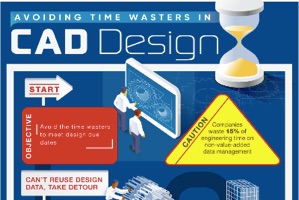

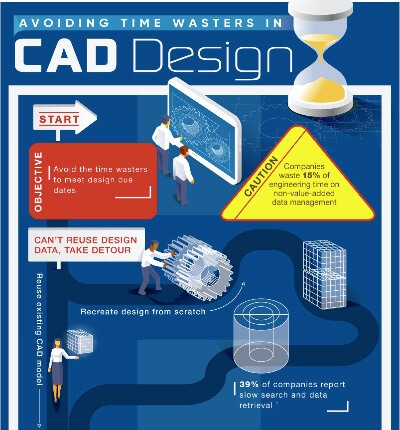

How can engineers avoid wasting precious design time on non-value-added data management tasks? Take a look at our new infographic Avoiding Time Wasters in CAD Design to see a graphical representation of our research. The “CAD Design Challenge” turns design into a board game that highlights key time wasters in design and the best practices…

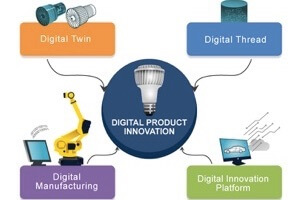

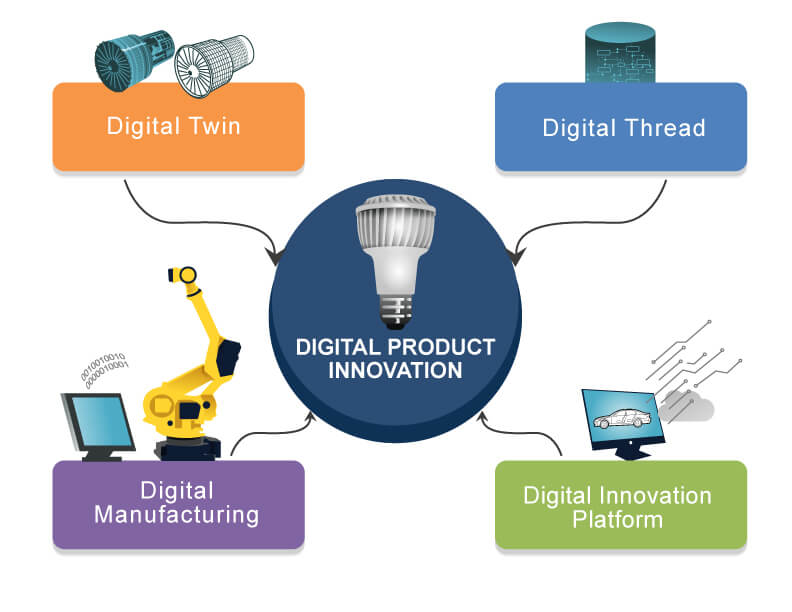

- Digital Twin

- Digital Thread

- Digital Manufacturing

- Digital Innovation Platform

Read More

Please click the synopsis below to read the full guest post on digital transformation for innovation including:- The four pillars of digital innovation

- How to understand your digital innovation maturity

- How to benchmark your maturity and get customized recommendations

- An invitation to take the assessment to benchmark your company

- Next steps

IT/OT convergence is beneficial and while mindsets must change, today's technologies make it possible to converge plant data.[/caption]

How can plants leverage all of their data more effectively? One foundation is for IT and OT to converge. But that does not have to be far in the future. My guest blog Practical Approaches to IT/OT Convergence discusses why and how to tear down the wall between manufacturing engineering and their operational technology (OT) and IT and their information technology (IT).

For the full post, please visit the Critical Manufacturing blog.

Blog topics:

IT/OT convergence is beneficial and while mindsets must change, today's technologies make it possible to converge plant data.[/caption]

How can plants leverage all of their data more effectively? One foundation is for IT and OT to converge. But that does not have to be far in the future. My guest blog Practical Approaches to IT/OT Convergence discusses why and how to tear down the wall between manufacturing engineering and their operational technology (OT) and IT and their information technology (IT).

For the full post, please visit the Critical Manufacturing blog.

Blog topics:

- Benefits of better IT/OT convergence, which are many and proven

- How current technologies can support this convergence at every stage of data:

- Gathering data effectively

- Putting IT and OT data into context

- Gaining consistent access

- Increasing visibility into performance

- Practical questions to ask to explore your next steps toward IT/OT convergence

TABLE OF CONTENTS*

- Opportunities for Better Plastic Parts

- How Do You Stay Competitive

- Common Design Challenges

- The Impact of Manufacturing Defects

- Where to Focus to Improve Part and Mold Design

- The Needs of Part and Mold Designers

- Conclusions

- Recommendations

- About the Research

- Acknowledgements

Opportunities for Better Plastic Parts

Lower the Cost of Quality

What’s the cost of poor-quality plastic parts? Tech-Clarity research finds that part quality is critical to product success, yet manufacturing defects in plastic parts is one of the top issues that negatively impacts product competitiveness. Unfortunately, it is hard to avoid manufacturing defects as 96% of surveyed manufacturers report finding them during mold trials. The cost is quite high as manufacturers find

that correcting these defects during the mold trial adds 26% to the total cost of the mold. Imagine if you could lower some of that cost by making better decisions during design to avoid those issues before the mold trial?

This research study, based on a survey of 265 manufacturers, examines common challenges with plastic part and mold design, their impacts, and how to overcome them. The research reveals five best practices to help you ensure your plastic parts will be produced as designed.

Lower the Cost of Quality

What’s the cost of poor-quality plastic parts? Tech-Clarity research finds that part quality is critical to product success, yet manufacturing defects in plastic parts is one of the top issues that negatively impacts product competitiveness. Unfortunately, it is hard to avoid manufacturing defects as 96% of surveyed manufacturers report finding them during mold trials. The cost is quite high as manufacturers find

that correcting these defects during the mold trial adds 26% to the total cost of the mold. Imagine if you could lower some of that cost by making better decisions during design to avoid those issues before the mold trial?

This research study, based on a survey of 265 manufacturers, examines common challenges with plastic part and mold design, their impacts, and how to overcome them. The research reveals five best practices to help you ensure your plastic parts will be produced as designed.

How Do You Stay Competitive?

Getting Ahead

What's most important to winning your customer’s business? It doesn't matter if you are designing plastic parts or the mold; companies indicate quality, cost, and reliability are most important (see lower graph). Unfortunately, if you don't meet these objectives, not only will you fail to win new business, but the final product will be less competitive.

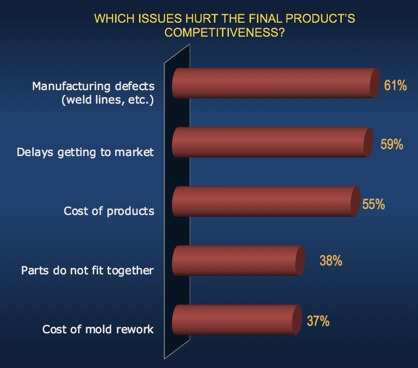

What Hurts Competitiveness?

If you can't produce plastic parts as designed, the entire product will be less successful. Companies rate manufacturing defects as the top issue to negatively impact competitiveness. Defects can range from cosmetic problems such as flow lines or burn marks to more severe issues that hurt the structural integrity. These problems ultimately gives customers the impression that the product suffers from poor quality.

Other resulting issues include market delays and excess cost. Problems found during the mold trial will contribute to both of these issues as the troubleshooting, reworking of the mold, or part design changes consume both time and budget. During that time, a competitor may beat you to market, or you may have a reduced window of opportunity to collect revenue. Excess costs either cut into profitability or dictate a less competitive price.

Improve Design

These problems reflect poorly on the entire product. Even an exceptional design will not realize its full market potential if the plastic parts give the impression the product is inferior. It’s critical to properly design plastic parts and ensure the mold produces them as designed.

Getting Ahead

What's most important to winning your customer’s business? It doesn't matter if you are designing plastic parts or the mold; companies indicate quality, cost, and reliability are most important (see lower graph). Unfortunately, if you don't meet these objectives, not only will you fail to win new business, but the final product will be less competitive.

What Hurts Competitiveness?

If you can't produce plastic parts as designed, the entire product will be less successful. Companies rate manufacturing defects as the top issue to negatively impact competitiveness. Defects can range from cosmetic problems such as flow lines or burn marks to more severe issues that hurt the structural integrity. These problems ultimately gives customers the impression that the product suffers from poor quality.

Other resulting issues include market delays and excess cost. Problems found during the mold trial will contribute to both of these issues as the troubleshooting, reworking of the mold, or part design changes consume both time and budget. During that time, a competitor may beat you to market, or you may have a reduced window of opportunity to collect revenue. Excess costs either cut into profitability or dictate a less competitive price.

Improve Design

These problems reflect poorly on the entire product. Even an exceptional design will not realize its full market potential if the plastic parts give the impression the product is inferior. It’s critical to properly design plastic parts and ensure the mold produces them as designed.

Recommendations

Recommendations and Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Facilitate collaboration between part and mold designers. Mold designers can provide insight to optimize the part design for injection molding, and part designers can clarify part requirements for the mold designer.

- Use technology to supplement experience. Modern software tools contain many automated features that will guide designers.

- Support design for manufacturability with injection molding simulation. Injection molding simulation will catch many manufacturing defects during design so that you can correct them early on, reducing the number of problems found during the mold trial.

- Use injection molding simulation early and regularly. The earlier you use injection molding simulation during part design, the more you can optimize the part for injection molding, so there is less risk of manufacturing defects, and the mold design can optimize cycle time.

- Integrate injection molding simulation and design. An integrated solution streamlines the process of preparing the design model for analysis, reducing a barrier to simulation.

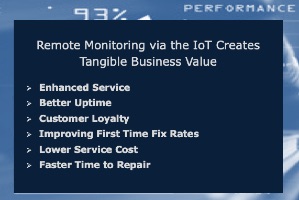

How has one of the largest integrated suppliers to the wood processing industry used the IoT to digitally transform their business and deliver new revenue? Learn how BID Group has improved throughput and performance for their customers by remotely monitoring their equipment through the IoT. Join this interactive IndustryWeek webcast, How BID Group Delivers New Revenue and Customer Value with the IoT, to hear Tech-Clarity's Jim Brown and Bid Group's Sefton Jubenvile discuss IoT remote monitoring goals, value, success, and adoption. Jim will discuss perspectives from Tech-Clarity's recent Service Transformation by Monitoring Customer Equipment eBook and Sefton will share his experience helping transform BID Group into a digital business.

Register for the PTC sponsored IndustryWeek webcast now (registration required).

Synopsis

How has one of the largest integrated suppliers to the wood processing industry used the IoT to digitally transform their business and deliver new revenue? Learn how BID Group has improved throughput and performance for their customers by remotely monitoring their equipment through the IoT. Join this interactive IndustryWeek webcast, How BID Group Delivers New Revenue and Customer Value with the IoT, to hear Tech-Clarity's Jim Brown and Bid Group's Sefton Jubenvile discuss IoT remote monitoring goals, value, success, and adoption. Jim will discuss perspectives from Tech-Clarity's recent Service Transformation by Monitoring Customer Equipment eBook and Sefton will share his experience helping transform BID Group into a digital business.

Register for the PTC sponsored IndustryWeek webcast now (registration required).

Synopsis

- How BID Group developed a solid digital transformation strategy for service verse building an in-house solution

- The importance of listening to customers and how to best incorporate those insights into a solution to guarantee added value

- The value of their production health module and how this improves customer satisfaction

- The unique benefits that are passed on to customers to improve mill efficiency and profitability

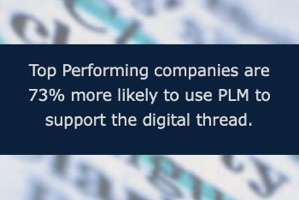

How can PLM enable manufacturers to streamline engineering and create digital continuity with a cohesive digital thread? What should they look for in a PLM system to support their digital thread initiative? Our new eBook, Choosing the Right Enterprise PLM to Support the Digital Thread, shares survey results analyzing the value of the digital thread and shares requirements to achieve the practices of top-performing companies.

Please enjoy the summary below. For the full report, please visit our sponsor PTC (registration required).

How can PLM enable manufacturers to streamline engineering and create digital continuity with a cohesive digital thread? What should they look for in a PLM system to support their digital thread initiative? Our new eBook, Choosing the Right Enterprise PLM to Support the Digital Thread, shares survey results analyzing the value of the digital thread and shares requirements to achieve the practices of top-performing companies.

Please enjoy the summary below. For the full report, please visit our sponsor PTC (registration required).

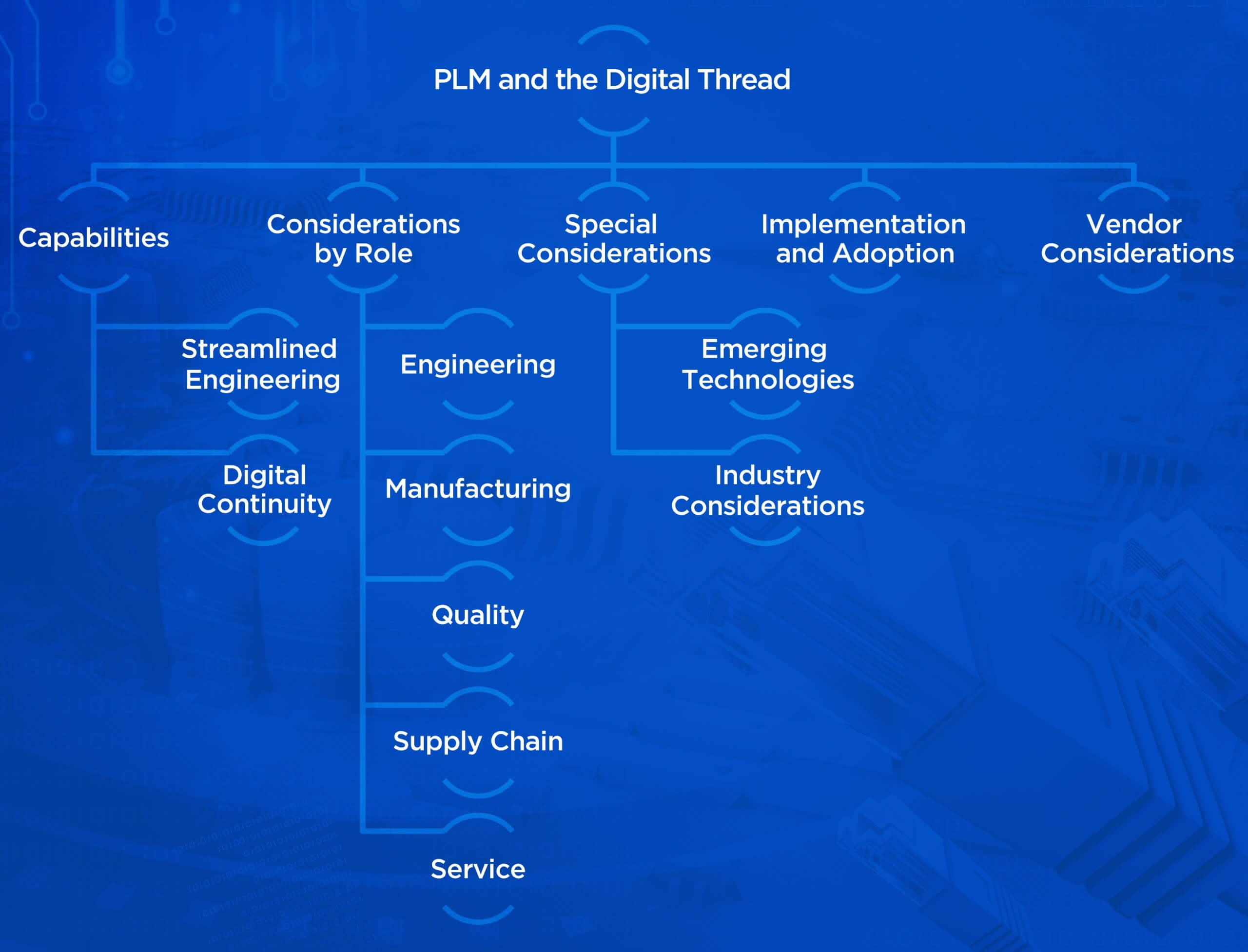

Table of Contents

- Choosing the Right PLM

- Introducing the Buyer’s Guide

- The Digital Thread Imperative

- What to Look for to Streamline Engineering

- What to Look for to Create Digital Continuity

- Digital Thread Business Value

- Considerations by Role – Engineering

- Considerations by Role – Manufacturing

- Considerations by Role – Quality

- Considerations by Role – IT

- Considerations by Role – Service

- PLM is the Digital Thread Backbone

- Special Considerations – Emerging Technologies

- Special Considerations – Industry Requirements

- Implementation Considerations

- Vendor Considerations

- Conclusions and Next Steps

- About the Research

- Acknowledgments

Introducing the PLM for Digital Thread Buyer's Guide

Digital Thread and PLM Survey Highlights A recent survey of over 250 manufacturers and engineering firms highlights the strategic value of the digital thread and the vital role that PLM plays to achieving their objectives. In fact, over three-quarters of manufacturers view the digital thread as either important or critical to achieving their business strategy. Structure of this Guide This buyer’s guide analyzes the strategic value of the digital thread and then shares the things companies should consider when choosing a supporting solution. The guide shares functional requirements needed to streamline engineering and create digital continuity across the product lifecycle. It also shares some critical things to look for by key roles in the manufacturing enterprise. The guide then goes beyond functional considerations to identify special considerations, vendor requirements, and important factors to ensure successful implantation and adoption.

The Digital Thread Imperative

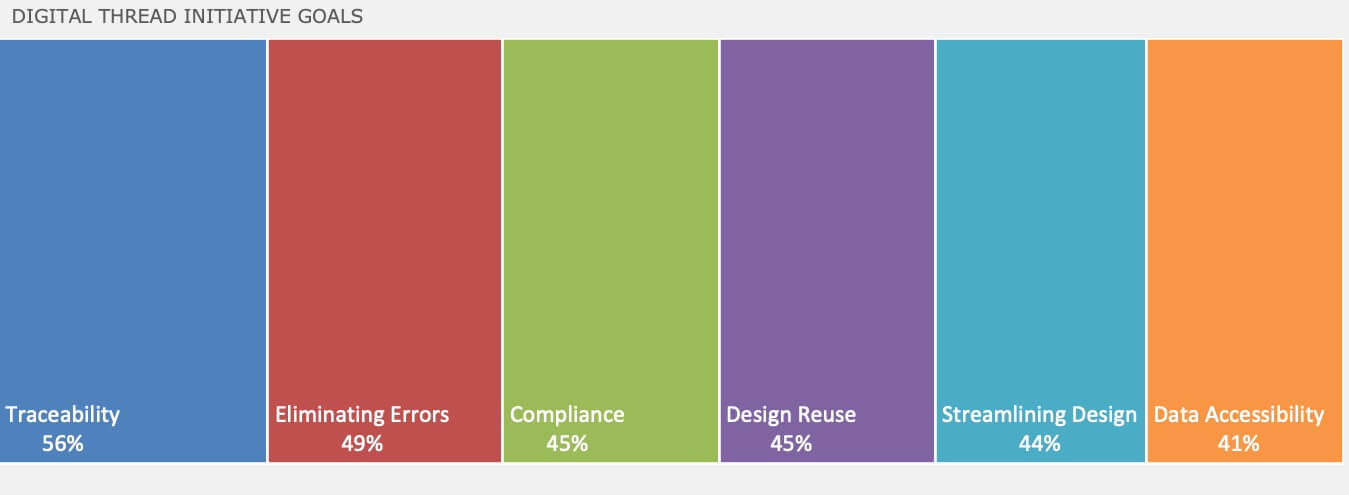

Business Strategies Demand a Cohesive Digital Thread Over three-quarters of companies say that the digital thread is either important or critical to achieving their business strategy. Surveyed companies report a variety of important goals for their digital thread initiative (see chart). The range of goals highlights the many potential digital thread benefits. While definitions vary, there are two primary values of the digital thread; streamlined engineering and digital continuity. Streamlined Engineering

The digital thread streamlines design by allowing product development teams to share and reuse design data across the stages of innovation. Design continuity along the digital thread allows designers to add their design information to a cohesive design model, directly incorporating and extending design data from prior steps.

Digital Continuity

The digital thread ties product information, decisions, and history together in a structured, integrated way that captures product innovation and knowledge throughout the product lifecycle. It establishes traceability from early in the front end of innovation through development, manufacturing, service, and field operation.

Streamlined Engineering

The digital thread streamlines design by allowing product development teams to share and reuse design data across the stages of innovation. Design continuity along the digital thread allows designers to add their design information to a cohesive design model, directly incorporating and extending design data from prior steps.

Digital Continuity

The digital thread ties product information, decisions, and history together in a structured, integrated way that captures product innovation and knowledge throughout the product lifecycle. It establishes traceability from early in the front end of innovation through development, manufacturing, service, and field operation.

Conclusions and Next Steps

Invest in the Digital Thread

Invest in the digital thread to streamline engineering and create digital continuity. Top Performers are 2.6 times as likely to view the digital thread as critical to supporting their business strategy.

Extend the Thread across the Lifecycle

Adopt a comprehensive scope that incorporates cross-departmental data. Top Performers are more likely to include manufacturing, quality, and service plans in the scope of their digital thread, and enrich it with actual data from the IoT.

Leverage PLM as the Digital Manufacturing Backbone

Adopt PLM to support the digital thread. Top Performing companies are 2.4 times as likely to view PLM as critical to supporting the digital thread and are much more likely to use PLM to support the digital thread.

Enjoy the Benefits

The digital thread provides significant, measurable benefits including, increased engineering efficiency, improved quality, faster time to market, enhanced innovation, and better compliance. Top Performers gain even higher benefits than others. For example, these more successful product developers enable their technical resources to spend 27% more time, on average, on value-added activities than their poorer performing counterparts.

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Choosing PLM for Digital Thread Initiatives (buyer's guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-for-digital-thread

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:01

[post_modified_gmt] => 2022-11-15 03:28:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8609

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 8595

[post_author] => 2

[post_date] => 2020-03-05 16:01:43

[post_date_gmt] => 2020-03-05 21:01:43

[post_content] =>

Invest in the Digital Thread

Invest in the digital thread to streamline engineering and create digital continuity. Top Performers are 2.6 times as likely to view the digital thread as critical to supporting their business strategy.

Extend the Thread across the Lifecycle

Adopt a comprehensive scope that incorporates cross-departmental data. Top Performers are more likely to include manufacturing, quality, and service plans in the scope of their digital thread, and enrich it with actual data from the IoT.

Leverage PLM as the Digital Manufacturing Backbone

Adopt PLM to support the digital thread. Top Performing companies are 2.4 times as likely to view PLM as critical to supporting the digital thread and are much more likely to use PLM to support the digital thread.

Enjoy the Benefits

The digital thread provides significant, measurable benefits including, increased engineering efficiency, improved quality, faster time to market, enhanced innovation, and better compliance. Top Performers gain even higher benefits than others. For example, these more successful product developers enable their technical resources to spend 27% more time, on average, on value-added activities than their poorer performing counterparts.

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Choosing PLM for Digital Thread Initiatives (buyer's guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-for-digital-thread

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:01

[post_modified_gmt] => 2022-11-15 03:28:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8609

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 8595

[post_author] => 2

[post_date] => 2020-03-05 16:01:43

[post_date_gmt] => 2020-03-05 21:01:43

[post_content] =>  What should manufacturers look for in a solution to digitalize and transform service through IoT remote monitoring? What can they do to change the relationship they have with their products and customers to increase business value for themselves and those using their products?

Join this interactive webcast, How to Select the Right Digital Transformation Solution, to hear Tech-Clarity's Jim Brown and PTC's Jon Kadane discuss IoT remote monitoring goals, value, and adoption requirements. Jim will discuss perspectives from his recent Service Transformation by Monitoring Customer Equipment eBook and Jon will share related experience working with customers.

Register for the PTC sponsored webcast replay now (registration required).

Synopsis

What should manufacturers look for in a solution to digitalize and transform service through IoT remote monitoring? What can they do to change the relationship they have with their products and customers to increase business value for themselves and those using their products?

Join this interactive webcast, How to Select the Right Digital Transformation Solution, to hear Tech-Clarity's Jim Brown and PTC's Jon Kadane discuss IoT remote monitoring goals, value, and adoption requirements. Jim will discuss perspectives from his recent Service Transformation by Monitoring Customer Equipment eBook and Jon will share related experience working with customers.

Register for the PTC sponsored webcast replay now (registration required).

Synopsis

Julie Fraser here, and if you came in through Iyno Advisors, let me explain why I’m so excited to be part of Tech-Clarity now.

Julie Fraser here, and if you came in through Iyno Advisors, let me explain why I’m so excited to be part of Tech-Clarity now.

- Focus on making the business value of technology clear

- Greater visibility in the market and more activity on the website

- Better capabilities to conduct original research

- Broader focus on the full lifecycle of manufacturing enterprise software needs from concept, engineering and planning through manufacturing and service

- Video and other multi-media approaches as well as papers and webcasts

- An amazing team with deep expertise and values I share

Is your company prepared to respond to the critical business issues facing the high-tech industry? What key issues must your business prepare for in this fast paced high-tech market?

Tech-Clarity’s Solving High-Tech’s Top Six Critical Business Issues eBook identifies the top six critical business issues that high-tech companies should address. This will help them respond to market disruption and to stay relevant. As new technologies such as 5G, artificial intelligence, machine learning, quantum computing, and others create opportunities for innovation, there is even more pressure on development teams. The pace of innovation is so fast, high-tech development teams cannot afford to be hindered by process bottlenecks.. This eBook provides recommendations and guidance to enable greater agility to help high-tech companies stay competitive.

Please enjoy the summary* below. For the full report, please visit our sponsor SOLIDWORKS (registration required).

Is your company prepared to respond to the critical business issues facing the high-tech industry? What key issues must your business prepare for in this fast paced high-tech market?

Tech-Clarity’s Solving High-Tech’s Top Six Critical Business Issues eBook identifies the top six critical business issues that high-tech companies should address. This will help them respond to market disruption and to stay relevant. As new technologies such as 5G, artificial intelligence, machine learning, quantum computing, and others create opportunities for innovation, there is even more pressure on development teams. The pace of innovation is so fast, high-tech development teams cannot afford to be hindered by process bottlenecks.. This eBook provides recommendations and guidance to enable greater agility to help high-tech companies stay competitive.

Please enjoy the summary* below. For the full report, please visit our sponsor SOLIDWORKS (registration required).

TABLE OF CONTENTS*

- Opportunities and Threats for High-Tech Companies

- The Speed of Innovation in High-Tech

- High-Tech Business Drivers

- Product Challenges Facing High-Tech

- How to Address the 6 Business Issues

- 1. Take Cost Out

- 2. Avoid Quality Problems

- 3. Enable Higher Productivity and Operational Agility

- 4. Facilitate Innovation

- 5. Ensure Performance and Reliability

- 6. Comply with Environmental and Regulatory Requirements

- Conclusions

- Acknowledgement

The Speed of Innovation in High-Tech

Technology Is Disruptive

Imagine all the ways technology has impacted our lives. It can be mind-boggling. Just think, how many high-tech products do you rely on every day that didn’t even exist not so long ago? Can you imagine life without the internet, smart phones, or a GPS? Not only are those relatively newer technologies commonplace, they’ve led to numerous other high-tech businesses, many of which have been disruptive.

It Is Hard to Stay Relevant

It is hard to believe today’s high school students don’t remember a world without the iPhone or have no concept of waiting to develop film after a family vacation. At the same time, some of today’s hottest products will eventually meet the same fate as the Walkman and VHS player, products we could not live without in the 80s, but are completely irrelevant today. In the high-tech industry, if you are unable to rapidly respond to today’s critical business issues, you risk becoming tomorrow’s Palm, the first company to produce personal digital assistants (PDAs), but it did too little, too late to maintain its market share. Interestingly, a study conducted by Innosight projects that nearly 50% of the current S&P 500 will be replaced over the next decade. Consequently, high-tech companies should take the right steps now to avoid that fate.

Implement Solutions for Today’s Critical Business Issues

The number of companies expected to fail highlights that too many companies rely on their current success. They avoid putting solutions in place for today’s critical business issues. Unfortunately, old approaches that helped you get by in the past, may no longer be enough. The significant competitive pressure leaves little room for missteps, so it is critical that you address these important issues to position your company to win.

Technology Is Disruptive

Imagine all the ways technology has impacted our lives. It can be mind-boggling. Just think, how many high-tech products do you rely on every day that didn’t even exist not so long ago? Can you imagine life without the internet, smart phones, or a GPS? Not only are those relatively newer technologies commonplace, they’ve led to numerous other high-tech businesses, many of which have been disruptive.

It Is Hard to Stay Relevant

It is hard to believe today’s high school students don’t remember a world without the iPhone or have no concept of waiting to develop film after a family vacation. At the same time, some of today’s hottest products will eventually meet the same fate as the Walkman and VHS player, products we could not live without in the 80s, but are completely irrelevant today. In the high-tech industry, if you are unable to rapidly respond to today’s critical business issues, you risk becoming tomorrow’s Palm, the first company to produce personal digital assistants (PDAs), but it did too little, too late to maintain its market share. Interestingly, a study conducted by Innosight projects that nearly 50% of the current S&P 500 will be replaced over the next decade. Consequently, high-tech companies should take the right steps now to avoid that fate.

Implement Solutions for Today’s Critical Business Issues

The number of companies expected to fail highlights that too many companies rely on their current success. They avoid putting solutions in place for today’s critical business issues. Unfortunately, old approaches that helped you get by in the past, may no longer be enough. The significant competitive pressure leaves little room for missteps, so it is critical that you address these important issues to position your company to win.

Product Challenges Facing High-Tech

The Unique Challenges for High-Tech To address these business issues, there are several challenges high-tech companies must consider to succeed. The difficulties arise from unique design trends in the high-tech industry. Miniaturization One key design trend is miniaturization. While electronics get smaller and smaller, more innovative features and function must be packed into those tiny packages. Miniaturization leads to greater complexity and very dense packaging. The situation is only going to get harder as Tech-Clarity research3 finds that 56% of high-tech companies continue to feel pressure to incorporate even more software and electronics into their products over the next five years. Increased density brings with it more challenges as engineers have to manage heat. With heat being a leading cause of electronics failure, cooling solutions become a critical design requirement. Smarter and More Connected Products Another key trend is that products are becoming smarter and more connected. Product intelligence requires more engineering disciplines, making collaboration across the team critical, especially to overcome the inherent silos within engineering disciplines.

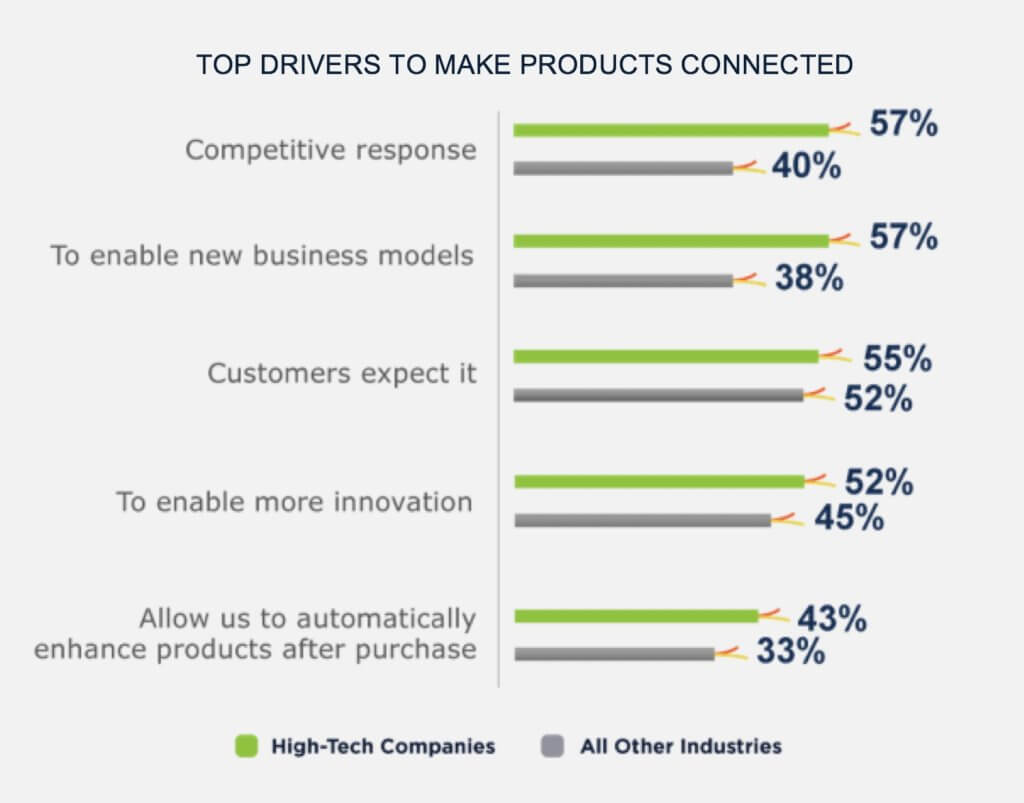

Ignoring this trend is not an option as 50% of high-tech companies report they will lose market share if they don't make their products smarter, and 50% also say they will lose revenue. Further, high-tech companies also feel pressure to make products connected. As can be seen in the graph, 57% of high-tech companies say it is a competitive response which means it is a trend they can not ignore because their competitors are already looking at connectivity. However, while connectivity will make them more competitive, it adds to the complexity and extends the need for excellent collaboration

Another key trend is that products are becoming smarter and more connected. Product intelligence requires more engineering disciplines, making collaboration across the team critical, especially to overcome the inherent silos within engineering disciplines.

Ignoring this trend is not an option as 50% of high-tech companies report they will lose market share if they don't make their products smarter, and 50% also say they will lose revenue. Further, high-tech companies also feel pressure to make products connected. As can be seen in the graph, 57% of high-tech companies say it is a competitive response which means it is a trend they can not ignore because their competitors are already looking at connectivity. However, while connectivity will make them more competitive, it adds to the complexity and extends the need for excellent collaboration

Conclusions

It is a very exciting time for the high-tech industry. Companies have lots of opportunities to innovate with options such as smart and connected products. At the same time, the market moves at a rapid pace. Plus design trends such as miniaturization create unique challenges for high-tech companies. By supporting excellent collaboration with an integrated ECAD/MCAD design environment, companies can overcome many challenges. To address the top critical business issues facing the industry, high-tech companies should focus on the following:- Take cost out

- Avoid quality problems

- Enable Higher Productivity and Operational Agility

- Facilitate Innovation

- Ensure Performance and Reliability

- Comply with Environmental and Regulatory Requirements

Tech-Clarity is pleased to announce that we are expanding our research team and extending our coverage to manufacturing operations software! Industry veteran and long-time research analyst Julie Fraser joins Tech-Clarity as Vice President of Research, Manufacturing Software. Julie brings with her a wealth of depth in manufacturing, scheduling, quality, maintenance, and smart manufacturing. Please visit Julie's bio page for more on her background.

As a team, we look forward to expanding and deepening our coverage of software across the manufacturing lifecycle. New technologies are emerging and existing technologies are converging, allowing manufacturers to digitally transform their business. Leading manufacturers are eliminating the gaps between product innovation, product development, engineering, manufacturing, and service. Today's leading software vendors are expanding their product portfolios to support this trend, developing comprehensive solution portfolios across the product lifecycle. Product Innovation Platforms offering CAD, CAE, PDM, and PLM are aligning and integrating much more closely with manufacturing operations solutions including MES / MOM, QMS, and more. "This is a strategic move," explains Jim Brown, President and Founder of Tech-Clarity. "As manufacturers integrate engineering and manufacturing operations, it's important for us to cover a broader perspective of the manufacturing and engineering systems landscape. Julie brings great experience and credibility, we are excited to have such a proven analyst join our team to help continue our mission of making the value of technology clear.”

Julie’s research focus will include smart manufacturing, Industry 4.0, manufacturing, quality, maintenance, scheduling, and related technologies. Please follow Julie on Twitter and join our mailing list to read Julie’s research.

For more information or to schedule a briefing please feel free to contact us.

[post_title] => Tech-Clarity adds Manufacturing Software Analyst Julie Fraser

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => fraser-joins

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-15 09:57:33

[post_modified_gmt] => 2022-11-15 14:57:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8548

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 8563

[post_author] => 2

[post_date] => 2020-02-07 18:13:21

[post_date_gmt] => 2020-02-07 23:13:21

[post_content] =>

Tech-Clarity is pleased to announce that we are expanding our research team and extending our coverage to manufacturing operations software! Industry veteran and long-time research analyst Julie Fraser joins Tech-Clarity as Vice President of Research, Manufacturing Software. Julie brings with her a wealth of depth in manufacturing, scheduling, quality, maintenance, and smart manufacturing. Please visit Julie's bio page for more on her background.

As a team, we look forward to expanding and deepening our coverage of software across the manufacturing lifecycle. New technologies are emerging and existing technologies are converging, allowing manufacturers to digitally transform their business. Leading manufacturers are eliminating the gaps between product innovation, product development, engineering, manufacturing, and service. Today's leading software vendors are expanding their product portfolios to support this trend, developing comprehensive solution portfolios across the product lifecycle. Product Innovation Platforms offering CAD, CAE, PDM, and PLM are aligning and integrating much more closely with manufacturing operations solutions including MES / MOM, QMS, and more. "This is a strategic move," explains Jim Brown, President and Founder of Tech-Clarity. "As manufacturers integrate engineering and manufacturing operations, it's important for us to cover a broader perspective of the manufacturing and engineering systems landscape. Julie brings great experience and credibility, we are excited to have such a proven analyst join our team to help continue our mission of making the value of technology clear.”

Julie’s research focus will include smart manufacturing, Industry 4.0, manufacturing, quality, maintenance, scheduling, and related technologies. Please follow Julie on Twitter and join our mailing list to read Julie’s research.

For more information or to schedule a briefing please feel free to contact us.

[post_title] => Tech-Clarity adds Manufacturing Software Analyst Julie Fraser

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => fraser-joins

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-15 09:57:33

[post_modified_gmt] => 2022-11-15 14:57:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8548

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 8563

[post_author] => 2

[post_date] => 2020-02-07 18:13:21

[post_date_gmt] => 2020-02-07 23:13:21

[post_content] =>

Julie Fraser is the Vice President of Research for Operations for Tech-Clarity. She covers Industry 4.0, Supply Chain, Smart Manufacturing, AI in operations, MES/MOM, QMS, APS, WMS, APM/CMS, IIoT, CFW, IT/OT, AR/VR, and other technologies and solutions for manufacturing and supply chain success.

Julie has over 25 years as an industry analyst in addition to experience in marketing and strategy (Berclain/Baan, now Infor) and editorial roles for computer and technology publications. She worked as an assembler over college summers and that got her hooked on manufacturing. She has a B.A. in German and French, Magna cum laude, Phi Beta Kappa, from Lawrence University in Wisconsin. She has been awarded lifetime membership in MESA International.

Julie’s current areas of research include the realities of moving Industry 4.0 from vision to reality; making supply chains and operations resilient in the face of uncertainty; the role of AI in the new landscape; continuous improvement and transformational change; approaches to empower frontline workers and their leaders; IT/OT convergence; personalized and local manufacturing; and more. She is fascinated by the organizational, cultural and personal transformations required to drive success with new technology and approaches to manufacturing.

Julie is a certified yoga, laughter yoga, and meditation teacher plus a certified business change agent and conscious business ambassador. When she’s in love with life, good things like the opportunity to work for Tech-Clarity come at the right time.

Simulation for design engineers can be a powerful tool to provide directional insight and guide design decisions. But, are your design engineers using the right tool?

When design engineers use the right simulation tool, they can save your company time and lower the cost of innovation. However, the wrong tool can make it significantly harder to realize the potential value. Tech-Clarity’s 6 Issues to Avoid in a Simulation Tool for Design Engineers checklist identifies what a company should avoid when looking for a simulation tool for design engineers.

To learn more, please see the full infographic from our sponsor PTC (no registration required).

For more information, see the related Simulation Buyer’s Guide.

[post_title] => Simulation for Design Engineers: 6 Issues to Avoid

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => issues-to-avoid-simulation-for-design-engineers

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-11 21:02:33

[post_modified_gmt] => 2024-01-12 02:02:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7911

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 8509

[post_author] => 2

[post_date] => 2020-02-04 09:16:23

[post_date_gmt] => 2020-02-04 14:16:23

[post_content] =>

Simulation for design engineers can be a powerful tool to provide directional insight and guide design decisions. But, are your design engineers using the right tool?

When design engineers use the right simulation tool, they can save your company time and lower the cost of innovation. However, the wrong tool can make it significantly harder to realize the potential value. Tech-Clarity’s 6 Issues to Avoid in a Simulation Tool for Design Engineers checklist identifies what a company should avoid when looking for a simulation tool for design engineers.

To learn more, please see the full infographic from our sponsor PTC (no registration required).

For more information, see the related Simulation Buyer’s Guide.

[post_title] => Simulation for Design Engineers: 6 Issues to Avoid

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => issues-to-avoid-simulation-for-design-engineers

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-11 21:02:33

[post_modified_gmt] => 2024-01-12 02:02:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=7911

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 8509

[post_author] => 2

[post_date] => 2020-02-04 09:16:23

[post_date_gmt] => 2020-02-04 14:16:23

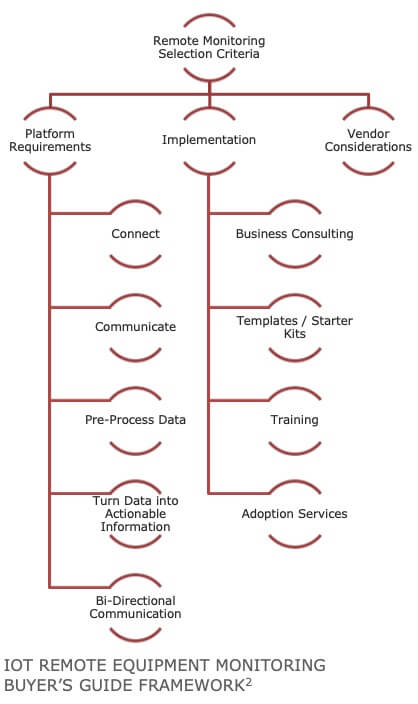

[post_content] =>  How can equipment manufacturers transform their customer and equipment relationships to drive greater value for themselves and their customers? Digital service transformation by monitoring equipment via the IoT holds the key to improving service, satisfaction, and customer success.

Please enjoy the summary below. For the full eBook, please visit our sponsor PTC.

How can equipment manufacturers transform their customer and equipment relationships to drive greater value for themselves and their customers? Digital service transformation by monitoring equipment via the IoT holds the key to improving service, satisfaction, and customer success.

Please enjoy the summary below. For the full eBook, please visit our sponsor PTC.

Table of Contents*

- Digitally Transform Customer Relationships

- Practical First Step: Remote Monitoring

- Connect and Communicate with Equipment

- Put Equipment Data to Work

- Next Steps

- Acknowledgments

Digitally Transform Customer Relationships

Digital Transformation is Critical

Equipment manufacturers are making major business improvements by digitally transforming customer relationships using the Internet of Things (IoT). They’re moving beyond selling a machine to providing ongoing value throughout the life of their product.

Service transformation lowers costs and drives more service revenue. Some companies expand on this value, exploring new business models like selling outcomes versus products or shifting to a predictive service model.

Become a Strategic Partner

Beyond direct financial benefits, digitalizing service allows manufacturers to become a strategic partner by increasing the value their customers gain from their equipment, improving both customer satisfaction and success.

Start with Remote Monitoring

The most common (and achievable) first step is remotely monitoring your equipment in customers’ facilities. This gives you the real-time information you need to quickly identify issues and fix equipment more efficiently, improving service and reducing cost while also supporting high customer productivity.

This eBook shares suggestions on what equipment producers can do to get their machines connected, start gathering data, and put the data to use to improve customer service, satisfaction, and success. Let’s get started!

Digital Transformation is Critical

Equipment manufacturers are making major business improvements by digitally transforming customer relationships using the Internet of Things (IoT). They’re moving beyond selling a machine to providing ongoing value throughout the life of their product.

Service transformation lowers costs and drives more service revenue. Some companies expand on this value, exploring new business models like selling outcomes versus products or shifting to a predictive service model.

Become a Strategic Partner

Beyond direct financial benefits, digitalizing service allows manufacturers to become a strategic partner by increasing the value their customers gain from their equipment, improving both customer satisfaction and success.

Start with Remote Monitoring

The most common (and achievable) first step is remotely monitoring your equipment in customers’ facilities. This gives you the real-time information you need to quickly identify issues and fix equipment more efficiently, improving service and reducing cost while also supporting high customer productivity.

This eBook shares suggestions on what equipment producers can do to get their machines connected, start gathering data, and put the data to use to improve customer service, satisfaction, and success. Let’s get started!

Next Steps

Start Small and Gain Value Quickly Remote monitoring using the IoT can provide rapid value by helping your company gain visibility to your equipment. The value is strategic, but getting started doesn’t need to be intimidating. You can start small and grow value over time. Your investment can provide a valuable foundation to build on as you connect more equipment or implement more advanced features. Select the Right IoT Platform It’s important to find an IoT platform that offers a variety of predefined connectivity and application options so you don’t need to undertake a large integration project from scratch. Find a solution and IoT-savvy partner that can get you started with a simple project, but that offers the business knowledge and advanced tools needed to help you expand on your early success. Get Started

Remote equipment monitoring lets companies reduce service cost, increase service revenue, develop stronger customer relationships, and start the transition to proactive and predictive service. It also increases a company’s value as a strategic partner by allowing them to improve their customers’ productivity. It’s time to get started to improve value for your company and your customers.

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Service Transformation by Monitoring Customer Equipment (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => service-transformation

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:06

[post_modified_gmt] => 2022-11-15 03:28:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8509

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 8500

[post_author] => 2

[post_date] => 2020-01-30 09:49:42

[post_date_gmt] => 2020-01-30 14:49:42

[post_content] =>

Get Started

Remote equipment monitoring lets companies reduce service cost, increase service revenue, develop stronger customer relationships, and start the transition to proactive and predictive service. It also increases a company’s value as a strategic partner by allowing them to improve their customers’ productivity. It’s time to get started to improve value for your company and your customers.

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Service Transformation by Monitoring Customer Equipment (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => service-transformation

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:06

[post_modified_gmt] => 2022-11-15 03:28:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8509

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 8500

[post_author] => 2

[post_date] => 2020-01-30 09:49:42

[post_date_gmt] => 2020-01-30 14:49:42

[post_content] =>  Why should manufacturers make the cloud transition for product innovation and engineering solutions like CAD, Simulation, and PLM? Our research shows it's not what you think.

Why should manufacturers make the cloud transition for product innovation and engineering solutions like CAD, Simulation, and PLM? Our research shows it's not what you think.

Cloud Transition is a Means to an End

The decision on cloud timing varies based on each company’s scenario. The first step in the transition is to understand what your company’s goals are in the first place. The change driver may be reaching the limits of an existing solution, requiring new capabilities to support digital transformation, consolidating acquisitions, or choosing to modernize IT infrastructure. The impetus for moving to the cloud helps set the right objectives. Our prior posts discussed a variety of benefits related to cost, risk, time, and resource requirements. They also looked at some special areas that the cloud offers unique for collaboration and simulation. Cloud innovation and engineering software offers some very tangible value when companies are ready to make the move. But what is the overarching value of adopting cloud product innovation and engineering software? What should you consider for cloud justification? The cloud should not be the driver, in the same way that the goal of a software implementation should never be to “go live” with the software. There has to be some tangible business value. For product innovation and engineering software, what better reason could there be than to improve product innovation and engineering performance? The cloud is a means to an end. The real value is helping manufacturers improve the pace and level of innovationRead More

The post goes further to discuss:- How to improve the pace of innovation (not just of your products, but your engineering processes)

- How to improve the level of innovation (including how your company works and procures solutions)

- What to think about to get started

Join Mailing List

To join our mailing list for survey invitations, newsletters, or other publications please enter your address below:

[post_title] => Register

[post_excerpt] =>

[post_status] => publish

[comment_status] => closed

[ping_status] => closed

[post_password] =>

[post_name] => register

[to_ping] =>

[pinged] =>

[post_modified] => 2020-01-03 18:01:07

[post_modified_gmt] => 2020-01-03 23:01:07

[post_content_filtered] =>

[post_parent] => 24

[guid] => https://tech-clarity.com/?page_id=8492

[menu_order] => 0

[post_type] => page

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 8480

[post_author] => 2

[post_date] => 2019-12-16 09:32:23

[post_date_gmt] => 2019-12-16 14:32:23

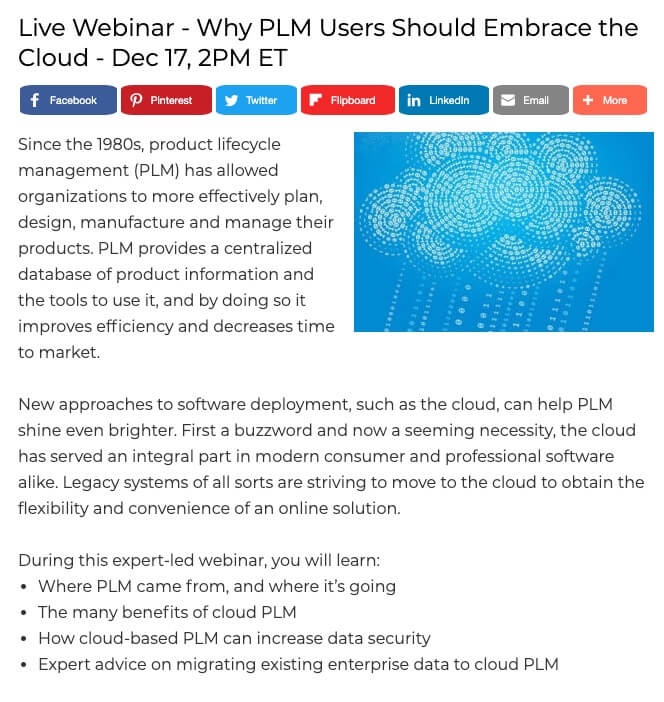

[post_content] => Jim Brown joins an educational cloud PLM webcast sharing the benefits of product lifecycle management solutions and the trend toward cloud PLM adoption. Jim presents with Mohit Daga, SOLIDWORKS Senior Product Portfolio Manager and ENGINEERING.com's Director of Content, Roopinder Tara on this Engineering.com web presentation. The speakers will examine why PLM users should consider cloud PLM and discuss considerations about transitioning critical product data to the cloud.

Engineering.com indicates that PDH Certificates will be provided to all registrants that attend the live cloud PLM webcast for a minimum of 30 minutes. Certificates will be sent by email within 72 hours after completion.

Register for the cloud PLM webcast or the recorded webcast replay on Engineering.com now.

[post_title] => Cloud PLM Webcast with Engineering.com

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-plm-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:56

[post_modified_gmt] => 2022-11-15 03:25:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8480

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 8463

[post_author] => 2

[post_date] => 2019-12-04 12:46:10

[post_date_gmt] => 2019-12-04 17:46:10

[post_content] =>

[post_title] => Cloud PLM Webcast with Engineering.com

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-plm-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:56

[post_modified_gmt] => 2022-11-15 03:25:56

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8480

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 8463

[post_author] => 2

[post_date] => 2019-12-04 12:46:10

[post_date_gmt] => 2019-12-04 17:46:10

[post_content] =>  Is trading off security to enjoy the benefits of the cloud worth it? Is the cloud-security tradeoff necessary? Why are some manufacturers still uneasy about adopting cloud software for product innovation and engineering?

There are clear benefits, but the transition started slowly. For a while, one of the most significant inhibitors to cloud adoption was a lack of “apples to apples” capabilities between traditional applications and those available on the cloud. But that disparity is no longer the issue as the market has evolved. So what’s leaving manufacturers hesitant about cloud migration?

For some companies we speak to, security still makes them uncomfortable starting their cloud transformation. It’s an important issue and one that they must consider. Let’s take a look at how companies perceive the security-cloud benefits tradeoff, the reality of the situation, and what they can do to objectively evaluate risks and rewards.

Read the full guest post in the Digital Transformation section of the Siemens PLM Community blog. The post covers the cloud-security tradeoff and how to evaluate security and mitigate risk in order to enjoy the implementation, operational, business, and strategic benefits of the cloud.

You can also learn more in our Cloud Security Discussion with Siemens EVP Bob Jones video interview.

Please enjoy the latest in a series of Tech-Clarity guest posts including The Subtle Shift to “Why Not Cloud?”, Cloud Engineering Software: More than Just Engineering Software on the Cloud, and Why Not to Justify Cloud Engineering Software.

[post_title] => The Cloud-Security Tradeoff for Product Innovation and Engineering Software (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-security-tradeoff

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:37

[post_modified_gmt] => 2022-11-15 03:25:37

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8463

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 8443

[post_author] => 2

[post_date] => 2019-12-03 10:20:06

[post_date_gmt] => 2019-12-03 15:20:06

[post_content] =>

Is trading off security to enjoy the benefits of the cloud worth it? Is the cloud-security tradeoff necessary? Why are some manufacturers still uneasy about adopting cloud software for product innovation and engineering?

There are clear benefits, but the transition started slowly. For a while, one of the most significant inhibitors to cloud adoption was a lack of “apples to apples” capabilities between traditional applications and those available on the cloud. But that disparity is no longer the issue as the market has evolved. So what’s leaving manufacturers hesitant about cloud migration?

For some companies we speak to, security still makes them uncomfortable starting their cloud transformation. It’s an important issue and one that they must consider. Let’s take a look at how companies perceive the security-cloud benefits tradeoff, the reality of the situation, and what they can do to objectively evaluate risks and rewards.

Read the full guest post in the Digital Transformation section of the Siemens PLM Community blog. The post covers the cloud-security tradeoff and how to evaluate security and mitigate risk in order to enjoy the implementation, operational, business, and strategic benefits of the cloud.

You can also learn more in our Cloud Security Discussion with Siemens EVP Bob Jones video interview.

Please enjoy the latest in a series of Tech-Clarity guest posts including The Subtle Shift to “Why Not Cloud?”, Cloud Engineering Software: More than Just Engineering Software on the Cloud, and Why Not to Justify Cloud Engineering Software.

[post_title] => The Cloud-Security Tradeoff for Product Innovation and Engineering Software (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-security-tradeoff

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:37

[post_modified_gmt] => 2022-11-15 03:25:37

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8463

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 8443

[post_author] => 2

[post_date] => 2019-12-03 10:20:06

[post_date_gmt] => 2019-12-03 15:20:06

[post_content] =>  How can smaller companies and design teams manage CAD data without taking away from their time to innovate and respond to customers? Smaller companies and design teams compete based on innovation and agility but face many of the same challenges in managing 3D CAD files that their larger competitors do. CAD Data Management for Small Companies and Design Teams is designed to help companies with five and fewer designers address CAD Data Management complexity.

Please enjoy the summary below. For the full report, please visit our sponsor SOLIDWORKS (registration required).

How can smaller companies and design teams manage CAD data without taking away from their time to innovate and respond to customers? Smaller companies and design teams compete based on innovation and agility but face many of the same challenges in managing 3D CAD files that their larger competitors do. CAD Data Management for Small Companies and Design Teams is designed to help companies with five and fewer designers address CAD Data Management complexity.

Please enjoy the summary below. For the full report, please visit our sponsor SOLIDWORKS (registration required).

Table of Contents*

Addressing CAD Data Management Complexity

Addressing CAD Data Management Complexity- Managing CAD is Challenging Regardless of Size

- CAD Management Difficulties Hamper Productivity

- The Persistent Struggle with Broken CAD Assemblies

- Smaller Companies Lack the Tools to Manage CAD

- Missed Targets are Common, but not Inevitable

- Managing CAD Helps Even the Smallest Companies

- Automating CAD Processes Improves Performance

- CAD Management Benefits and Research Conclusions

- About the Research

- Acknowledgments

Managing CAD is Challenging Regardless of Size

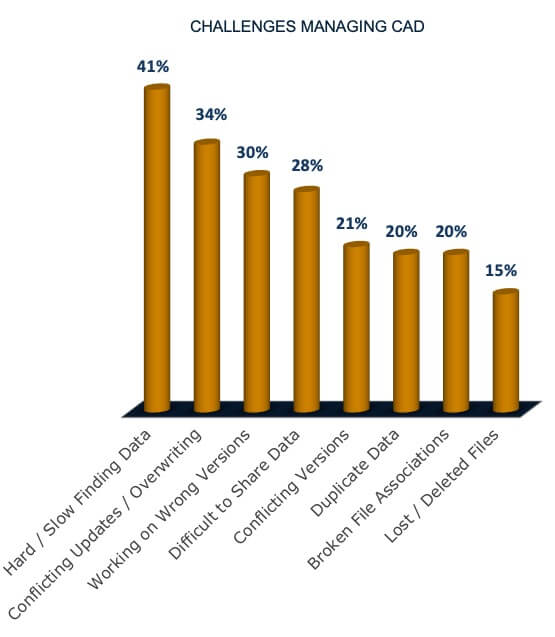

CAD Management Challenges Managing CAD data is challenging. Respondents for this survey indicate that they suffer from typical data management challenges. They report issues with CAD data management basics – controlling, accessing, and sharing design data. The most commonly reported difficulty is searching for information. Far too often, technical resources struggle to find the CAD files they need to do their job. Respondents also face multiple challenges related to managing CAD files, including file conflicts, uncontrolled revisions, file duplication, and data loss. Many companies also report trouble collaborating because of difficulty sharing designs with others. Smaller Companies Suffer as Well

The top CAD management challenges are relatively consistent across engineering teams including those as small as five or fewer engineers. The analysis only uncovered a couple of minor differences between the “five or fewer” respondents and those with twenty or more engineers. Smaller teams are:

Smaller Companies Suffer as Well

The top CAD management challenges are relatively consistent across engineering teams including those as small as five or fewer engineers. The analysis only uncovered a couple of minor differences between the “five or fewer” respondents and those with twenty or more engineers. Smaller teams are:

- 28% more likely to work on the wrong revisions. This is likely because they have less formal processes and tools.

- 40% less likely to have issues with duplicate data. This may be due to the simplicity of their organization and less reuse of designs across regional and organizational boundaries.

CAD Management Difficulties Hamper Productivity

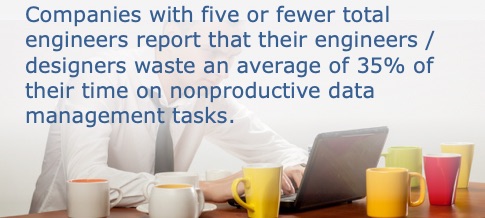

Challenges Cause Business Impacts Data management challenges are certainly frustrating to engineers. In some ways, though, they are so common that many simply consider them the cost of working with 3D CAD. But the impact is more than just an individual nuisance. Low Productivity is the Status Quo

The clear business impact of CAD management challenges is wasted engineering time and effort. This time is spent searching for data and fixing problems. Over three-quarters, (79%) of small companies indicate they struggle with this.

Low Productivity is the Status Quo

The clear business impact of CAD management challenges is wasted engineering time and effort. This time is spent searching for data and fixing problems. Over three-quarters, (79%) of small companies indicate they struggle with this.

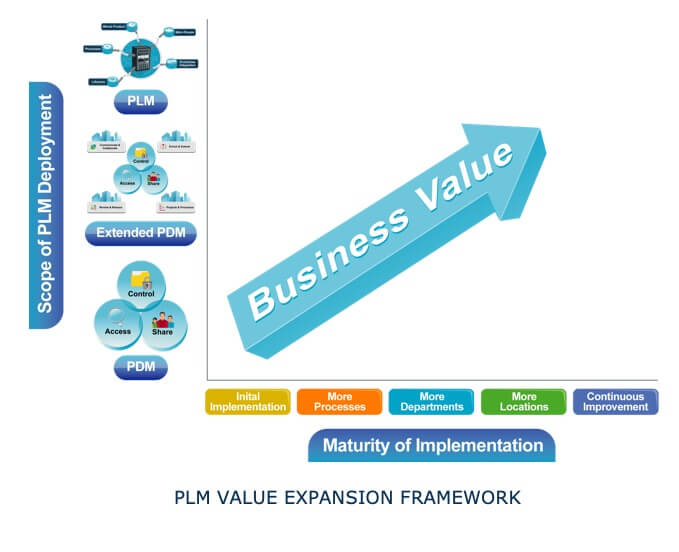

CAD Management Benefits and Research Conclusions

Benefits of CAD Data Management CAD data management solutions provide the ability to control, access, and share CAD data. Extended PDM can go beyond this and offers greater value to include more communication / collaboration, enriched / extended product data, process automation, and a project / program focus. PLM offers even broader benefits. Those with Five or Fewer Engineers Report Important Benefits Companies with five or fewer engineers leverage a variety of design data management solutions ranging from core CAD management to PLM. Responses to an open ended question on benefits show that they primarily perceive the value of the basics – keeping data under control, making it easy to find, and being able to share it with others. The results reported include improved design efficiency and throughput.

Conclusion

Survey analysis leads us to conclude that design data management solutions including PDM, PLM, or more focused CAD / Engineering Data Management solutions help even the smallest companies hit their product development targets.

Recommendations

Based on our experience and the results of this research, we recommend that:

Companies with five or fewer engineers leverage a variety of design data management solutions ranging from core CAD management to PLM. Responses to an open ended question on benefits show that they primarily perceive the value of the basics – keeping data under control, making it easy to find, and being able to share it with others. The results reported include improved design efficiency and throughput.

Conclusion

Survey analysis leads us to conclude that design data management solutions including PDM, PLM, or more focused CAD / Engineering Data Management solutions help even the smallest companies hit their product development targets.

Recommendations

Based on our experience and the results of this research, we recommend that:

- Smaller companies looking to improve product development performance should implement a design data management solution

- These companies should look for a solution with automation for basic processes like revision control and check in / check out

- Companies should start small, but make sure to leave themselves room to grow in the future by extending their CAD Data Management solution

You can download a PDF of the Escalating Cloud Value Along the Path to Cloud Adoption and Maturity infographic here, courtesy of Siemens.

[post_title] => Escalating Cloud Value by Adoption & Maturity (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-value-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:09

[post_modified_gmt] => 2022-11-15 03:26:09

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8373

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 8412

[post_author] => 2

[post_date] => 2019-11-14 10:16:38

[post_date_gmt] => 2019-11-14 15:16:38

[post_content] =>

You can download a PDF of the Escalating Cloud Value Along the Path to Cloud Adoption and Maturity infographic here, courtesy of Siemens.

[post_title] => Escalating Cloud Value by Adoption & Maturity (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-value-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:09

[post_modified_gmt] => 2022-11-15 03:26:09

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8373

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 8412

[post_author] => 2

[post_date] => 2019-11-14 10:16:38

[post_date_gmt] => 2019-11-14 15:16:38

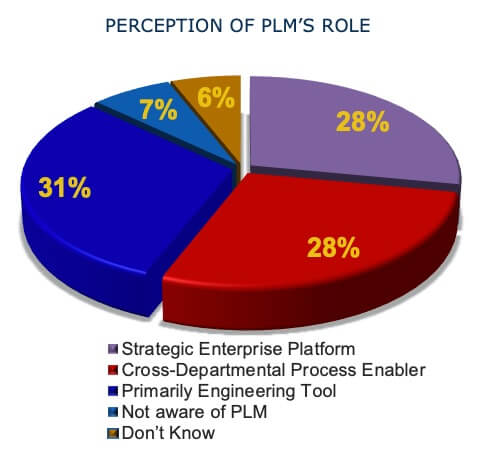

[post_content] =>  What’s the right size PLM to fit a midsized manufacturer? When looking for PLM for SMB (small to midsized businesses) it's important to remember that midsized companies need capabilities, but have limited resources. Midsized manufacturers need to choose a PLM system that brings core product design and development capabilities within reach, but also offers room to grow value over time. This eBook explores how much PLM is right for midsized companies.

Please enjoy the summary below, or click the report to download a PDF overview.

For the full report on PLM for SMB, please visit our sponsor Dassault Systemes (registration required).

What’s the right size PLM to fit a midsized manufacturer? When looking for PLM for SMB (small to midsized businesses) it's important to remember that midsized companies need capabilities, but have limited resources. Midsized manufacturers need to choose a PLM system that brings core product design and development capabilities within reach, but also offers room to grow value over time. This eBook explores how much PLM is right for midsized companies.

Please enjoy the summary below, or click the report to download a PDF overview.

For the full report on PLM for SMB, please visit our sponsor Dassault Systemes (registration required).

Table of Contents*

- Midsized Manufacturers Stuck In-Between

- The Allure of Simple Solutions

- “Simple” Simply Falls Short for Midsized Manufacturers

- Collaborate for Successful New Product Development

- Manage Products and Programs Holistically

- Start Fast, Plan for the Future

- Consider the Cloud

- Get Started with the Right PLM Solution

- Acknowledgments

Midsized Manufacturers Stuck In-Between

Midsized Companies Compete on Speed and Agility Midsized manufacturers are taking advantage of growth opportunities armed with a combination of product innovation, agility, smart manufacturing, and digitalization. But developing successful products today is complex. These smaller companies have to innovate and introduce new products quickly and efficiently to compete with larger competitors. PDM May not be Enough, PLM May be too Much Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may be able to control, access, and share product data with relatively simple Product Data Management (PDM) tools, larger manufacturers rely on full-featured PLM systems.

Midsized companies may find themselves in-between because:

Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may be able to control, access, and share product data with relatively simple Product Data Management (PDM) tools, larger manufacturers rely on full-featured PLM systems.

Midsized companies may find themselves in-between because:

- Product and organizational complexity drive them beyond basic PDM capabilities

- A full-featured PLM implementation may feel out of reach

Get Started with the Right PLM Solution

Get Started to Gain Value Core PLM can quickly add value to midsized manufacturers by helping them combat complexity, improve productivity, and collaborate. Recognize the potential value of a fully featured PLM with all of the bells and whistles, but be honest with yourself about whether your company can afford the time and effort to get there (at least right away). Start Small Start with the basics and get value quickly, but avoid the shortcomings of simple file sharing solutions that fall short for complex products and product development environments. Look for a solution that allows you to design in the context of your products in real time, but also in the context of processes and product development projects. In addition, look for PLM with automatic CAD and project updates to keep engineers focused on innovation instead of managing files and tasks. Leave Room to Expand Finally, make sure to leave room to grow as your business dictates, using the initial implementation as a foundation for greater value and improvement. *This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => PLM for SMB - Finding PLM to Fit Midsized Manufacturers (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-for-smb

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:19

[post_modified_gmt] => 2022-11-15 03:28:19

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8412

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 8684

[post_author] => 2

[post_date] => 2020-03-31 10:32:35

[post_date_gmt] => 2020-03-31 14:32:35

[post_content] => How can engineers avoid wasting precious design time on non-value-added data management tasks? Take a look at our new infographic Avoiding Time Wasters in CAD Design to see a graphical representation of our research. The "CAD Design Challenge" turns design into a board game that highlights key time wasters in design and the best practices that help engineers avoid them.

We've shared the introduction and the first challenge that leads to wasting design time - the inability to reuse data - below. To view the full infographic, please visit our sponsor Siemens Digital Industries Software (no registration required)

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => PLM for SMB - Finding PLM to Fit Midsized Manufacturers (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-for-smb

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:19

[post_modified_gmt] => 2022-11-15 03:28:19

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8412

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 8684

[post_author] => 2

[post_date] => 2020-03-31 10:32:35

[post_date_gmt] => 2020-03-31 14:32:35

[post_content] => How can engineers avoid wasting precious design time on non-value-added data management tasks? Take a look at our new infographic Avoiding Time Wasters in CAD Design to see a graphical representation of our research. The "CAD Design Challenge" turns design into a board game that highlights key time wasters in design and the best practices that help engineers avoid them.

We've shared the introduction and the first challenge that leads to wasting design time - the inability to reuse data - below. To view the full infographic, please visit our sponsor Siemens Digital Industries Software (no registration required)

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full infographic is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Avoid Wasting Design Time (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => wasting-design-time-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:09

[post_modified_gmt] => 2022-11-15 03:26:09

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8684

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 877

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => a099f5bf05852e63549faff703f37dda

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)