How can startup companies improve their chances of success? Our Startup Survival Guide reveals both how and why simulation can provide startups an edge to launch a successful product. As part of a cloud platform, CAE can also be more accessible to startups. Please enjoy the summary* below. For the full research, please visit our…

- Access more funding

- Improve profitability

- Get the product right

- Validate market needs

- Leverage the right talent

Table of Contents

- The Opportunities for Startups

- 1. Access More Funding

- 2. Improve Profitability

- 3. Get the Product Right

- 4. Validate Market Needs

- 5. Leverage the Right Talent

- Recommendations

- Acknowledgments

Recommendations

Recommendations and Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

- Use simulation to demonstrate progress to investors to help justify additional funding.

- Leverage a cloud platform to preserve capital by avoiding high upfront costs for software licenses and investments in high-end hardware.

- Optimize your product for quality and cost to maximize profitability and allow you to price your product competitively.

- Support rapid iterations with simulation to develop a more innovative, competitive product.

- Take advantage of simulation in the cloud to validate your product early and often with potential customers to verify it will meet market needs.

- Tap into additional expertise as needed with a simulation cloud platform that will provide flexibility to easily collaborate with third parties.

How can you ensure that you choose the right PDM software and partner for your business? The right system serves as the backbone for digital transformation and impacts productivity, product success, and profitability. How can you make sure to get it right?

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

How can you ensure that you choose the right PDM software and partner for your business? The right system serves as the backbone for digital transformation and impacts productivity, product success, and profitability. How can you make sure to get it right?

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

Table of Contents

- Introducing the PDM Buyer's Guide

- Using the PDM Buyer's Guide

- Analyze PDM Capabilities: Control

- Analyze PDM Capabilities: Access

- Analyze PDM Capabilities: Share

- Assess Service Requirements

- Service Requirements: Implementation

- Service Requirements: User Adoption

- Service Requirements: Support

- Consider Vendor Requirements

- Identify Unique Company Needs

- Support the Digital Enterprise

- Conclusion

- Recommendations

- Acknowledgments

Introducing the PDM Buyer's Guide

Product Data Management (PDM) is an important tool to help manufacturers overcome the complexities of designing, developing, producing, and supporting today’s products and product development processes. Manual and ad-hoc approaches such as shared folders, cloud storage, and hard drives are simply not effective solutions to manage critical, complex product information. These approaches may work for very small organizations, but quickly falter as organizations grow and must share information beyond a few core engineers. These techniques also fail to manage data relationships and complex file structures common to 3D CAD systems. PDM systems are purpose-built to address these issues.

PDM is a structured, collaborative solution that helps manufacturers control, access, and share crucial product data. Selecting the right PDM system can have a large impact on productivity, product success, and profitability. How can you ensure that you choose the right software and partner for your business?

Purpose of the Guide

The PDM Buyer’s Guide is not intended to provide an all-encompassing requirements list. Instead, it covers the high points that manufacturers should look for in a PDM system. Think of this as a “PDM litmus test” to see if a solution is a good high-level fit for your business before spending significant time and effort analyzing detailed features and functions.

Consider Broader Requirements

Although the checklists focus only on PDM requirements, it’s important to consider more than your current needs when choosing a system. Many companies eventually want to grow beyond basic PDM to a more complete PDM system. These more advanced capabilities are covered in our Expanding Beyond Your Outgrown PDM System Buyer’s Guide. Other companies may start with PDM and evolve through a maturity process to a more complete Product Lifecycle Management (PLM) environment. PLM extends the core PDM foundation to support more product development and engineering processes, manage a richer view of products, include more people in product development, and support processes further upstream and downstream from Engineering in the product lifecycle (Figure 1).

Product Data Management (PDM) is an important tool to help manufacturers overcome the complexities of designing, developing, producing, and supporting today’s products and product development processes. Manual and ad-hoc approaches such as shared folders, cloud storage, and hard drives are simply not effective solutions to manage critical, complex product information. These approaches may work for very small organizations, but quickly falter as organizations grow and must share information beyond a few core engineers. These techniques also fail to manage data relationships and complex file structures common to 3D CAD systems. PDM systems are purpose-built to address these issues.

PDM is a structured, collaborative solution that helps manufacturers control, access, and share crucial product data. Selecting the right PDM system can have a large impact on productivity, product success, and profitability. How can you ensure that you choose the right software and partner for your business?

Purpose of the Guide

The PDM Buyer’s Guide is not intended to provide an all-encompassing requirements list. Instead, it covers the high points that manufacturers should look for in a PDM system. Think of this as a “PDM litmus test” to see if a solution is a good high-level fit for your business before spending significant time and effort analyzing detailed features and functions.

Consider Broader Requirements

Although the checklists focus only on PDM requirements, it’s important to consider more than your current needs when choosing a system. Many companies eventually want to grow beyond basic PDM to a more complete PDM system. These more advanced capabilities are covered in our Expanding Beyond Your Outgrown PDM System Buyer’s Guide. Other companies may start with PDM and evolve through a maturity process to a more complete Product Lifecycle Management (PLM) environment. PLM extends the core PDM foundation to support more product development and engineering processes, manage a richer view of products, include more people in product development, and support processes further upstream and downstream from Engineering in the product lifecycle (Figure 1).

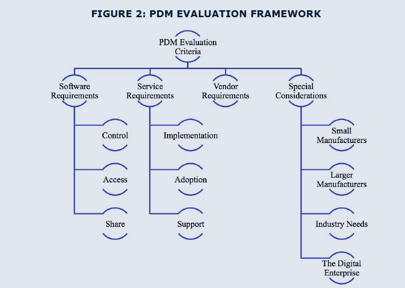

Conclusion

Adopt Common Requirements for PDM PDM helps manufacturers address complexity and improve business performance. When evaluating PDM, manufacturers need to take into account:- Product requirements

- Implementation, adoption, and support requirements

- Vendor / business requirements

- Special requirements based on company size (particularly for very small or very large organizations)

- Special considerations to meet industry needs

- Future requirements as the manufacturing industry continues to digitally transform

Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Identify and weigh PDM requirements based on company needs, company size, industry, and any unique company needs

- Use high-level requirements such as the ones in this guide to evaluate solutions based on business fit before engaging in detailed, technical evaluations

- Consider using the cloud or managed services solutions for companies that wish to move quickly, have limited IT resources, want to reduce overhead, or want to modernize their IT infrastructure

- Take user adoption into account, including simplified access, increased visualization, and task-specific apps for non-engineering resources

- Take into account long-term business and process growth needs including digital transformation, AR / VR, and IoT initiatives

- Consider the potential to expand to a more capable extended PDM or PLM system, but start small and get value along the way during implementation

How do you manage system family engineering?

How do you manage system family engineering?

Table of Contents

- New Semiconductor Imperatives

- Topic: Skyrocketing Demand Puts Pressure on Fabs

- Innovation Issues

- Meeting Demand

- Processing Challenges

- Progress Matters

- Quality Demands

- Empowering the Workforce

- IT Overwhelm

- Streamlining Information Systems

- MES Reimagined

- Reimagine and Reinvest in MES

- Acknowledgements

New Semiconductor Imperatives

New Semiconductor Imperatives

Keeping up with rising demand, product portfolio growth, complex products, processing mix, and new application requirements creates tremendous challenges for semiconductor makers. Companies must increase their pace of both learning and ramping up new products and processes.

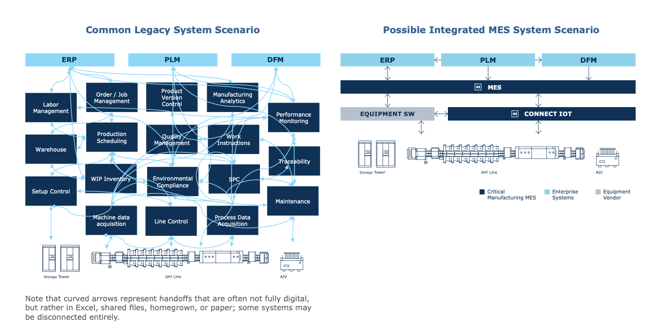

Production operations are a pinch point. To handle new demands, companies must optimize further. Thus, it is imperative to reimagine the manufacturing execution system (MES) for semiconductor to meet today’s needs.

MES must expand beyond work-in-process (WIP) and track and trace to become the data platform for production innovation, change, and efficiency. All types of facilities face this need, and modern MES can serve silicon, R&D, front-end fabs, back end, and even module production. While no longer isolated, front-end fabs face particular challenges and urgency due to their array of advanced capabilities.

Reimagine and Reinvest in MES

Expect More in Software Over the past several years, fab processes have changed, and your Manufacturing IT must as well. Open your minds to reimagine what MES is and does. Evaluate MES against customer requirements and strategic business needs. As this paper describes, modern MES solutions go far beyond track and trace and WIP management to support advanced semiconductor processing capabilities. Evaluate the Need Most semiconductor fabs have a vast “hidden fab” where workarounds have become the norm. To understand that count how many systems you use to support fab operations today measure how much time, effort, and energy your team spends finding and consolidating data for day-to-day operations understand how much time the Manufacturing IT team spends maintaining and customizing the MES. If you’re dissatisfied with the answers, look for software that supports your fab’s advanced capabilities. Reinvest in MES Push MES providers to get what you need. Some specifics you might need are in Figure 5. Beyond specifics, you need a smooth and coherent flow of data in the fab and into the enterprise. Speed of learning all you need to ramp up for NPI and continue improving yield and serving the market opportunities lies in that manufacturing data management. Investing is urgent – you can’t be as resilient nor as profitable as you want without data that’s in context and ready to use. *This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor Critical Manufacturing for the full research (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Reimagining Semiconductor MES (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => semiconductor-mes [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:26 [post_modified_gmt] => 2022-11-15 03:28:26 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=11059 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 11049 [post_author] => 2 [post_date] => 2022-01-12 16:01:14 [post_date_gmt] => 2022-01-12 21:01:14 [post_content] => I had the pleasure of joining Dassault Systemes’ special ENOVIA Champions Advisory Board Meeting at the end of 2021. It was a unique learning opportunity because the Champions are a global community of people that use or support ENOVIA and the 3DEXPERIENCE platform at their companies. It was also nice to see some industry friends at the meeting.

I was impressed by the group’s Program activities and participation. The awards presented at the event reflect significant community engagement. The participants are active and not only have a great networking opportunity, they are empowered to learn, engage and influence the ENOVIA leadership team to help drive solution strategy to benefit their companies. Individuals who apply to the ENOVIA Champions Program represent a wide variety of Dassault Systemes customers across virtually every industry from across the globe.

I was also pleased to see the level of organization and support provided by Dassault Systemes. Its logistics support makes participation in the sessions and other related community activities relatively easy. The involvement by the Dassault Systems ENOVIA team, including executive participation by ENOVIA CEO Stéphane Declee and Program leadership by Susan Lenzi, demonstrates that Dassault Systemes’ values interaction with its users. This program is a good example of a highly, mutually-beneficial vendor–customer relationship.

I had the pleasure of joining Dassault Systemes’ special ENOVIA Champions Advisory Board Meeting at the end of 2021. It was a unique learning opportunity because the Champions are a global community of people that use or support ENOVIA and the 3DEXPERIENCE platform at their companies. It was also nice to see some industry friends at the meeting.

I was impressed by the group’s Program activities and participation. The awards presented at the event reflect significant community engagement. The participants are active and not only have a great networking opportunity, they are empowered to learn, engage and influence the ENOVIA leadership team to help drive solution strategy to benefit their companies. Individuals who apply to the ENOVIA Champions Program represent a wide variety of Dassault Systemes customers across virtually every industry from across the globe.

I was also pleased to see the level of organization and support provided by Dassault Systemes. Its logistics support makes participation in the sessions and other related community activities relatively easy. The involvement by the Dassault Systems ENOVIA team, including executive participation by ENOVIA CEO Stéphane Declee and Program leadership by Susan Lenzi, demonstrates that Dassault Systemes’ values interaction with its users. This program is a good example of a highly, mutually-beneficial vendor–customer relationship.

My Message to ENOVIA Champions

I shared two key things from our research:- The business imperative of digital transformation for manufacturers

- How PLM supports digital transformation at the highest level while driving engineering efficiency gains

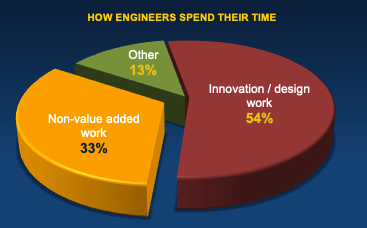

Did you know engineers waste so much time on non-value-added work, they only spend about 54% of their time actually designing? How can you prevent them from wasting too much time on non-value-added work?

Our research uncovered some significant engineering inefficiencies that contribute to this including:

Did you know engineers waste so much time on non-value-added work, they only spend about 54% of their time actually designing? How can you prevent them from wasting too much time on non-value-added work?

Our research uncovered some significant engineering inefficiencies that contribute to this including:

- 29% percent of engineering time is spent working with outdated information

- After implementing a change, depending on product complexity, it takes 4.7 to 10.3 days for to get updated data to the entire team

- 94% say they need updated data faster than they currently get it

The Value of Engineering Time

Engineering Time Is a Valuable Asset How can you reduce non-value-added engineering work? Engineers are under constant pressure to meet tight deadlines. They need time to balance quality, cost, and performance criteria as well as to innovate and solve problems. Unfortunately, they waste too much of their valuable time on non-value-added work. Imagine the opportunities if engineers could reduce those tedious activities to focus more energy on engineering work that leads to better designs. This Research Based on a survey of over 220 manufacturers, this research study examines how engineers spend their time. It identifies time-consuming activities that waste time and present opportunities for improvement. This research is an updated look at a study of 248 manufacturers conducted in 2014 and examines how trends have evolved over the last seven years.

Table of Contents

- Executive Summary

- Identify Bottlenecks

- Assess Non-Value-Added-Time

- Preparing Data for Others

- Business Value of Eliminating Non-Value-Added Work

- Recognize the Time Required for Check-ins

- Outdated Information Impacts Engineering Changes

- The Impact of Outdated Information on Collaboration

- Identifying the Top Performers

- Strategies to Improve Efficiency

- Technology as a Collaboration Solution

- Consider the Security Risks of Email

- The Benefits of Real-Time Data Updates

- Recommendations

- About the Research

- Acknowledgments

Executive Overview

Engineering is Key to Competitive Differentiation Today's market is so competitive; it is hard to stand out. To be successful, companies must empower their engineering teams to differentiate products on innovation, quality, performance, and cost. While finding the time to balance those criteria is challenging, many current processes make it even harder. Consequently, engineers report they waste a third of their time on non-value-added work, which is consistent with what we saw in 2014. Worse, 29% of their time is spent working with outdated information. It has become an even bigger problem than it was in 2014 when engineers reported working with outdated data 20% of the time. Unfortunately, this leads to even more wasted effort and rework. Further, companies anticipate that going forward, 43% of engineering work will be done in flexible, work anywhere environments. This will only add to the complexity of engineering team environments, creating even more risk for outdated information and additional non-value-added work. Engineers need new ways of working. One way companies can improve this situation is to provide engineers with real-time access to design data, in the right context. This keeps the data up-to-date and at their fingertips. The result should be increased engineering bandwidth, allowing more time to focus on making products more competitive. This approach also improves the growing need to improve collaboration beyond design engineers, with 83% saying it would be helpful if design data could be shared more easily with analysts and 86% wanting to share design data more easily with manufacturing. Determining Best Practices To determine best practices for accessing design information, Tech-Clarity analyzed survey responses from over 220 manufacturers to understand how they manage data, communicate engineering changes, and collaborate with both internal and external development team members. The research shows that to improve efficiency, companies who are most successful, Top Performers, are 56% more likely than their lesser performing competitors to enable real-time access to design information and 52% more likely to adopt a platform of integrated engineering tools. What Can You Learn from This Research?

This report explores best practices for streamlining access to design data in real-time. It also exposes some challenges manufacturers should be aware of as they strive to maintain a competitive edge in today's complex and cutthroat environment. The report also reveals how manufacturers can plan for a modern design environment that will support them through the 2020s.

What Can You Learn from This Research?

This report explores best practices for streamlining access to design data in real-time. It also exposes some challenges manufacturers should be aware of as they strive to maintain a competitive edge in today's complex and cutthroat environment. The report also reveals how manufacturers can plan for a modern design environment that will support them through the 2020s.

Recommendations

Recommendations and Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Understand how engineers spend their time and improve processes and collaboration to minimize time wasted on non-value-added work.

- Consider solutions such as PLM or PDM to centralize design information and support change management and collaboration.

- Evaluate options to design components in the context of the overall assembly. This will improve collaboration, make it easier to identify interdependencies between components, and provide a better understanding of the impact of changes.

- Consider technologies that enable real-time updates to keep CAD data up-to-date while minimizing or eliminating check-in times.

- Establish means for secure, real-time collaboration with both internal teams and third parties to minimize delays in getting updated CAD data from them and assuring your IP is protected.

How can manufacturers succeed in the face of uncertainty that creates new needs for decision-makers at every level? Read (Re)Gaining Control in Manufacturing: The Right ERP can Ensure Uncertainty Doesn’t Restrict Your Growth to learn how and hear from three executives who have done it.

How can manufacturers succeed in the face of uncertainty that creates new needs for decision-makers at every level? Read (Re)Gaining Control in Manufacturing: The Right ERP can Ensure Uncertainty Doesn’t Restrict Your Growth to learn how and hear from three executives who have done it.

- Why the right fit modern, comprehensive, and factory-capable ERP opens up visibility and control.

- Ways consistent information maintains the advantage of being agile to pivot confidently as the company grows.

- How to impress customers and prospects by delivering detailed information with every product at no additional cost or effort.

Table of Contents

- Responding in an Uncertain World

- The Growth Conundrum

- Expanding the Advantage

- Digital Ways of Working

- Digital Manufacturing in Reach

- What to Look for in ERP Software

- Choosing an ERP Partner

- Executives on ERP

- Control the Business

Executive Summary

Given the ever-shifting realities of today’s manufacturing environment, how can business leaders (re)gain control? The answer is to have an enterprise resources planning system (ERP) that fits and spans their business. Many companies are finding their current ways of working restrict their ability to respond. These companies are at an inflection point and will benefit from seeking out and investing in ERP that enables instant yet profitable decisions using complete information from across their business and plant operations.

Given the ever-shifting realities of today’s manufacturing environment, how can business leaders (re)gain control? The answer is to have an enterprise resources planning system (ERP) that fits and spans their business. Many companies are finding their current ways of working restrict their ability to respond. These companies are at an inflection point and will benefit from seeking out and investing in ERP that enables instant yet profitable decisions using complete information from across their business and plant operations.

Responding in an Uncertain World

Uncertainty Defines the Market No one doubts that their environment is uncertain. Nearly every business is feeling the impact of world affairs, including the COVID-19 pandemic, natural disasters, political upheaval, trade wars, and tariffs. Raising Key Questions As a result, manufacturers face a plethora of market questions.- Demand – Will customer orders be up or down or swing wildly between the two?

- Supply – Will raw materials to meet that demand be available now or later or not?

- Labor – Can the company hire and retain employees with the needed skills and experience in the face of an enormous talent shortage nearly everywhere?

- Sustainability – Can the business keep up with ever-changing and more stringent government and customer requirements?

Control the Business

Despite Uncertainty Uncertainty is a feature of the “new normal;” don’t expect it to go away. Digital is a reality every manufacturer must keep up with, especially since competitors are. Today’s manufacturing-centric ERP allows you to gain visibility, control, and analyze not just past performance but likely future scenarios. Because of these benefits, 50% of companies are planning or actively investing in ERP3. People Matter Technology is only one aspect of this change to digital manufacturing. For ERP to succeed, expect to put effort into changing processes and mindsets as

well. People will be both the enabler and the most significant obstacle in most cases. Those who are now the key holders of knowledge may feel threatened.

Project Readiness

Setting up a manufacturing ERP project is a significant undertaking. The most successful selections and implementations result from the of best subject-matter experts in every department devoting time to them. For the project to work well, their understanding of best practices and real-world processes will be essential. Plan for resistance and plenty of hard work, with ups and downs in the mood.

*This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor Dassault Systèmes for the full research (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => (Re)Gaining Control in Manufacturing (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-erp-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:26

[post_modified_gmt] => 2022-11-15 03:28:26

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10977

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 10968

[post_author] => 2574

[post_date] => 2021-10-28 08:28:47

[post_date_gmt] => 2021-10-28 12:28:47

[post_content] =>

Technology is only one aspect of this change to digital manufacturing. For ERP to succeed, expect to put effort into changing processes and mindsets as

well. People will be both the enabler and the most significant obstacle in most cases. Those who are now the key holders of knowledge may feel threatened.

Project Readiness

Setting up a manufacturing ERP project is a significant undertaking. The most successful selections and implementations result from the of best subject-matter experts in every department devoting time to them. For the project to work well, their understanding of best practices and real-world processes will be essential. Plan for resistance and plenty of hard work, with ups and downs in the mood.

*This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor Dassault Systèmes for the full research (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => (Re)Gaining Control in Manufacturing (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-erp-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:26

[post_modified_gmt] => 2022-11-15 03:28:26

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10977

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 10968

[post_author] => 2574

[post_date] => 2021-10-28 08:28:47

[post_date_gmt] => 2021-10-28 12:28:47

[post_content] =>  Given the unpredictable supply and market, how can electronics manufacturers prosper? Read Boosting Operating Margins in a Changing World: Why Electronics Manufacturers Need MES More than Ever to see that even the best SMT software is not enough. You’ll hear from us and three major electronics companies’ executives on:

Given the unpredictable supply and market, how can electronics manufacturers prosper? Read Boosting Operating Margins in a Changing World: Why Electronics Manufacturers Need MES More than Ever to see that even the best SMT software is not enough. You’ll hear from us and three major electronics companies’ executives on:

- Recognizing that new business models have expanded the scope and negative impact of the hidden factory

- Meeting customer expectations with smooth IT/OT data flows inherent in Industry 4.0

- Focusing on end-to-end manufacturing data flows

- Standardizing on modern electronics MES for greater profit margins

Table of Contents

- Revenue Opportunity Puts Pressure on Plants

- Hidden Factory

- New Business Models

- Manufacturing Data Challenges

- Managing Manufacturing Data

- Industry 4.0

- Business Pressure to Invest

- Helping Manufacturing Data Flow

- Benefits of Standardizing on MES

- Recommendations

- Conclusion / Call to Action

Executive Summary

The smart connected world presents enormous growth opportunities for electronics manufacturers, including components, boards, substrates, contract manufacturers, and OEMs. Yet, that growth comes with product and application diversity and price pressures. That combination of factors creates tremendous challenges to keep operating margins and profit healthy. Improved manufacturing data management can address many of those challenges. Fortunately, a proven solution is to add a modern Industry 4.0-ready manufacturing execution system (MES).Conclusion

Operational Benefits Modernizing the manufacturing data landscape has clear benefits for electronics operations. Systems must deliver visibility and coherent data for • day-to-day operating • ease of delivering data to customers • being agile in the face of relentless change • ability to support advanced analytics for continued improvements Bottom-line Impact Good manufacturing data management can also support lower operating costs, continuous improvement, and productivity. Modern MES, with its data flows and context, can help nearly everyone. This includes IT and OT staff trying to maintain their systems, engineers working to understand how well their designs are performing, operators and supervisors making splitsecond decisions, or executives making business and partnership decisions. Top-line Impact Customers demand that electronics companies ship reliable and complete data with products. Modern MES delivers track and trace, but so much more to ensure data and products meet requirements. In this way, MES can boost top-line revenues, design wins, and ongoing loyalty. Act Now to Protect Profits Electronics companies must not be complacent. Applications, products, and business models are changing. Many older systems cannot support the business’s most profitable aspects, such as outsourced services for design, assembly, testing, and logistics. The good news is, today’s modern MES can act as the manufacturing data management system you need to meet expectations and boost operating profits. *This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor Critical Manufacturing for the full research (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Boosting Electronics Operating Margins in an Uncertain World (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => electronics-mes-ebook [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:25 [post_modified_gmt] => 2022-11-15 03:28:25 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10968 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 10947 [post_author] => 2 [post_date] => 2021-10-06 22:15:14 [post_date_gmt] => 2021-10-07 02:15:14 [post_content] => What’s the difference between the vision and the reality of the AEC digital twin? What do clients really want? This webinar asks the experts to weigh in.

Increasing focus on digitalization has spurred interest in the concepts and benefits of digital twins. Companies and organizations worldwide strive to leverage digital twins to become more efficient and ensure the reliability and safety of their products, services, and facilities. But do we all understand the digital twin concept in the same way? This webinar on October 21st at 12PM EDT will explore the nature of related technologies, dig into the differences between the digital twin and BIM, and cover other hot questions the industry wants to know.

Register now to hear from industry experts. For more information on the event and panelists, visit AMC Bridge's event page.

What’s the difference between the vision and the reality of the AEC digital twin? What do clients really want? This webinar asks the experts to weigh in.

Increasing focus on digitalization has spurred interest in the concepts and benefits of digital twins. Companies and organizations worldwide strive to leverage digital twins to become more efficient and ensure the reliability and safety of their products, services, and facilities. But do we all understand the digital twin concept in the same way? This webinar on October 21st at 12PM EDT will explore the nature of related technologies, dig into the differences between the digital twin and BIM, and cover other hot questions the industry wants to know.

Register now to hear from industry experts. For more information on the event and panelists, visit AMC Bridge's event page.

Moderator: Jim Brown, Tech-Clarity

Panelists:

Moderator: Jim Brown, Tech-Clarity

Panelists:

- Igor Tsinman, Co-Founder and President of AMC Bridge

- Marzia Bolpagni, UK BIM Alliance Ambassador

- Rick Dunlap, Technical Services Vice President of BrandSafway

- David Craig Weir-McCall, Business Development Manager of Unreal Engine Enterprise of Epic Games

- Jim Quanci, Senior Director of ADN partnerships of Autodesk

Should quality management and product lifecycle management be a single system?

As companies seek better digital continuity, the answer might appear to be yes. And yet, it may not work in every company. Register now to hear arguments on both sides of this debate on Tuesday, October 13 at 11 am Eastern, 8 am Pacific, 17:00 GMT. We’ll respond to these questions:

Should quality management and product lifecycle management be a single system?

As companies seek better digital continuity, the answer might appear to be yes. And yet, it may not work in every company. Register now to hear arguments on both sides of this debate on Tuesday, October 13 at 11 am Eastern, 8 am Pacific, 17:00 GMT. We’ll respond to these questions:

- Must PLM and QMS be part of the same system?

- How will PLM and QMS software providers respond to industry trends such as data management platforms, focusing on customer experience, creating vertical solutions?

- What interesting things are happening in the PLM and QMS markets?

- What do we think of Propel and its approach?

- What’s in the crystal ball for the next couple of years?

How can manufacturers adopt cloud PLM to support digital transformation but avoid being stuck with a dead-end, custom system? Is it time to force a hard decision between customization and the cloud? Read Digital Transformation Driving PLM to the Cloud to learn what three leading manufacturers and our research have to say.

How can manufacturers adopt cloud PLM to support digital transformation but avoid being stuck with a dead-end, custom system? Is it time to force a hard decision between customization and the cloud? Read Digital Transformation Driving PLM to the Cloud to learn what three leading manufacturers and our research have to say.

- How today’s manufacturers are leveraging cloud PLM to support their digital transformation initiatives

- The business triggers that lead to upgrading current PLM solutions

- The compelling benefits of cloud and architecture choices that need to be made

- How low-code PLM can support digital transformation

Table of Contents

- Executive Summary

- The Manufacturer's Viewpoint on PLM

- The Need to Upgrade PLM

- Cloud is Compelling

- Evaluating PLM Deployment Options

- Out-of-the-Box (OOTB) is a Fallacy

- Functionality First

- Cloud and Custom Aren't Incompatible

- Key Takeaways

- Acknowledgments

Executive Summary

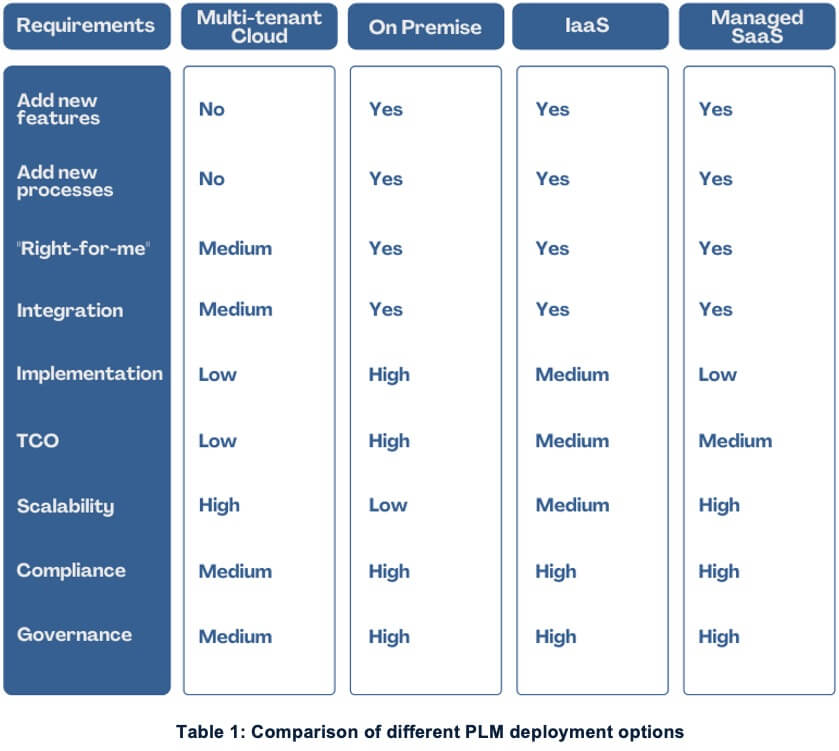

Digital Transformation Demands New Capabilities, Agility Digital transformation is intensifying the need to tailor PLM systems to serve as a company’s digital backbone and support new ways of innovating and operating. Engineers need the latest features and capabilities, but also need to keep the “right-for-me” PLM capabilities they already have. PLM solutions that are customized to achieve these goals, however, can create an ongoing need for specialized services that can limit agility and prevent adoption of new features and software versions. Transitioning to the Cloud Cloud solutions are compelling but are not commonly as tailorable as traditional solutions to provide a customized experience. Cloud offers numerous business and technical advantages including lower costs, less need for IT support, strong security, high availability, and practically infinite scalability. The tradeoff is typically a more out-of-the-box (OOTB) solution with lower ability to customize to enforce company standards and provide the right experience to the end user. "Cloud" and "Customization" can Co-Exist Our experience shows that most PLM implementations are not OOTB, especially for large organizations. This creates tension between cloud benefits and creating the new digital backbone and a “right-for-me” experience. As our experience and the research for this eBook shows, however, the right balance between cloud benefits and desired customization may be available through the emerging alternative to customization, low-code / no-code development.Evaluating PLM Deployment Options

Cloud Comes in a Variety of Options Cloud is compelling, but “the cloud” is not a single option. There are multiple ways to implement PLM. Let’s look at the impacts of the different options on factors like cost, agility, and the ability to customize for the “right for me” experience. Note that these are generalizations and we recognize that there are exceptions to every rule.

Key Takeaways

Research for this report leads our analysts to the following conclusions:

Research for this report leads our analysts to the following conclusions:

- PLM is becoming the digital backbone for manufacturers’ digital transformation strategy

- Most engineers prioritize PLM functionality and the “right-for-me” experience over cloud benefits. Traditional customization approaches lead to large technical debt and can result in dead-end customizations.

- PLM is a business imperative, and like the business, it’s a moving target. It’s important to have the ability to adapt the PLM system as needs change, to remain agile, without adding technical debt.

- Cloud and customization can both be options at the same time. The right PLM architecture can provide cloud benefits while also enabling customization without incurring significant technical debt.

Would you like to learn more about one of the fastest growing best practices for systems engineering, MBSE: The Unsung Hero?

Michelle Boucher joined an expert panel to discuss MBSE as the unsung hero of systems engineering and a key enabler of innovation in complex products. The panel discussed:

Would you like to learn more about one of the fastest growing best practices for systems engineering, MBSE: The Unsung Hero?

Michelle Boucher joined an expert panel to discuss MBSE as the unsung hero of systems engineering and a key enabler of innovation in complex products. The panel discussed:

- How MBSE is different

- The value of a model-based approach vs. document-based

- Success factors for a model-based approach

- Challenges to look out for

- Advice to implement it

- Shelly Kramer, Lead Analyst and Founding Partner, Futurum Research

- Jim Anderton, Director of Content, engineering.com

- Douglas Orellana Ph.D, CSEP, OCSMP, ITIL4, SPC5, Vice President of Intelligent Systems Engineering, ManTech

- Michelle Boucher, Vice President of Research for Engineering Practices, Tech-Clarity, Inc

- Saulius Pavalkis, Industry Business Senior Consultant and MBSE Transformation Leader, CATIA Dassault Systèmes

- Sept. 22: Digital Transformation-Where Do We Go From Here?

- Sept. 23: How Manufacturing Success starts with Virtual + Real Operations

[post_title] => MBSE: The Unsung Hero

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => mbse-virtual-event

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-08 21:52:01

[post_modified_gmt] => 2024-01-09 02:52:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10883

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 10875

[post_author] => 2574

[post_date] => 2021-09-16 12:26:01

[post_date_gmt] => 2021-09-16 16:26:01

[post_content] =>

[post_title] => MBSE: The Unsung Hero

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => mbse-virtual-event

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-08 21:52:01

[post_modified_gmt] => 2024-01-09 02:52:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10883

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 10875

[post_author] => 2574

[post_date] => 2021-09-16 12:26:01

[post_date_gmt] => 2021-09-16 16:26:01

[post_content] =>  Manufacturing is constantly evolving, so how do you define advanced manufacturing?

In this podcast episode, Julie Fraser and James Zhang, VP Market Development, Connected Operations at PTC, share their views. It starts with what constitutes advanced manufacturing today and how that has changed.

New technologies can play a role, but are not sufficient. How a manufacturer uses these technologies with what they already have to improve business outcomes points to whether it's advanced. COVID and global supply chain disruptions have changed which business metrics are vital - and sometimes what plants make. So agility and resilience matter.

The conversation also touches on effective processes and employee mindsets, and how technology can impact those. For example, what's the role of having employees feel more energized - now and in the future? Can people work together more effectively and be more empowered in these changed socially distanced environments? Julie and James think so. Yet, it might require you re-think your business and your shop floor.

Listen to the podcast to hear ideas and examples of agility, resilience, safety, empowerment, and production innovation. Thank you to PTC for the opportunity to have this discussion.

For more information, see our related research:

Manufacturing is constantly evolving, so how do you define advanced manufacturing?

In this podcast episode, Julie Fraser and James Zhang, VP Market Development, Connected Operations at PTC, share their views. It starts with what constitutes advanced manufacturing today and how that has changed.

New technologies can play a role, but are not sufficient. How a manufacturer uses these technologies with what they already have to improve business outcomes points to whether it's advanced. COVID and global supply chain disruptions have changed which business metrics are vital - and sometimes what plants make. So agility and resilience matter.

The conversation also touches on effective processes and employee mindsets, and how technology can impact those. For example, what's the role of having employees feel more energized - now and in the future? Can people work together more effectively and be more empowered in these changed socially distanced environments? Julie and James think so. Yet, it might require you re-think your business and your shop floor.

Listen to the podcast to hear ideas and examples of agility, resilience, safety, empowerment, and production innovation. Thank you to PTC for the opportunity to have this discussion.

For more information, see our related research:

- Lower Six Manufacturing Costs with IoT (eBook)

- What is the Cost of Poor Quality in Your Environment (guest blog post)

- How Advanced Analytics in Manufacturing Can Lead to Cost Cuts (guest post)

Understanding MBSE: Your Secret Weapon for System Complexity

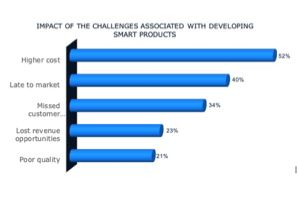

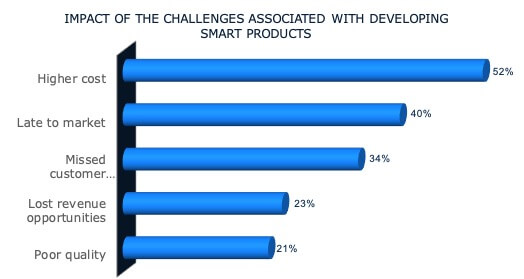

Staying Competitive Has Led to Increased Complexity Competition is fierce for today’s manufacturers as they seek to win market share from both traditional competitors and emerging start-ups, often at a global level. Consequently, product engineering and innovation play a crucial role in competitive differentiation. Innovation opportunities range from smarter features to new service offerings, which require increases in software, electronics, connectivity, sensors, components, and more. In fact, a Tech-Clarity study, Transformational Product Design: How to Achieve Success Designing Smarter Products, found that 71% of survey respondents report feeling pressure to add more software and electronics.

While this is a powerful way to attract customers, it increases product complexity, making an engineer’s job even more challenging. Tech-Clarity’s research study, How to Engineer High-Performing, Quality Products with Extra Cost, finds that 67% of survey respondents say complexity has grown over the last five years, and 44% find it’s even harder to make critical design decisions. Yet, Top Performers are 58% more likely than their competitors to be confident in their decisions. These results show that while the job may be getting harder, there are practices that will help.

However, getting it wrong is expensive. Companies that don’t make it easier for engineers will suffer negative consequences (see graph).

Competition is fierce for today’s manufacturers as they seek to win market share from both traditional competitors and emerging start-ups, often at a global level. Consequently, product engineering and innovation play a crucial role in competitive differentiation. Innovation opportunities range from smarter features to new service offerings, which require increases in software, electronics, connectivity, sensors, components, and more. In fact, a Tech-Clarity study, Transformational Product Design: How to Achieve Success Designing Smarter Products, found that 71% of survey respondents report feeling pressure to add more software and electronics.

While this is a powerful way to attract customers, it increases product complexity, making an engineer’s job even more challenging. Tech-Clarity’s research study, How to Engineer High-Performing, Quality Products with Extra Cost, finds that 67% of survey respondents say complexity has grown over the last five years, and 44% find it’s even harder to make critical design decisions. Yet, Top Performers are 58% more likely than their competitors to be confident in their decisions. These results show that while the job may be getting harder, there are practices that will help.

However, getting it wrong is expensive. Companies that don’t make it easier for engineers will suffer negative consequences (see graph).

This blog post explores the reasons for these business impacts. It also discusses why new approaches are needed, what MBSE is, and how it can help.

Learn More

To learn more about this exciting topic, Michelle joined a panel of experts for an interactive discussion on MBSE. Among other issues, the panel discussed how to justify MBSE and shared advice to implement it. You can access the recording by registering.

This blog post explores the reasons for these business impacts. It also discusses why new approaches are needed, what MBSE is, and how it can help.

Learn More

To learn more about this exciting topic, Michelle joined a panel of experts for an interactive discussion on MBSE. Among other issues, the panel discussed how to justify MBSE and shared advice to implement it. You can access the recording by registering.

[post_title] => Understanding MBSE

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => understanding-mbse

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-08 21:57:29

[post_modified_gmt] => 2024-01-09 02:57:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10851

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 10833

[post_author] => 2

[post_date] => 2021-09-10 14:26:55

[post_date_gmt] => 2021-09-10 18:26:55

[post_content] =>

[post_title] => Understanding MBSE

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => understanding-mbse

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-08 21:57:29

[post_modified_gmt] => 2024-01-09 02:57:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10851

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 10833

[post_author] => 2

[post_date] => 2021-09-10 14:26:55

[post_date_gmt] => 2021-09-10 18:26:55

[post_content] =>  How can you navigate digitalization challenges in a way that will evolve with current and future needs? Join this webcast where we’ll share the results of Tech-Clarity’s research on how manufacturers accelerate digital transformation with low-code applications, and Siemens’ Christopher Merz will share practical experience from the field.

You will learn:

How can you navigate digitalization challenges in a way that will evolve with current and future needs? Join this webcast where we’ll share the results of Tech-Clarity’s research on how manufacturers accelerate digital transformation with low-code applications, and Siemens’ Christopher Merz will share practical experience from the field.

You will learn:

- The importance of digital transformation to business strategy

- The impact of digitalization on existing applications

- Which transformation initiatives generate the most gaps

- Common challenges developing apps

- The benefits of a low-code development approach

You can also learn more from the underlying research study, Filling Digital Transformation Gaps with Low-Code.

[post_title] => Solve Digital Transformation Gaps with Low-Code (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => low-code-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-09 20:47:47

[post_modified_gmt] => 2024-09-10 00:47:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10833

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 10810

[post_author] => 2

[post_date] => 2021-09-08 13:12:57

[post_date_gmt] => 2021-09-08 17:12:57

[post_content] =>

You can also learn more from the underlying research study, Filling Digital Transformation Gaps with Low-Code.

[post_title] => Solve Digital Transformation Gaps with Low-Code (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => low-code-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-09 20:47:47

[post_modified_gmt] => 2024-09-10 00:47:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10833

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 10810

[post_author] => 2

[post_date] => 2021-09-08 13:12:57

[post_date_gmt] => 2021-09-08 17:12:57

[post_content] =>  What is more important to meeting new product development due dates, individual engineering productivity or product development efficiency? We surveyed over 160 companies to find out.

Please enjoy the summary below.* For the full report, please visit our sponsor SOLIDWORKS (registration required).

What is more important to meeting new product development due dates, individual engineering productivity or product development efficiency? We surveyed over 160 companies to find out.

Please enjoy the summary below.* For the full report, please visit our sponsor SOLIDWORKS (registration required).

Table of Contents

- Executive Overview

- Individual Productivity or Process Efficiency?

- The Impact of Product Development Efficiency

- Process Efficiency from Better Collaboration and Coordination

- Process Efficiency from Data Management

- How Can Companies Improve NPD Performance?

- Top Performers Have Better NPD Coordination, Collaboration

- Top Performers Have Digital Data Continuity

- Top Performers Have a Cohesive Product Data Model

- Recommendations and Next Steps

- About the Research

- Acknowledgments

Executive Overview

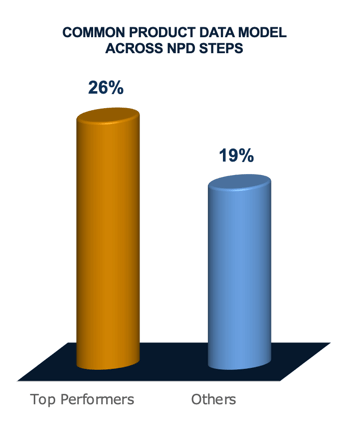

Manufacturers Consistently Miss NPD Targets New product development (NPD) speed and agility have a clear impact on competitiveness and product profitability. Unfortunately, an earlier Tech-Clarity study found that manufacturers miss project launch dates 45% of the time2. The research also showed that time-to-market demands had increased for about two-thirds of manufacturers. Engineering Inefficiency is a Big Issue New product development (NPD) speed and agility have a clear impact on competitiveness and product profitability. Unfortunately, an earlier Tech-Clarity study found that manufacturers miss project launch dates 45% of the time2. The research also showed that time-to-market demands had increased for about two-thirds of manufacturers. Identifying Best Practices in NPD Is improving engineering efficiency enough to solve the long-time issue of missed product development dates? We believe there is more to this puzzle. We analyzed survey responses from 167 companies and identified those that were better able to develop products rapidly and efficiently while maintaining product development agility. Then, we analyzed what these “Top Performers” do differently than the poorer-performing “Others.” Top Performers Streamline NPD with a Cohesive Digital Thread Researchers found that the Top Performers are more likely to streamline their NPD process by creating digital continuity. In specific, they are twice as likely as Others to have full digital data continuity across phases or steps in their product development process. In a related finding, they are 37% more likely to leverage a common data model across the stages of new product development. This common product definition with full digital continuity creates a cohesive digital thread. The report explains these findings in depth and shares additional capabilities that Top Performers have mastered more than Others. Read more to learn how your company can improve NPD performance and profitability.Individual Productivity or Process Efficiency?

Time-to-Market Takes More Than Individual Productivity First, let’s be clear that manufacturers can’t choose between individual engineering efficiency and product development speed and agility. They are clearly inextricably related. NPD relies on efficient and effective engineering, but developing a successful product requires input and coordination from multiple disciplines, departments, and the supply chain. Process and project-level challenges can cause productivity loss on a grand scale.

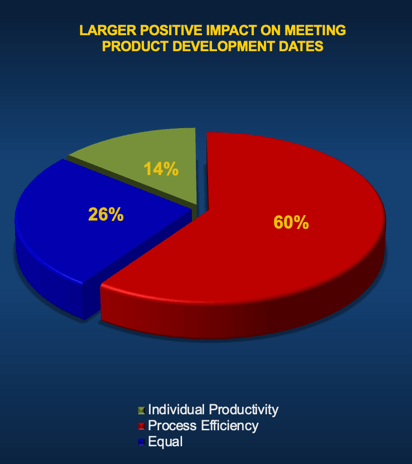

Process Efficiency Outweighs Individual Productivity

When it comes to meeting product development due dates, inefficient NPD processes can make even the most efficient engineering teams miss time-to-market objectives. Researchers asked what has a larger positive impact on meeting product development due dates:

First, let’s be clear that manufacturers can’t choose between individual engineering efficiency and product development speed and agility. They are clearly inextricably related. NPD relies on efficient and effective engineering, but developing a successful product requires input and coordination from multiple disciplines, departments, and the supply chain. Process and project-level challenges can cause productivity loss on a grand scale.

Process Efficiency Outweighs Individual Productivity

When it comes to meeting product development due dates, inefficient NPD processes can make even the most efficient engineering teams miss time-to-market objectives. Researchers asked what has a larger positive impact on meeting product development due dates:

- Productivity of individual contributors (designers, engineers, etc.)

- Overall process efficiency (workflows, project execution, collaboration, coordination, working as a team, etc.)

- Both equally

Recommendations and Next Steps

Improve Product Development Capabilities, Drive NPD Results Clearly, manufacturers can’t choose between engineering efficiency and product development speed, productivity, and agility. They need both. In addition to reducing non-value-added work in engineering, they must adopt the Top Performers’ best practice processes in order to improve new product development speed, efficiency, and agility. The challenges and benchmarked capabilities lead us to recommend that manufacturers should streamline new product development with full digital continuity on a common data model, creating a complete digital thread to improve NPD performance. To do this, they should adopt best practice processes and technology. Streamline Processes and Transitions Manufacturers should streamline transitions between project phases by:- Implementing formal, cross-departmental processes

- Providing cohesive design and product development data needed for reviews, approvals, and change management

Manufacturers should leverage a product innovation platform that streamlines product development by:

Manufacturers should leverage a product innovation platform that streamlines product development by:

- Providing a common data model and digital data continuity across product design and development phases

- Promoting communication and collaboration across departmental boundaries and encouraging project-level coordination

Transcript:

Jim: Welcome to not your typical industry interview, where we ask industry experts some questions that are really important. And then add in a few that maybe are just there for fun. Today, I'm joined by Paul Brown. He's a longtime industry friend and industry expert, and also the senior marketing director at Siemens digital industry software. Paul, welcome. Paul: Hi Jim, good to talk to you. Jim: So Paul, I think people are still learning a lot about the cloud for product innovation, product development and engineering, what are some of the misconceptions that you still find companies have about the cloud? Paul: Well, I think the biggest misconception is that it's an either or discussion. They will either say, "I think, it's cloud, or it's desktop?" And the answer really is using the right tools at the right time, in my processes, and being able to mix them, being able to share data between the two. It's not a one or other discussion. That's the important thing. And I think that's the big misconception people have. Jim: How did you first know that you were either blessed or cursed with the engineering gene, depending on how you look at it? Paul: Well, that was... When I was a kid, one of the things that I absolutely was addicted to was a thing that we called it... over here, it's called Meccano. I think, in the US it's Erector. It’s the sets, strips of steel, nuts and bolts, and you... And I would spend hours building stuff. I just loved it. Jim: Yeah, I think the people today, as they're growing up, they'll probably have the Lego set with a Raspberry Pi, that's probably cloud connected to their smartphone. And that's their Meccano or Erector set. Do you think the overall mood or view of cloud for product innovation, product development, and engineering software has changed? We definitely have seen an increased interest in adoption. But do you think that just the feeling has changed about it? Paul: Oh, absolutely. I think, as the current situation, the world situation has evolved, companies have been faced with this challenge about how do I work with my people at home? Here in the UK, we're still in lockdown. They're still all the rules that say, don't go into the office unless you absolutely have to. So companies have to carry on, on how they can run their business with their workforce working from home distribute... I want secure access to data, I want people to be able to carry on doing their jobs, but without risking my information going around. Sending memory sticks home is not an answer to collaborative design. So, leveraging the cloud for those sorts of things. And I think people are recognizing that cloud based technologies, using the cloud in that way, is allowing businesses to carry on and thrive in this environment. Jim: Yeah, we've actually got some research that shows that the impact of the pandemic has actually been an acceleration and increased focus on digital transformation, and in the cloud. So, certainly things are changing more quickly than they had been. Paul, when did you realize how different today's smart cloud connected products are than traditional products? Paul: It was about three and a half years ago. Now, I had actually had some say, what for me was major surgery. For the doctors, they actually... Doc told me, "Don't worry, it's minor surgery. You don't have to worry about it. It's absolutely fine that... Yeah, a heart bypass. Yeah, we do these every day." But what happened obviously, after that I was in my recuperation, and I like cycling, I'm very keen on cycling. And one of my goals was getting back on my bike, and I started back on the bike indoors. Now I have a friend who's also a coach who sets me kind of programs to do, and he was helping me plan out my recovery. I'd got on the bike one evening, I did an hour, and I'd stopped; literally, within a minute of me stopping, he sent me a text message that said, "I never told you... I thought I told you to keep your heart rate below 140." Because not only on the app, he had gone up to the cloud, he had come back to his device, he had seen I'd done a workout. He had seen what cadence I'd done, what my heart rate had been... How my heart rate had varied throughout that hour, through the whole thing, and how much power I'd been putting out. He saw all those measurements on his phone, and so then he sent me a message to tell me that I was pushing too hard and I should be, I should be more patient. So that was it, he was like, "Wow, you cannot avoid that." And that was when I started saying, "Okay, that's the power of all this internet, interconnected technologies and cloud based apps." Jim: Great. Paul, thank you so much for sharing your views, always a pleasure and I always learn something. Paul: My pleasure. Thanks for talking Jim, speak to you again soon. Jim: Thanks for joining us today on the web show where we ask industry experts mostly the wrong questions. It's been a lot of fun. I'd like to thank our sponsor, Siemens. You can learn more about cloud software for product innovation, product development, engineering, and other industrial needs by visiting Siemens Digital Industry Software. Thanks for coming. [post_title] => NYT Cloud Perceptions Discussion with Siemens’ Paul Brown (video) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => nyt-cloud-perceptions [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:29:24 [post_modified_gmt] => 2022-11-15 03:29:24 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10791 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [17] => WP_Post Object ( [ID] => 10787 [post_author] => 2577 [post_date] => 2021-09-04 10:47:30 [post_date_gmt] => 2021-09-04 14:47:30 [post_content] => How can a customized PLM system be moved to the cloud and avoid becoming stuck in a dead-end? Join James White, VP Digital Innovation Research, Tech-Clarity, and Mark Reisig, VP of Product Marketing, Aras Corporation, as they discuss:

How can a customized PLM system be moved to the cloud and avoid becoming stuck in a dead-end? Join James White, VP Digital Innovation Research, Tech-Clarity, and Mark Reisig, VP of Product Marketing, Aras Corporation, as they discuss:

- How today’s manufacturers are leveraging cloud PLM to support their digital transformation initiatives

- The business triggers that lead to upgrading a custom PLM solution

- The compelling benefits of cloud and the choices that need to be made

- Merging the operational phase of the product lifecycle with the voice of the customer

- Closing the loop to deliver a true customer-centric product experience

- Integrating product and customer experience elements from several underlying systems

[post_title] => Extending the Digital Thread to the Customer Experience (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => customer-experience-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:07

[post_modified_gmt] => 2022-11-15 03:27:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10769

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 10761

[post_author] => 2574

[post_date] => 2021-08-12 12:57:48

[post_date_gmt] => 2021-08-12 16:57:48

[post_content] =>

[post_title] => Extending the Digital Thread to the Customer Experience (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => customer-experience-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:07

[post_modified_gmt] => 2022-11-15 03:27:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10769

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[19] => WP_Post Object

(

[ID] => 10761

[post_author] => 2574

[post_date] => 2021-08-12 12:57:48

[post_date_gmt] => 2021-08-12 16:57:48

[post_content] =>  What’s the one constant for manufacturers today? Change.

The market is uncertain, and disruptions continue. Manufacturers cannot control demand for their products. Yet, with the right foundational technologies, they can respond confidently.

Hear Tech-Clarity’s Julie Fraser, VP of Research for Operations and Manufacturing at Tech-Clarity, and Allan Fine, Manager Sage X3 Field Sales Engineers, as they discuss technologies to boost success. Specifically, they will address planning and scheduling in the face of constant change. They will highlight better ways to utilize production capacity and manage inventory. Another concept they will discuss is the benefit of knowing the current status as well as projecting scenarios to keep the supply chain in sync with ever-changing realities to respond confidently.

View the this webcast on-demand on the Sage X3 website. Click the white box on the left in the top blue banner.

[post_title] => 3 Ways Manufacturers Can Respond Confidently in the Face of Unpredictable Demand (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => respond-confidently-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:07

[post_modified_gmt] => 2022-11-15 03:27:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10761

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 11122

[post_author] => 2572

[post_date] => 2022-02-28 08:25:32

[post_date_gmt] => 2022-02-28 13:25:32

[post_content] =>

What’s the one constant for manufacturers today? Change.

The market is uncertain, and disruptions continue. Manufacturers cannot control demand for their products. Yet, with the right foundational technologies, they can respond confidently.

Hear Tech-Clarity’s Julie Fraser, VP of Research for Operations and Manufacturing at Tech-Clarity, and Allan Fine, Manager Sage X3 Field Sales Engineers, as they discuss technologies to boost success. Specifically, they will address planning and scheduling in the face of constant change. They will highlight better ways to utilize production capacity and manage inventory. Another concept they will discuss is the benefit of knowing the current status as well as projecting scenarios to keep the supply chain in sync with ever-changing realities to respond confidently.

View the this webcast on-demand on the Sage X3 website. Click the white box on the left in the top blue banner.

[post_title] => 3 Ways Manufacturers Can Respond Confidently in the Face of Unpredictable Demand (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => respond-confidently-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:07

[post_modified_gmt] => 2022-11-15 03:27:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10761

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 11122

[post_author] => 2572

[post_date] => 2022-02-28 08:25:32

[post_date_gmt] => 2022-02-28 13:25:32

[post_content] =>  How can startup companies improve their chances of success?

Our Startup Survival Guide reveals both how and why simulation can provide startups an edge to launch a successful product. As part of a cloud platform, CAE can also be more accessible to startups.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

For more information on simulation, see our related research How to Survive and Win New Markets By Getting Even More Value from Simulation and How to Engineer High-Performing, Quality Products without Extra Cost.

How can startup companies improve their chances of success?

Our Startup Survival Guide reveals both how and why simulation can provide startups an edge to launch a successful product. As part of a cloud platform, CAE can also be more accessible to startups.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

For more information on simulation, see our related research How to Survive and Win New Markets By Getting Even More Value from Simulation and How to Engineer High-Performing, Quality Products without Extra Cost.

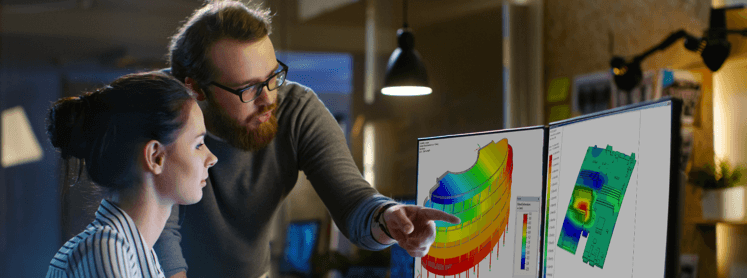

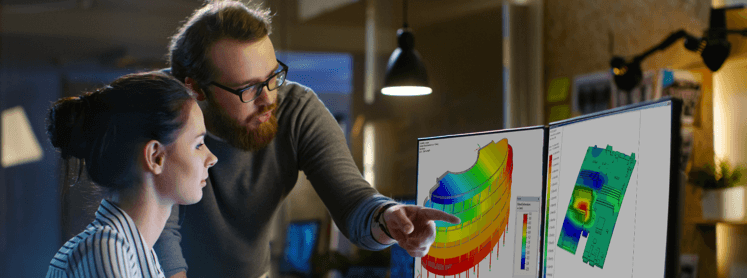

Executive Summary

Endless Possibilities Recessions and the years following them often mark the birth of new businesses, making this a very exciting time for entrepreneurs. With expanded options for funding and opportunities for new technologies to enable innovation, there are endless possibilities for startups. As a result, we are now seeing more successful new companies than ever before. Unfortunately, for every success story, there are even more startups that do not make it. It is hard to start a new business from scratch as funding is limited, and competing with more established companies that have more resources can be challenging. The good news is that for many, modern software tools are closing the resource gap. New software solutions, supported by a modern infrastructure, allow even the smallest businesses access to resources that previously were available only to large companies with deep pockets. Cloud-Based Simulation A cloud-based simulation software platform is one such tool. Simulation software allows you to evaluate more options in less time, optimize the design, and catch problems early in the design process. In addition, startups can avoid significant upfront investments in software and hardware by using a cloud-based solution. Plus, companies do not need to worry about investing precious resources in an IT department to implement and maintain it. This Report This report discusses the most common reasons startups fail and explains how a cloud-based simulation platform can help. By taking advantage of the technology, it can allow you to:- Access more funding

- Improve profitability

- Get the product right

- Validate market needs

- Leverage the right talent

Table of Contents

- The Opportunities for Startups

- 1. Access More Funding

- 2. Improve Profitability

- 3. Get the Product Right

- 4. Validate Market Needs

- 5. Leverage the Right Talent

- Recommendations

- Acknowledgments

Recommendations

Recommendations and Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

- Use simulation to demonstrate progress to investors to help justify additional funding.

- Leverage a cloud platform to preserve capital by avoiding high upfront costs for software licenses and investments in high-end hardware.

- Optimize your product for quality and cost to maximize profitability and allow you to price your product competitively.

- Support rapid iterations with simulation to develop a more innovative, competitive product.

- Take advantage of simulation in the cloud to validate your product early and often with potential customers to verify it will meet market needs.

- Tap into additional expertise as needed with a simulation cloud platform that will provide flexibility to easily collaborate with third parties.

All Results for "All"

Choose the Right PDM System (buyer’s guide)

How can you ensure that you choose the right PDM software and partner for your business? The right system serves as the backbone for digital transformation and impacts productivity, product success, and profitability. How can you make sure to get it right? Please enjoy the summary* below. For the full research, please visit our sponsor…

A Digital Approach to System Family Engineering