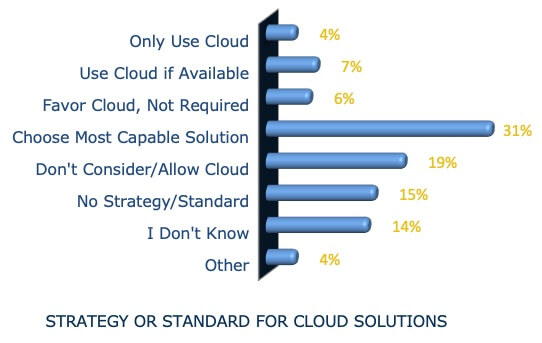

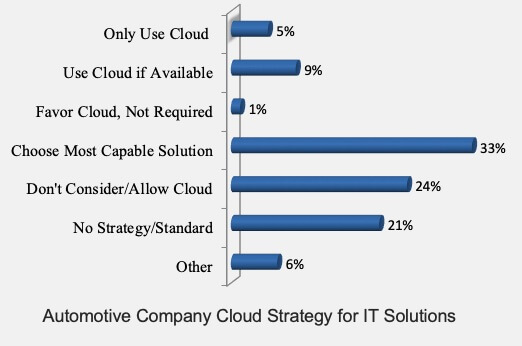

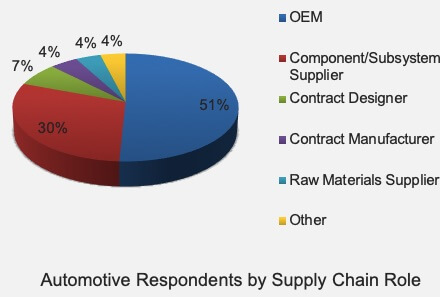

How can Automotive and Transportation companies leverage the cloud to improve innovation, engineering, and manufacturing across the product lifecycle? We conducted a survey to find out how Automotive manufacturers are approaching the cloud PIP opportunity. We gathered over 250 survey responses from manufacturing and engineering services firms, and took a closer look at approximately 100 of them in the Automotive industry. The research analyzes both challenges faced and benefits achieved by Auto companies using cloud-based applications. The eBook shares implementation, adoption, operational, and business benefits of cloud systems and how they impact today's digital auto manufacturer. The report also touches on some specific topics including the use of cloud standards and audits to help mitigate security risk and how cloud platforms enable value-added services in the context of innovation tasks.

Please enjoy the full eBook below for no charge or

How can Automotive and Transportation companies leverage the cloud to improve innovation, engineering, and manufacturing across the product lifecycle? We conducted a survey to find out how Automotive manufacturers are approaching the cloud PIP opportunity. We gathered over 250 survey responses from manufacturing and engineering services firms, and took a closer look at approximately 100 of them in the Automotive industry. The research analyzes both challenges faced and benefits achieved by Auto companies using cloud-based applications. The eBook shares implementation, adoption, operational, and business benefits of cloud systems and how they impact today's digital auto manufacturer. The report also touches on some specific topics including the use of cloud standards and audits to help mitigate security risk and how cloud platforms enable value-added services in the context of innovation tasks.

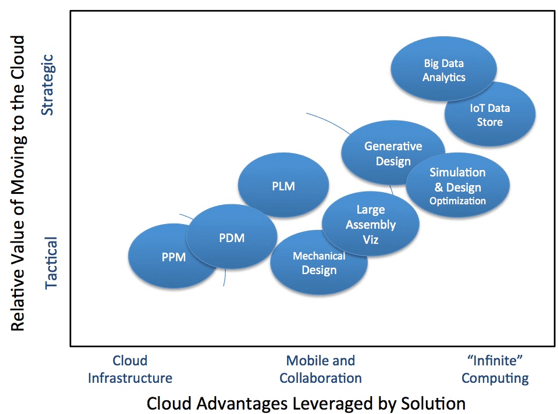

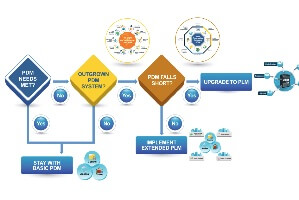

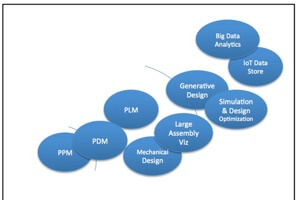

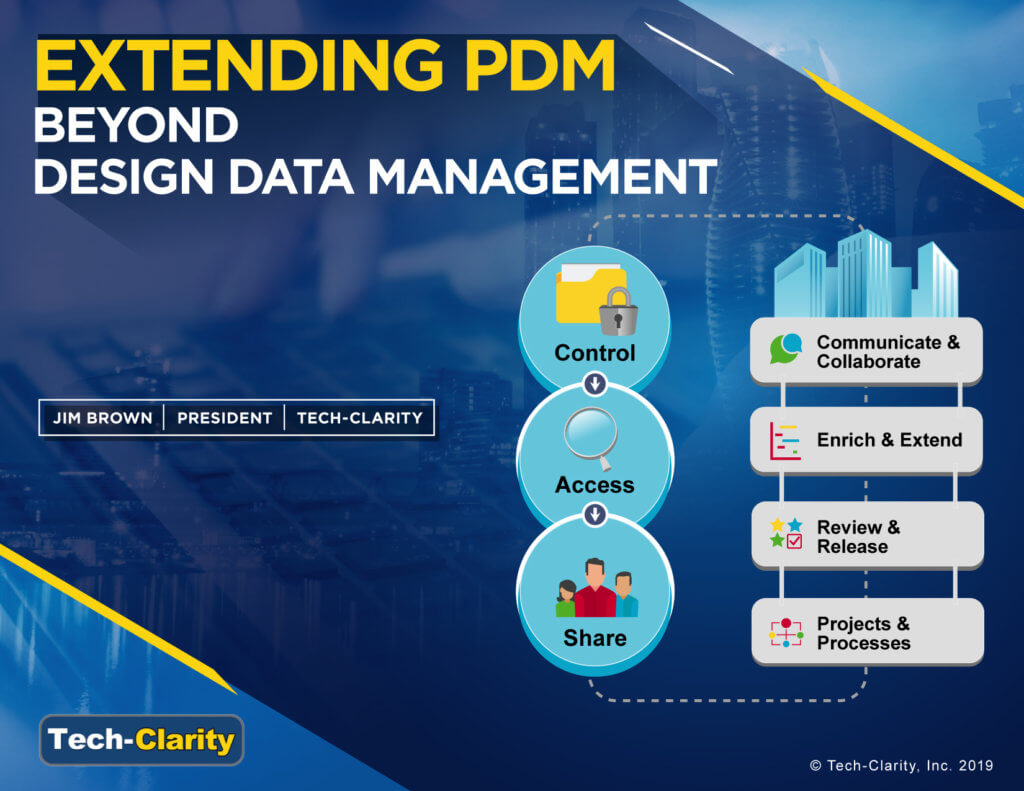

Please enjoy the full eBook below for no charge or  Before we explore the evolution to the cloud, it’s important to understand how PIP solutions have evolved. Engineering solutions have enabled companies to design products with unprecedented levels of innovation. They’ve advanced to model and simulate new materials, advanced manufacturing methods, systems, and other characteristics to more accurately predict product behavior.

These engineering tools are integrated with data and process management solutions that support products, processes, and programs. These PLM tools have expanded to support a broader view of the product and support a wider range of processes ranging from ideation to launch.

Needs Expand for the Digital Enterprise

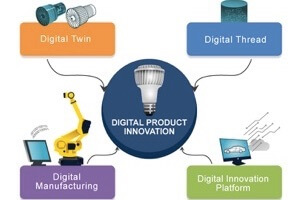

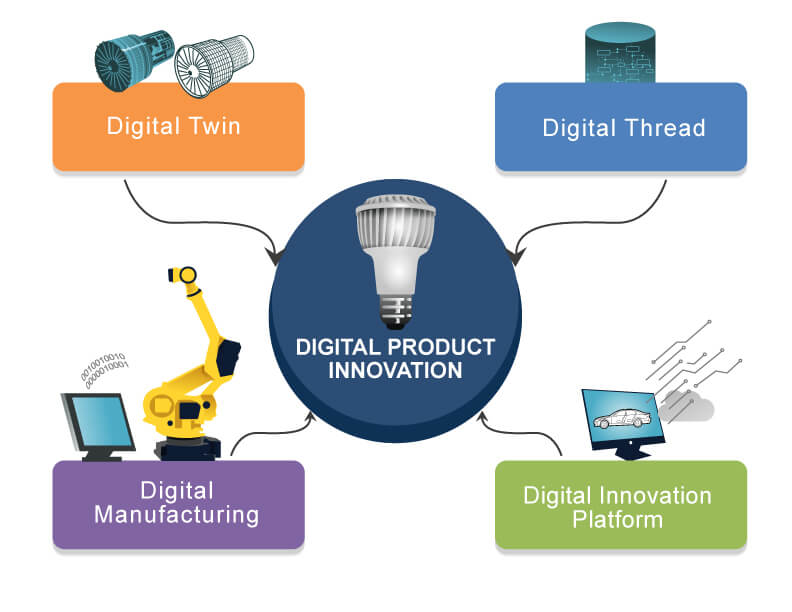

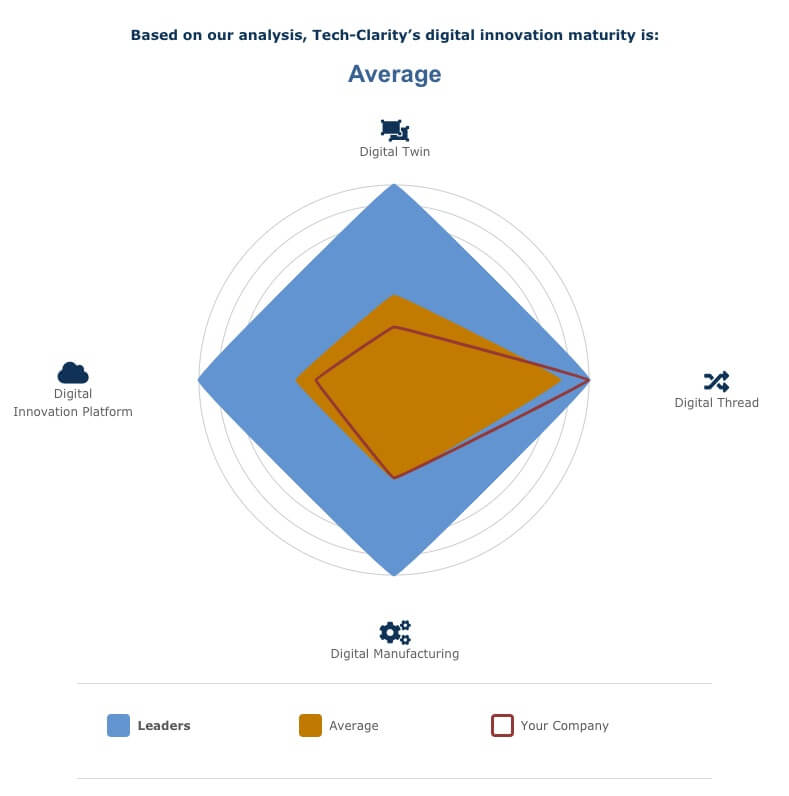

The digital transformation demands more. Solutions must support a more integrated approach, enable data-driven design, and support model-based systems engineering. They need to support digital continuity where each engineering discipline contributes their design into a comprehensive, cohesive model. They must enable real-time, secure collaboration across domains and the supply chain whenever and wherever needed.

The PIP creates a comprehensive digital thread, supports a cohesive digital twin, and breaks the paradigm of disparate, file-based systems. And it’s now available on the cloud.

Before we explore the evolution to the cloud, it’s important to understand how PIP solutions have evolved. Engineering solutions have enabled companies to design products with unprecedented levels of innovation. They’ve advanced to model and simulate new materials, advanced manufacturing methods, systems, and other characteristics to more accurately predict product behavior.

These engineering tools are integrated with data and process management solutions that support products, processes, and programs. These PLM tools have expanded to support a broader view of the product and support a wider range of processes ranging from ideation to launch.

Needs Expand for the Digital Enterprise

The digital transformation demands more. Solutions must support a more integrated approach, enable data-driven design, and support model-based systems engineering. They need to support digital continuity where each engineering discipline contributes their design into a comprehensive, cohesive model. They must enable real-time, secure collaboration across domains and the supply chain whenever and wherever needed.

The PIP creates a comprehensive digital thread, supports a cohesive digital twin, and breaks the paradigm of disparate, file-based systems. And it’s now available on the cloud.

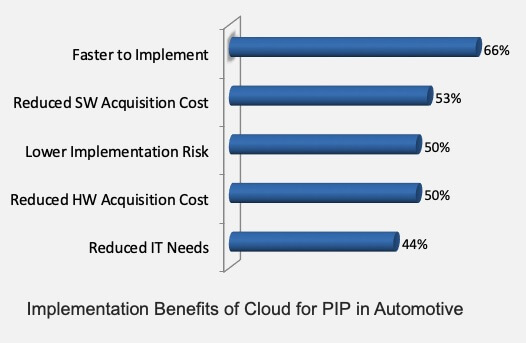

Manufacturers and suppliers across industries have begun to adopt cloud solutions. Our research finds that an increasing number of companies are transitioning to the cloud in order to take advantage of significant benefits, including:

Manufacturers and suppliers across industries have begun to adopt cloud solutions. Our research finds that an increasing number of companies are transitioning to the cloud in order to take advantage of significant benefits, including:

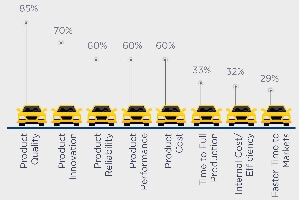

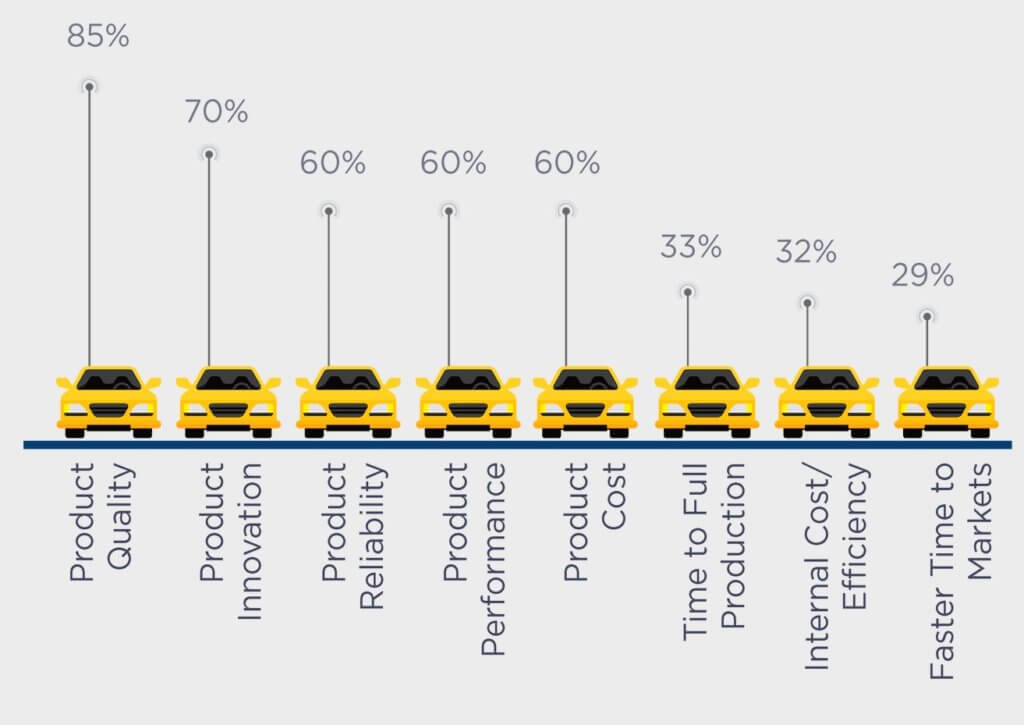

The PIP Delivers Product Excellence and Agility

Our research shows that an effective PIP can help improve all of these factors. These platforms, incorporating engineering tools and PLM capabilities, are proven to drive better product development results. The cloud is reducing the barriers to these PIP solutions and provides benefits in multiple dimensions, including affordability, flexibility, and agility. We explore these further in the survey.

The PIP Delivers Product Excellence and Agility

Our research shows that an effective PIP can help improve all of these factors. These platforms, incorporating engineering tools and PLM capabilities, are proven to drive better product development results. The cloud is reducing the barriers to these PIP solutions and provides benefits in multiple dimensions, including affordability, flexibility, and agility. We explore these further in the survey.

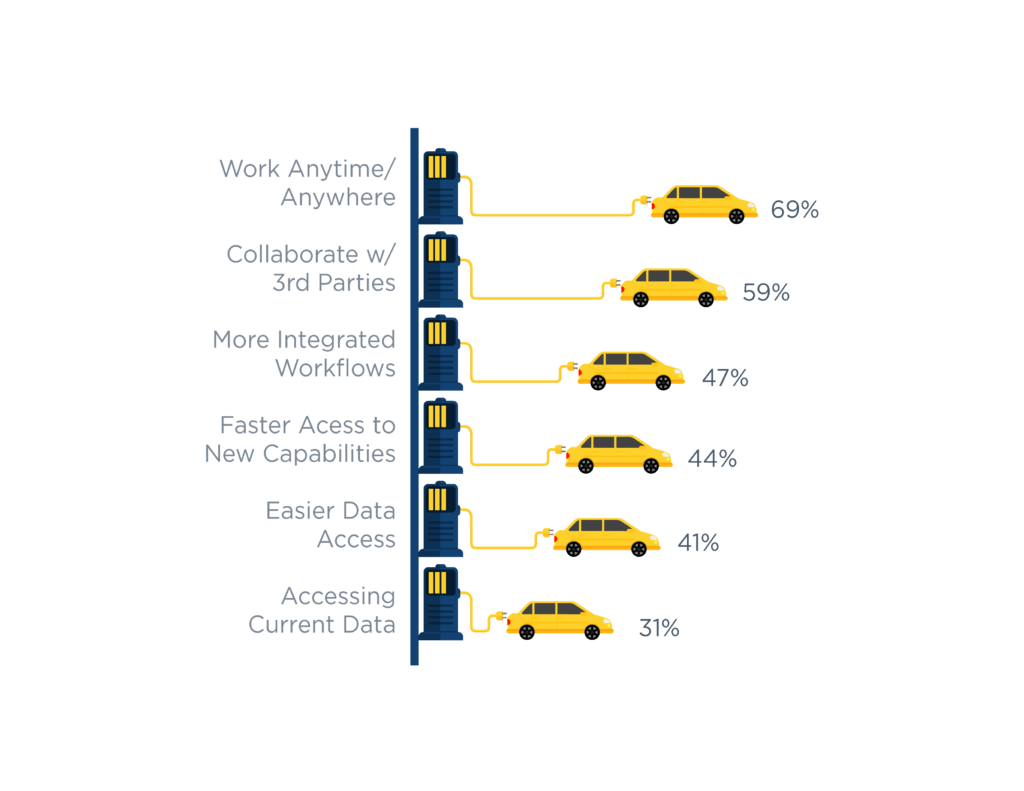

Cloud Enables to Working Anytime, Anywhere

The most commonly reported business benefit is the flexibility to work anytime / anywhere, reported by two-thirds of participants. This is followed by ease of collaboration. This capability, along with the ability to have more integrated workflows as reported by about one-half of companies, allows OEMs and the supply chain to work together more efficiently and effectively. This is particularly important for Automotive companies given the global nature of their business, the need to be agile, and the integrated nature of the automotive value chain.

Automotive companies also pointed out the value of faster access to new capabilities, helping them get more value from their applications. The cloud gives companies flexibility in the capabilities they adopt and accelerates time to value.

Cloud Enables to Working Anytime, Anywhere

The most commonly reported business benefit is the flexibility to work anytime / anywhere, reported by two-thirds of participants. This is followed by ease of collaboration. This capability, along with the ability to have more integrated workflows as reported by about one-half of companies, allows OEMs and the supply chain to work together more efficiently and effectively. This is particularly important for Automotive companies given the global nature of their business, the need to be agile, and the integrated nature of the automotive value chain.

Automotive companies also pointed out the value of faster access to new capabilities, helping them get more value from their applications. The cloud gives companies flexibility in the capabilities they adopt and accelerates time to value.

Other Benefits

Other benefits mentioned include lower hardware costs and reduced IT needs. Each of these can provide additional savings. It’s also interesting to note that reduced IT needs gives companies the flexibility to implement solutions faster because they don’t have to wait for internal resource availability.

Other Benefits

Other benefits mentioned include lower hardware costs and reduced IT needs. Each of these can provide additional savings. It’s also interesting to note that reduced IT needs gives companies the flexibility to implement solutions faster because they don’t have to wait for internal resource availability.

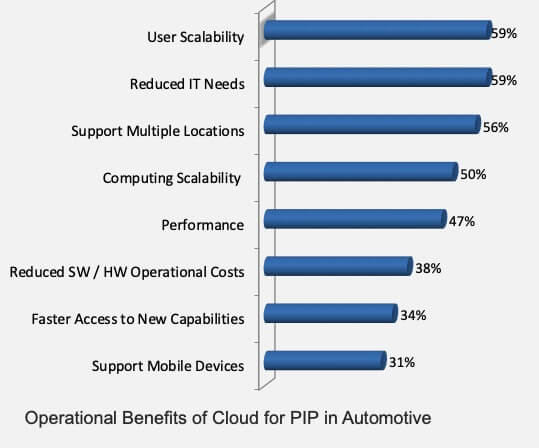

Cloud Benefits Improve the Business, not Just IT

Ease of supporting multiple locations is reported by over one-half of participants. This can be a significant benefit for companies with global footprints that must support multiple sites. In addition, about one-third mention ease of supporting mobile devices. These results highlight the fact that the cloud makes accessing solutions easier, helping companies take advantage of their applications to improve the business. These factors also enable easier collaboration that can help drive the quality, innovation, reliability, performance, and cost improvements that automotive companies seek.

Lastly, it's an interesting note that about one-third observe that the cloud helps them get faster access to new capabilities - again helping companies be more nimble and get greater value from their applications.

Cloud Benefits Improve the Business, not Just IT

Ease of supporting multiple locations is reported by over one-half of participants. This can be a significant benefit for companies with global footprints that must support multiple sites. In addition, about one-third mention ease of supporting mobile devices. These results highlight the fact that the cloud makes accessing solutions easier, helping companies take advantage of their applications to improve the business. These factors also enable easier collaboration that can help drive the quality, innovation, reliability, performance, and cost improvements that automotive companies seek.

Lastly, it's an interesting note that about one-third observe that the cloud helps them get faster access to new capabilities - again helping companies be more nimble and get greater value from their applications.

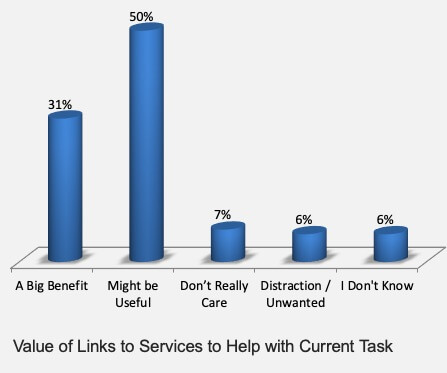

Automotive Companies Value New Services

Automotive companies have a very positive view on the value of services that could help them with their current task. The vast majority say these services might be useful or a big benefit, while very few share indifference or a belief that it would be distracting.

The Cloud Provides Targeted Services

Cloud software can provide targeted help because it’s aware of the function that users are performing and can provide tailored offers. It can also dynamically link to the right sources of assistance in a marketplace format, to help bring people together.

Finding help where it’s easy for people to connect via the Internet when they need something can be much more expedient than a typical search and procurement process. This is another area that can help companies deliver the quality, innovation, reliability, performance, and cost improvements they need to succeed.

Automotive Companies Value New Services

Automotive companies have a very positive view on the value of services that could help them with their current task. The vast majority say these services might be useful or a big benefit, while very few share indifference or a belief that it would be distracting.

The Cloud Provides Targeted Services

Cloud software can provide targeted help because it’s aware of the function that users are performing and can provide tailored offers. It can also dynamically link to the right sources of assistance in a marketplace format, to help bring people together.

Finding help where it’s easy for people to connect via the Internet when they need something can be much more expedient than a typical search and procurement process. This is another area that can help companies deliver the quality, innovation, reliability, performance, and cost improvements they need to succeed.

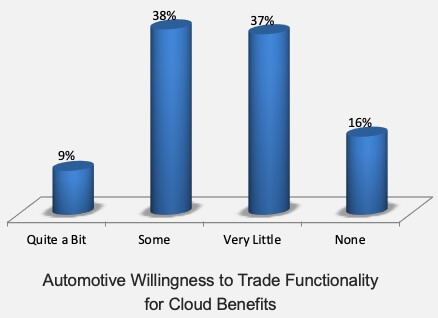

Mature Cloud PIP is now Available for Automotive

We believe taking this “software first” approach is the right priority for Automotive companies, because software capabilities provide the benefits of the Product Innovation Platform, including the highest success and profitability factors – quality, innovation, reliability, performance, and product cost. Now, Automotive companies can leverage robust PIP capabilities on the cloud.

Mature Cloud PIP is now Available for Automotive

We believe taking this “software first” approach is the right priority for Automotive companies, because software capabilities provide the benefits of the Product Innovation Platform, including the highest success and profitability factors – quality, innovation, reliability, performance, and product cost. Now, Automotive companies can leverage robust PIP capabilities on the cloud.

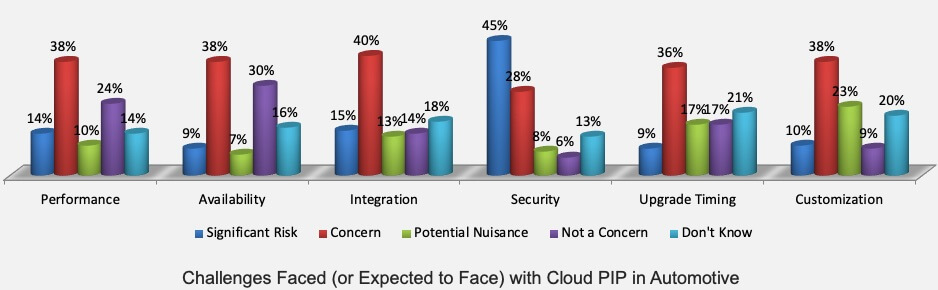

Other Concerns

There are other concerns as well, but none that were reported as a significant risk by more than 15% of respondents. Companies should still pay attention to these needs and consider including key performance criteria in Service Level Agreements (SLAs) that incent providers to perform in these areas.

Automotive companies adopting the cloud will likely have to adjust their approach to upgrades, integration, and customization to work with their deployment option. But these solutions are well known as cloud experience across multiple domains has become commonplace.

Other Concerns

There are other concerns as well, but none that were reported as a significant risk by more than 15% of respondents. Companies should still pay attention to these needs and consider including key performance criteria in Service Level Agreements (SLAs) that incent providers to perform in these areas.

Automotive companies adopting the cloud will likely have to adjust their approach to upgrades, integration, and customization to work with their deployment option. But these solutions are well known as cloud experience across multiple domains has become commonplace.

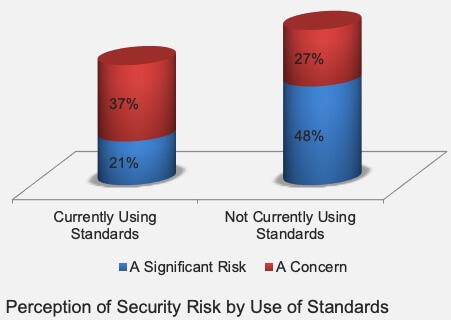

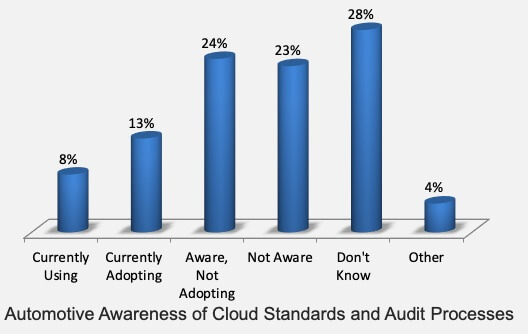

Lack of Awareness of Standards and Audits

About one-quarter of respondents say their company is unaware of cloud standards and audits. About another one-quarter are aware but not adopting them. Over another one-quarter say they don’t know if their company is aware of them. Implementing standards and audits is a clear opportunity for education and improvement that can help mitigate security risk.

Lack of Awareness of Standards and Audits

About one-quarter of respondents say their company is unaware of cloud standards and audits. About another one-quarter are aware but not adopting them. Over another one-quarter say they don’t know if their company is aware of them. Implementing standards and audits is a clear opportunity for education and improvement that can help mitigate security risk.

Based on this research and our experience, we recommend that Automotive companies:

Based on this research and our experience, we recommend that Automotive companies:

[post_title] => Automotive Industry Adopting Cloud Innovation Platforms (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => auto-cloud

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:17

[post_modified_gmt] => 2022-11-15 03:28:17

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7972

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 7965

[post_author] => 2

[post_date] => 2019-07-01 16:59:55

[post_date_gmt] => 2019-07-01 20:59:55

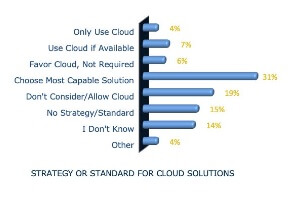

[post_content] => What unique value does the cloud offer to companies using product innovation and engineering software? Our research identifies five categories of cloud benefits and finds some areas where the cloud really stands out for product innovation platforms.

[post_title] => Automotive Industry Adopting Cloud Innovation Platforms (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => auto-cloud

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:17

[post_modified_gmt] => 2022-11-15 03:28:17

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7972

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 7965

[post_author] => 2

[post_date] => 2019-07-01 16:59:55

[post_date_gmt] => 2019-07-01 20:59:55

[post_content] => What unique value does the cloud offer to companies using product innovation and engineering software? Our research identifies five categories of cloud benefits and finds some areas where the cloud really stands out for product innovation platforms.