What’s the one constant for manufacturers today? Change. The market is uncertain, and disruptions continue. Manufacturers cannot control demand for their products. Yet, with the right foundational technologies, they can respond confidently. Hear Tech-Clarity’s Julie Fraser, VP of Research for Operations and Manufacturing at Tech-Clarity, and Allan Fine, Manager Sage X3 Field Sales Engineers, as…

- The Smart Product Imperative

- The Continuing Smart Product Revolution

- What's Driving Smart Products?

- Beyond Smart Equipment to Digital Business Models

- Multi-faceted Business Benefits

- Smart Products Improve Profitability

- Business Challenges

- Technical Issues

- How Can Companies Improve Performance?

- What Do Top Performers Do Differently?

- Top Performers Have More Integrated Systems

- Conclusions

- About the Research

- Acknowledgments

The Smart Product Imperative

Smart Products are Mandatory

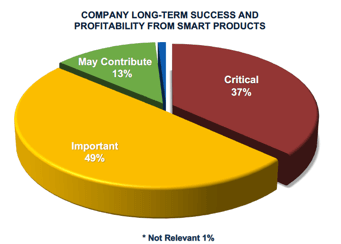

Our research on smart products has clearly shown the importance and expected growth of smart products. Since our earlier studies, our experience shows that companies have been aggressively transitioning to smarter products as predicted. At this time, survey respondents clearly indicate how critical the transformation has become. A full 86% of respondents indicate that smart products are important to support the long-term success and profitability of their company. Over one-third say they are critical.

Smart Product Requirements are Expanding

The move to smart products, however, is a journey. Not all companies with smart products have reached their full potential. Already in 2017, our research showed that over one-half of companies developing smart products feared losing market share unless they continually made products smarter2.

Are Smart Products Enough?

At this time researchers set out to investigate whether even making products “smarter” is enough to continually leverage smart products for profitability. There is a wide variety of maturity in how these products are used to drive value. We believe that smart products merely set the stage for even greater levels of business value unlocked by new, digital business models. Let’s take a look.

Smart Products are Mandatory

Our research on smart products has clearly shown the importance and expected growth of smart products. Since our earlier studies, our experience shows that companies have been aggressively transitioning to smarter products as predicted. At this time, survey respondents clearly indicate how critical the transformation has become. A full 86% of respondents indicate that smart products are important to support the long-term success and profitability of their company. Over one-third say they are critical.

Smart Product Requirements are Expanding

The move to smart products, however, is a journey. Not all companies with smart products have reached their full potential. Already in 2017, our research showed that over one-half of companies developing smart products feared losing market share unless they continually made products smarter2.

Are Smart Products Enough?

At this time researchers set out to investigate whether even making products “smarter” is enough to continually leverage smart products for profitability. There is a wide variety of maturity in how these products are used to drive value. We believe that smart products merely set the stage for even greater levels of business value unlocked by new, digital business models. Let’s take a look.

How Can Companies Improve Performance?

Identifying the Top Performers Researchers used our performance banding process to understand what companies that excel at profiting from smart products do differently. Respondents were asked to compare their performance as compared to their competition over the prior 24 months in a number of business metrics for smart products:- Revenue growth

- Profit margin expansion

- Service cost reduction

- Customer retention

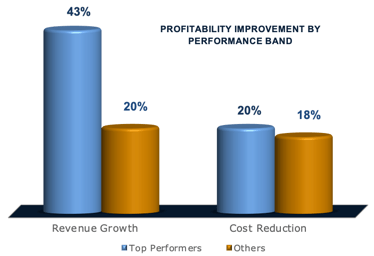

Quantifying the Advantage

Researchers quantified the reported performance advantages by comparing the profitability improvements of the Top Performers as compared to the Others.

They found that Top Performers have, on average, increased revenue by 43%. That’s twice as much as Others. They have also decreased cost by about 11% more than Others. Clearly, these companies are doing something differently.

Identifying Best Practices

Researchers examined the practices, capabilities, and technology of the Top Performers in order to understand what they do differently. They found important differences in the capabilities and technology that reflect higher maturity related to smart products. Then, they used this information to make recommendations to Others to improve their own performance.

Quantifying the Advantage

Researchers quantified the reported performance advantages by comparing the profitability improvements of the Top Performers as compared to the Others.

They found that Top Performers have, on average, increased revenue by 43%. That’s twice as much as Others. They have also decreased cost by about 11% more than Others. Clearly, these companies are doing something differently.

Identifying Best Practices

Researchers examined the practices, capabilities, and technology of the Top Performers in order to understand what they do differently. They found important differences in the capabilities and technology that reflect higher maturity related to smart products. Then, they used this information to make recommendations to Others to improve their own performance.

Conclusions

Smart Products are Mandatory Smart products are important or critical to the long-term profitability of most manufacturers. The vast majority of companies surveyed have transitioned to smart products and about one-half of their equipment, devices, and machines are smart. The Benefits are Compelling The transition to smart products provides significant business benefits, including double-digit revenue increase and cost reduction. The leaders, the Top Performers, are gaining even more significant gains from smart equipment, including on average:- 43% revenue growth

- 20% cost reduction

How can engineers improve efficiency, personal productivity and find the information they need faster? Join this live Onshape webcast with James White, VP of Digital Innovation Research at Tech-Clarity; Theo Richardson, founding partner and Director of Development at Rich Brilliant Willing (RBW); and Dave Corcoran, Head of Products at Onshape to gain insight into how top performing companies overcome the challenges of legacy file-based CAD and PDM systems.

Register now to gain insight into how top performing companies overcome the challenges of legacy file-based CAD and PDM systems.

For related research, read Accelerating Product Development with the Cloud.

[post_title] => Transforming CAD Data Management

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cad-data-management-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 13:38:13

[post_modified_gmt] => 2023-12-15 18:38:13

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10685

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 10670

[post_author] => 2574

[post_date] => 2021-07-19 13:31:58

[post_date_gmt] => 2021-07-19 17:31:58

[post_content] =>

How can engineers improve efficiency, personal productivity and find the information they need faster? Join this live Onshape webcast with James White, VP of Digital Innovation Research at Tech-Clarity; Theo Richardson, founding partner and Director of Development at Rich Brilliant Willing (RBW); and Dave Corcoran, Head of Products at Onshape to gain insight into how top performing companies overcome the challenges of legacy file-based CAD and PDM systems.

Register now to gain insight into how top performing companies overcome the challenges of legacy file-based CAD and PDM systems.

For related research, read Accelerating Product Development with the Cloud.

[post_title] => Transforming CAD Data Management

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cad-data-management-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 13:38:13

[post_modified_gmt] => 2023-12-15 18:38:13

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10685

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 10670

[post_author] => 2574

[post_date] => 2021-07-19 13:31:58

[post_date_gmt] => 2021-07-19 17:31:58

[post_content] =>  Could medical device companies improve both patient outcomes and profit? Yes, and Predictive Quality for Medical Devices: Comprehensive Data to Move Risk-based Approaches into Production discusses how to modernize the quality system for best results. The predictive approach to quality is proactive and requires strong manufacturing data management. The report includes insights from executives at medical device companies already making strides toward these improvements.

For related research, please read The Manufacturing Data Challenge.

Please enjoy the summary* below. Please visit our sponsor, Critical Manufacturing, for the full research (registration required).

Could medical device companies improve both patient outcomes and profit? Yes, and Predictive Quality for Medical Devices: Comprehensive Data to Move Risk-based Approaches into Production discusses how to modernize the quality system for best results. The predictive approach to quality is proactive and requires strong manufacturing data management. The report includes insights from executives at medical device companies already making strides toward these improvements.

For related research, please read The Manufacturing Data Challenge.

Please enjoy the summary* below. Please visit our sponsor, Critical Manufacturing, for the full research (registration required).

Table of Contents

- Predictive Quality

- Risk-based Approach

- The Next Level of Risk-Based Approaches

- Feedback Loops

- Data Flows for Good Decisions

- Manufacturing Data Platform

- Advanced Quality Analytics

- Predictive Quality Recommendations

- Getting to Action

- Software for Predictive Quality

- Conclusions

- Recommendations

- Acknowledgements

Predictive Quality

Beyond Traditional Quality Systems Quality is the cornerstone of medical device manufacturers’ success and touches every aspect of the business. Quality is paramount not only for cost and compliance but for patient outcomes. As a result, many companies use sophisticated simulation and analysis to predict outcomes in research and development (R&D). Yet, that is only a part of the quality system. It’s time to expand predictive quality into production – and to create feedback loops.

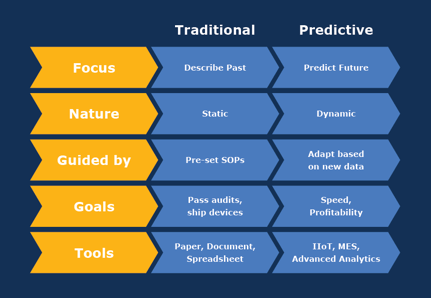

Predictive vs. Traditional Quality

Traditional quality is reactive or preventive at best. Rigid standards and procedures guide all activity, and samples and testing are frequent to be safe. Predictive quality is more proactive and adaptive – within the validated envelope. This new quality approach leverages data from product and process design, inventory, and supplier quality. It combines that data with real-time production information to foresee whether a product will meet quality specs.

Predictive Quality to Meet Market Pressures

Medical device manufacturers are under new pressures from both the market and regulators. Predictive quality is a foundational approach to meet those pressures:

Quality is the cornerstone of medical device manufacturers’ success and touches every aspect of the business. Quality is paramount not only for cost and compliance but for patient outcomes. As a result, many companies use sophisticated simulation and analysis to predict outcomes in research and development (R&D). Yet, that is only a part of the quality system. It’s time to expand predictive quality into production – and to create feedback loops.

Predictive vs. Traditional Quality

Traditional quality is reactive or preventive at best. Rigid standards and procedures guide all activity, and samples and testing are frequent to be safe. Predictive quality is more proactive and adaptive – within the validated envelope. This new quality approach leverages data from product and process design, inventory, and supplier quality. It combines that data with real-time production information to foresee whether a product will meet quality specs.

Predictive Quality to Meet Market Pressures

Medical device manufacturers are under new pressures from both the market and regulators. Predictive quality is a foundational approach to meet those pressures:

- Margin: Lower costs through reduced scrap, rework, sampling and testing

- Speed of new products: Improve design for manufacturability and quality (DFM/DFQ)

- Risk: Realize regulators’ vision of minimizing both regulatory non-compliance harm and potential health hazards

- Cycle time: Products move in the process envelope with complete documentation at every step

- Quality: Fewer non-conformances during production

- Field outcomes: Reduced customer complaints, adverse events, and in-use products issues, and ability to quickly improve

Conclusions

Predictive quality allows a medical device manufacturer not only to comply, but to improve its business results. Building on the risk-based approach to more fully encompass the complete quality system, including production, is a logical next step. Yet, traditional software approaches leave too many gaps in the information flow. Predictive quality is only possible when medical device manufacturers have an agile, responsive, and integrated manufacturing data system to support it. The platform must pull in many data streams, put them in context, and conduct effective predictive analysis. It must integrate both to OT and enterprise, creating feedback loops at many levels. There are companies starting to do that today. Medical device industry leaders are building out the information systems to enable automated release. So, beyond documentation of the process and product, the system will understand whether all processes stayed within the designed envelope to ensure a high-quality product result. Companies that can step into this next level of predictive quality will have advantages in speed, regulatory compliance, cost, and confidence. *This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor Critical Manufacturing for the full research (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Predictive Quality for Medical Devices (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => predictive-quality-ebook [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:25 [post_modified_gmt] => 2022-11-15 03:28:25 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10670 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [6] => WP_Post Object ( [ID] => 10650 [post_author] => 2 [post_date] => 2021-07-13 14:36:29 [post_date_gmt] => 2021-07-13 18:36:29 [post_content] => With the crisis phase of COVID-19 passing, how are companies adjusting corporate strategies and priorities to address intensified business risk and disruption? How are they setting transformation strategies to ensure long-term business success and profitability in the face of rapidly evolving business models, new technology adoption, environmental concerns, socio-economic issues, and political uncertainty? We surveyed 246 organizations to find out.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes.

You can also read our 2020 research, Business Sustainability and Survival 2020, as well as our 2019 research, Executive Strategies for Long Term Business Success.

With the crisis phase of COVID-19 passing, how are companies adjusting corporate strategies and priorities to address intensified business risk and disruption? How are they setting transformation strategies to ensure long-term business success and profitability in the face of rapidly evolving business models, new technology adoption, environmental concerns, socio-economic issues, and political uncertainty? We surveyed 246 organizations to find out.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes.

You can also read our 2020 research, Business Sustainability and Survival 2020, as well as our 2019 research, Executive Strategies for Long Term Business Success.

Table of Contents

- Business Risk and Disruptions Have Grown

- COVID-19 Disruption Brought Surprises

- Some Are More Prepared For Future Disruptions

- 2021 Returns to Balanced Response to Disruption

- Actions and Strategies Realigned (Exiting Crisis Mode)

- Strategic Drivers Return to Long-Term Sustainability

- Importance of Technology To Long-Term Success

- A Wide Variety of Technologies Are Strategic

- Pursuing A Variety of Tech-Supported Initiatives

- Executing Initiatives Is Still A Challenge

- Technology Adoption Challenges

- Conclusions and Next Steps

- About the Research

- Acknowledgments

Risk and Disruption Countered By Transformation

The Crisis Is Passing, But Business Risk and Disruption Persist In 2019, our Executive Strategies for Long-Term Business Success1 study found that business risk and disruption had increased for about three-quarters of survey participants over the prior five years. Clearly, business risk and disruption are not new. In 2020, our Business Sustainability (and Survival) Strategies 20202 research found that the COVID-19 disruption led many organizations to go into survival mode. The impact of the pandemic was unpredictable and had a more prolonged impact than other recent disruptions including earthquakes, tsunamis, volcanic activity, hurricanes, and human-created events like terrorism and armed conflict. Although they remained committed to important strategic initiatives like digital transformation and innovation, they lost focus on other essential pillars of long-term business sustainability. Although some are still struggling personally and professionally, our 2021 survey of 246 organizations finds that many organizations have emerged stronger because they innovated and implemented new technology to survive. The result is a market divided into organizations that are more agile and prepared for the next disruption and others who are at significant survival risk.

2021 Returns to Balanced Response to Disruption

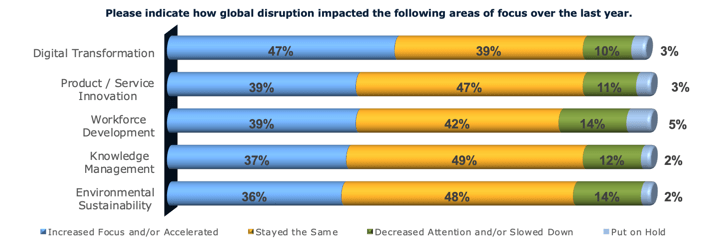

Survival Mode 2020 In 2020, we shared how organizations were responding to the disruption. The results were simultaneously encouraging and discouraging. We saw that organizations enhanced their activity on some long-term business sustainability priorities while putting others on the back burner. We believe this was a short-term survival tactic. We learned that organizations were:- Accelerating digital transformation

- Maintaining investment in innovation and agility

- Decreased attention, slowed down, or even put on hold developing the workforce of the future and improving environmental impact

2021 Reaction Reflects a More Long-term View

The current survey results indicate that organizations are returning to a more balanced response across the pillars of business sustainability. Over the last year, we've seen workforce development and environmental sustainability focus rebound. The number of organizations that report they are increasing focus or accelerating environmental sustainability efforts tripled from 12% to 36%, and those that are increasing attention on workforce development grew by 255%. These changes are encouraging, but also reflect the reality that many took a step back from these needs due to the magnitude of the disruption. The return to a balanced approach will help organizations recover and transition to a new normal.

2021 Reaction Reflects a More Long-term View

The current survey results indicate that organizations are returning to a more balanced response across the pillars of business sustainability. Over the last year, we've seen workforce development and environmental sustainability focus rebound. The number of organizations that report they are increasing focus or accelerating environmental sustainability efforts tripled from 12% to 36%, and those that are increasing attention on workforce development grew by 255%. These changes are encouraging, but also reflect the reality that many took a step back from these needs due to the magnitude of the disruption. The return to a balanced approach will help organizations recover and transition to a new normal.

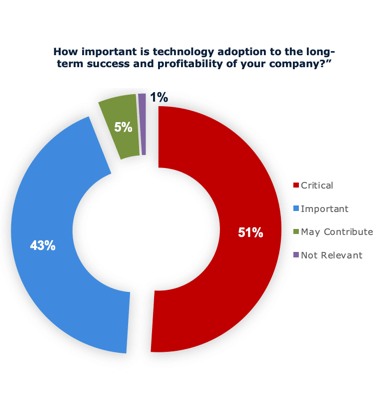

Importance of Technology To Long-Term Success

Digital Transformation Is Becoming The Norm

We put greater emphasis on technology in this year's survey because almost one-half of businesses increased focus and/or accelerated digital transformation last year due to the pandemic. This is not just due to the pandemic, of course. Our survey on the state of digital transformation3 found that more than one-half of respondents believe that digital initiatives are "important" if not "critical" to their business strategy. This survey supports that, showing the high strategic importance of digital transformation. It also points to the need to enable more remote work and collaboration, which requires new, digital technologies.

Sustainability Requires New Technology Adoption

How important, then, did respondents report that technology adoption is to their company's long-term success and profitability? Just over half say it's critical, and a full 94% state that it's at least important. The answer is not surprising. Many traditional organizations are in the process of becoming digital businesses. The message is clear; technology is a vital enabler of long-term business sustainability.

Digital Transformation Is Becoming The Norm

We put greater emphasis on technology in this year's survey because almost one-half of businesses increased focus and/or accelerated digital transformation last year due to the pandemic. This is not just due to the pandemic, of course. Our survey on the state of digital transformation3 found that more than one-half of respondents believe that digital initiatives are "important" if not "critical" to their business strategy. This survey supports that, showing the high strategic importance of digital transformation. It also points to the need to enable more remote work and collaboration, which requires new, digital technologies.

Sustainability Requires New Technology Adoption

How important, then, did respondents report that technology adoption is to their company's long-term success and profitability? Just over half say it's critical, and a full 94% state that it's at least important. The answer is not surprising. Many traditional organizations are in the process of becoming digital businesses. The message is clear; technology is a vital enabler of long-term business sustainability.

Conclusions and Next Steps

The Crisis Is Subsiding Our 2021 survey finds that responding to COVID-19 disruption is no longer the most pressing inhibitor to focusing strategy on long-term business success and profitability. Researchers found that company strategies are now more balanced and organizations can better address all of the pillars of long-term business success – including those related to corporate responsibility. Stronger Capabilities During the disruption, many organizations accelerated digital transformation, enhanced innovation, and increased their agility. They also adopted new, digital technologies and ways of working to better collaborate and support remote work. In many ways, those organizations that invested in these types of digital transformation are better prepared for the next disruption. Risk, Disruption, and Opportunity Despite the reduced impact of the current disruption, business risk skyrocketed between 2019 and 2021. The disruption led to new risks like new competitors. Further, organizations still need to address rapidly evolving business models, new technology adoption, environmental concerns, socio-economic issues, and political uncertainty. Be Better, Adapt, Or Risk Being Obsolete Now that the short-term crisis has passed, organizations can focus on the three pillars of long-term business sustainability. But organizations must remain agile, continue to transform, and learn to be prepared to respond to future disruptions. They must continue to adopt new technology and business models, despite initiative execution and technology adoption challenges. Lastly, they must remember to maintain a balanced strategy that includes product and service innovation, workforce development, environmental stewardship, and corporate social responsibility. *This summary is an abbreviated version of the ebook and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes. If you have difficulty obtaining a copy of the research, please contact us. [post_title] => Business Sustainability and Transformation Strategies [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => transformation-strategies-ebook [to_ping] => [pinged] => [post_modified] => 2025-01-06 21:36:27 [post_modified_gmt] => 2025-01-07 02:36:27 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10650 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [7] => WP_Post Object ( [ID] => 10639 [post_author] => 2 [post_date] => 2021-07-10 00:11:55 [post_date_gmt] => 2021-07-10 04:11:55 [post_content] => What does a top expert in the engineering software market say about cloud migration for product innovation, engineering, and industrial software? What interesting things can we learn about Schnitger Corp’s Monica Schnitger during her interview with Tech-Clarity’s Jim Brown? Tune into this episode of (Not Your Typical) Tech Interview, the show where we make it interesting by asking some important industry questions and then add a couple more to have some fun and learn something about our industry experts. Want to find out why Monica thinks her first computer was really cool? Or why she hated the first one she worked on? Tune in to find out. https://youtu.be/WgXZAs6z5B8 For more information on industry readiness for the cloud, please see the first video of this series, (Not Your Typical) Cloud Interview with Siemens' Paul Brown. For more information on the engineering market's rapid shift to the cloud, please see the third video of this series, (Not Your Typical) Cloud Interview with Allan Behrens. For more information cloud perceptions, please see the fourth and final video of this series, (Not Your Typical) Cloud Perceptions Discussion with Siemens' Paul Brown. To get insights into your own company's cloud readiness please check out our Cloud PLM Advisor.Transcript

Jim: Hi, this is Jim Brown with Tech-Clarity. Welcome to the show where we ask industry experts some really important questions, and maybe some that are just for fun. *Not Your Typical Tech Interview Intro* Today, I'm joined by Monica Schnitger of Schnitger Corporation. She is the President and Principal Analyst there. She's an industry thought leader, she really helps people understand technology for engineers, designers and makers, and today we're getting together to talk about the adoption of the cloud for product innovation, engineering and industrial software. But like we usually do, we're going to make sure to ask a couple of questions, just to keep things interesting. Welcome Monica. Hi Monica, thanks for joining. Monica: Hi Jim. Jim: What changes have you seen over the last year or so related to the cloud for product innovation, engineering and industrial software? Monica: Clearly, the news of the last year has been the pandemic, and the fact that we all needed to do our jobs from some place other than normal, we were communicating by Zoom meetings, we might be doing CAD in the cloud or CAD virtualized or something else. I think that in the last year, we've really compressed maybe five years, maybe 10 years, depending on the company, of movement to the cloud into a really short time period. And I think that's awesome, and I think that's going to stay. Jim: Alright, so we'd like to ask some wildcard questions. Monica, what's your favorite browser? Monica: My favorite browser is Mozilla's Firefox, because I am told that it is the most secure. I don't know, that's what they say Jim: Do you think that manufacturers are looking at the shift to the cloud as an all or nothing proposition? Monica: Oh, absolutely not. I think that they're choosing what they do where. I think that they may have CAD on the desktop, but collaboration using the cloud, they may have simulation both locally because they can, and on the cloud for either extra capacity, extra compute power, or when their HPC center is full. I think that they're choosing what they do where, because they know that they can create their own environment the best way that they want to use it. Jim: Monica, what was the first computer that you ever used? Monica: That I ever used? I don't even remember. It was a terminal thing that was this horrible “teletype-y” kind of thing that went to a mainframe somewhere. It was awful. It was truly awful. Jim: So what opportunities are there for the cloud that are specific to the kind of software we deal with, product innovation, engineering, more industrial things that maybe aren't just the same as running another application on the cloud? Monica: Yeah, we can't discount the normal benefits, right? The lower cost of entry, the fact that somebody else is responsible for product updates and all that stuff, but I think that the real advantage in our space of the cloud is that it allows companies to get more types of users involved because of the lower cost of entry, perhaps, or because it's easier to use, it's also easier and less risky for them to try new things. And I think that's really important. One thing that these companies all need to do is improve their resilience and adaptability because this wasn't the only shock that they're going to see and they'll be better prepared for next time. Jim: Monica, what was the first computer you ever owned? Monica: Ah, that was cool, that was a Mac. It was one of the first ones that hit the market, it had a little tiny screen and you got a cassette in the box and you had to use your boom box. And so you listened to the cassette and then did things with that Mac. It was really fun and very approachable and not at all intimidating. And of course today we can connect to the cloud and get videos and all sorts of cool stuff for doing things, but back then, this was so different and really an awesome way to get started with personal computing. Jim: Monica, what advice would you have for manufacturers that are out looking at the cloud right now for more of their engineering industrial software? Monica: It's a great question. I think what we're starting to see is a bit of a digital divide where companies that jumped on this early in the pandemic, or even before the pandemic and sort of had this road map that they were able to execute last year, and then companies that haven't even started. So, for the companies that are already on this path, keep going, you're doing great. For the companies that haven't started, start taking a look at what your options are. Do you maybe want to do more collaboration in the cloud? That's an easy way to get started. Do you do simulation? Do you want to do some of that in the cloud? The basic idea is to get your feet wet and to try to become comfortable with security and access and uptime and all of those other things, and then expanding your footprint in the cloud as you get more comfortable with it. But you do have to start because your competitors are all doing this now. So it's time to get moving. Jim: Monica, thank you so much for joining today. I always enjoy talking to you, especially when you say “boom box,” and also learn something from you every time we talk. Thanks. Monica: Thank you, Jim. Me too. Jim: Thanks for joining us today on the web show where we ask some questions that most people might not think to ask. I'd like to thank our sponsor, Siemens Digital Industries Software You can learn more about how the cloud really can help quite a bit in product innovation, development, engineering and other industrial areas from the Siemens website [post_title] => NYT Cloud Migration Interview with Monica Schnitger (video) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => nyt-cloud-migration [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:29:24 [post_modified_gmt] => 2022-11-15 03:29:24 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10639 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 10610 [post_author] => 2 [post_date] => 2021-07-07 10:26:47 [post_date_gmt] => 2021-07-07 14:26:47 [post_content] => How can manufacturers get closer to customers, gain more intimacy, and create more business value for themselves and their customers? How does extending the digital thread into the customer experience and operational phase of the product lifecycle help? Our eBook shares the results of interviews with eight manufacturers to shed some light.

Please enjoy the summary* below. For the full research, please visit our sponsor Propel.

How can manufacturers get closer to customers, gain more intimacy, and create more business value for themselves and their customers? How does extending the digital thread into the customer experience and operational phase of the product lifecycle help? Our eBook shares the results of interviews with eight manufacturers to shed some light.

Please enjoy the summary* below. For the full research, please visit our sponsor Propel.

Table of Contents

- Digital Thread Context and Definition(s)

- Digital Thread Maturity

- The Business Value of Extending the Digital Thread

- Merge Product Threads with Customer Experience

- Identify Hurdles to Extending the Digital Thread

- Not an "All or Nothing" Proposition

- Reduce the Barriers

- Conclusion

- Next Steps

- Acknowledgments

Digital Transformation Unlocks Customer Value

Digital Transformation Drives Greater Customer Intimacy and Profitability Our research shows that 95% of companies view digital transformation as either important or critical to the long-term success of their company. The survey further finds the only thing more critical to a company's long-term business success than digital transformation is their customer relationships. This eBook explores extending the digital thread into the operational phase of the product lifecycle – capturing the current, as-is configuration of the product and how the customer actually uses it. Read on to learn how capturing the customer experience helps manufacturers gain new levels of intelligence and insight into products and customers so they can develop stronger customer relationships and drive higher levels of profitability.Digital Thread Maturity

Dimensions of Digital Thread Maturity

Our interviews discovered a variety of digital thread maturity levels with expanding levels of value. We found significant variation in the maturity of digital threads capabilities in:

Dimensions of Digital Thread Maturity

Our interviews discovered a variety of digital thread maturity levels with expanding levels of value. We found significant variation in the maturity of digital threads capabilities in:

- The approach, ranging from maintaining basic history in spreadsheets and text documents to more rigorous, structured data approaches

- The scope, starting from developing a partial picture and expanding to capture information from more disciplines

- The lifecycle, representing a variety of maturity that ranges from only design and engineering phases to extension to the in-use phase

Next Steps - Incorporate the Customer Experience

Extend the Digital Thread Extend the digital thread to the customer experience to achieve even greater value:- Develop a more intimate understanding of the customer and product experience.

- Create new value from increasing profitability with lower costs and higher revenue from spares, suppliers, upgrades, replacements, and cross-selling opportunities.

- Unlock new potential by closing the loop for continuous improvement.

The value is available, and each company should decide how best to take advantage of it. In the process, they will need to consider organizational elements like incentives, training, and developing buy-in. They should adopt best practice processes that incorporate data collection and install a sense of data quality ownership. Lastly, they should look to create a platform of solutions that integrates all of the product and customer experience elements together from underlying systems, including; PLM, ERP, MES, SLM, and CRM. The vision is achievable and starts with a strategy that can be implemented over time to drive new value.

*This summary is an abbreviated version of the ebook and does not contain the full content. For the full research, please visit our sponsor Propel.

If you have difficulty obtaining a copy of the research, please contact us.

[post_title] => Extending Digital Threads to the Customer Experience (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => customer-experience-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:23

[post_modified_gmt] => 2022-11-15 03:28:23

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10610

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 10577

[post_author] => 2572

[post_date] => 2021-06-28 18:02:02

[post_date_gmt] => 2021-06-28 22:02:02

[post_content] =>

The value is available, and each company should decide how best to take advantage of it. In the process, they will need to consider organizational elements like incentives, training, and developing buy-in. They should adopt best practice processes that incorporate data collection and install a sense of data quality ownership. Lastly, they should look to create a platform of solutions that integrates all of the product and customer experience elements together from underlying systems, including; PLM, ERP, MES, SLM, and CRM. The vision is achievable and starts with a strategy that can be implemented over time to drive new value.

*This summary is an abbreviated version of the ebook and does not contain the full content. For the full research, please visit our sponsor Propel.

If you have difficulty obtaining a copy of the research, please contact us.

[post_title] => Extending Digital Threads to the Customer Experience (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => customer-experience-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:23

[post_modified_gmt] => 2022-11-15 03:28:23

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10610

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 10577

[post_author] => 2572

[post_date] => 2021-06-28 18:02:02

[post_date_gmt] => 2021-06-28 22:02:02

[post_content] =>  What is the best way for engineers to manage multiple design criteria, impacted by multiple physics, yet still meet deadlines, cost targets, and quality requirements?

Tech-Clarity’s eBook, How to Engineer High-Performing, Quality Products without Extra Cost, examines this question. The eBook shares findings based on the results of a survey of 272 manufacturers. It also examines the reality today’s engineers face, and the variety of factors they must consider.

The results show that exceptional engineering is critical to the success of today’s products. At the same time, this is driving product complexity. As products continue to become more complex, it becomes even harder for engineers to make the right design decisions. Interestingly, Tech-Clarity research finds that Top Performers are 2.2 times more likely than Others to have effective processes to understand trade-offs and optimize products. A key differentiator leading to their success is their ability to simulate multiple physics. Top Performers are 89% more likely than Others to find analyzing multiple physics makes design decisions easier. Simulation with CAE can be a valuable asset. The research identifies more details about what Top Performers do differently and the benefits they enjoy as a result.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes SOLIDWORKS (registration required).

For a related research, please see our eBook, How to Survive and Win New Markets by Getting Even More Value from Simulation.

What is the best way for engineers to manage multiple design criteria, impacted by multiple physics, yet still meet deadlines, cost targets, and quality requirements?

Tech-Clarity’s eBook, How to Engineer High-Performing, Quality Products without Extra Cost, examines this question. The eBook shares findings based on the results of a survey of 272 manufacturers. It also examines the reality today’s engineers face, and the variety of factors they must consider.

The results show that exceptional engineering is critical to the success of today’s products. At the same time, this is driving product complexity. As products continue to become more complex, it becomes even harder for engineers to make the right design decisions. Interestingly, Tech-Clarity research finds that Top Performers are 2.2 times more likely than Others to have effective processes to understand trade-offs and optimize products. A key differentiator leading to their success is their ability to simulate multiple physics. Top Performers are 89% more likely than Others to find analyzing multiple physics makes design decisions easier. Simulation with CAE can be a valuable asset. The research identifies more details about what Top Performers do differently and the benefits they enjoy as a result.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes SOLIDWORKS (registration required).

For a related research, please see our eBook, How to Survive and Win New Markets by Getting Even More Value from Simulation.

Table of Contents

- Executive Summary

- What It Takes to Succeed

- What Holds Engineers Back?

- Consider the Variety of Engineering Problems

- Better Insight Early on Will Improve Products

- Identifying Top Performing Companies

- Make Design Decisions Easier

- Benefits Regardless of Product Complexity

- Benefits of Analyzing Multiple Physics

- Best Practices for Multiple Physics

- Access What You Need, When You Need It

- Recommendations and Conclusions

- About the Research

- Acknowledgments

Executive Summary

Engineering Is Critical to Success With global competition and an uncertain economy, companies face significant pressure to develop the right products. To attract customers, engineers must balance numerous criteria, often conflicting, to meet product requirements for quality, reliability, innovation, and performance. They must assess the impact of an assortment of complex materials, components, and subsystems and evaluate how they will perform in a wide range of scenarios. Missing the mark can put market share at risk.

Growing Complexity

Navigating this complexity is no small feat as it requires a deep level of expertise. The sheer variety of physics involved make it incredibly difficult for engineers to confidently make decisions. Personal experience simply isn’t enough. In fact, 67% of survey respondents say complexity has grown over the last five years, and 44% find it has gotten even harder to make critical design decisions. Yet, Top Performers are 58% more likely than their competitors to be confident in their decisions.

Better Decisions

Despite complexity, Top Performers are 2.2 times more likely than Others to have effective processes to understand trade-offs and optimize products. A key differentiator leading to their success it their ability to simulate multiple physics. Top Performers are 89% more likely than Others to find analyzing multiple physics makes design decisions easier. Even those developing simple products reveal simulating multiple physics helps them become more competitive.

With global competition and an uncertain economy, companies face significant pressure to develop the right products. To attract customers, engineers must balance numerous criteria, often conflicting, to meet product requirements for quality, reliability, innovation, and performance. They must assess the impact of an assortment of complex materials, components, and subsystems and evaluate how they will perform in a wide range of scenarios. Missing the mark can put market share at risk.

Growing Complexity

Navigating this complexity is no small feat as it requires a deep level of expertise. The sheer variety of physics involved make it incredibly difficult for engineers to confidently make decisions. Personal experience simply isn’t enough. In fact, 67% of survey respondents say complexity has grown over the last five years, and 44% find it has gotten even harder to make critical design decisions. Yet, Top Performers are 58% more likely than their competitors to be confident in their decisions.

Better Decisions

Despite complexity, Top Performers are 2.2 times more likely than Others to have effective processes to understand trade-offs and optimize products. A key differentiator leading to their success it their ability to simulate multiple physics. Top Performers are 89% more likely than Others to find analyzing multiple physics makes design decisions easier. Even those developing simple products reveal simulating multiple physics helps them become more competitive.

Recommendations

Recommendations and Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

- To win over customers, ensure engineers are empowered measure KPIs and make the right design decisions that will lead to high quality, reliable, innovative, top-performing products.

- Recognize the variety of materials, components, and subsystems engineers must work with and analyze in the context of the entire product.

- Empower engineers to solve a wide variety of engineering problems while considering the complexity of the components and materials involved.

- Simulate multiple physics to get a more accurate and realistic insight into product performance.

- Ensure design engineers have access to the simulation licenses your company has so that they can simulate a variety of physics.

Could your overall equipment effectiveness (OEE) metrics do more to accelerate improvement? Most manufacturers' can, but not necessarily by doing what they have been doing. Read our eBook, Getting Beyond Percentages to Insights with OEE, to learn more.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

For related research, watch the Power in the Hidden Factory webcast.

Could your overall equipment effectiveness (OEE) metrics do more to accelerate improvement? Most manufacturers' can, but not necessarily by doing what they have been doing. Read our eBook, Getting Beyond Percentages to Insights with OEE, to learn more.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

For related research, watch the Power in the Hidden Factory webcast.

Table of Contents

- True to Continuous Improvement

- OEE: Beyond the Number

- OEE for Everyone

- How Advanced Manufacturing Enhances CI

- More, Faster Data for the CI Process

- Everyone Engaged

- OEE to Improve in the Ways that Matter Most

- Acknowledgments

Introduction

A New Normal for Overall Equipment Effectiveness and Continuous Improvement Overall Equipment Effectiveness (OEE) and Continuous Improvement (CI) are not new approaches, but the conditions in which manufacturers deploy them are. Today’s conditions include remote working, constant change, new competitors, and business uncertainty with large quantities of data that are not always used. Fortunately, many new technologies support CI processes and improve the accuracy, timeliness, and ability to act on OEE measurements. As a result, new opportunities for improving business results will arise from using digital analytics-based CI approaches.OEE to Improve in the Ways that Matter Most

Digital Advances to Boost the Basics With today’s new conditions, it is time to get back continuous improvement intentions, but do it with advanced digital analytics. Those primary intentions revolve around eliminating waste through process improvements that can impact the business. Digital matters because it delivers speed and accuracy of analysis for insights from OEE. Those characteristics enable high confidence in decisions, focused understanding of where losses occur, and thus greater improvements. *This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor PTC for the full research (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Getting Beyond Percentages to Insights with OEE (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => insights-with-oee-ebook [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:22 [post_modified_gmt] => 2022-11-15 03:28:22 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10556 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [11] => WP_Post Object ( [ID] => 10541 [post_author] => 2 [post_date] => 2021-06-21 17:31:10 [post_date_gmt] => 2021-06-21 21:31:10 [post_content] => How ready are manufacturers and AEC companies to embrace the cloud in engineering?

AMC Bridge's live webcast, hosted by Jim Brown, explores whether now is the right time to move toward cloud engineering software and data.

Hear the panel of speakers share their deep experience and unique perspectives:

How ready are manufacturers and AEC companies to embrace the cloud in engineering?

AMC Bridge's live webcast, hosted by Jim Brown, explores whether now is the right time to move toward cloud engineering software and data.

Hear the panel of speakers share their deep experience and unique perspectives:

- Igor Tsinman, Co-founder and President of AMC Bridge,

- Oleg Shilovitsky, Co-founder and CEO of OpenBOM

- Marc Lind, Sr. Vice President, Strategy of Aras

- Lynn Allen, Global Technology Evangelist of Dassault Systèmes.

You can also watch the first of AMC Bridge's webcast series with Tech-Clarity here: How Software Enables Industrial Additive Manufacturing.

[post_title] => Embracing Cloud Engineering Software and Data (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-engineering-software-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10541

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 10531

[post_author] => 2

[post_date] => 2021-06-14 11:28:41

[post_date_gmt] => 2021-06-14 15:28:41

[post_content] => What do the experts say about cloud readiness in product innovation, engineering, and industrial software? What else can we learn about Siemens’ Paul Brown from his conversation with Tech-Clarity’s Jim Brown (no relation)? Tune into this episode of (Not Your Typical) Tech Interview, the show where we have a little fun by asking some important industry questions and then adding a few more to get to know our industry experts a little bit better. Want to find out what Paul's first computer was? His favorite browser? One of the answers might surprise you!

https://www.youtube.com/watch?v=5-4cmeZWS9M

For more information on cloud migration, please see the second video of this series, (Not Your Typical) Cloud Migration Interview with Schnitger Corp’s Monica Schnitger.

For more information on the engineering market's rapid shift to the cloud, please see the third video of this series, (Not Your Typical) Cloud Market Shift Interview with Allan Behrens.

For more information cloud perceptions, please see the fourth and final video of this series, (Not Your Typical) Cloud Perceptions Discussion with Siemens' Paul Brown.

Get more information about cloud readiness and Siemens' Cloud Solutions from Siemens Digital Industries Software. For related research, please check out our Cloud Advisor PLM Assessment.

You can also watch the first of AMC Bridge's webcast series with Tech-Clarity here: How Software Enables Industrial Additive Manufacturing.

[post_title] => Embracing Cloud Engineering Software and Data (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-engineering-software-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10541

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 10531

[post_author] => 2

[post_date] => 2021-06-14 11:28:41

[post_date_gmt] => 2021-06-14 15:28:41

[post_content] => What do the experts say about cloud readiness in product innovation, engineering, and industrial software? What else can we learn about Siemens’ Paul Brown from his conversation with Tech-Clarity’s Jim Brown (no relation)? Tune into this episode of (Not Your Typical) Tech Interview, the show where we have a little fun by asking some important industry questions and then adding a few more to get to know our industry experts a little bit better. Want to find out what Paul's first computer was? His favorite browser? One of the answers might surprise you!

https://www.youtube.com/watch?v=5-4cmeZWS9M

For more information on cloud migration, please see the second video of this series, (Not Your Typical) Cloud Migration Interview with Schnitger Corp’s Monica Schnitger.

For more information on the engineering market's rapid shift to the cloud, please see the third video of this series, (Not Your Typical) Cloud Market Shift Interview with Allan Behrens.

For more information cloud perceptions, please see the fourth and final video of this series, (Not Your Typical) Cloud Perceptions Discussion with Siemens' Paul Brown.

Get more information about cloud readiness and Siemens' Cloud Solutions from Siemens Digital Industries Software. For related research, please check out our Cloud Advisor PLM Assessment.

Transcript

Jim: Welcome to "Not Your Typical Industry Interview" where we ask industry experts some really important questions and then, throw some in that most people probably wouldn't ask them. Jim: Hi, this is Jim Brown, with Tech-Clarity, and welcome to the web show where we ask industry experts some questions that you might not think to ask. Today, I'm joined by Paul Brown, he is a long-time friend, industry friend, industry expert. He is a Senior Marketing Director at Siemens Digital Industry Software. Paul, welcome. Paul: Hi Jim! Good to talk to you! Jim: Today we're going to talk about how companies can tell that they're ready to move to the cloud for product innovation, product development, engineering, and other related industrial software. Are you ready to get started, Paul? And I’ve got to warn you, we've got a couple of little twists up our sleeve today. Jim: Paul, we've seen just a tremendous amount of increased interest in the cloud for engineering types of solutions, CAD, CAM, CAE, PLM, and other more digital solutions. What do you think are some of the key signs that a company is ready to make the transition to the cloud? Paul: Well, I think Jim, the big thing here now is when people are looking at the current environment and their need to collaborate, that's one of the big triggers. And once you start recognizing that you're working with other companies, you've got people working at home, remotely, if you can start... Once you start seeing that opportunity and that need to build up these communities of people together, that's when cloud technologies can really help you. And I think that that's one of those flags that says, "Actually really, you should be thinking hard about how can I bring this into my business." Jim: Paul, what's your favorite web browser? I'll go first. Mine's Chrome. Paul: Yeah, I'm using Chrome, I'll use Chrome pretty much all the time. Now and again, we get... There are things that pop up and say "This is better off in Edge," but I always try and I'll try it in Chrome first just to see... Jim: Well, are there any red flags that say a company maybe shouldn't be taking their product innovation and engineering software into the cloud? Paul: There is the obvious red flag, which everyone jumps to straight away, which is that I work on secure projects, I work military, I work... And obviously, that's one of those factors, that's the business environment you're working in. But the other red flag, and I think is more important, that companies can actually control themselves is having a plan as to what they want to achieve with the cloud. If they're just talking about, "Well, I'm going there because that's the current trend. Everyone is talking about cloud, I need to be on the cloud," that's not really a good business reason. You've got to have a goal and a business goal as to why you're going to benefit from the cloud. Otherwise, it's just change for change's sake, and that's never going to give you returns on investment that you want. Jim: What was your first personal computer? Paul: I guess my first personal computer, the one I had at home was, there was a company that was in the UK called Tiny. So that was my first home PC. And when I look at technology now and how we all are interconnected, if I think about it, my first real... The work PC, the one I first trained on CAD, that was, for those people that remember, there was a company called Digital Equipment Corporation a long, long time ago, and we had a micro, a VAX11750. We had to put it into a separate room, air-conditioned in our drawing office, it supported four workstations, and it cost the company by the time they got the four workstations plus the hardware, it cost the company about a million dollars for... Just for the hardware. And now we run technology on our laptops, on our phones, on our tablets, all connected through the web, running technologies, using cloud technologies in our own sort of personalized environment that we have without even thinking about it, and... So the change over the years. And I think the other thing is, I've always learned... I've now definitely, I'm a proponent of you never say never. I mean, I remember in the old days saying, you'd never run a CAD product on a laptop, those sorts of conversations that you used to have, and it's like everything is now... Becomes possible. Jim: Well, thanks so much for joining me. It's always a pleasure to talk to you both from a personal perspective, but from also a professional perspective. I always learn something new and love to share in your insights into the industry. Paul: Great. Thanks, Jim. Great to speak to you. And look forward to doing it again. Jim: Thanks for joining the web show where we asked industry experts mostly the wrong questions. We had a lot of fun today and certainly looking forward to more of these. If you'd like to learn more about product innovation, product development, engineering and other industrial software and how the cloud can really make that better, visit our sponsor, Siemens Digital Industry Software. [post_title] => NYT Cloud Readiness Tech Interview with Siemens’ Paul Brown (video) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cloud-readiness-nyt-interview-one [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:29:24 [post_modified_gmt] => 2022-11-15 03:29:24 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10531 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [13] => WP_Post Object ( [ID] => 10513 [post_author] => 2 [post_date] => 2021-06-02 21:00:08 [post_date_gmt] => 2021-06-03 01:00:08 [post_content] => What are the core fundamentals that manufacturers need in their digital thread? What do they need in their PLM system to serve as their digital thread backbone? Read our eBook, The Seven Building Blocks of the Digital Thread, to learn more.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

For related research, read our original buyer's guide Choosing PLM for Digital Thread Initiatives.

What are the core fundamentals that manufacturers need in their digital thread? What do they need in their PLM system to serve as their digital thread backbone? Read our eBook, The Seven Building Blocks of the Digital Thread, to learn more.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

For related research, read our original buyer's guide Choosing PLM for Digital Thread Initiatives.

Table of Contents

- Introducing the Guide

- Why Digital Thread?

- Supporting the Digital Thread

- 1) Managing Engineering Data

- 2) BOMs, Configurations, and DMU

- 3) Production Planning

- 4) Part and Supplier Management

- 5) Product Traceability and Closed-Loop Quality

- 6) Enterprise Change

- 7) Secure Collaboration

- Implementation and Adoption

- Special Considerations

- Vendor Considerations

- Conclusions and Next Steps

- Acknowledgments

Executive Overview

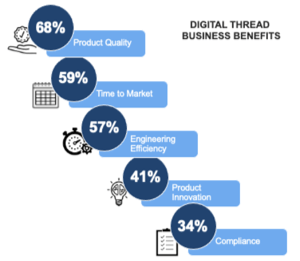

The Digital Thread is Essential Over three-quarters of manufacturers view the digital thread as either important or critical to achieving their business strategy. These industrial companies view the digital thread as a fundamental way to improve performance and gain an advantage over their competitors. Our research, however, shows that only about one-quarter of companies have implemented a digital thread initiative. Having a comprehensive digital thread is moving from an advantage to a competitive necessity. But many companies struggle to define their needs and start an initiative. This guide introduces the top 7 fundamentals that manufacturers should consider to implement and support their digital thread, along with some key solution requirements to support them.

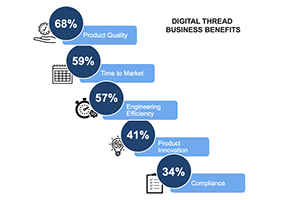

Why Digital Thread?

Business Benefits of the Digital Thread There are numerous definitions of the digital thread. Our research highlights two primary value drivers, streamlining engineering and creating digital continuity. More importantly, these factors are the means to significant business improvements. Benefits include improved quality, greater efficiency, lead-time reduction, enhanced innovation, and more. Specifically, our study shows that companies that have adopted a digital thread enable their technical resources to spend 10% more value-added time on innovation, design, and development work.

This value is the outcome of reduced handoffs and translations, a complete and cohesive data model, connected data, traceability, reuse, and better collaboration. This is why the digital thread is such a critical capability for manufacturers.

There are numerous definitions of the digital thread. Our research highlights two primary value drivers, streamlining engineering and creating digital continuity. More importantly, these factors are the means to significant business improvements. Benefits include improved quality, greater efficiency, lead-time reduction, enhanced innovation, and more. Specifically, our study shows that companies that have adopted a digital thread enable their technical resources to spend 10% more value-added time on innovation, design, and development work.

This value is the outcome of reduced handoffs and translations, a complete and cohesive data model, connected data, traceability, reuse, and better collaboration. This is why the digital thread is such a critical capability for manufacturers.

Conclusions and Next Steps

Achieving the Business Value of the Digital Thread The digital thread is crucial to business performance and competition for today’s manufacturer. We believe that those companies that adopt the efficiencies and traceability available from the digital thread have an opportunity to outperform their competitors. In fact, our research shows that Top Performers, those that outperform their competitors across key product development metrics, are almost two and one-half times as likely to have already implemented a digital thread initiative. Secure the Foundation of the Digital Thread with PLM The digital thread starts in Engineering and PLM is the foundation. Our survey finds that Top Performing companies are 2.4 times as likely to view PLM as critical to supporting the digital thread. PLM supports the basics of data management, processes, and collaboration that make up the seven foundational necessities of the digital thread. But PLM provides much more than that, supporting more advanced capabilities, integration, and technologies that will allow manufacturers to extend the value of their digital thread over time and continue to create competitive advantages. But they can start with the fundamentals and grow their capabilities – and value – over time. Get the Right PLM and Get Started As with any technology, it’s important to recognize the importance of not only software capabilities but also factors like implementation, adoption, vendor considerations, industry needs, and specific company needs. Most importantly, manufacturers should get started because the window where the digital thread provides an advantage is closing as basic digital thread maturity becomes the industry norm. *This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor PTC for the full research (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Seven Building Blocks of the Digital Thread (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => digital-thread-fundamentals-book [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:22 [post_modified_gmt] => 2022-11-15 03:28:22 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10513 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [14] => WP_Post Object ( [ID] => 10507 [post_author] => 2574 [post_date] => 2021-05-24 09:55:29 [post_date_gmt] => 2021-05-24 13:55:29 [post_content] => Are your manufacturing workers safe? Many companies don’t know. Yet, the risk of not knowing workplace safety is high. The global COVID-19 pandemic has brought a new focus to the health and safety of onsite frontline employees. Those workers are in high demand, and part of knowing who is at risk comes down to their training, certifications, and qualifications. Another part is analyzing the types of issues that commonly arise in each work area and having preventive measures in place. A modern and proactive enterprise approach to health and safety software and processes is essential. For many companies, it’s quite different from the piecemeal and reactive processes currently in place. Watch this webinar with Tech-Clarity’s Julie Fraser and ComplianceQuest’s Michael Bower to learn more. Enjoy this important discussion about the rightful place of health and safety in your company’s strategy. Hear about ways to lower workplace safety and health risks. [post_title] => Could You Reduce your Manufacturing Workplace Safety Risks? (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => workplace-safety-webcast-10507-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10507

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 10472

[post_author] => 2

[post_date] => 2021-05-17 11:15:31

[post_date_gmt] => 2021-05-17 15:15:31

[post_content] => [caption id="attachment_10486" align="alignright" width="212"]

[post_title] => Could You Reduce your Manufacturing Workplace Safety Risks? (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => workplace-safety-webcast-10507-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10507

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 10472

[post_author] => 2

[post_date] => 2021-05-17 11:15:31

[post_date_gmt] => 2021-05-17 15:15:31

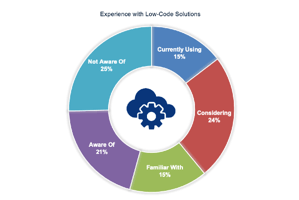

[post_content] => [caption id="attachment_10486" align="alignright" width="212"] Experience with low-code solutions[/caption]

Some see low-code as a promising new technology, but is it really new? No. Is it promising for digital transformation? Our survey says yes.

Please enjoy the summary below or see Jim Brown's full guest post on the Siemen's blog to learn how the low-code technology "breakthrough" helps fill digital transformation gaps.

Digital Transformation Gaps

Digital transformation is creating new value for manufacturers. The digital revolution, whether under the banner of Industry 4.0, Smart Manufacturing, or some more overarching initiative, is a high priority to survive and thrive in the new normal. Even before the disruption from the recent pandemic, Tech-Clarity’s research on digital maturity in manufacturing shows that two-thirds of industrial companies viewed digitalization as either “important” or “critical” to achieving their business strategy.

Our recent survey, Filling Digital Transformation Gaps with Applications, shares that manufacturers’ digital initiatives create or uncover process, organizational, and technology gaps. They must overcome these “digital transformation gaps” to achieve their digitalization goals, such as driving internal efficiencies, creating new business models, or finding new revenue opportunities.

[caption id="attachment_10473" align="alignleft" width="157"]

Experience with low-code solutions[/caption]

Some see low-code as a promising new technology, but is it really new? No. Is it promising for digital transformation? Our survey says yes.

Please enjoy the summary below or see Jim Brown's full guest post on the Siemen's blog to learn how the low-code technology "breakthrough" helps fill digital transformation gaps.

Digital Transformation Gaps

Digital transformation is creating new value for manufacturers. The digital revolution, whether under the banner of Industry 4.0, Smart Manufacturing, or some more overarching initiative, is a high priority to survive and thrive in the new normal. Even before the disruption from the recent pandemic, Tech-Clarity’s research on digital maturity in manufacturing shows that two-thirds of industrial companies viewed digitalization as either “important” or “critical” to achieving their business strategy.

Our recent survey, Filling Digital Transformation Gaps with Applications, shares that manufacturers’ digital initiatives create or uncover process, organizational, and technology gaps. They must overcome these “digital transformation gaps” to achieve their digitalization goals, such as driving internal efficiencies, creating new business models, or finding new revenue opportunities.

[caption id="attachment_10473" align="alignleft" width="157"] Jim Brown in 2003 when the original article was published[/caption]

[caption id="attachment_10477" align="alignright" width="157"]

Jim Brown in 2003 when the original article was published[/caption]

[caption id="attachment_10477" align="alignright" width="157"] Jim Brown currently[/caption]

A "breakthrough" technology

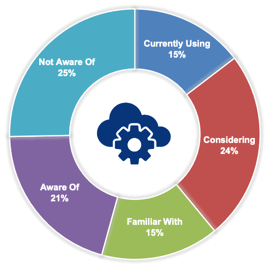

Some see low-code as a promising new technology, but is it really? New technology? No. Despite the fact that a full 25% of industrial companies aren’t aware of it, it’s not new. The low-code approach has gone by different names, including model-based programming. In fact, I first wrote about it with Olin Thompson of Process ERP Partners in 2003 in a series of Technology Evaluation articles titled “What’s Wrong with Application Software.” In that we pointed out that “Early adopters are learning that Model Based Architectures create significant efficiencies throughout the application lifecycle.”

Take advantage of low-code to fill gaps

As we said over a decade ago “Model based architecture is … a tool that leverages existing applications and fills in the cracks that exist in your business processes.” That’s even more applicable today, given the higher demand – and value – of rapid application development in the digital era. It’s time for more manufacturers to adopt low-code in order to meet their critical digital transformation needs. Fortunately, it’s well suited to start small, prove the value, and grow. It’s time to get started.

For related commentary on how companies can fill IoT gaps with low-code applications, read the Fill IoT Gaps with Low-Code guest post.

[post_title] => The Low-Code Technology “Breakthrough” (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => low-code-breakthrough-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-09 20:48:30

[post_modified_gmt] => 2024-09-10 00:48:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10472

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 10464

[post_author] => 2574

[post_date] => 2021-05-13 19:38:28

[post_date_gmt] => 2021-05-13 23:38:28

[post_content] =>

Jim Brown currently[/caption]

A "breakthrough" technology

Some see low-code as a promising new technology, but is it really? New technology? No. Despite the fact that a full 25% of industrial companies aren’t aware of it, it’s not new. The low-code approach has gone by different names, including model-based programming. In fact, I first wrote about it with Olin Thompson of Process ERP Partners in 2003 in a series of Technology Evaluation articles titled “What’s Wrong with Application Software.” In that we pointed out that “Early adopters are learning that Model Based Architectures create significant efficiencies throughout the application lifecycle.”

Take advantage of low-code to fill gaps

As we said over a decade ago “Model based architecture is … a tool that leverages existing applications and fills in the cracks that exist in your business processes.” That’s even more applicable today, given the higher demand – and value – of rapid application development in the digital era. It’s time for more manufacturers to adopt low-code in order to meet their critical digital transformation needs. Fortunately, it’s well suited to start small, prove the value, and grow. It’s time to get started.