Jim Brown joins Carl Smith of IMAGINiT as they discuss how to improve collaboration, time-to-market, and efficiency using the cloud in Engineering. View the recorded webcast (free of charge, registration required).

- If you already completed the survey –> please share with a colleague or on social media using the “Share/Save” options above.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

In addition, 50 respondents will receive a $10 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes to complete. Individual responses will be kept confidential.

Thank you for your help and support!

In addition, 50 respondents will receive a $10 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes to complete. Individual responses will be kept confidential.

Thank you for your help and support!

Interested in other Materials Research?

If you have interests in some of the latest trends in materials, you may also be interested in our Materials Trends Survey. We are researching how the use of new materials impacts the design and production process. For more information on the study go here or feel free to directly access the 10-15 minute survey here.Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => Materials Innovation Survey [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => matrl_inn [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:31 [post_modified_gmt] => 2022-11-15 03:28:31 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4755 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [5] => WP_Post Object ( [ID] => 4743 [post_author] => 2 [post_date] => 2015-09-15 09:34:06 [post_date_gmt] => 2015-09-15 13:34:06 [post_content] => Join Tech-Clarity's Jim Brown and Dassault Systemes' Raymond Wodar as they present on a CGT webcast, New Approaches to Improve Product Development. The presentation focuses on how to compete in today's complex markets and ensure innovative products reach consumers quickly despite tight regulations, disperse supply chains, and severe cost pressure. Learn how Top Performing CPG companies are moving beyond point solutions and disconnected processes and adopting more holistic product development approaches.

Join Tech-Clarity's Jim Brown and Dassault Systemes' Raymond Wodar as they present on a CGT webcast, New Approaches to Improve Product Development. The presentation focuses on how to compete in today's complex markets and ensure innovative products reach consumers quickly despite tight regulations, disperse supply chains, and severe cost pressure. Learn how Top Performing CPG companies are moving beyond point solutions and disconnected processes and adopting more holistic product development approaches.

Register Now (free of charge, registration required)

[post_title] => Webcast on Improving Product Development in CPG

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cgt-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:38

[post_modified_gmt] => 2022-11-15 03:26:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4743

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 4733

[post_author] => 2

[post_date] => 2015-09-09 07:35:17

[post_date_gmt] => 2015-09-09 11:35:17

[post_content] =>

Register Now (free of charge, registration required)

[post_title] => Webcast on Improving Product Development in CPG

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cgt-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:38

[post_modified_gmt] => 2022-11-15 03:26:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4743

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 4733

[post_author] => 2

[post_date] => 2015-09-09 07:35:17

[post_date_gmt] => 2015-09-09 11:35:17

[post_content] => Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => Product Configuration and “To Order” Manufacturing Survey [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => eto-survey [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:30 [post_modified_gmt] => 2022-11-15 03:28:30 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4733 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [7] => WP_Post Object ( [ID] => 4728 [post_author] => 2572 [post_date] => 2015-08-31 22:26:35 [post_date_gmt] => 2015-09-01 02:26:35 [post_content] => Concept Design Survey

Concept Design Survey

How do leading companies develop conceptual models?

Please share your experience. We are conducting new research on concept development. We are exploring questions such as, what are best practices for developing concepts? Are there approaches to concept development that will save time during detail design? Can technology help??

- If you already completed the survey –> please share with a colleague or on social media using the “Share/Save” options above.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

In addition, 20 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes to complete. Individual responses will be kept confidential.

Thank you for your help and support!

In addition, 20 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes to complete. Individual responses will be kept confidential.

Thank you for your help and support!

Interested in CAE Research?

If you have interests in simulation and analysis, you may also be interested in our CAE Survey. We are researching best approaches to pre and post processing. For more information on the study go here or feel free to directly access the 10-15 minute survey here.Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => Concept Design Survey [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => concept-survey [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:30 [post_modified_gmt] => 2022-11-15 03:28:30 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4728 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 6 [filter] => raw ) [8] => WP_Post Object ( [ID] => 4697 [post_author] => 2 [post_date] => 2015-08-18 11:45:26 [post_date_gmt] => 2015-08-18 15:45:26 [post_content] => The Getting the Most from PLM - PLM Drives Tangible Business Value eBook is the result of a joint research project between research firm Tech-Clarity and innovation consulting firm Kalypso. We researched over 100 companies to determine how some companies get much higher levels of value from their Product Lifecycle Management implementations. The report shows that leading companies go beyond tactical (yet valuable) cost and efficiency gains to improve innovation and drive higher profit margins and revenue.

Please enjoy the summary below, or click the eBook to download a PDF overview (free of charge, no registration required).

For the full report, please visit our research partner Kalypso (free of charge, no registration required).

The Getting the Most from PLM - PLM Drives Tangible Business Value eBook is the result of a joint research project between research firm Tech-Clarity and innovation consulting firm Kalypso. We researched over 100 companies to determine how some companies get much higher levels of value from their Product Lifecycle Management implementations. The report shows that leading companies go beyond tactical (yet valuable) cost and efficiency gains to improve innovation and drive higher profit margins and revenue.

Please enjoy the summary below, or click the eBook to download a PDF overview (free of charge, no registration required).

For the full report, please visit our research partner Kalypso (free of charge, no registration required).

PLM and Business Value

Product lifecycle management (PLM) drives significant business improvements that show up in investor calls and annual reports. PLM implementations enable important improvements, but the value is tactical and limited to improved efficiency and reduced cost. While these are worthwhile improvements (and often pay for the whole initiative), they fail to exploit the full potential of PLM. PLM can drive innovation, improve differentiation and lead to significant revenue growth. But most PLM implementations fall short of this. Why?

All PLM Initiatives Are Not Equal

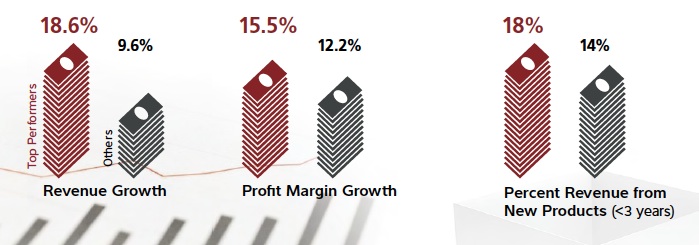

This eBook explains how some get the most out of PLM and shares practical tips for how you can drive real business value from PLM in your business. Most of the companies surveyed report that PLM helped improve their top line and drive higher margins. But some did better than others. To find out why, we looked at the companies that rated themselves the highest on revenue growth, profit margin growth and percent of sales from new products (less than three years old) – the “Top Performers.”- Top Performers grew revenue almost twice as much as others while growing profit margins 29 percent more. This is a significant difference on the bottom line.

- Top Performers also grew revenue from new products more than Others, indicating better innovation and product development performance.

Tech-Clarity’s Michelle Boucher will share recent research on PDM, PLM and the cloud at an event put on by MasterGraphics, "Cloud ERP / PLM: Gaining a Competitive Advantage with Connected Data." She will discuss some misconceptions and how to set the right foundation for incremental strategic improvement.

The event will be held in Milwaukee on August 13th. More information about the event can be found here.

[post_title] => Cloud ERP / PLM: Gaining a Competitive Advantage with Connected Data

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-erp-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:38

[post_modified_gmt] => 2022-11-15 03:26:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4689

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 4677

[post_author] => 2

[post_date] => 2015-08-06 13:35:27

[post_date_gmt] => 2015-08-06 17:35:27

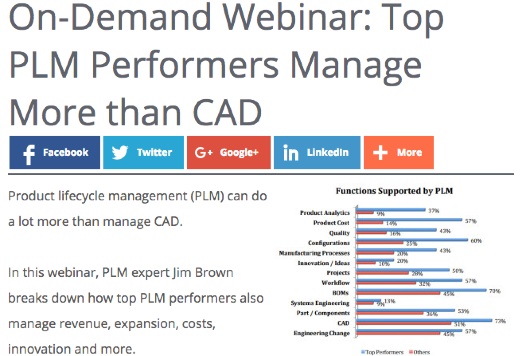

[post_content] => Jim Brown presented findings from his recent research on Enterprise PLM in this Engineering.com webcast, Top PLM Performers Manage More Than CAD. The recording is now available on-demand, including a very active Q&A session.

Tech-Clarity’s Michelle Boucher will share recent research on PDM, PLM and the cloud at an event put on by MasterGraphics, "Cloud ERP / PLM: Gaining a Competitive Advantage with Connected Data." She will discuss some misconceptions and how to set the right foundation for incremental strategic improvement.

The event will be held in Milwaukee on August 13th. More information about the event can be found here.

[post_title] => Cloud ERP / PLM: Gaining a Competitive Advantage with Connected Data

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-erp-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:38

[post_modified_gmt] => 2022-11-15 03:26:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4689

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 4677

[post_author] => 2

[post_date] => 2015-08-06 13:35:27

[post_date_gmt] => 2015-08-06 17:35:27

[post_content] => Jim Brown presented findings from his recent research on Enterprise PLM in this Engineering.com webcast, Top PLM Performers Manage More Than CAD. The recording is now available on-demand, including a very active Q&A session.

Watch the replay now (no charge, registration required)

Sponsored by Autodesk PLM 360

[post_title] => On-Demand Webinar - Top Performers Do More than Manage CAD with PLM!

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-plm-ent

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:43

[post_modified_gmt] => 2022-11-15 03:26:43

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4677

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 4658

[post_author] => 2

[post_date] => 2015-07-28 13:23:50

[post_date_gmt] => 2015-07-28 17:23:50

[post_content] =>

Watch the replay now (no charge, registration required)

Sponsored by Autodesk PLM 360

[post_title] => On-Demand Webinar - Top Performers Do More than Manage CAD with PLM!

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webinar-plm-ent

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:43

[post_modified_gmt] => 2022-11-15 03:26:43

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4677

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 4658

[post_author] => 2

[post_date] => 2015-07-28 13:23:50

[post_date_gmt] => 2015-07-28 17:23:50

[post_content] =>  Product Lifecycle Management Beyond Managing CAD, The Business Value of PLM shares survey results exploring the value of PLM beyond managing design files such as CAD. While the research finds that most Top Performers manage CAD in PLM, they also do a lot more. The research shows that Top Performers - the ones that report higher revenue growth, margin expansion, cost reduction, and product innovation - are much more likely to extend PLM further and take more holistic, process-oriented, enterprise-wide view.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit Engineering.com (free of charge, registration required, sponsored by Autodesk).

Product Lifecycle Management Beyond Managing CAD, The Business Value of PLM shares survey results exploring the value of PLM beyond managing design files such as CAD. While the research finds that most Top Performers manage CAD in PLM, they also do a lot more. The research shows that Top Performers - the ones that report higher revenue growth, margin expansion, cost reduction, and product innovation - are much more likely to extend PLM further and take more holistic, process-oriented, enterprise-wide view.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit Engineering.com (free of charge, registration required, sponsored by Autodesk).

Table of Contents

- Executive Overview

- Benefits of Product Lifecycle Management

- Putting PLM in the Business Perspective

- Battling Complexity

- Combatting the Business Impacts of Complexity

- Identifying the Top Performers

- Adopting a Process-Centric PLM Approach

- Expanding PLM Across the Enterprise

- Expanding PLM Across the Supply Chain

- Explore the Relationship Between PLM and PDM

- Integrating PLM with Other Systems

- Taking a Process versus Data-Centric View

- What about the Cloud?

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

The concept of Product Lifecycle Management (PLM) software and the reality do not always match. PLM software started as a way to expand the value of Product Data Management (PDM) by adding additional information such as release status, BOMs, and ECOs. But the real promise of PLM – supporting enterprise-level processes for product innovation, product development, and engineering – offers much higher, strategic value. So why haven’t more companies taken advantage of the benefits of process-centric PLM? Some of the reason is historical, because most early PLM systems were really CAD data management with some added features. But another part is simply how important good data management is. As Tech-Clarity’s recent The Facts about Managing Product Data shows, “PDM’s ability to help companies control, access, and share product data is a powerful tool that helps companies improve top- and bottom-line performance.” PDM adds value on it’s own and is a logical starting point. But many implementations stop there, while others continue on to support more processes. Alternatively, today’s modern, enterprise-focused PLM systems offer the opportunity to start with processes in the first place. So which drives higher value, a data-centric or process-centric approach? We surveyed over 200 companies to understand if they take a data management or process-centric view of PLM to find out. We identified the “Top Performers,” those that excel beyond their peers in revenue growth, margin expansion, innovation, and cost reduction, and analyzed their PLM approach to see what leads to better performance. The survey results lead us to believe that process-centric, Enterprise PLM drives better business performance, but also finds that core PDM capabilities are an important value driver. Specifically, the survey finds that Top Performers are more likely to:- Execute processes that go beyond the technical definition of the product to the commercial aspects of the offering

- Leverage more advanced PLM processes including cost and quality management

- Have more departments and third parties using PLM

- Use core PDM capabilities more than “Others”

- Tightly integrate PDM and PLM

- Integrate PLM with other enterprise information systems and engineering tools

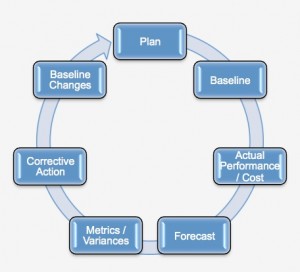

Reducing Program Risk with Earned Value Management explores the business value of Earned Value Management (EVM) processes and tools and how they can streamline program execution and drive down risk. The eBook shares a brief overview of EVM in business terms and shares how EVM helps companies gain control of programs, monitor and correct program health, boost visibility and management oversight, and demonstrate program control to customers. The eBook also shares how companies can leverage PLM to file the gap most companies have in creating an Earned Value Management (EVMS) system.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Dassault Systèmes (free of charge, registration required).

Reducing Program Risk with Earned Value Management explores the business value of Earned Value Management (EVM) processes and tools and how they can streamline program execution and drive down risk. The eBook shares a brief overview of EVM in business terms and shares how EVM helps companies gain control of programs, monitor and correct program health, boost visibility and management oversight, and demonstrate program control to customers. The eBook also shares how companies can leverage PLM to file the gap most companies have in creating an Earned Value Management (EVMS) system.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Dassault Systèmes (free of charge, registration required).

Why Earned Value Management?

Large programs are notoriously difficult to deliver on time and on budget. But expectations are high on program managers and program management offices (PMOs) even in the face of increased complexity from multi-discipline initiatives, intense budget scrutiny, and globally dispersed supply chains. Earned Value Management (EVM) helps reduce risk on high cost, high risk, time-sensitive programs. It improves a program’s odds for success and provides accountability and traceability into cost and schedule variances. It adds a new level of control, oversight, discipline, and rigor to program management to prevent cost overruns, missed scheduled milestones, and late delivery dates.

EVM improves program management by eliminating subjectivity. The approach lets program managers factually quantify program spending and progress. It provides a mechanism to identify and mitigate issues early before things get too far off track. It also offers a standard, proven way for customers and program sponsors to audit progress to gain confidence that the programs they’re funding are on track. Many companies choose to adopt EVM to improve program success. Others are required to use EVM for specific customers, contract types, and contract values or may need to demonstrate earned value to justify billing. Either way, EVM adds value and improves confidence in program delivery.

Large programs are notoriously difficult to deliver on time and on budget. But expectations are high on program managers and program management offices (PMOs) even in the face of increased complexity from multi-discipline initiatives, intense budget scrutiny, and globally dispersed supply chains. Earned Value Management (EVM) helps reduce risk on high cost, high risk, time-sensitive programs. It improves a program’s odds for success and provides accountability and traceability into cost and schedule variances. It adds a new level of control, oversight, discipline, and rigor to program management to prevent cost overruns, missed scheduled milestones, and late delivery dates.

EVM improves program management by eliminating subjectivity. The approach lets program managers factually quantify program spending and progress. It provides a mechanism to identify and mitigate issues early before things get too far off track. It also offers a standard, proven way for customers and program sponsors to audit progress to gain confidence that the programs they’re funding are on track. Many companies choose to adopt EVM to improve program success. Others are required to use EVM for specific customers, contract types, and contract values or may need to demonstrate earned value to justify billing. Either way, EVM adds value and improves confidence in program delivery.

Compliance with ANSI/EIA-748 is required for DoD cost or incentive type contracts valued at or greater than $20 million. For cost or incentive type contracts valued at or greater than $50 million, compliance with the management attributes of the ANSI/EIA-748 32 GLs is demonstrated through a formal EVMS validation process. - Defense Contract Management Agency Instruction 208

Compliance with ANSI/EIA-748 is required for DoD cost or incentive type contracts valued at or greater than $20 million. For cost or incentive type contracts valued at or greater than $50 million, compliance with the management attributes of the ANSI/EIA-748 32 GLs is demonstrated through a formal EVMS validation process. - Defense Contract Management Agency Instruction 208

Conclusion and Recommendations

EVM helps mitigate program schedule and budget risk. It helps companies manage large, complex, time-sensitive, risky programs. Further, it’s required to do business in some industries. EVM provides control, connects program data, helps monitor and correct program health, provides visibility to improve management insight, and demonstrates control to customers to increase their confidence. EVM requires an organizational and systems investment. Today’s advanced PLM systems provide an opportunity to extend existing infrastructure to connect disparate program information from schedule and cost systems, calculate EVM, and provide management insights in context with products and programs. Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Leverage PLM as the backbone for the EVMS, connecting EVM with programs and program deliverables.

- Look for solutions that already incorporate the right data model, processes, and algorithms. There is no need to create this from scratch.

- Look for a solution that offers flexibility to extend reporting and processes to accommodate additional customer or management needs.

Tech-Clarity's new eBook, An Action Plan to Improve Your Product Portfolio, helps companies start down the path to better product profitability through PPM. The research shares insights on how to recognize the need for PPM, prepare your organization for the PPM journey,determine the potential ROI, and select a software vendor partner. It's a comprehensive look at how your company can start down the path to better portfolios (and profits).

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Planview (free of charge, registration required).

Tech-Clarity's new eBook, An Action Plan to Improve Your Product Portfolio, helps companies start down the path to better product profitability through PPM. The research shares insights on how to recognize the need for PPM, prepare your organization for the PPM journey,determine the potential ROI, and select a software vendor partner. It's a comprehensive look at how your company can start down the path to better portfolios (and profits).

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor Planview (free of charge, registration required).

Overview

Product Portfolio Management improvements drive top line growth, expand margins, improve corporate agility, and reduce overhead costs. Given the value, is it any wonder that more manufacturers are turning to PPM? Product Portfolio Management (PPM) has become mission critical for today’s product development companies. It helps companies drive strategic value by filling the pipeline with the right ideas, selecting the right projects and products, applying the right resources, and providing the right level of visibility to manage and make good decisions. Benchmarks show PPM processes and technology offer powerful business improvements, including double-digit percentage improvements in:

- Efficiency

- Project cycle times

- Innovation capacity

This guide is intended to help you get started. Tech-Clarity Buyer’s Guides help lead companies through vendor selection for their critical enterprise applications. For the most part, our guides focus on software, service, and vendor requirements. But several things make acquiring PPM different:

- Many organizations are implementing PPM for the first time (at least on an enterprise scale or with enterprise class business solutions)

- PPM requires a greater degree of domain expertise to implement and adopt

- PPM disciplines, tools, and value are not as well know in most companies (although some might be able to leverage lessons learned from IT Portfolio Management)

- Identifying the need for PPM

- Preparing for the PPM journey (and making the business case)

- Selecting a solution and vendor partner

Material Trends for Engineering and Production

Material Trends for Engineering and Production

How are new materials impacting your design and production processes?

Please share your experience. What are your plans for new materials? What challenges should you be aware of when using new materials? What are so of the best practices when using new materials such as composites?

- If you already completed the survey –> please share with a colleague or on social media using the “Share/Save” options above.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

In addition, 20 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10-15 minutes to complete. Individual responses will be kept confidential.

Thank you for your help and support!

In addition, 20 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10-15 minutes to complete. Individual responses will be kept confidential.

Thank you for your help and support!

Interested in CAD Research?

If you have interests in CAD, you may also be interested in our CAD survey. We are researching top considerations on making a change in CAD tools. For more information on the study go here or feel free to access the 10 minute survey here.Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => Survey: Material Trends for Engineering and Production [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => materials [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:45 [post_modified_gmt] => 2022-11-15 03:27:45 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4627 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 4 [filter] => raw ) [15] => WP_Post Object ( [ID] => 4618 [post_author] => 2572 [post_date] => 2015-07-07 11:54:12 [post_date_gmt] => 2015-07-07 15:54:12 [post_content] => Switching CAD Tools

Switching CAD Tools

Have you gone through a change in CAD tools? Are you considering a change?

Please share your experience. How did the process go? What drove the change? What should companies expect when making a change?

- If you already completed the survey –> please share with a colleague or on social media using the “Share/Save” options above.

- If you haven’t taken the survey –> please:

CLICK HERE TO TAKE THE SURVEY NOW!

In addition, 20 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes to complete. Individual responses will be kept confidential.

In addition, 20 respondents will receive a $20 Amazon gift card. See rules and eligibility requirements below.

The survey should take about 10 minutes to complete. Individual responses will be kept confidential.

Rules

To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of products. Vendors and consultants who sell software, solutions, or services to support product development are not eligible. Students without relevant professional work experience are also not eligible. A valid work email is required to receive the gift card. To verify eligibility, your work email must include the domain of your place of employment. Email addresses will be kept confidential and will not be used for any direct sales or marketing purposes. Duplicate responses will be disqualified. Winners will be notified when the survey is closed.

[post_title] => CAD Survey [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cad-survey [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:30 [post_modified_gmt] => 2022-11-15 03:28:30 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=4618 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 2 [filter] => raw ) [16] => WP_Post Object ( [ID] => 4604 [post_author] => 2572 [post_date] => 2015-06-15 12:22:26 [post_date_gmt] => 2015-06-15 16:22:26 [post_content] => Michelle Boucher will join Kenneth Wong, Senior Editor from Desktop Engineering and Simon Floyd, Director of Innovation and Product Lifecycle Management Solutions from Microsoft for a very interesting webcast on Thursday, June 25, 2015 at 2:00 pm EDT.

The webinar will examine some of the latest advancements in product development technologies, specifically the combination of topology optimization software and 3D printers, and how they can be used to solve some of today's key design challenges. Topology optimization software allows you to achieve material savings and lower weight by placing material only where it is needed. However, the unique shapes proposed by the software are not always manufacturable with traditional manufacturing techniques. 3D Printing creates exciting new opportunities to produce these optimized shapes.

Michelle Boucher will join Kenneth Wong, Senior Editor from Desktop Engineering and Simon Floyd, Director of Innovation and Product Lifecycle Management Solutions from Microsoft for a very interesting webcast on Thursday, June 25, 2015 at 2:00 pm EDT.

The webinar will examine some of the latest advancements in product development technologies, specifically the combination of topology optimization software and 3D printers, and how they can be used to solve some of today's key design challenges. Topology optimization software allows you to achieve material savings and lower weight by placing material only where it is needed. However, the unique shapes proposed by the software are not always manufacturable with traditional manufacturing techniques. 3D Printing creates exciting new opportunities to produce these optimized shapes.

Register here!

[post_title] => Webcast - Optimization and 3D Printing Revolutionize Design

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webcast-optimization-and-3d-printing-revolutionize-design

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:42

[post_modified_gmt] => 2022-11-15 03:26:42

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4604

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 4586

[post_author] => 2

[post_date] => 2015-05-21 20:35:35

[post_date_gmt] => 2015-05-22 00:35:35

[post_content] => What is PLM software anyway? You probably know it's "Product Lifecycle Management" but beyond that most definitions get weak. At best they're circular. We ponder that question in a tongue-in-cheek way before transitioning into an insightful interview between Tech-Clarity's Jim Brown and "KJ" Carlson of Club W. KJ shares some unique perspectives and uses of PLM across departments as diverse as Compliance, Finance, and Legal and into the supply chain tool. His experience can help others find news ways to get value out of PLM beyond managing CAD data. As Jim says, "it's not your grandfather's PLM."

[post_title] => Webcast - Optimization and 3D Printing Revolutionize Design

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webcast-optimization-and-3d-printing-revolutionize-design

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:42

[post_modified_gmt] => 2022-11-15 03:26:42

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4604

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 4586

[post_author] => 2

[post_date] => 2015-05-21 20:35:35

[post_date_gmt] => 2015-05-22 00:35:35

[post_content] => What is PLM software anyway? You probably know it's "Product Lifecycle Management" but beyond that most definitions get weak. At best they're circular. We ponder that question in a tongue-in-cheek way before transitioning into an insightful interview between Tech-Clarity's Jim Brown and "KJ" Carlson of Club W. KJ shares some unique perspectives and uses of PLM across departments as diverse as Compliance, Finance, and Legal and into the supply chain tool. His experience can help others find news ways to get value out of PLM beyond managing CAD data. As Jim says, "it's not your grandfather's PLM."

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/Zicn7i_gB58

The video series is brought to you by Autodesk PLM360.

PLM411 brings you straight talk about how manufacturers can accelerate product innovation and product development with PLM.

For more visit PLM411.com or the Tech-Clarity YouTube Channel.

https://youtu.be/Zicn7i_gB58

Prior Episode: Does ingesting a three letter acronym like ERP, CRM, or PLM improve business? Of course not. But implementing the right combination of enterprise software can improve manufacturing business performance. Enjoy our spoof on software acronyms and then listen to a more sincere discussion between Gavin Davidson of NetSuite and Tech-Clarity’s Jim Brown.

Prior Episode: Does ingesting a three letter acronym like ERP, CRM, or PLM improve business? Of course not. But implementing the right combination of enterprise software can improve manufacturing business performance. Enjoy our spoof on software acronyms and then listen to a more sincere discussion between Gavin Davidson of NetSuite and Tech-Clarity’s Jim Brown.

Next Episode: We take a silly look at solving the problem of fragmented product data and processes with a mythical integration product called FlōSēl. Then we get down to business with Tech-Clarity's Jim Brown and CIMdata's Stan Przybylinski discussing the reasons people customize their PLM systems, the potential downfalls of doing it, and the changing customization / configuration scenario given recent software architecture changes like web services and the Cloud.

[post_title] => PLM411 PLM Deep Thoughts / Club W PLM Interview with KJ Carlson

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-09

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:53

[post_modified_gmt] => 2022-11-15 03:29:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4586

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 4567

[post_author] => 2

[post_date] => 2015-05-20 11:49:30

[post_date_gmt] => 2015-05-20 15:49:30

[post_content] => PDM/PLM Satisfaction Survey - Status Quo is Satisfactory but Needs are Changing

Next Episode: We take a silly look at solving the problem of fragmented product data and processes with a mythical integration product called FlōSēl. Then we get down to business with Tech-Clarity's Jim Brown and CIMdata's Stan Przybylinski discussing the reasons people customize their PLM systems, the potential downfalls of doing it, and the changing customization / configuration scenario given recent software architecture changes like web services and the Cloud.

[post_title] => PLM411 PLM Deep Thoughts / Club W PLM Interview with KJ Carlson

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm411-09

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:29:53

[post_modified_gmt] => 2022-11-15 03:29:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4586

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 4567

[post_author] => 2

[post_date] => 2015-05-20 11:49:30

[post_date_gmt] => 2015-05-20 15:49:30

[post_content] => PDM/PLM Satisfaction Survey - Status Quo is Satisfactory but Needs are Changing  shares the results of a survey of over 500 PLM users exploring their satisfaction with their Product Data Management (PDM) and/or Product Lifecycle Management (PLM) systems. The report conveys the perspectives of a large number of PLM users ranging in seniority, position, and industry. The study includes statistics based on survey responses and analysis of open-ended questions and concludes that PLM users are generally satisfied with current PLM systems but have low expectations, and that those expectations will likely grow as they become more accustomed to today's consumer-oriented applications.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information on PLM, please visit our sponsor Aras.

shares the results of a survey of over 500 PLM users exploring their satisfaction with their Product Data Management (PDM) and/or Product Lifecycle Management (PLM) systems. The report conveys the perspectives of a large number of PLM users ranging in seniority, position, and industry. The study includes statistics based on survey responses and analysis of open-ended questions and concludes that PLM users are generally satisfied with current PLM systems but have low expectations, and that those expectations will likely grow as they become more accustomed to today's consumer-oriented applications.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information on PLM, please visit our sponsor Aras.

Table of Contents

- Executive Overview

- Overall PLM Satisfaction

- Does PLM Help People with Their Jobs?

- Executives Like PLM

- Design Engineers are Less Happy

- Familiarity Expands Satisfaction

- What Would Users Change?

- Conclusion

- Recommendations

- About the Author

- About the Research

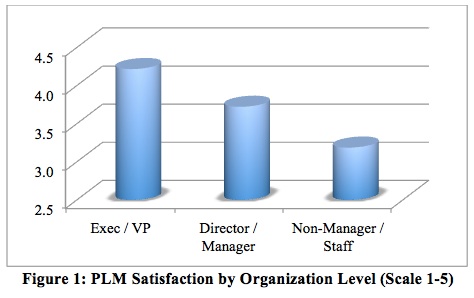

Executive Overview

Tech-Clarity conducted an online survey of over 500 PLM users to gauge their satisfaction with their PDM/PLM systems. The survey attracted a wide and experienced base of users. One-half of survey respondents have more than five years of experience with PLM, and over three-quarters have used more than one PLM system in their careers. The survey evaluated satisfaction with the PLM system, the use of it, and how well their PLM system is supported. Perhaps more importantly, they were asked whether PLM helps make their jobs easier. The results show a varied level of PLM system satisfaction. The most interesting findings relates to PLM satisfaction based on the individual’s role in the organization and how often they use their PLM system, specifically:- The higher in the organization, the happier respondents are with PLM (Figure)

- Design engineers (those that contribute the majority of the deliverables to PLM), are less satisfied compared to those leveraging the information downstream

- Infrequent users are less satisfied with their PLM

The research shows that there is significant room for improvement in PLM. Today’s PLM is a valuable business system that offers benefits to executives and downstream users but frequently burdens companies’ direct contributors and challenges infrequent users due to complex user interfaces which result in long learning curves. Although users express satisfaction with the current state of PLM, they were quick to offer areas that need improvement. The most frequently requested changes include improvements to:

The research shows that there is significant room for improvement in PLM. Today’s PLM is a valuable business system that offers benefits to executives and downstream users but frequently burdens companies’ direct contributors and challenges infrequent users due to complex user interfaces which result in long learning curves. Although users express satisfaction with the current state of PLM, they were quick to offer areas that need improvement. The most frequently requested changes include improvements to:

- Ease of use / user interface

- Configurability / customizability

- Search

- System performance and stability

- Integration with design applications and other enterprise systems

Conclusion

Our conclusion from the data is that PLM satisfaction is relative strong but varies widely. Based on the data, respondents’ comments, and our experience we believe this correlates with their familiarity with PLM and how they use it based on their role. PLM users are satisfied with their PLM systems because they appear to have modest expectations or they have used PLM systems for a long time and have grown accustomed to how they work. Many recognize that the system they use is on par with what they expect in the industry, saying for example “It is good enough, I don't want to change anything now.” It appears that users are as satisfied with PLM as they are with the general state of enterprise software and perhaps don’t feel there are better alternatives. Long learning curves and poor usability, however, will hinder user adoption as PLM demands increase with the rising complexity of products and product development environments. We also believe that the expectations for PLM to come close to the ease of use and simplicity of consumer-based applications like Dropbox, Google Drive, and others will grow. As users get used to these systems in their everyday lives their desire for comparable usability will increase in the workspace. There is opportunity for improvement to place less burden on engineers while still adding value at the enterprise level and downstream. The PLM industry needs to address usability and configurability along with improved system performance and stability. Today’s status quo products must evolve to take advantage of concepts from newer software solutions including the social, mobile, and connected applications that are becoming commonplace in personal use. As one survey respondent commented “We need a future PLM. The current PLM is not ready to solve future challenges.”Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Leverage PLM to add value across the enterprise and the value chain

- Look for more intuitive systems to help less frequent users

- Choose systems with better ease of use and fewer clicks in order to place less burden on users, especially design engineers

- Make system performance, stability, and reliability a criteria

- Place importance on the ability to customize the PLM system to support specific roles and specialized processes to ensure productivity and value

- Pay special attention to common improvement areas such as user friendliness, user interface, search, mobile access, Multi-CAD integration including ECAD, and ERP integration when evaluating systems

- Start thinking ahead now. Begin planning for the future state of PLM to address user needs for tomorrow’s more complex products and product development environments, higher user expectations, and fast-moving markets

A Ten Point Guide Using the Internet of Things to Change the Game for You Business eBook shares ten tips for companies who would like to know what they should think about to evolve their business and its products for the Internet of Things (IoT). The IoT offers new opportunities for innovation, but it came be difficult to know where to start. These ten tips provide guidance to help companies identify where they should focus their initial efforts.

Please enjoy the summary below, or click the report title above to download the full PDF for more details (free of charge, no registration required). Special thanks to IBM for sponsoring the distribution of this research. For more information, visit IBM’s continuous engineering page.

A Ten Point Guide Using the Internet of Things to Change the Game for You Business eBook shares ten tips for companies who would like to know what they should think about to evolve their business and its products for the Internet of Things (IoT). The IoT offers new opportunities for innovation, but it came be difficult to know where to start. These ten tips provide guidance to help companies identify where they should focus their initial efforts.

Please enjoy the summary below, or click the report title above to download the full PDF for more details (free of charge, no registration required). Special thanks to IBM for sponsoring the distribution of this research. For more information, visit IBM’s continuous engineering page.

THE NEW PRODUCT DEVELOPMENT IMPERATIVE

With intense global competition, many of today’s product companies struggle to set themselves apart from their competition. The Internet of Things (IoT) offers exciting options for innovation through new business models and services that create new revenue opportunities. Companies that successfully take advantage of this disruption have a chance to create a competitive advantage and bound ahead of their competition. The challenge is knowing where to start. Businesses may even need to rethink their business aspirations and how they create revenue. To be successful, businesses must consider how they transform their business model, the infrastructure they need, and the impact on engineering. Tech-Clarity offers the following ten tips to help companies transform their business to take advantage of this opportunity and prepare for growth and profitability:- Rethink Products

- Consider Delivery Models

- Improve Customer Experiences

- Keep it Secure

- Support Standards

- Identify and Manage Requirements

- Derive Insight with Analytics

- Enable Reuse

- Continuously Verify and Validate

- Plan for Future Revenue

[post_title] => Webcast on Leveraging the Cloud in Engineering

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webcast-cloud-engineering

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:38

[post_modified_gmt] => 2022-11-15 03:26:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4811

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => 8a597c9f0a1cf7664841e3efa3223864

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:25940774a35c67cdfec301ec118efff9:0.96754300 17690505870.97749400 1769050587

)

[post_title] => Webcast on Leveraging the Cloud in Engineering

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => webcast-cloud-engineering

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:38

[post_modified_gmt] => 2022-11-15 03:26:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=4811

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => 8a597c9f0a1cf7664841e3efa3223864

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:25940774a35c67cdfec301ec118efff9:0.96754300 17690505870.97749400 1769050587

)

All Results for "All"

Product Data Integration Humor / Interview on PLM Customization with Stan Przybylinski

We take a silly look at solving the problem of fragmented product data and processes with a mythical integration product called FlōSēl. Then we get down to business with Tech-Clarity’s Jim Brown and CIMdata’s Stan Przybylinski discussing the reasons people customize their PLM systems, the potential downfalls of doing it, and the changing customization / configuration scenario…

What Businesses will 3D Printing “Amazon” (Guest Blog Post on GrabCAD Blog)

Jim Brown contributed his views on the potential business impacts of 3D Printing in this guest blog post on the GrabCAD blog, What Businesses are about to get “Amazonned” by the 3D Printing Revolution?

How Much PDM is Right for You? (animated video)

This short, animated Tech-Clarity TV episode explores the different Product Data Management options available to manufacturers. It explains that value of full-featured PDM as a step beyond CAD File Management and a stepping stone toward PLM for more advanced capabilities as needed. This episode is sponsored by Siemens PLM. Learn more about Siemens PLM and their…

Materials Innovation Survey

How are leading companies enabling their teams to be more innovative? How are they taking advantage of the latest material advancements? Please share your experience. We are conducting new research on product innovation. This survey is targeted at those who either develop new materials or look to use new materials to support their innovation goals. We are…

Webcast on Improving Product Development in CPG

Join Tech-Clarity’s Jim Brown and Dassault Systemes’ Raymond Wodar as they present on a CGT webcast, New Approaches to Improve Product Development. The presentation focuses on how to compete in today’s complex markets and ensure innovative products reach consumers quickly despite tight regulations, disperse supply chains, and severe cost pressure. Learn how Top Performing CPG companies are moving…

Product Configuration and “To Order” Manufacturing Survey

How do leading “to order” manufacturers support their sales, quote, and manufacturing processes? The survey is closed, thank you. Thank you for your help and support! Rules To be eligible for this offer, you must complete the survey and be a professional with job responsibilities related to or supporting the development, release, or manufacture of…

Concept Design Survey

Concept Design Survey How do leading companies develop conceptual models? Please share your experience. We are conducting new research on concept development. We are exploring questions such as, what are best practices for developing concepts? Are there approaches to concept development that will save time during detail design? Can technology help?? If you already completed the survey –>…

Getting Higher Strategic Value out of PLM

The Getting the Most from PLM – PLM Drives Tangible Business Value eBook is the result of a joint research project between research firm Tech-Clarity and innovation consulting firm Kalypso. We researched over 100 companies to determine how some companies get much higher levels of value from their Product Lifecycle Management implementations. The report shows that…

Cloud ERP / PLM: Gaining a Competitive Advantage with Connected Data

Tech-Clarity’s Michelle Boucher will share recent research on PDM, PLM and the cloud at an event put on by MasterGraphics, “Cloud ERP / PLM: Gaining a Competitive Advantage with Connected Data.” She will discuss some misconceptions and how to set the right foundation for incremental strategic improvement. The event will be held in Milwaukee on August…

On-Demand Webinar – Top Performers Do More than Manage CAD with PLM!

Jim Brown presented findings from his recent research on Enterprise PLM in this Engineering.com webcast, Top PLM Performers Manage More Than CAD. The recording is now available on-demand, including a very active Q&A session. Watch the replay now (no charge, registration required) Sponsored by Autodesk PLM 360

PLM Beyond Managing CAD

Product Lifecycle Management Beyond Managing CAD, The Business Value of PLM shares survey results exploring the value of PLM beyond managing design files such as CAD. While the research finds that most Top Performers manage CAD in PLM, they also do a lot more. The research shows that Top Performers – the ones that report higher…

Reducing Program Risk with EVM

Reducing Program Risk with Earned Value Management explores the business value of Earned Value Management (EVM) processes and tools and how they can streamline program execution and drive down risk. The eBook shares a brief overview of EVM in business terms and shares how EVM helps companies gain control of programs, monitor and correct program health, boost visibility…

An Action Plan to Improve Your Product Portfolio

Tech-Clarity’s new eBook, An Action Plan to Improve Your Product Portfolio, helps companies start down the path to better product profitability through PPM. The research shares insights on how to recognize the need for PPM, prepare your organization for the PPM journey,determine the potential ROI, and select a software vendor partner. It’s a comprehensive look at…

Survey: Material Trends for Engineering and Production

Material Trends for Engineering and Production How are new materials impacting your design and production processes? Please share your experience. What are your plans for new materials? What challenges should you be aware of when using new materials? What are so of the best practices when using new materials such as composites? If you already completed the…

CAD Survey

Switching CAD Tools Have you gone through a change in CAD tools? Are you considering a change? Please share your experience. How did the process go? What drove the change? What should companies expect when making a change? If you already completed the survey –> please share with a colleague or on social media using the “Share/Save”…

Webcast – Optimization and 3D Printing Revolutionize Design

Michelle Boucher will join Kenneth Wong, Senior Editor from Desktop Engineering and Simon Floyd, Director of Innovation and Product Lifecycle Management Solutions from Microsoft for a very interesting webcast on Thursday, June 25, 2015 at 2:00 pm EDT. The webinar will examine some of the latest advancements in product development technologies, specifically the combination of topology…

PLM411 PLM Deep Thoughts / Club W PLM Interview with KJ Carlson

What is PLM software anyway? You probably know it’s “Product Lifecycle Management” but beyond that most definitions get weak. At best they’re circular. We ponder that question in a tongue-in-cheek way before transitioning into an insightful interview between Tech-Clarity’s Jim Brown and “KJ” Carlson of Club W. KJ shares some unique perspectives and uses of PLM…

PDM/PLM User Satisfaction Survey

PDM/PLM Satisfaction Survey – Status Quo is Satisfactory but Needs are Changing shares the results of a survey of over 500 PLM users exploring their satisfaction with their Product Data Management (PDM) and/or Product Lifecycle Management (PLM) systems. The report conveys the perspectives of a large number of PLM users ranging in seniority, position, and industry. The study…

A 10 Point Guide for IoT eBook

A Ten Point Guide Using the Internet of Things to Change the Game for You Business eBook shares ten tips for companies who would like to know what they should think about to evolve their business and its products for the Internet of Things (IoT). The IoT offers new opportunities for innovation, but it came be difficult to know where…