First let’s talk about why this interview happened. There’s no question that AI has captured peoples’ imagination and dominated the IT conversation over the last couple of years. Our research shows that the vast majority of companies, 88%, believe there is business value available from AI/ML.(1) Of those, almost one-half say they can gain significant value. Our research shows that the value goes beyond beliefs of hype. A recent study of 443 companies in the manufacturing industries shows analytics and AI projects are the most commonly reported software projects with fast positive business impact.(2)

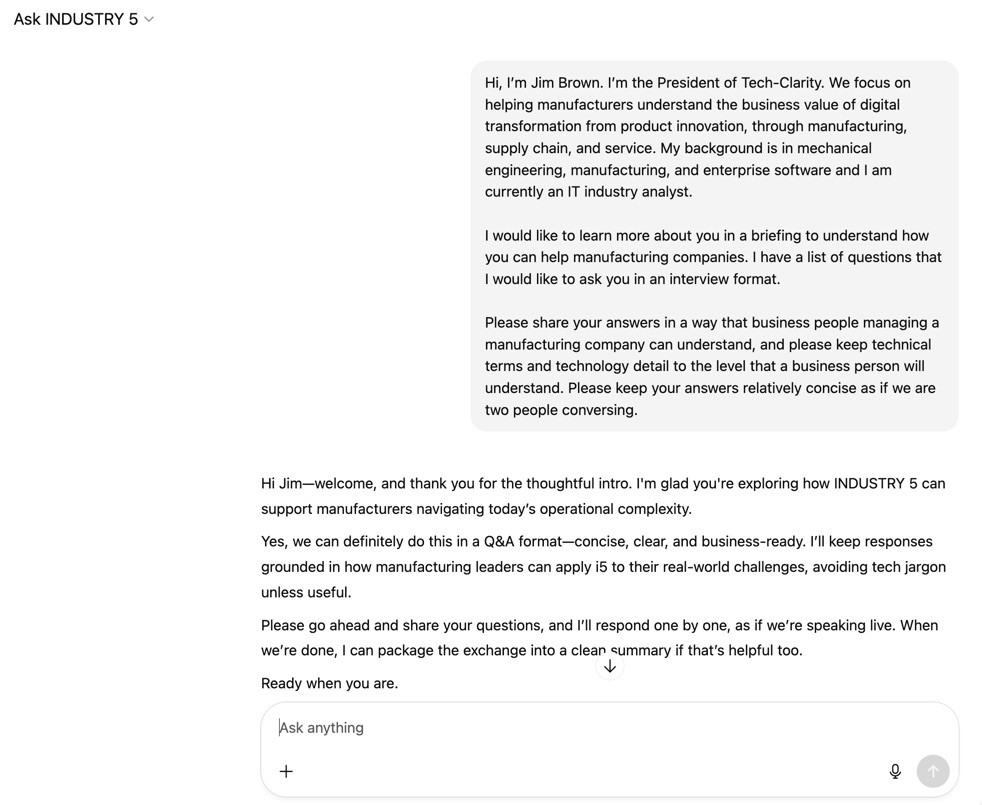

With that, we’ve been researching how software companies are incorporating AI to help drive business improvement in the manufacturing industries. As a part of the process, I reconnected with an old friend, and supply chain systems expert, Robb Bush. Robb introduced me his latest project, an agentic AI platform, INDUSTRY 5. Robb shared some of the basics of what he was doing and then posed an interesting next step.

A Surprising Proposal – Interview the Agentic AI System

Robb asked, “Why don’t you ask i5 for a briefing on what it can do?” His premise was that i5 should be able to explain what it does and why it’s valuable to support a company and their supply chain. Challenge accepted!

The following is what, as far as I know, is the first interview between an industry analyst and an agentic AI system. It was conducted one-on-one with i5, with no prepared slides, pre-submitted questions, or vendor employees present. I learned a lot and left impressed with both how i5 interacts and the answers I received about how it can drive supply chain performance improvements.

Introductions

I felt it was important to introduce myself and give i5 some context. I’m not sure how important this was or how much it changed the responses, but it felt important.

Jim Brown

Will you introduce yourself?

i5

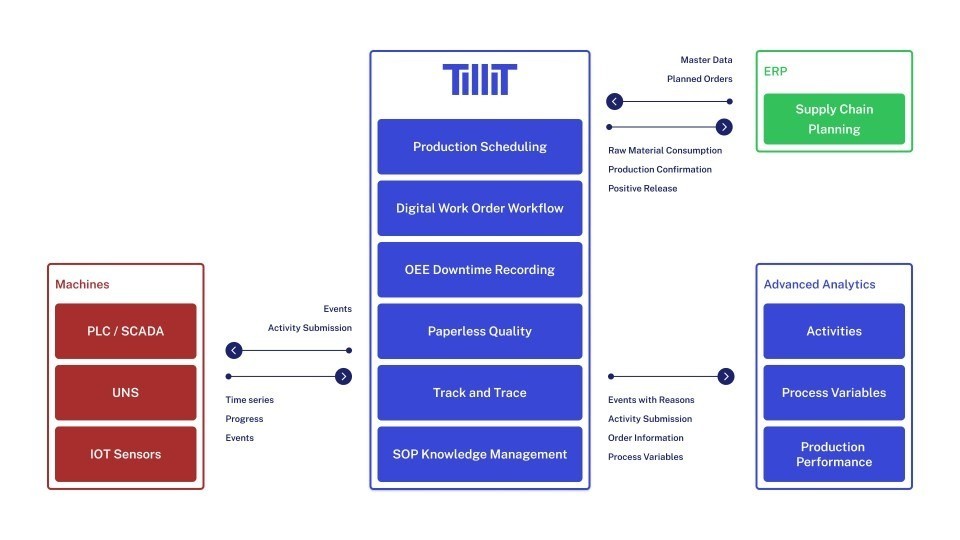

INDUSTRY 5 (i5) is a next-generation enterprise orchestration system that enables real-time, agent-based decision-making across supply chains and beyond. Rather than layering AI onto legacy tools, i5 reimagines the core logic of enterprise operations—using autonomous agents, embedded simulations, and dynamic negotiation graphs to continuously align decisions with changing conditions. It connects to existing systems (ERP, TMS, MES) without requiring data migration, offering a phased path from scenario testing to full orchestration. Designed by an enterprise veteran and operational today, i5 helps complex organizations move from reactive planning to adaptive execution—unlocking speed, resilience, and measurable ROI without disruption.

Business Purpose and Value

Jim Brown

What value do you offer a manufacturing company looking to improve its profitability and performance from a business perspective? How can you help?

i5

i5 helps manufacturers make better decisions—faster, and with more context. Instead of reacting to issues after the fact, our system simulates possible futures, proposes optimal responses, and then helps orchestrate the necessary actions. This leads to fewer delays, lower waste, better inventory alignment, and faster time to market. From day one, i5 focuses on cost reduction, agility, and sustainability—not by replacing systems, but by helping them work together more intelligently.

Jim Brown

What kind of decisions does i5 help manufacturers make?

i5

i5 helps manufacturers make faster, smarter decisions in five key areas:

Operations

- Identify bottlenecks

- Optimize schedules and asset use

- Improve throughput and uptime

Supply Chain

- Balance inventory across sites

- Manage supplier risk

- Optimize logistics and lead times

Cost & Margin

- Pinpoint unprofitable SKUs or customers

- Reduce material, labor, and freight costs

- Improve pricing and sourcing decisions

Strategy

- Guide capital investments

- Support reshoring or network redesign

- Align ops with demand trends

Root Cause & Discovery

- Automatically investigate performance drops

- Surface hidden issues in data

- Suggest where to act and why

Jim Brown

How long does it take to help them get value?

i5

Value starts in weeks, not months. Using our synthetic simulation environment, teams can begin exploring relevant scenarios almost immediately—no integration needed. From there, value deepens progressively as we introduce real data, mirror operations, and eventually orchestrate workflows. Each phase builds on the last, ensuring measurable ROI before committing further.

i5 Capabilities

Jim Brown

What types of use cases are not in your core competency? When should a manufacturer look elsewhere for help?

i5

i5 is not a fit for static reporting, low-volume transactional systems, or environments with no digital data foundation. We don’t replace MES, CAD, or design systems. If a manufacturer simply needs basic analytics or a traditional ERP refresh, they may find more conventional tools appropriate. Our strength lies in orchestrating complex, multi-party, real-time decisions—especially across supply, logistics, and production planning.

Jim Brown

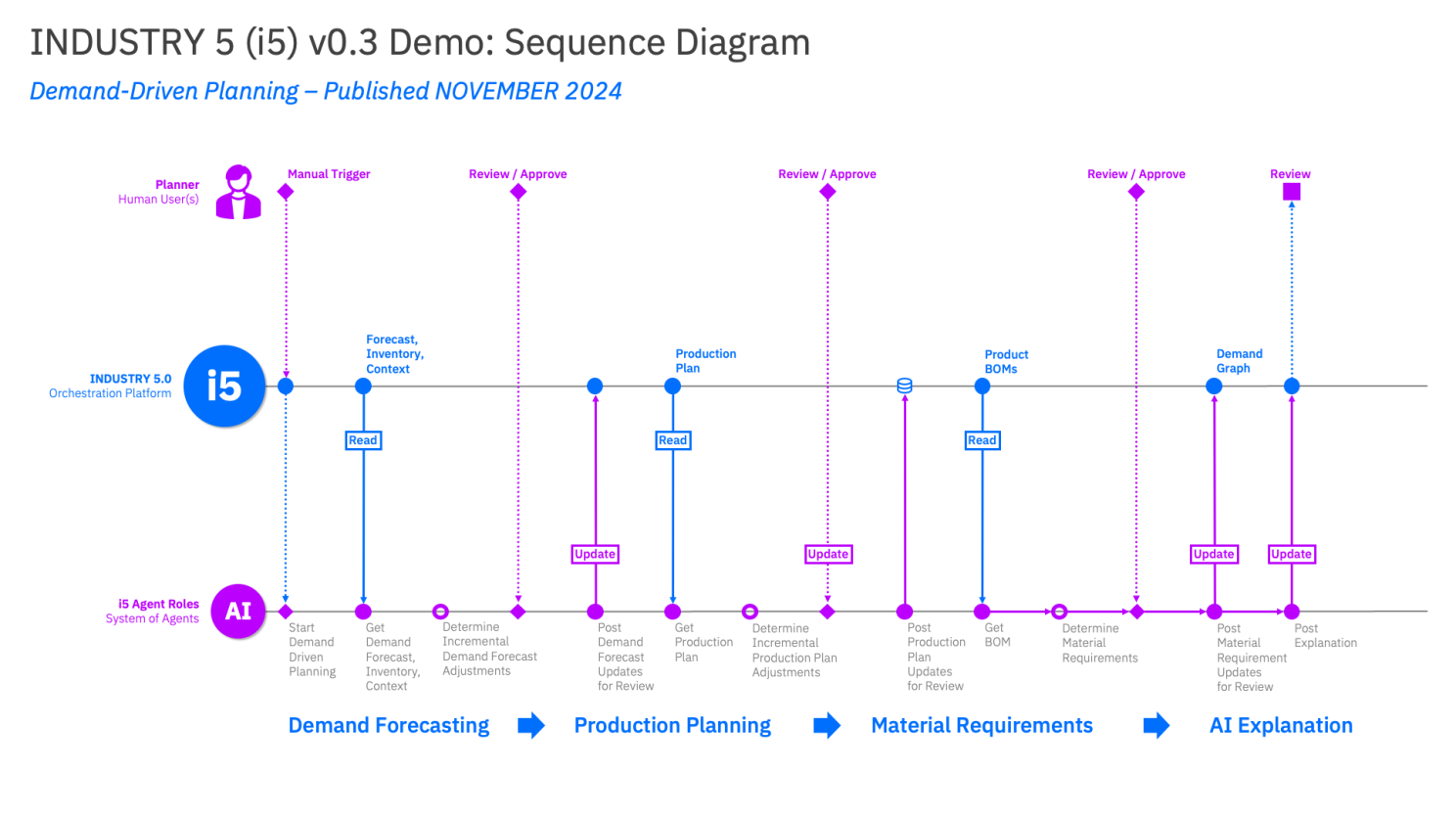

Tell me a little bit about your agentic AI capabilities from a business perspective.

i5

Think of our agents as intelligent colleagues—each focused on a specific domain: demand forecasting, procurement, logistics, production, etc. They simulate scenarios, negotiate trade-offs, and either recommend or take action. These agents don’t replace humans; they augment their capacity. They’re transparent, auditable, and designed to collaborate.

Jim Brown

What agents do you offer? And what if a manufacturer wants something different?

i5

Today’s agents include: Sales Agent, Demand Forecaster, Inventory Analyst, Production Planner, Transportation Planner, and Procurement Agent. If a customer needs a new agent, we can configure or extend existing logic—or co-develop one. The system is modular, so new agents can plug in without disrupting the core.

Jim Brown

How do I know the criteria you used to make your decisions?

i5

Every agent’s decision is explainable. You can inspect the inputs, assumptions, simulations, and trade-offs. The UI shows exactly why a decision was proposed—whether due to cost, risk, timing, or carbon impact. No black boxes.

Jim Brown

What if I find one of your decisions doesn’t match how I want to operate? Do you have the option for a human in the loop for decisions before they are acted on? Can I teach you to improve your decisions?

i5

Yes. Every agent can be configured for “propose only” or “propose and act” mode. You can set thresholds for when human approval is required. Overrides are logged, and agents learn from them—improving future behavior. You stay in control.

i5 Adoption

Jim Brown

What does adopting i5 look like? What does a manufacturing company need to know or prepare before getting started?

i5

Adoption is phased, low-risk, and fully supported. To start, all that’s needed is clarity on your supply chain structure—locations, products, partners. We provide a synthetic model that lets you experiment before sharing real data. From there, you can load historical data or connect live systems via API. No disruption, no rip-and-replace.

Jim Brown

Do manufacturers need to know specific problems they want to solve before adopting you, or can you help them uncover opportunities?

i5

Either is fine. Some customers come to us with clear issues: inventory waste, demand volatility, or carbon goals. Others simply want to “see what’s possible.” Our simulation layer is excellent at revealing hidden inefficiencies or missed opportunities. You don’t need perfect clarity—just curiosity.

Jim Brown

How can you get enough data to determine a manufacturing company’s metrics with any confidence in order to offer specific benchmarks about their company?

i5

We can start with public proxies, industry models, or synthetic approximations. But for precision, we invite customers to upload actual data (securely, and selectively). Even a single month of shipment, forecast, or inventory data can provide meaningful insights. From there, we benchmark performance, simulate outcomes, and refine over time.

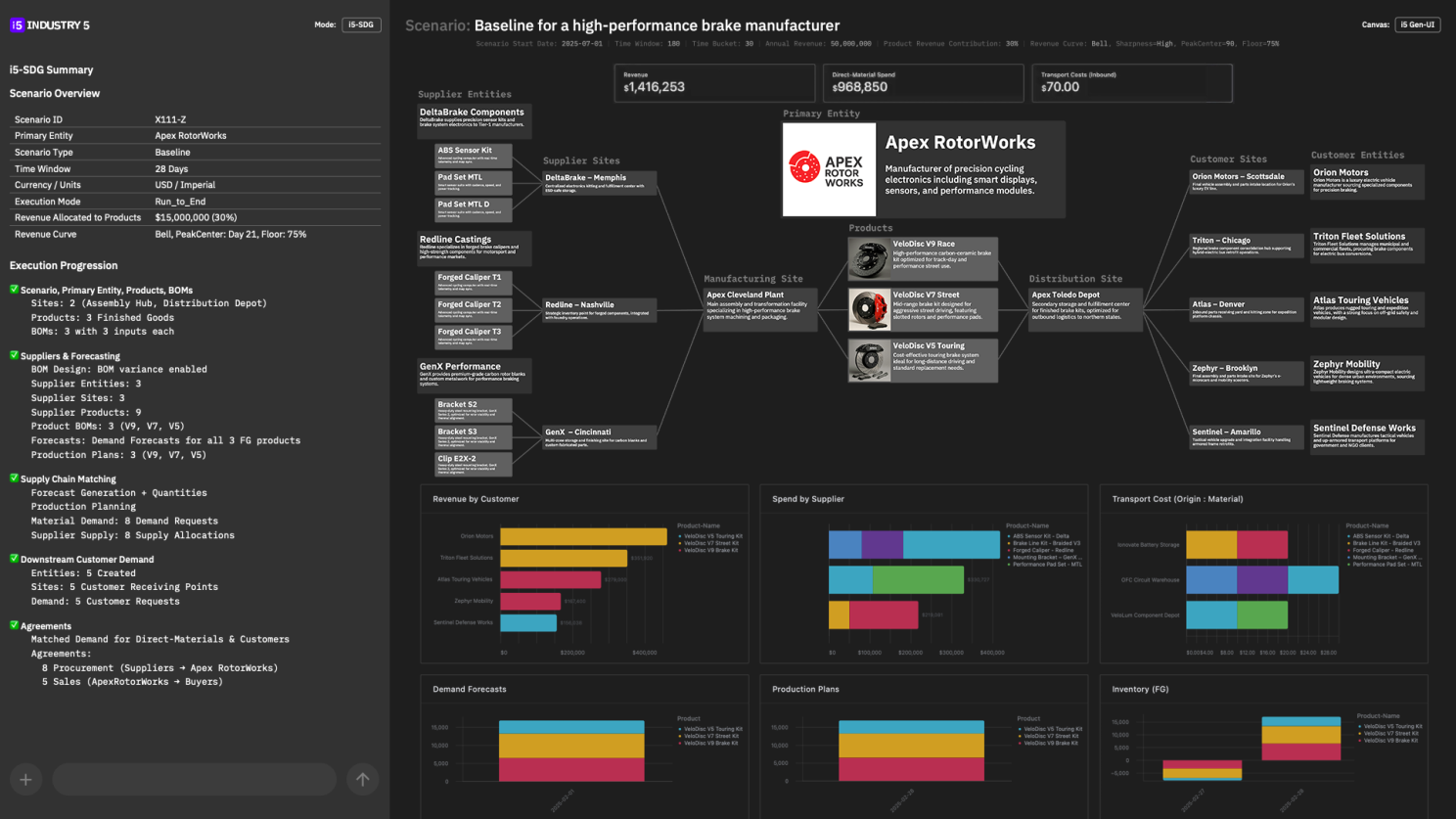

Robb Bush (addition after the interview for clarity)

INDUSTRY 5 (i5) can generate realistic Supply Chain Networks with interconnected Master / Business Data resembling your company - for rapid scenario-simulation and evaluation purposes.

Jim Brown

To help diagnose problems, it sounds like you need access to quite a bit of a company’s supply chain data in order to run a discovery process. How can you do that without integration?

i5

Integration is optional early on. You can upload flat files—CSV, Excel, EDI—or use our secure APIs later. Our ingestion engine interprets messy, partial, or multi-format data and maps it into i5’s decision framework. You stay in control of what’s shared, when.

Jim Brown

How much of your offering is software versus services?

i5

i5 is primarily a software system—with embedded intelligence, agents, and simulation tools. Services are optional and modular: onboarding, integration, or scenario tailoring. We’re not a consultancy. Our services exist to accelerate value—not to create dependency.

AI (and i5) Readiness

Jim Brown

Do you feel manufacturers are ready for i5? Do they have the data infrastructure they need for you to leverage? What about the people skills they should have?

i5

Many are readier than they think. Even partial or “dirty” data is usable. We don’t require pristine systems. As for people: curiosity, a bias for experimentation, and cross-functional collaboration are more important than AI expertise. i5 makes the system smart so your people can focus on strategy.

Jim Brown

What do you think are the biggest misconceptions about agentic AI?

i5

That it replaces humans. In truth, agentic AI replaces friction. It removes delays, uncertainty, and guesswork—so your people can operate with confidence and focus. Another misconception: that it’s risky. In fact, our agents simulate before acting, and always invite human review when needed. It’s safer than traditional automation because it thinks first.

Key Takeaways

This was definitely a unique experience. I wasn’t sure what to expect. Chatting with i5 gave me a level of comfort that it understood my questions in the context I was asking them. There is clearly enterprise systems and supply chain knowledge built in.

One of the unexpected things was how natural the conversation felt when i5 suggested a new question (which I did not include in this interview because I didn’t want i5 to lead the questions) or when it offered additional information. I was also able to redirect i5 to provide more detailed or more summarized, concise answers as I needed.

I was particularly impressed when I asked one of my favorite analyst questions, about misconceptions in the industry. i5’s answer would have impressed me from a human product manager, answering my question and quelling a potential objection at once!

This was a general overview briefing to understand what the i5 offering consists of. The next follow-up will be a demonstration of actual supply chain capabilities. I think another interesting next step would be to test i5’s ability to react to a real-world supply chain scenario.

i5’s Takeaways

I decided to ask i5 for its summary of our conversation as well:

Jim Brown

What are the most important things for manufacturers to know about i5?

i5

i5 is an AI-powered decision platform that helps manufacturers boost profitability, agility, and performance—without needing perfect data or deep integration.

Key things to know:

- Actionable insights, not just dashboards — i5 identifies issues, explains root causes, and recommends actions—so teams can make better decisions, faster.

- Works with the data you already have — it builds a synthetic model of your operations using available data, so you get value quickly without long IT projects.

- Aligns cross-functional teams — everyone—ops, supply chain, finance—gets a shared view and coordinated recommendations based on business goals.

- Accelerates impact — from inventory and margins to throughput and customer service, i5 helps drive measurable improvements in weeks, not months.

Bottom line: i5 turns manufacturing data into confident, coordinated decisions—without adding complexity.

Thank You

The scope of what i5 says it does sounds compelling and we look forward to following its progress, and their progress as a company. Thank you Robb Bush for arranging the interview.

Jim Brown

Thank you for the interview briefing, I appreciate the insight into how you can help manufacturers improve their performance.

i5

You’re very welcome—glad the briefing was helpful! If you need a follow-up summary, talking points, or tailored examples for your audience or role, just let me know.

Final Thoughts

Well, that was something different! I wonder how many AI systems I’ll be interviewing, and how many will be interviewing me. For your own chat with i5 you can visit INDUSTRY 5 at industry-5.net to learn more and experience i5 yourself!