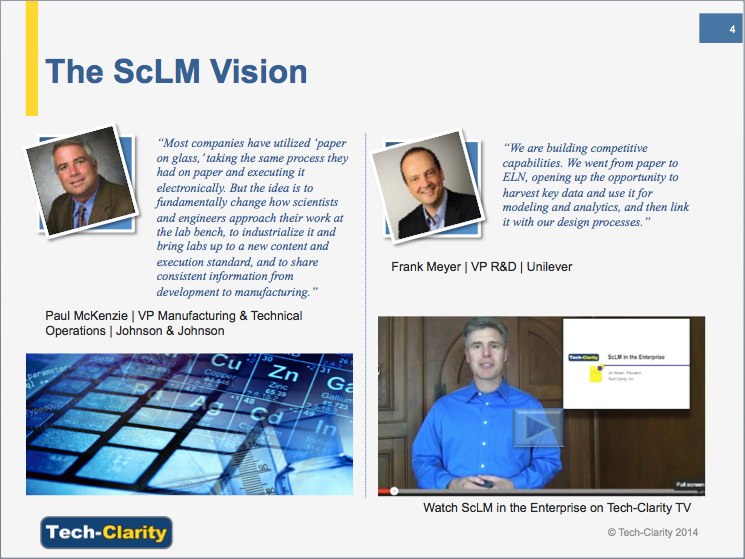

This episode of Tech-Clarity TV shares our views on the importance of Science Lifecycle Management (ScLM) and how ScLM complements ERP and PLM in the enterprise systems ecosystem. The report complements a recent Tech-Clarity eBook on ScLM that features interviews with R&D, Manufacturing, and Operations experts from J&J and Unilever.

- Strong corporate sustainability mindset

- Proven, scalable compliance processes

- Rich part and supplier data

- Responsive supply chain

- Comprehensive automation and infrastructure

- Experience extending capabilities to new regulations

Find more information from our sponsor, PTC, on their Regulatory Compliance Resource Center.

[post_title] => Infographic - Regulatory Explosion Demands Product Development Changes

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => infographic-regulatory-explosion

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:39

[post_modified_gmt] => 2022-11-15 03:27:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3870

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 3846

[post_author] => 2

[post_date] => 2014-05-21 15:41:54

[post_date_gmt] => 2014-05-21 19:41:54

[post_content] =>

Find more information from our sponsor, PTC, on their Regulatory Compliance Resource Center.

[post_title] => Infographic - Regulatory Explosion Demands Product Development Changes

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => infographic-regulatory-explosion

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:39

[post_modified_gmt] => 2022-11-15 03:27:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3870

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 3846

[post_author] => 2

[post_date] => 2014-05-21 15:41:54

[post_date_gmt] => 2014-05-21 19:41:54

[post_content] =>  This ebook, Science Lifecycle Management in the Enterprise Ecosystem, explains the value of Science Lifecycle Management (ScLM) solutions and how they complement other enterprise solutions like Product Lifecycle Management (PLM) and ERP. It provides a quick way to get up to speed on the ScLM vision by sharing insights from Unilever, Johnson & Johnson, and Eli Lilly. The eBook overviews how ScLM integrates scientific functions ranging from electronic lab notebooks (ELN) to informatics and simulation with other solution suites to improve quality, efficiency, compliance, and scientific innovation.

Please enjoy the excerpt below, or click the eBook or title to download the full PDF (free of charge, no registration required).

This ebook, Science Lifecycle Management in the Enterprise Ecosystem, explains the value of Science Lifecycle Management (ScLM) solutions and how they complement other enterprise solutions like Product Lifecycle Management (PLM) and ERP. It provides a quick way to get up to speed on the ScLM vision by sharing insights from Unilever, Johnson & Johnson, and Eli Lilly. The eBook overviews how ScLM integrates scientific functions ranging from electronic lab notebooks (ELN) to informatics and simulation with other solution suites to improve quality, efficiency, compliance, and scientific innovation.

Please enjoy the excerpt below, or click the eBook or title to download the full PDF (free of charge, no registration required).

ERP and PLM are the two primary systems used to enable manufacturing businesses. Tech-Clarity’s research describes the roles ERP and PLM play and how they work alongside other enterprise systems. But the discussion has always stopped short of the lab and the value of R&D – developing and validating new materials, compounds, and processes that are the building blocks for product-level innovation.

The lab is involved in all phases of the product lifecycle. Now, visionary companies are taking a more holistic, integrated view of how science enables the enterprise. An integrated ecosystem of solutions has emerged, Scientific Lifecycle Management (ScLM). ScLM starts in early discovery with capabilities like high throughput science, molecular simulation, and lab notebooks and extends through product development, testing, and validation.

Leading companies are extending the advantage of ScLM by integrating it more broadly into their enterprise processes and systems including ERP and PLM. This eBook shares insights and experience from two companies that have started their ScLM journeys with visions toward fully integrated enterprise ecosystems that support the business of manufacturing, product innovation, and scientific exploration and discovery.

[post_title] => Science Lifecycle Management in the Enterprise Ecosystem

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => sclm-role

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:39

[post_modified_gmt] => 2022-11-15 03:27:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3846

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 3807

[post_author] => 2

[post_date] => 2014-05-14 12:43:16

[post_date_gmt] => 2014-05-14 16:43:16

[post_content] =>

ERP and PLM are the two primary systems used to enable manufacturing businesses. Tech-Clarity’s research describes the roles ERP and PLM play and how they work alongside other enterprise systems. But the discussion has always stopped short of the lab and the value of R&D – developing and validating new materials, compounds, and processes that are the building blocks for product-level innovation.

The lab is involved in all phases of the product lifecycle. Now, visionary companies are taking a more holistic, integrated view of how science enables the enterprise. An integrated ecosystem of solutions has emerged, Scientific Lifecycle Management (ScLM). ScLM starts in early discovery with capabilities like high throughput science, molecular simulation, and lab notebooks and extends through product development, testing, and validation.

Leading companies are extending the advantage of ScLM by integrating it more broadly into their enterprise processes and systems including ERP and PLM. This eBook shares insights and experience from two companies that have started their ScLM journeys with visions toward fully integrated enterprise ecosystems that support the business of manufacturing, product innovation, and scientific exploration and discovery.

[post_title] => Science Lifecycle Management in the Enterprise Ecosystem

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => sclm-role

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:39

[post_modified_gmt] => 2022-11-15 03:27:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3846

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 1

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 3807

[post_author] => 2

[post_date] => 2014-05-14 12:43:16

[post_date_gmt] => 2014-05-14 16:43:16

[post_content] =>  Issue in Focus - The Evolution of Digital Prototyping - Extending "Right First Time" Value Beyond Design explains that manufacturers must go beyond getting form, fit, and function right to compete in today's global markets. Digital prototyping offers tremendous business benefits by letting designers get innovative products right. But it also allows them to make intelligent tradeoffs to optimize products for sustainability, cost, weight, supply, and more. Digital Prototyping can add significant additional value by allowing companies to get products "right for market" and get manufacturing processes right early in design. The evolution and expansion of 3D design, simulation, and digital prototyping suites now makes these capabilities more accessible.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information on digital prototyping and how to improve product performance, visit our sponsor Autodesk's Manufacturing Genius Site.

Issue in Focus - The Evolution of Digital Prototyping - Extending "Right First Time" Value Beyond Design explains that manufacturers must go beyond getting form, fit, and function right to compete in today's global markets. Digital prototyping offers tremendous business benefits by letting designers get innovative products right. But it also allows them to make intelligent tradeoffs to optimize products for sustainability, cost, weight, supply, and more. Digital Prototyping can add significant additional value by allowing companies to get products "right for market" and get manufacturing processes right early in design. The evolution and expansion of 3D design, simulation, and digital prototyping suites now makes these capabilities more accessible.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information on digital prototyping and how to improve product performance, visit our sponsor Autodesk's Manufacturing Genius Site.

Table of Contents

- Introducing the Issue

- Extended Digital Prototyping

- The Business Value of Digital Prototyping

- Move Beyond Form, Fit, and Function

- Pursue Right to Market

- Go Beyond Design for Manufacturability

- Conclusion

- Recommendations

- About the Author

Executive Summary

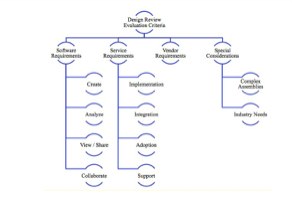

Digital prototyping helps manufacturers get products right the first time by letting them define, design, develop, and validate products in a virtual environment before committing to time-consuming and expensive physical prototyping. The technique enables them to efficiently develop high performance, high quality products and optimize them for form, fit, and function. Formerly accessible only by those with deep pockets and highly trained simulation specialists, digital prototyping has become much more accessible in the last decade due to reduced solution cost and complexity. This ease of access has allowed many manufacturers to take advantage of the significant business value and competitive advantage available from leveraging digital prototyping. The best product, however, is no longer enough to differentiate and compete in today’s crowded, competitive, global markets. Manufacturers have to be agile to adapt to threats and take advantage of opportunities on a global scale. They must be able to shift production as business strategies dictate, for example moving manufacturing closer to consumers or raw materials or shifting production from developing countries as advantages fade due to changing economic and business conditions. They must be ready to take on new competitors as formerly “low cost” countries take a more direct role in innovating and bringing their own products to market. They must be able to respond to new competitors as they arise, potentially competing with new business models like 3D product models sold to be printed at home via 3D printing. In addition, they must find innovative ways to engage with customers to rise above the noise. To compete in this environment manufacturers must holistically improve the way they design, develop, produce, and sell products. Status quo is a failing strategy. They have to enhance their ability to innovate and deliver products from concept to customers rapidly, efficiently, and with confidence. Digital prototyping has evolved to meet these needs and now offers manufacturers a significant opportunity to achieve benefits beyond getting product design right up front. [post_title] => The Evolution of Digital Prototyping [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => evolution-dp [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:39 [post_modified_gmt] => 2022-11-15 03:27:39 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3807 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [6] => WP_Post Object ( [ID] => 3797 [post_author] => 2 [post_date] => 2014-04-30 16:03:27 [post_date_gmt] => 2014-04-30 20:03:27 [post_content] => Tech-Clarity's Design Review Buyer's Guide - Selecting the Right Visualization and Collaboration Solution helps manufacturers develop criteria to evaluate design review software based on a set of high level criteria. Tech-Clarity's Buyer's Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

helps manufacturers develop criteria to evaluate design review software based on a set of high level criteria. Tech-Clarity's Buyer's Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

- Software capabilities

- Implementation

- User adoption

- Support

- Vendor characteristics / attributes

- Industry or unique business needs

Please enjoy the summary below, or click the report to download the PDF (free of charge, no registration required) thanks to our sponsor, PTC.

You can also hear more about the Design Review Buyer's Guide on Tech-Clarity TV on our YouTube channel.

Table of Contents

- Executive Overview

- The Design Review Business Case

- Analyze Design Review Solution Capabilities

- Assess Service Requirements

- Consider Vendor Requirements

- Special Considerations

- Conclusion

- Recommendations

- About the Author

Executive Overview

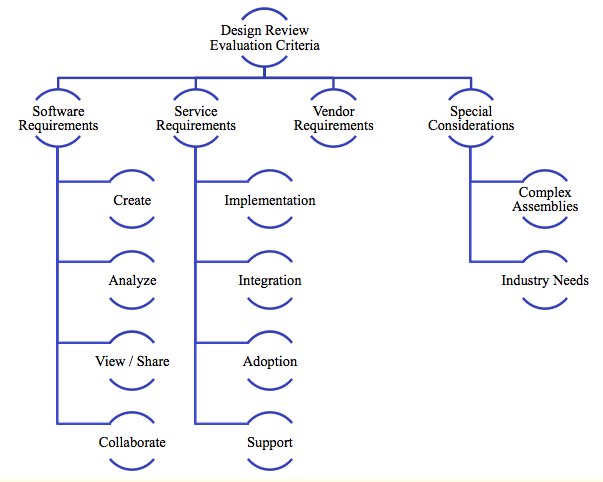

The Design Review Buyer’s Guide is a reference tool to help manufacturers select the right software to support design review and validation. The guide is composed of four sections covering software functionality, service requirements, vendor attributes, and special company considerations (Figure 1). Each section includes a checklist of key requirements that should be analyzed when selecting visualization and collaboration software to enable and improve design review. Design review is a proven, low-risk process that helps manufacturers enhance quality, reduce time to market, improve productivity, and bring more innovative products to market. It supports a product development process that solicits input and feedback from a variety of people with varied expertise and points of view. This collaborative approach allows manufacturers to tap into their distributed product expertise and get products right the first time.

Achieving these desirable benefits requires more than sharing CAD files or implementing visualization tools. The guide identifies key business capabilities that must be adopted and the software needed to support them. It goes beyond software functionality to address the broader needs of the business, offering buying criteria that cover product, infrastructure, implementation, service, and business requirements. The guide also touches on special considerations for those with highly complex products and a few special considerations to consider by industry.

[post_title] => Design Review Buyer's Guide

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => design-review

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:38

[post_modified_gmt] => 2022-11-15 03:27:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3797

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 3681

[post_author] => 2

[post_date] => 2014-03-24 15:55:23

[post_date_gmt] => 2014-03-24 19:55:23

[post_content] =>

Design review is a proven, low-risk process that helps manufacturers enhance quality, reduce time to market, improve productivity, and bring more innovative products to market. It supports a product development process that solicits input and feedback from a variety of people with varied expertise and points of view. This collaborative approach allows manufacturers to tap into their distributed product expertise and get products right the first time.

Achieving these desirable benefits requires more than sharing CAD files or implementing visualization tools. The guide identifies key business capabilities that must be adopted and the software needed to support them. It goes beyond software functionality to address the broader needs of the business, offering buying criteria that cover product, infrastructure, implementation, service, and business requirements. The guide also touches on special considerations for those with highly complex products and a few special considerations to consider by industry.

[post_title] => Design Review Buyer's Guide

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => design-review

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:38

[post_modified_gmt] => 2022-11-15 03:27:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3797

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 3681

[post_author] => 2

[post_date] => 2014-03-24 15:55:23

[post_date_gmt] => 2014-03-24 19:55:23

[post_content] =>  This eBook, A Guide to Manufacturing Transformation, discusses the current resurgence of global manufacturing and shares how ERP and PLM systems help. It offers advice for manufacturers to capitalize on new opportunities presented by the recovery and evolution of the manufacturing industry. The eBook is a collaboration between Cindy Jutras of Mint Jutras and Jim Brown of Tech-Clarity.

Please enjoy the summary below, or click the report to download the eBook (free of charge, no registration required).

Visit this page for more information and a case study on modernizing modern manufacturing, including how cloud systems can help, provided by our sponsors, Autodesk and NetSuite.

This eBook, A Guide to Manufacturing Transformation, discusses the current resurgence of global manufacturing and shares how ERP and PLM systems help. It offers advice for manufacturers to capitalize on new opportunities presented by the recovery and evolution of the manufacturing industry. The eBook is a collaboration between Cindy Jutras of Mint Jutras and Jim Brown of Tech-Clarity.

Please enjoy the summary below, or click the report to download the eBook (free of charge, no registration required).

Visit this page for more information and a case study on modernizing modern manufacturing, including how cloud systems can help, provided by our sponsors, Autodesk and NetSuite.

The manufacturing industry is undergoing one if its most significant transformations in decades. The years of industrialized nations gaining significant economic advantages from shifting production to low cost, developing nations are coming to an end. Today’s economic landscape and rising wages in formerly low-cost countries make offshoring less attractive.

Developed nations are now “right shoring” their operations and adopting “design anywhere – build anywhere” strategies that allow them to shift work across the globe and produce closer to raw materials or customers. Manufacturers in emerging economies are moving up the value chain to develop more innovative, high quality products. These shifts are causing many changes and creating many opportunities. They are also introducing new competition and new threats.

Manufacturers are turning to systems and automation to help them take advantage of the manufacturing transformation. Enterprise systems are enabling the transformation much the same way Enterprise Resource Planning (ERP) played a significant role in streamlining and re-engineering manufacturing enterprises in the 1990’s. As the bar is raised on expectations from today’s manufacturers, both ERP and Product Lifecycle Management (PLM) can play a significant role in helping companies stay ahead or leapfrog their competition.

The manufacturing transformation is underway. The enterprise systems ecosystem supporting manufacturing is changing as well. Are today’s enterprise systems ready to support this more competitive environment? Will they be within the reach of companies that weren’t able to take advantage of them in the past?

[post_title] => Guide to Manufacturing Transformation - Are Your Enterprise Systems Ready?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => transformation-erp-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:38

[post_modified_gmt] => 2022-11-15 03:27:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3681

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 3645

[post_author] => 2

[post_date] => 2014-03-19 14:16:27

[post_date_gmt] => 2014-03-19 18:16:27

[post_content] =>

The manufacturing industry is undergoing one if its most significant transformations in decades. The years of industrialized nations gaining significant economic advantages from shifting production to low cost, developing nations are coming to an end. Today’s economic landscape and rising wages in formerly low-cost countries make offshoring less attractive.

Developed nations are now “right shoring” their operations and adopting “design anywhere – build anywhere” strategies that allow them to shift work across the globe and produce closer to raw materials or customers. Manufacturers in emerging economies are moving up the value chain to develop more innovative, high quality products. These shifts are causing many changes and creating many opportunities. They are also introducing new competition and new threats.

Manufacturers are turning to systems and automation to help them take advantage of the manufacturing transformation. Enterprise systems are enabling the transformation much the same way Enterprise Resource Planning (ERP) played a significant role in streamlining and re-engineering manufacturing enterprises in the 1990’s. As the bar is raised on expectations from today’s manufacturers, both ERP and Product Lifecycle Management (PLM) can play a significant role in helping companies stay ahead or leapfrog their competition.

The manufacturing transformation is underway. The enterprise systems ecosystem supporting manufacturing is changing as well. Are today’s enterprise systems ready to support this more competitive environment? Will they be within the reach of companies that weren’t able to take advantage of them in the past?

[post_title] => Guide to Manufacturing Transformation - Are Your Enterprise Systems Ready?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => transformation-erp-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:38

[post_modified_gmt] => 2022-11-15 03:27:38

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3681

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 3645

[post_author] => 2

[post_date] => 2014-03-19 14:16:27

[post_date_gmt] => 2014-03-19 18:16:27

[post_content] =>  Tech-Clarity Insight The Basics of Managing CAD - When Brute Force Fails and PDM is too Much explains the need to manage CAD files and the current options available to manufacturers. The report analyzes the positives and negatives of manually managed approaches, implementing PDM/PLM, and utilizing cloud-based file management services. The research then reviews the basic necessities of CAD management - controlling, accessing, and sharing files - in order to uncover what a "just the basics" solution requires to determine if there are lower overhead methods (such as cloud services) that can be applied. The report shares the experience of two companies, Hippo Engineering and HemoSonics, that have adopted a cloud based approach to managing CAD files.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, GrabCAD (free of charge, registration required).

Table of Contents

Tech-Clarity Insight The Basics of Managing CAD - When Brute Force Fails and PDM is too Much explains the need to manage CAD files and the current options available to manufacturers. The report analyzes the positives and negatives of manually managed approaches, implementing PDM/PLM, and utilizing cloud-based file management services. The research then reviews the basic necessities of CAD management - controlling, accessing, and sharing files - in order to uncover what a "just the basics" solution requires to determine if there are lower overhead methods (such as cloud services) that can be applied. The report shares the experience of two companies, Hippo Engineering and HemoSonics, that have adopted a cloud based approach to managing CAD files.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit our sponsor, GrabCAD (free of charge, registration required).

Table of Contents

- Executive Overview

- Understand the Need to Manage CAD Data

- Explore CAD Data Management Options

- Explore the Options – Manual Approaches

- Explore the Options – PDM or PLM

- Explore the Options – Cloud File-Sharing

- Identify Basic Requirements for CAD Management

- Gain Control

- Provide Access

- Share Your CAD

- Get the Basics without the Overhead?

- Conclusion

- Recommendations

- About the Author

Executive Overview

Engineering, by its nature, is a logical and structured discipline. It’s no surprise, then, to see the level of organization that engineers apply to managing their CAD files. Unfortunately, many engineers manage files using meaningful file names on their hard drive. As the number of engineers on a project increases, managing files in a directory structure gets increasingly risky. Simply transforming the directory structure to a shared drive is not enough to manage multiple design iterations and have confidence that you can always find the current version. Or make sure that another designer doesn’t overwrite your hard work. Or really ever expect to find what you are looking for. Some recognize the shortcomings and risks of a manual CAD management approach, while others are one mistake away from learning the hard way. “An unmanaged approach works OK for one person, but when you ask for something they spend a half a day scrambling to get data together,” cautions Jake Myre, owner of Hippo Engineering. “Then, they end up having a part made for a prototype and find out it’s three versions old. That’s not good.” Beyond managing their own work, few engineers work in a vacuum. They must coordinate with other designers, contractors, suppliers, prototype shops, contract manufacturers, and others that need CAD data to do their jobs. PDM and PLM are formal, traditional systems designed to help manufacturers control, access, and share their CAD data. But as Tech-Clarity’s Managing Design Data with SharePoint concludes, “Unfortunately, data management solutions have been out of reach … due to cost and lack of IT resources.” But engineers have to do something. Living in an unmanaged, manual environment is highly inefficient and prone to errors. For companies that have outgrown chaos and are tired of crossing their fingers and hoping they don’t order or produce the wrong part, it’s time for a practical solution. Fortunately, there are more options available today than ever before, including new cloud-based tools. It’s time for a rational discussion to explore the basic requirements for CAD data management and discuss whether they can be achieved without the cost and complexity that make traditional solutions impractical for many smaller manufacturers. This report concludes that a simplified, cloud-based CAD data management approach can provide important benefits with significantly reduced investment of time, money, and IT expertise. [post_title] => The Basics of Managing CAD [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cad-management [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:38 [post_modified_gmt] => 2022-11-15 03:27:38 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3645 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 2 [filter] => raw ) [9] => WP_Post Object ( [ID] => 3640 [post_author] => 2 [post_date] => 2014-03-06 13:05:39 [post_date_gmt] => 2014-03-06 18:05:39 [post_content] => This episode of Tech-Clarity TV looks at the future of product design software (CAD) and product development environments (PLM) and how they should work together. The video is based on our Integrating Product Design and Development report that shares how a well-integrated CAD-PLM continuum helps improve engineering and product development performance. http://youtu.be/4hqn1MoppbI Please see our sponsor Dassault Systemes for more information on this topic and a discussion of how their products meet these needs (free of charge, registration required). [post_title] => Tech-Clarity TV - CAD-PLM Integration [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => tctv-cad-plm [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:29:49 [post_modified_gmt] => 2022-11-15 03:29:49 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3640 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 4 [filter] => raw ) [10] => WP_Post Object ( [ID] => 3624 [post_author] => 2 [post_date] => 2014-02-27 13:13:22 [post_date_gmt] => 2014-02-27 18:13:22 [post_content] => Tech-Clarity is pleased to announce the expansion of our research team! Industry veteran and former Aberdeen Group Senior Research Analyst Michelle Boucher joins Tech-Clarity as Vice President of Research covering engineering software. Michelle brings a wealth of depth in engineering, product development, and research. For more on Michelle's background please visit her bio page.

As a combined team, we look forward to expanding and deepening our coverage of the product innovation, product development, and engineering software market as we continue our mission to make the value of technology clear to business. Jim Brown, President and Founder of Tech-Clarity says "Michelle brings new depth in research capabilities and market coverage, we are excited to have such a proven analyst joining our team."

Michelle’s research focus will include engineering tools and other software enablers for engineering and product development. Please follow Michelle on twitter and subscribe to Tech-Clarity to read Michelle's research.

For more information or to schedule a briefing please feel free to contact us.

[post_title] => Tech-Clarity adds VP Engineering Software Research Michelle Boucher

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => boucher-joins

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:52

[post_modified_gmt] => 2022-11-15 03:25:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3624

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 2

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 3608

[post_author] => 2572

[post_date] => 2014-02-27 08:31:59

[post_date_gmt] => 2014-02-27 13:31:59

[post_content] =>

Tech-Clarity is pleased to announce the expansion of our research team! Industry veteran and former Aberdeen Group Senior Research Analyst Michelle Boucher joins Tech-Clarity as Vice President of Research covering engineering software. Michelle brings a wealth of depth in engineering, product development, and research. For more on Michelle's background please visit her bio page.

As a combined team, we look forward to expanding and deepening our coverage of the product innovation, product development, and engineering software market as we continue our mission to make the value of technology clear to business. Jim Brown, President and Founder of Tech-Clarity says "Michelle brings new depth in research capabilities and market coverage, we are excited to have such a proven analyst joining our team."

Michelle’s research focus will include engineering tools and other software enablers for engineering and product development. Please follow Michelle on twitter and subscribe to Tech-Clarity to read Michelle's research.

For more information or to schedule a briefing please feel free to contact us.

[post_title] => Tech-Clarity adds VP Engineering Software Research Michelle Boucher

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => boucher-joins

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:52

[post_modified_gmt] => 2022-11-15 03:25:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3624

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 2

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 3608

[post_author] => 2572

[post_date] => 2014-02-27 08:31:59

[post_date_gmt] => 2014-02-27 13:31:59

[post_content] =>

Michelle Boucher is the Vice President of Research for Engineering Practices for Tech-Clarity. Ms. Boucher has spent over 20 years in various roles in engineering, marketing, management, and as an analyst. She has broad experience with topics such as product design, simulation, systems engineering, mechatronics, embedded systems, PCB design, additive manufacturing, improving product performance, process improvement, and mass customization. She graduated magna cum laude with an MBA from Babson College and earned a BS in Mechanical Engineering, with distinction, from Worcester Polytechnic Institute.

Ms. Boucher began her career holding various roles as a mechanical engineer at Pratt & Whitney and KONA (now Synventive Molding Solutions). She then spent over 10 years at PTC, a leading MCAD and PLM solution provider. While at PTC, she developed a deep understanding of end user needs through roles in technical support, management, and product marketing. She worked in technical marketing at Moldflow Corporation (acquired by Autodesk), the market leader in injection molding simulation. Here she was instrumental in developing product positioning and go-to-market messages. Ms. Boucher then joined Aberdeen Group and covered product innovation, product development, and engineering processes, eventually running the Product Innovation and Engineering practice.

Ms. Boucher is an experienced researcher and author. She has benchmarked over 7000 product development professionals and published over 90 reports on product development best practices. She focuses on helping companies manage the complexity of today’s products, markets, design environments, and value chains to achieve higher profitability.

[post_title] => Michelle Boucher [post_excerpt] => [post_status] => publish [comment_status] => closed [ping_status] => closed [post_password] => [post_name] => michelle-boucher [to_ping] => [pinged] => [post_modified] => 2025-05-05 13:56:25 [post_modified_gmt] => 2025-05-05 17:56:25 [post_content_filtered] => [post_parent] => 24 [guid] => http://tech-clarity.com/?page_id=3608 [menu_order] => -12 [post_type] => page [post_mime_type] => [comment_count] => 1 [filter] => raw ) [12] => WP_Post Object ( [ID] => 3595 [post_author] => 2 [post_date] => 2014-02-26 13:00:24 [post_date_gmt] => 2014-02-26 18:00:24 [post_content] =>

Issue in Focus Integrating Product Design and Development Environments - Battling Complexity, Improving Productivity, and Compressing Time

discusses how a well-integrated CAD-PLM platform helps improve engineering and product development performance. This report describes the requirements and capabilities that manufacturers should look for in the latest generation of integrated systems for product design and development.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required). For the full report, please visit our sponsor Dassault Systemes (free of charge, registration required).

Table of Contents

Issue in Focus Integrating Product Design and Development Environments - Battling Complexity, Improving Productivity, and Compressing Time

discusses how a well-integrated CAD-PLM platform helps improve engineering and product development performance. This report describes the requirements and capabilities that manufacturers should look for in the latest generation of integrated systems for product design and development.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required). For the full report, please visit our sponsor Dassault Systemes (free of charge, registration required).

Table of Contents

- Introducing the Issue

- Take Advantage of Integrated Design Suites

- Tap the Value of Integrated Design and Lifecycle Management

- Expect Digital Mockups in Real Time

- Enable Engineers to Design in Context

- Proactively Manage Variant Configurations

- Advance Collaboration to Team-based Design

- Collaborate in Context at the Team Level

- Support the Business of Product Design and Development

- Conclusion

- Recommendations

- About the Author

Introducing the Issue

The status quo for product development is no longer acceptable. Manufacturers have to continuously improve their ability to design, develop, and introduce products around the world or lose relevance to stiff global competition. Today, leading manufacturers compete on speed and innovation. At the same time, they can’t afford escalating complexity to impact their productivity or quality. Product designers and developers are rising to the challenge. Manufacturers have made significant progress in battling complexity and improving time to market over the last decade. They have adopted platform and modular design techniques. They have learned to connect engineers from around the world to streamline product development. Engineering and enterprise software have played a critical role in these improvements. CAD and CAE have allowed engineers to design products they could only dream about in the past. PLM and digital manufacturing have enabled them to coordinate global design and manufacturing networks to improve productivity, increase speed, and reduce errors. But that is not enough for the future. The bar is now raised and requires companies to strive toward a new plateau of performance. The product development benchmark for the next decade will be the ability to simultaneously introduce localized products around the globe with increased personalization. To accomplish this, manufacturers will need to compress the time it takes to design global product variants without compromising quality or cost. As if this isn’t enough, they have to do this at the same time they adapt to the complexity of developing smarter, mechatronic products. Manufacturers are once again looking to their enabling technologies to take them to the next level. Most current engineering software implementations, however, will not support the real-time, concurrent, design-in-context environment required. The current best in class technology offers seamless integration between authoring, analysis, and enterprise tools and allows engineers and product developers to work together in a real-time environment. This paper explores the possibilities available from the latest generation of integrated design and development environments. [post_title] => Integrating Product Design and Development Environments [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cad-plm [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:37 [post_modified_gmt] => 2022-11-15 03:27:37 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3595 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [13] => WP_Post Object ( [ID] => 3588 [post_author] => 2 [post_date] => 2014-02-20 12:09:40 [post_date_gmt] => 2014-02-20 17:09:40 [post_content] => In this episode of Tech-Clarity TV Jim Brown discusses the financial and strategic benefits of consolidating onto a single CAD tool. The information is based on a recent Tech-Clarity report, Consolidating CAD - The Benefits of a Unified CAD Strategy. The report provides a way to calculate the cost savings available from systems rationalization. These savings go far beyond license or maintenance cost reduction. These cost cutting measure are how most companies will justify the project to standardize on a single CAD package. The report goes beyond cost savings to share the strategic value of rationalizing CAD systems (reuse, collaboration, corporate flexibility, IT specialization, and process standardization), which are even more compelling (if slightly less tangible and harder to calculate). http://youtu.be/gIDBmaL-woM The full report and a downloadable spreadsheet to help you analyze cost savings for your company are available from our sponsor PTC as a part of their CAD Consolidation Kit (free of charge, registration required). [post_title] => Tech-Clarity TV - Consolidating CAD Strategy and ROI [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => tctv-cad-consolidation [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:29:49 [post_modified_gmt] => 2022-11-15 03:29:49 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3588 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [14] => WP_Post Object ( [ID] => 3574 [post_author] => 2 [post_date] => 2014-01-27 13:46:32 [post_date_gmt] => 2014-01-27 18:46:32 [post_content] => Read Kalypso founding partner George Young and Tech-Clarity President Jim Brown discuss their perspectives on enabling software for NPDI in Consumer Goods Technology's 2014 Readers Choice Awards for New Product Development and Introduction Software. [post_title] => Kalypso's Young and Tech-Clarity's Brown in CGT Reader's Choice on NPDI Technology [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cgt-npdi [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:25:52 [post_modified_gmt] => 2022-11-15 03:25:52 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3574 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [15] => WP_Post Object ( [ID] => 3566 [post_author] => 2 [post_date] => 2014-01-22 13:07:04 [post_date_gmt] => 2014-01-22 18:07:04 [post_content] => Tech-Clarity Insight - Consolidating CAD - The Benefits of a Unified CAD Strategy offers insight into the strategic value companies can achieve by standardizing on a single CAD package. The report explains how to calculate an ROI for CAD consolidation based on direct cost savings. Perhaps more importantly, the research identifies a number of strategic benefits achievable by using a single solution across the enterprise.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report and a downloadable spreadsheet to help you calculate the value for your company please visit our sponsor PTC's for their CAD Consolidation Kit (free of charge, registration required).

Tech-Clarity Insight - Consolidating CAD - The Benefits of a Unified CAD Strategy offers insight into the strategic value companies can achieve by standardizing on a single CAD package. The report explains how to calculate an ROI for CAD consolidation based on direct cost savings. Perhaps more importantly, the research identifies a number of strategic benefits achievable by using a single solution across the enterprise.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report and a downloadable spreadsheet to help you calculate the value for your company please visit our sponsor PTC's for their CAD Consolidation Kit (free of charge, registration required).

Table of Contents

- Executive Overview

- Lean IT Overhead

- Reuse

- Collaboration

- Enabling the Bigger Product Development Picture

- The Corporate Advantage

- The IT Advantage

- Conclusion

- Recommendations

- About the Author

- About the Research

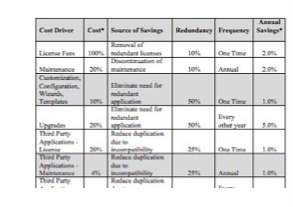

Executive Overview

Manufacturers must remain vigilant about managing cost in today’s uncertain economic times. Lean IT organizations and budgets lead many to consider the benefits of rationalizing their software systems. One system that manufacturers should consider standardizing is Computer Aided Design (CAD). Even in the best of times, manufacturers should consider standardizing on a single CAD solution. Cost savings are attractive and are certainly attainable through consolidation. Beyond cost savings, though, are even greater strategic benefits. At the workgroup level, manufacturers can take advantage of better design collaboration and CAD model reuse. Broader benefits include the ability to share best practices across teams. The ability to unify product development processes and data across the enterprise is even more strategic. Common processes and centralized data are particularly advantageous as a part of a full system for product design and development that supports design, analysis, data management, product compliance, documentation, and other related innovation tools. At the highest level, standardizing CAD software offers corporate benefits. For example, a single CAD environment can enable a “design anywhere – build anywhere” strategy. This approach allows companies to rapidly adjust to market changes and resource shortages by offering the ability to transfer design or production to new facilities without concern for incompatible design data, tools, or processes. From the IT perspective, consolidation provides the ability to focus resources on a smaller number of solutions. This reduces workload and cost and allows IT to provide a higher level of business support with today’s lean organizations. Of course not all businesses have the opportunity to unify their CAD solutions due to customer and supplier constraints, but there are multiple advantages for those that can. [post_title] => Consolidating CAD - Benefits of a Unified CAD Strategy [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => consolidating-cad-2 [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:37 [post_modified_gmt] => 2022-11-15 03:27:37 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3566 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [16] => WP_Post Object ( [ID] => 3557 [post_author] => 2 [post_date] => 2014-01-17 13:23:48 [post_date_gmt] => 2014-01-17 18:23:48 [post_content] => In this episode of Tech-Clarity TV, Jim Brown shares Tech-Clarity's views on how manufacturers can analyze and optimize costs for manufactured goods during the design phase. It also shares the value of using a knowledge-based cost to negotiate and make process improvements with suppliers. http://youtu.be/uXxUmHOEb9E Learn more from the related report, Product Cost Management - A Knowledge-Based Approach to Optimizing Product Cost Tony Lockwood of Desktop Engineering shared his thoughts on Tech-Clarity's Consolidating Design Software, Extending Value Beyond 3D CAD Consolidation. I like his description of "working in a multi-CAD environment with multiple disconnected tools and multiple money pits bleeding you dry at every junction of your process."

Read the short article by Tony on Desktop Engineering.

[post_title] => Desktop Engineering Views on CAD Consolidation Research

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => de-mulitcad

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:51

[post_modified_gmt] => 2022-11-15 03:25:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3501

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 3491

[post_author] => 2

[post_date] => 2013-12-23 10:38:21

[post_date_gmt] => 2013-12-23 15:38:21

[post_content] =>

Tony Lockwood of Desktop Engineering shared his thoughts on Tech-Clarity's Consolidating Design Software, Extending Value Beyond 3D CAD Consolidation. I like his description of "working in a multi-CAD environment with multiple disconnected tools and multiple money pits bleeding you dry at every junction of your process."

Read the short article by Tony on Desktop Engineering.

[post_title] => Desktop Engineering Views on CAD Consolidation Research

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => de-mulitcad

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:51

[post_modified_gmt] => 2022-11-15 03:25:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=3501

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 3491

[post_author] => 2

[post_date] => 2013-12-23 10:38:21

[post_date_gmt] => 2013-12-23 15:38:21

[post_content] =>  Product Cost Management - A Knowledge Based Approach to Optimizing Product Cost explains how manufacturers can design products for optimal cost in order to improve profitability. The research shares interviews with three industrial manufacturers on the way they work with their supply chains to reduce cost using an analytical, fact-based methodology to drive out unnecessary cost and negotiate fair pricing. The interviews also point out the value of enterprise-class software to enable PCM.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information on PCM from our sponsor please visit Siemens PLM's Teamcenter Product Cost Management page.

Please also see the related Tech-Clarity TV Episode - Optimizing Product Cost with PCM

Product Cost Management - A Knowledge Based Approach to Optimizing Product Cost explains how manufacturers can design products for optimal cost in order to improve profitability. The research shares interviews with three industrial manufacturers on the way they work with their supply chains to reduce cost using an analytical, fact-based methodology to drive out unnecessary cost and negotiate fair pricing. The interviews also point out the value of enterprise-class software to enable PCM.

Please enjoy the summary below, or click the report or title to download the full PDF (free of charge, no registration required).

For more information on PCM from our sponsor please visit Siemens PLM's Teamcenter Product Cost Management page.

Please also see the related Tech-Clarity TV Episode - Optimizing Product Cost with PCM

Executive Overview

Many things factor into the profitability of a product. Innovation, satisfying customer wishes, and product performance drive sales, command price premiums, and boost top-line results. These get a lot of attention and engineers focus passionately on the form, fit, and function of their designs. But engineers don’t have the ability to evaluate the product cost impacts of their decisions to drive profitability from the expense perspective. Too few companies include a thorough “design for cost” analysis in their product development process to optimize profits. Engineers must optimize cost and make design tradeoffs early in the lifecycle when there is still design flexibility. “You need to have the right concept early on,” advises the Manager of Cost Engineering for a major automotive OEM. “The leverage you have is much higher when you start.” It’s critical to get the cost right as early as possible, particularly for high-volume parts. Most engineers don’t have visibility to the impact their decisions have on cost. They can’t optimize cost with other design parameters because they don’t have the right information. Product Cost Management (PCM) processes and software enable manufactures to design for cost by providing early visibility to the cost implications of design decisions. PCM allows companies to simulate and evaluate different manufacturing scenarios to develop an ideal “should cost” model based on detailed knowledge of materials, manufacturing processes, and supply chain costs. PCM benefits go beyond design. Most sourcing efforts result in suboptimal pricing because they aren’t based on how much a part should cost. Predicting manufacturing and supply costs confidently helps companies negotiate better prices based on facts and enables transparent, open discussion with suppliers. “We tell suppliers we aren’t looking for a cost reduction,” explains the Manager of Design Costing and Analysis for an agricultural machinery producer. “We want to improve their process and decrease their work so they can reduce the cost. It’s critical to start the discussion this way.” Beyond savings from one-time negotiations, PCM helps educate suppliers on how to get closer to an ideal should cost model. This win-win approach sets up continuous improvement with vendors to improve prices without putting unrealistic pressure on suppliers to blindly reduce cost. In the end, PCM changes negotiations to a battle of knowledge versus a battle of will and drives more sustainable cost reduction over time. [post_title] => Product Cost Management - A Knowledge Based Approach to Optimizing Product Cost [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => pcm-wp [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:37 [post_modified_gmt] => 2022-11-15 03:27:37 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=3491 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [19] => WP_Post Object ( [ID] => 3394 [post_author] => 2 [post_date] => 2013-10-28 12:15:36 [post_date_gmt] => 2013-10-28 16:15:36 [post_content] => The Business Value of Product Data Management - Achieving Rapid and Extendable Benefits with Preconfigured PDM shares the perspectives of three small to midsize manufacturers on the value they receive from PDM software. The report also offers Tech-Clarity's views on the business value of PDM and explains how preconfigured PDM solutions can help companies gain value quickly and cost effectively.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit the Teamcenter Rapid Start page on the Siemens PLM website (free of charge, registration required).

The Business Value of Product Data Management - Achieving Rapid and Extendable Benefits with Preconfigured PDM shares the perspectives of three small to midsize manufacturers on the value they receive from PDM software. The report also offers Tech-Clarity's views on the business value of PDM and explains how preconfigured PDM solutions can help companies gain value quickly and cost effectively.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required).

For the full report, please visit the Teamcenter Rapid Start page on the Siemens PLM website (free of charge, registration required).

Table of Contents

- Executive Overview

- The Business Value of PDM – Controlling Product Data

- The Business Value of PDM – Making Product Data Accessible

- The Business Value of PDM – Sharing Product Data

- Achieving Value Quickly with Preconfigured PDM

- Getting Started

- Taking Advantage of (and Extending) the Benefits

- Conclusion

- Recommendations

- About the Author

- About the Research

Executive Overview

Manufacturers today face challenging markets and an uncertain global economy. To survive they are trying to improve the speed of product development despite reduced headcount and budgets. One positive note is that many manufacturers are gaining significant value by implementing product data management (PDM) solutions. Tech-Clarity interviewed several small to midsize manufacturers (Table 1) to understand their experiences. Each of these companies implemented PDM for different business reasons, although several common themes were repeated. These themes are consistent with previous research on the topic, and include:- Control and secure product-related data

- Improve the ability to quickly find and reuse information

- Share product knowledge and collaborate with other departments

| Company | Description |

| Veeraja Industries | Total solutions provider of coolant filtration, chip removal and coolant management |

| Flovel Energy | Fully integrated hydro power equipment supplier |

| Weir Valves & Controls | End-to-end whole plant solutions to nuclear, fossil-fired and renewable power stations |

All Results for "All"

Webcast – The Three Elements Missing from your Innovation Process

Jim Brown of Tech-Clarity joined Carrie Nauyalis, NPD Solution Evangelist at Planview in this thirty minute webcast. The presentation shared how most companies lack consistency, transparency, and the right culture to successfully innovate and rapidly bring products to market. View a replay of the 30 minute Three Elements webcast presented by Planview (free, registration required)

Motorola Taps Product Compliance Capability for Conflict Minerals

Motorola Addresses Conflict Minerals with Compliance Infrastructure explains how Motorola extended the comprehensive platform that allows them to design products for environmental compliance to address US Dodd-Frank act conflict minerals requirements. The eBook explains how the process and software platform that enables Motorola to comply with RoHS, REACH, and other regulations gave them a tremendous head start when the need to track…

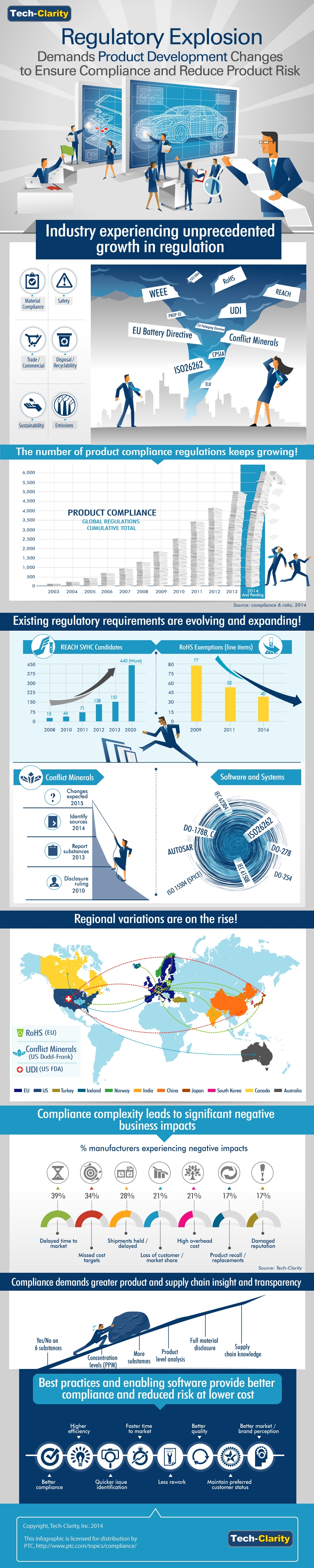

Infographic – Regulatory Explosion Demands Product Development Changes

Tech-Clarity’s Regulatory Explosion Demands Product Development Changes to Ensure Compliance and Reduce Product Risk offers a compelling view of the growth in the number of global product regulations, the expanding scope of these mandates, and the increase in local variations. The graphic also shares the resulting business impact of this complexity and points out important benefits that…

Science Lifecycle Management in the Enterprise Ecosystem

This ebook, Science Lifecycle Management in the Enterprise Ecosystem, explains the value of Science Lifecycle Management (ScLM) solutions and how they complement other enterprise solutions like Product Lifecycle Management (PLM) and ERP. It provides a quick way to get up to speed on the ScLM vision by sharing insights from Unilever, Johnson & Johnson, and Eli…

The Evolution of Digital Prototyping

Issue in Focus – The Evolution of Digital Prototyping – Extending “Right First Time” Value Beyond Design explains that manufacturers must go beyond getting form, fit, and function right to compete in today’s global markets. Digital prototyping offers tremendous business benefits by letting designers get innovative products right. But it also allows them to make intelligent tradeoffs to optimize products for…

Design Review Buyer’s Guide

Tech-Clarity’s Design Review Buyer’s Guide – Selecting the Right Visualization and Collaboration Solution helps manufacturers develop criteria to evaluate design review software based on a set of high level criteria. Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including: Software capabilities Implementation User adoption…

Guide to Manufacturing Transformation – Are Your Enterprise Systems Ready?

This eBook, A Guide to Manufacturing Transformation, discusses the current resurgence of global manufacturing and shares how ERP and PLM systems help. It offers advice for manufacturers to capitalize on new opportunities presented by the recovery and evolution of the manufacturing industry. The eBook is a collaboration between Cindy Jutras of Mint Jutras and Jim Brown…

The Basics of Managing CAD

Tech-Clarity Insight The Basics of Managing CAD – When Brute Force Fails and PDM is too Much explains the need to manage CAD files and the current options available to manufacturers. The report analyzes the positives and negatives of manually managed approaches, implementing PDM/PLM, and utilizing cloud-based file management services. The research then reviews the…

Tech-Clarity TV – CAD-PLM Integration

This episode of Tech-Clarity TV looks at the future of product design software (CAD) and product development environments (PLM) and how they should work together. The video is based on our Integrating Product Design and Development report that shares how a well-integrated CAD-PLM continuum helps improve engineering and product development performance. Please see our sponsor…

Tech-Clarity adds VP Engineering Software Research Michelle Boucher

Tech-Clarity is pleased to announce the expansion of our research team! Industry veteran and former Aberdeen Group Senior Research Analyst Michelle Boucher joins Tech-Clarity as Vice President of Research covering engineering software. Michelle brings a wealth of depth in engineering, product development, and research. For more on Michelle’s background please visit her bio page. As…

Michelle Boucher

Michelle Boucher is the Vice President of Research for Engineering Practices for Tech-Clarity. Ms. Boucher has spent over 20 years in various roles in engineering, marketing, management, and as an analyst. She has broad experience with topics such as product design, simulation, systems engineering, mechatronics, embedded systems, PCB design, additive manufacturing, improving product performance, process improvement,…

Integrating Product Design and Development Environments

Issue in Focus Integrating Product Design and Development Environments – Battling Complexity, Improving Productivity, and Compressing Time discusses how a well-integrated CAD-PLM platform helps improve engineering and product development performance. This report describes the requirements and capabilities that manufacturers should look for in the latest generation of integrated systems for product design and development. Please…

Tech-Clarity TV – Consolidating CAD Strategy and ROI

In this episode of Tech-Clarity TV Jim Brown discusses the financial and strategic benefits of consolidating onto a single CAD tool. The information is based on a recent Tech-Clarity report, Consolidating CAD – The Benefits of a Unified CAD Strategy. The report provides a way to calculate the cost savings available from systems rationalization. These…

Kalypso’s Young and Tech-Clarity’s Brown in CGT Reader’s Choice on NPDI Technology

Read Kalypso founding partner George Young and Tech-Clarity President Jim Brown discuss their perspectives on enabling software for NPDI in Consumer Goods Technology’s 2014 Readers Choice Awards for New Product Development and Introduction Software.

Consolidating CAD – Benefits of a Unified CAD Strategy

Tech-Clarity Insight – Consolidating CAD – The Benefits of a Unified CAD Strategy offers insight into the strategic value companies can achieve by standardizing on a single CAD package. The report explains how to calculate an ROI for CAD consolidation based on direct cost savings. Perhaps more importantly, the research identifies a number of strategic…

Tech-Clarity TV – Optimizing Product Cost with PCM

In this episode of Tech-Clarity TV, Jim Brown shares Tech-Clarity’s views on how manufacturers can analyze and optimize costs for manufactured goods during the design phase. It also shares the value of using a knowledge-based cost to negotiate and make process improvements with suppliers. Learn more from the related report, Product Cost Management – A Knowledge-Based Approach to Optimizing…

Desktop Engineering Views on CAD Consolidation Research

Tony Lockwood of Desktop Engineering shared his thoughts on Tech-Clarity’s Consolidating Design Software, Extending Value Beyond 3D CAD Consolidation. I like his description of “working in a multi-CAD environment with multiple disconnected tools and multiple money pits bleeding you dry at every junction of your process.” Read the short article by Tony on Desktop Engineering.

Product Cost Management – A Knowledge Based Approach to Optimizing Product Cost

Product Cost Management – A Knowledge Based Approach to Optimizing Product Cost explains how manufacturers can design products for optimal cost in order to improve profitability. The research shares interviews with three industrial manufacturers on the way they work with their supply chains to reduce cost using an analytical, fact-based methodology to drive out unnecessary…

The Business Value of Product Data Management

The Business Value of Product Data Management – Achieving Rapid and Extendable Benefits with Preconfigured PDM shares the perspectives of three small to midsize manufacturers on the value they receive from PDM software. The report also offers Tech-Clarity’s views on the business value of PDM and explains how preconfigured PDM solutions can help companies gain…