Composite Trends in the A&D Industry: Identifying Opportunities to Save Cost and Time reveals survey findings on design and manufacturing trends for composites in the Aerospace & Defense industry. The research examines two areas that can be a source for bottlenecks when working with composites: springback and manufacturing planning. The report details best practices to…

- Executive Overview

- Understanding Springback

- Corrective Actions for Springback

- Identifying the Top Performers

- Avoiding Springback

- Planning for Manufacturing

- Don’t Overlook the Time Impact of Changes

- Considering Programming Trends

- Conclusion

- Recommendations

- About the Author

- About the Research

- Copyright Notice

Conclusion

Many A&D companies have turned to composites to help them improve performance and realize better fuel economy. However, the A&D industry is also under significant pressure to lower costs. Addressing manufacturing defects such as springback as well as better manufacturing planning can help A&D companies take advantage of the benefits of composites while improving design and production efficiency and lowering costs. Springback can be a considerable source of excess cost and waste. Typically, springback causes parts to be out of tolerance so manufactures have to waste time correcting parts, or worse, scrapping them. By adopting best practices, such as using design guidelines, A&D manufacturers can avoid springback. Adopting best practices for manufacturing planning is another area where A&D manufacturers can improve quality. It is crucial that composite parts are manufactured as designed to ensure performance. By adopting practices such as leveraging the engineering composite model for manufacturing planning and automating changes, A&D manufacturers will be better positioned to produce parts as designed without quality issues.Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- To avoid springback, focus of identify potential occurrences during design

- Take advantage of design guidelines to help avoid springback.

- Consider solutions that offer embedded intelligence to provide guidance and support better decision to reduce the occurrence of springback.

- Communicate ply level design data to manufacturing via the engineering model

[post_title] => Medical Devices in a Digital World (podcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical-devices-podcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-12-02 15:34:39

[post_modified_gmt] => 2022-12-02 20:34:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6364

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 6343

[post_author] => 2572

[post_date] => 2017-10-17 11:30:30

[post_date_gmt] => 2017-10-17 15:30:30

[post_content] =>

[post_title] => Medical Devices in a Digital World (podcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical-devices-podcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-12-02 15:34:39

[post_modified_gmt] => 2022-12-02 20:34:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6364

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 6343

[post_author] => 2572

[post_date] => 2017-10-17 11:30:30

[post_date_gmt] => 2017-10-17 15:30:30

[post_content] =>  The How-to Guide for Adopting Model Based Definition (MBD) reveals advice and best practices for implementing MBD. The guide explains why 89% of companies are happy they made the transition and benefits they enjoy as a result. The hardest part of adopting MBD is overcoming the cultural resistance to change. The guide identifies what other companies have done to make the adoption of MBD a success, both internally and with suppliers.

This eBook is one in a series of three:

The How-to Guide for Adopting Model Based Definition (MBD) reveals advice and best practices for implementing MBD. The guide explains why 89% of companies are happy they made the transition and benefits they enjoy as a result. The hardest part of adopting MBD is overcoming the cultural resistance to change. The guide identifies what other companies have done to make the adoption of MBD a success, both internally and with suppliers.

This eBook is one in a series of three:

- Transitioning from 2D CAD to 3D CAD

- Migrating from 3D CAD to a new 3D CAD

- Adopting model-based definition (MBD)

Why Consider Model-Based Definition?

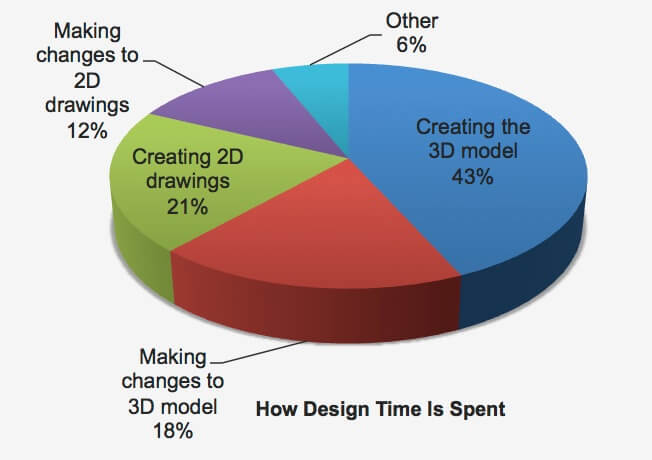

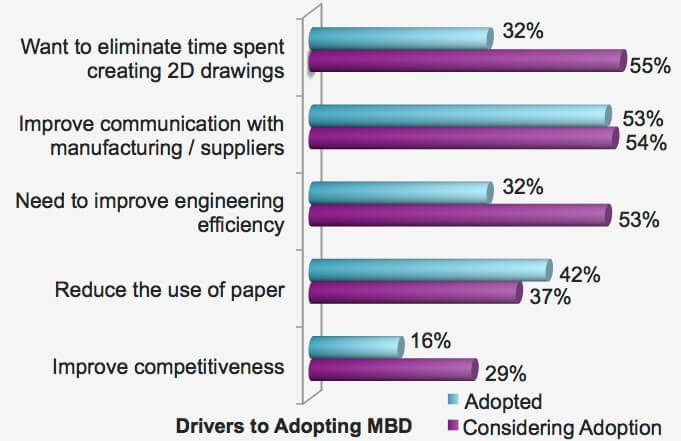

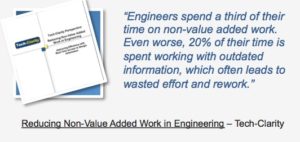

With fierce global competition, today's manufacturers have to work harder than ever to stay competitive. While time-to-market used to be the dominant pressure, Tech-Clarity's research shows that now cost and quality are equally pressing, with innovation and performance not far behind. With so many different pressures, engineers have their work cut out for them. Constant time-to-market pressures make it hard to look for ways to cut cost while improving quality. They desperately need to improve efficiency so that they have the bandwidth to accomplish all of this. Tech-Clarity discovered that 33 percent of design time is spent on drawings. Considering this mostly involves documenting what is already in the 3D model, that is a lot of time wasted on non-value-added efforts. Opportunities for improvement are significant. This is where model-based definition (MBD) comes in.What Is Driving MBD Adoption?

Initially, companies were most likely to adopt MBD to improve communication with manufacturing and suppliers. Compared to a 2D drawing, a 3D model makes it easier to visualize the final product. Plus, there is far less room for misinterpretation for things like assembly procedures. Also, in an effort to adopt more environmentally friendly policies as well as reduce costs, many companies turned to MBD as a way to reduce paper. These are still important drivers, but companies who are currently considering adopting MBD are looking at it more as a way to make better use of engineering time. By reducing all that time spent creating 2D drawings, engineers can focus more effort on value-added tasks that will improve the design and result in products that are more competitive. *This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => The How-to Guide for Adopting Model Based Definition (MBD)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => adopting-model-based-definition-mbd

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 13:40:30

[post_modified_gmt] => 2023-12-15 18:40:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6343

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 6330

[post_author] => 2

[post_date] => 2017-10-03 14:45:17

[post_date_gmt] => 2017-10-03 18:45:17

[post_content] => Jim Brown contributed a guest post to the Siemens PLM Community blog discussing how digitalization impacts the production of consumer packaged goods such as food and beverages. Digital enterprise in the food and beverage industry opens up a number of opportunities to improve manufacturing productivity and agility, all while maintaining or improving cost and quality. The post discusses benefits available from using digital approaches to design and validate products, production lines, and plants and operate them at very high levels of efficiency.

This is the third of several posts that drill down on Surviving the New Competitive Landscape in Food and Beverage, a post that shares three ways that consumer packaged goods (CPG) companies can start their digitalization journey and how the digital enterprise can help them avoid industry disruption.

The full post, Producing Food and Beverages in the Digital Age can be found on the Siemens PLM blog (free of charge, no registration required).

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => The How-to Guide for Adopting Model Based Definition (MBD)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => adopting-model-based-definition-mbd

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 13:40:30

[post_modified_gmt] => 2023-12-15 18:40:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6343

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 6330

[post_author] => 2

[post_date] => 2017-10-03 14:45:17

[post_date_gmt] => 2017-10-03 18:45:17

[post_content] => Jim Brown contributed a guest post to the Siemens PLM Community blog discussing how digitalization impacts the production of consumer packaged goods such as food and beverages. Digital enterprise in the food and beverage industry opens up a number of opportunities to improve manufacturing productivity and agility, all while maintaining or improving cost and quality. The post discusses benefits available from using digital approaches to design and validate products, production lines, and plants and operate them at very high levels of efficiency.

This is the third of several posts that drill down on Surviving the New Competitive Landscape in Food and Beverage, a post that shares three ways that consumer packaged goods (CPG) companies can start their digitalization journey and how the digital enterprise can help them avoid industry disruption.

The full post, Producing Food and Beverages in the Digital Age can be found on the Siemens PLM blog (free of charge, no registration required).

[post_title] => Producing Food and Beverages in the Digital Age (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => dig-mfg

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:33

[post_modified_gmt] => 2022-11-15 03:25:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6330

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 6319

[post_author] => 2

[post_date] => 2017-09-28 16:15:09

[post_date_gmt] => 2017-09-28 20:15:09

[post_content] => This infographic shares survey results about quality and cost management in the Consumer Packaged Goods industry. It visually communicates the results of our research that shows how Top Performing CPG companies are able to achieve better quality and better cost of quality, without trading one for the other. The research shares the methods these leading companies employ, including automation, integration, and a more holistic approach to managing quality.

[post_title] => Producing Food and Beverages in the Digital Age (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => dig-mfg

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:33

[post_modified_gmt] => 2022-11-15 03:25:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6330

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 6319

[post_author] => 2

[post_date] => 2017-09-28 16:15:09

[post_date_gmt] => 2017-09-28 20:15:09

[post_content] => This infographic shares survey results about quality and cost management in the Consumer Packaged Goods industry. It visually communicates the results of our research that shows how Top Performing CPG companies are able to achieve better quality and better cost of quality, without trading one for the other. The research shares the methods these leading companies employ, including automation, integration, and a more holistic approach to managing quality.

To learn more, please:

View the full Stop Choosing Between Cost and Quality in CPG infographic from our sponsor Dassault Systèmes BIOVIA (free or charge, registration required).

Download the full Reducing Cost of Quality in CPG report from our sponsor Dassault Systèmes BIOVIA (free or charge, registration required).

See the Reducing Cost of Quality for Consumer Packaged Goods survey report overview from out site (free of charge, no registration required)

To learn more, please:

View the full Stop Choosing Between Cost and Quality in CPG infographic from our sponsor Dassault Systèmes BIOVIA (free or charge, registration required).

Download the full Reducing Cost of Quality in CPG report from our sponsor Dassault Systèmes BIOVIA (free or charge, registration required).

See the Reducing Cost of Quality for Consumer Packaged Goods survey report overview from out site (free of charge, no registration required)

[post_title] => Choosing Cost versus Quality in CPG (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => quality-cpg

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:08

[post_modified_gmt] => 2022-11-15 03:26:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6319

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 6309

[post_author] => 2

[post_date] => 2017-09-26 12:02:56

[post_date_gmt] => 2017-09-26 16:02:56

[post_content] =>

[post_title] => Choosing Cost versus Quality in CPG (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => quality-cpg

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:08

[post_modified_gmt] => 2022-11-15 03:26:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6319

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 6309

[post_author] => 2

[post_date] => 2017-09-26 12:02:56

[post_date_gmt] => 2017-09-26 16:02:56

[post_content] =>  Jim Brown contributed a guest post, Innovation Platforms - the Operating System for the Digital Enterprise, on the value of innovation platforms published in the Dassault Systèmes' Navigate the Future blog. The post shares the value an integrated platform of solutions provides to engineers, the enterprise, and toward achieving digital transformation. The post also covers some basis of the innovation platform from people, process, and technology perspectives.

Read the post now (free of charge, no registration required).

Jim Brown contributed a guest post, Innovation Platforms - the Operating System for the Digital Enterprise, on the value of innovation platforms published in the Dassault Systèmes' Navigate the Future blog. The post shares the value an integrated platform of solutions provides to engineers, the enterprise, and toward achieving digital transformation. The post also covers some basis of the innovation platform from people, process, and technology perspectives.

Read the post now (free of charge, no registration required).

[post_title] => Innovation Platforms are the Operating Systems for the Digital Enterprise (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => i-platform

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:35

[post_modified_gmt] => 2022-11-15 03:25:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6309

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 6298

[post_author] => 2

[post_date] => 2017-09-19 14:25:06

[post_date_gmt] => 2017-09-19 18:25:06

[post_content] =>

[post_title] => Innovation Platforms are the Operating Systems for the Digital Enterprise (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => i-platform

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:35

[post_modified_gmt] => 2022-11-15 03:25:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6309

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 6298

[post_author] => 2

[post_date] => 2017-09-19 14:25:06

[post_date_gmt] => 2017-09-19 18:25:06

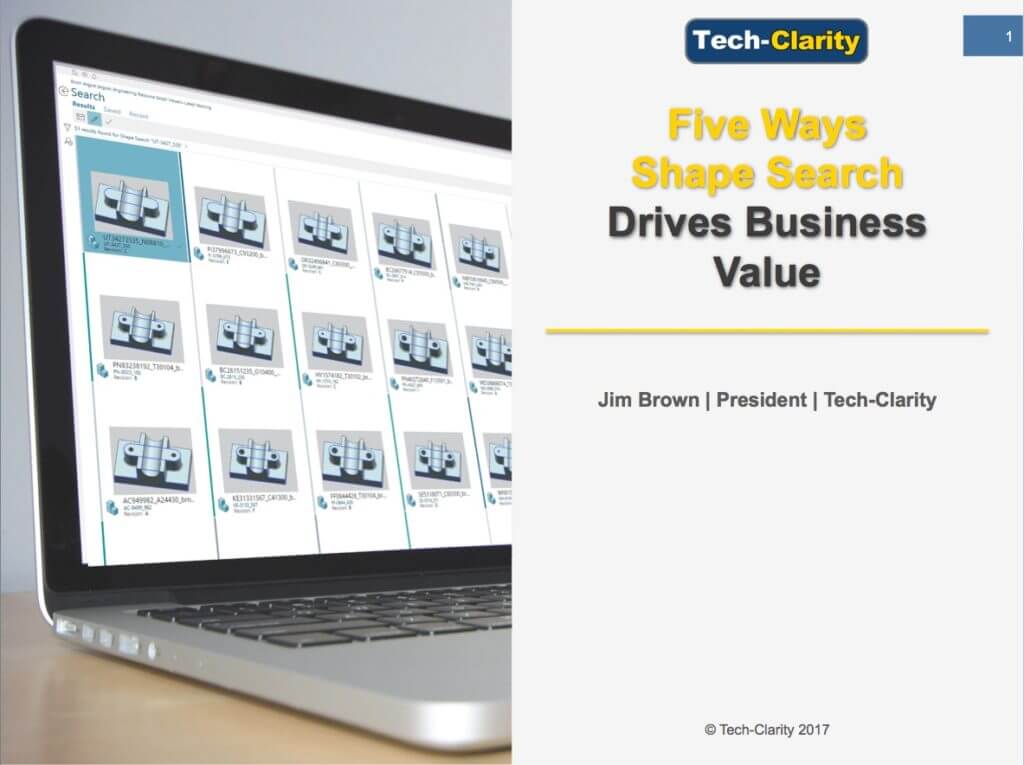

[post_content] =>  Five Ways Shape Search Drives Business Value shares the shortcomings of traditional search methodologies and how geometric search can complement them to drive new business value. The report includes some basics about shape search, five tangible ways it can improve business performance, and an example of how to calculate the ROI of a shape search investment.

Click here to view the full PDF, thank you to our sponsor Siemens PLM.

For more information, please visit the Siemens PLM Community blog to read the Shape Search for Engineering Productivity and related blog posts from Erwin Argyle.

Five Ways Shape Search Drives Business Value shares the shortcomings of traditional search methodologies and how geometric search can complement them to drive new business value. The report includes some basics about shape search, five tangible ways it can improve business performance, and an example of how to calculate the ROI of a shape search investment.

Click here to view the full PDF, thank you to our sponsor Siemens PLM.

For more information, please visit the Siemens PLM Community blog to read the Shape Search for Engineering Productivity and related blog posts from Erwin Argyle.

In Search of … Effective Search

Finding engineering data is frustrating. Search consistently shows up in our research as a challenge that leads to inefficiency for engineers and others relying on information to do their jobs. Poor search capabilities are more than just a nuisance, they cost companies time and money. Some may be surprised at not only the number of ways improving search can save money, but how it can positively impact top line revenue. We’ll explore these benefits and then provide a template to quantify the value companies can achieve.

A lot of energy has been put into helping companies find parts. There are multiple strategies and approaches to find parts including keyword, metadata, and semantic search. Another technology that’s reaching the mainstream is geometric search, also known as “shape search.”

These search tools are better when used in combination, and more valuable when coupled with strategies like filtering results. Of course it’s not finding just any part that’s difficult, it’s efficiently finding the part that you need to help you do your job when you need it. Speed is the name of the game for search, and efficient search relies on strategies like advanced indexing to perform quickly enough to be useful. Let’s learn more.

Poor search capabilities are more than just a nuisance, they cost companies time and money. Some may be surprised at not only the number of ways improving search can save money, but how it can positively impact top line revenue. We’ll explore these benefits and then provide a template to quantify the value companies can achieve.

A lot of energy has been put into helping companies find parts. There are multiple strategies and approaches to find parts including keyword, metadata, and semantic search. Another technology that’s reaching the mainstream is geometric search, also known as “shape search.”

These search tools are better when used in combination, and more valuable when coupled with strategies like filtering results. Of course it’s not finding just any part that’s difficult, it’s efficiently finding the part that you need to help you do your job when you need it. Speed is the name of the game for search, and efficient search relies on strategies like advanced indexing to perform quickly enough to be useful. Let’s learn more.

Conclusion

Search is an area that’s ripe for improvement. 3D shape search is a proven technology that can help, and is stronger when combined with other search methods. Shape search is becoming mainstream and more commonly integrated with underlying systems like PLM. It can be fast if indexing is done correctly ahead of time (pay attention here, solutions vary greatly in scalability).

Shape search helps reduce direct cost, but also improves innovation and time to market to drive top-line improvements. Because of the business value of reuse, shape search should be a best practice. It should be built into processes like new part requests to institutionalize it.

One of the biggest objections we hear about shape search is that “it sounds too good to be true.” We recommend that you pilot a solution using your own data to see for yourself.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Five Ways Shape Search Drives Business Value (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => shape-search

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:07

[post_modified_gmt] => 2022-11-15 03:28:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6298

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 6286

[post_author] => 2

[post_date] => 2017-09-12 13:06:02

[post_date_gmt] => 2017-09-12 17:06:02

[post_content] => Jim Brown contributed a guest post to the Siemens PLM Community blog discussing how R&D in the food and beverage industry can step up to the digital age to combat smaller, innovative companies that embrace the digital enterprise. This is the first of several posts that drill down on Surviving the New Competitive Landscape in Food and Beverage, a post that shares three ways that consumer packaged goods (CPG) companies can start their digitalization journey and discusses how that can help them avoid industry disruption.

The first opportunity we're looking into is how the digital enterprise can improve research and development to improve innovation and agility. This is the second in a four-part series of posts on the topic.

The full post, Food and Beverage R&D Enters the Digital Age can be found on the Siemens PLM blog (free of charge, no registration required).

Search is an area that’s ripe for improvement. 3D shape search is a proven technology that can help, and is stronger when combined with other search methods. Shape search is becoming mainstream and more commonly integrated with underlying systems like PLM. It can be fast if indexing is done correctly ahead of time (pay attention here, solutions vary greatly in scalability).

Shape search helps reduce direct cost, but also improves innovation and time to market to drive top-line improvements. Because of the business value of reuse, shape search should be a best practice. It should be built into processes like new part requests to institutionalize it.

One of the biggest objections we hear about shape search is that “it sounds too good to be true.” We recommend that you pilot a solution using your own data to see for yourself.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Five Ways Shape Search Drives Business Value (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => shape-search

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:07

[post_modified_gmt] => 2022-11-15 03:28:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6298

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 6286

[post_author] => 2

[post_date] => 2017-09-12 13:06:02

[post_date_gmt] => 2017-09-12 17:06:02

[post_content] => Jim Brown contributed a guest post to the Siemens PLM Community blog discussing how R&D in the food and beverage industry can step up to the digital age to combat smaller, innovative companies that embrace the digital enterprise. This is the first of several posts that drill down on Surviving the New Competitive Landscape in Food and Beverage, a post that shares three ways that consumer packaged goods (CPG) companies can start their digitalization journey and discusses how that can help them avoid industry disruption.

The first opportunity we're looking into is how the digital enterprise can improve research and development to improve innovation and agility. This is the second in a four-part series of posts on the topic.

The full post, Food and Beverage R&D Enters the Digital Age can be found on the Siemens PLM blog (free of charge, no registration required).

[post_title] => R&D Enters the Digital Age (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => dig-rd

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:33

[post_modified_gmt] => 2022-11-15 03:25:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6286

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 6281

[post_author] => 2572

[post_date] => 2017-09-11 13:22:52

[post_date_gmt] => 2017-09-11 17:22:52

[post_content] =>

[post_title] => R&D Enters the Digital Age (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => dig-rd

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:33

[post_modified_gmt] => 2022-11-15 03:25:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6286

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 6281

[post_author] => 2572

[post_date] => 2017-09-11 13:22:52

[post_date_gmt] => 2017-09-11 17:22:52

[post_content] => Listen to Tech-Clarity's Michelle Boucher, Mark Turner from Alcon Labs (Novartis), and Swapan Jha from PTC have a discussion on the right software solution for medical device engineering. The discussion featured an interactive discussion between the panelists coving topics such as:

- Challenges facing medical device manufacturers.

- Why to consider the complete product lifecycle with respect to:

- Managing product and requirements.

- Transitioning from document to product centric approaches.

- Enabling smart and connected products.

- The best selection criteria for choosing the right software to support quality initiatives.

[post_title] => Selecting the Right PLM Software for Medical Device Engineering (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical-device-engineering-software

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:53

[post_modified_gmt] => 2022-11-15 03:26:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6281

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 6272

[post_author] => 2572

[post_date] => 2017-09-06 11:30:15

[post_date_gmt] => 2017-09-06 15:30:15

[post_content] =>

[post_title] => Selecting the Right PLM Software for Medical Device Engineering (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical-device-engineering-software

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:53

[post_modified_gmt] => 2022-11-15 03:26:53

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6281

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 6272

[post_author] => 2572

[post_date] => 2017-09-06 11:30:15

[post_date_gmt] => 2017-09-06 15:30:15

[post_content] => Listen to Steve Partridge, Sr. Go To Market Solution Specialist for PTC, and Tech-Clarity's Michelle Boucher discuss the benefits of improving how requirements are managed, especially to support your IoT strategy. The discussion includes topics such as:

- How best practices for requirements management provide visibility into design decisions, changes, and tests

- Considerations to manage people, process and technology to make your requirements management process a success

- Suggested criteria to select the right requirements management software to meet your organization’s needs

- How requirements management can get you on the right track to develop smart connected products

[post_title] => Managing Requirements: A Prerequisite to Designing for the IoT (Webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => managing-requirements-iot

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:46

[post_modified_gmt] => 2022-11-15 03:26:46

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6272

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 6260

[post_author] => 2

[post_date] => 2017-08-23 08:57:44

[post_date_gmt] => 2017-08-23 12:57:44

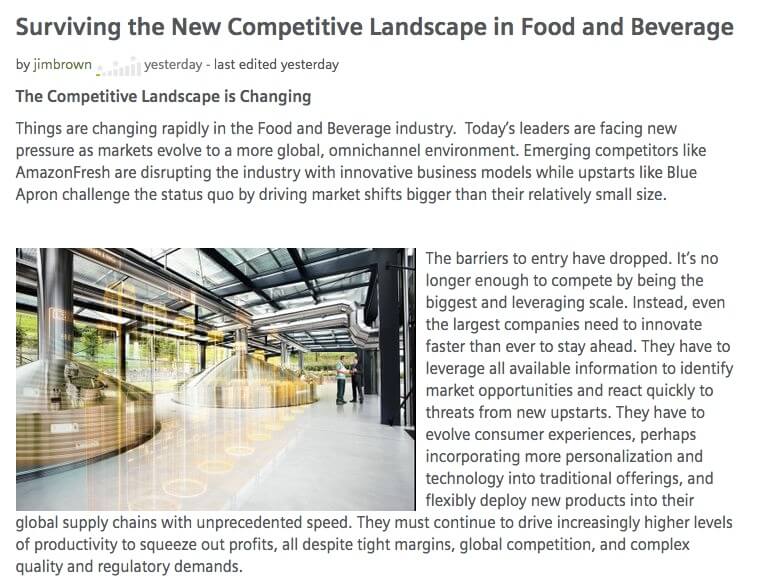

[post_content] => Jim Brown contributed a guest post to the Siemens PLM Community blog discussing the opportunity for food and beverage companies to leverage digitalization and the digital enterprise to combat market disruption from new, innovate companies that are challenging current industry leaders. The post offers several ways that consumer packaged goods (CPG) companies can get started on their digital journey, achieve tangible business value, and combat challengers like Blue Apron and Amazon Fresh that are disrupting the status quo.

The full post, Surviving the New Competitive Landscape in Food and Beverage, can be found on the Siemens PLM blog (free of charge, no registration required). This is the first in a four-part series of posts on the topic.

[post_title] => Managing Requirements: A Prerequisite to Designing for the IoT (Webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => managing-requirements-iot

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:46

[post_modified_gmt] => 2022-11-15 03:26:46

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6272

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 6260

[post_author] => 2

[post_date] => 2017-08-23 08:57:44

[post_date_gmt] => 2017-08-23 12:57:44

[post_content] => Jim Brown contributed a guest post to the Siemens PLM Community blog discussing the opportunity for food and beverage companies to leverage digitalization and the digital enterprise to combat market disruption from new, innovate companies that are challenging current industry leaders. The post offers several ways that consumer packaged goods (CPG) companies can get started on their digital journey, achieve tangible business value, and combat challengers like Blue Apron and Amazon Fresh that are disrupting the status quo.

The full post, Surviving the New Competitive Landscape in Food and Beverage, can be found on the Siemens PLM blog (free of charge, no registration required). This is the first in a four-part series of posts on the topic.

For the rest of the series, please see:

R&D Enters the Digital Age

Producing Food and Beverages in the Digital Age

The Analytics Opportunity for Food & Beverage in the Digital Age

[post_title] => Digitalization in Food and Beverage (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => dig-fb

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:33

[post_modified_gmt] => 2022-11-15 03:25:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6260

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 6177

[post_author] => 2

[post_date] => 2017-07-19 08:58:45

[post_date_gmt] => 2017-07-19 12:58:45

[post_content] =>

For the rest of the series, please see:

R&D Enters the Digital Age

Producing Food and Beverages in the Digital Age

The Analytics Opportunity for Food & Beverage in the Digital Age

[post_title] => Digitalization in Food and Beverage (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => dig-fb

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:33

[post_modified_gmt] => 2022-11-15 03:25:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6260

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 6177

[post_author] => 2

[post_date] => 2017-07-19 08:58:45

[post_date_gmt] => 2017-07-19 12:58:45

[post_content] =>  The Finding PLM to Fit Mid-Sized High-Tech Companies ebook explains how smaller companies in the high technology industry find themselves stuck between full-featured Product Lifecycle Management (PLM) systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can’t afford the errors and inefficiency inherent to informal data and process management, but can’t afford a large time, resource, and financial investment to fix their problems. Unfortunately simple solutions like web file sharing, while very attractive, fall short of their real needs, don’t help them improve their business the way they need to, and don’t leave them room to grow in the future. They need to find the “sweet spot” of a solution that helps them get started quickly with the basics of controlling, managing, and sharing product data but provides the features they need to be successful now and into the future.

Please enjoy the summary below, or click the report or title to download the full PDF from our sponsor, Dassault Systèmes (free of charge, registration required).

Watch the related webinar on demand on the Dassault Systèmes site (free of charge, registration required).

The Finding PLM to Fit Mid-Sized High-Tech Companies ebook explains how smaller companies in the high technology industry find themselves stuck between full-featured Product Lifecycle Management (PLM) systems that feel out of reach and less capable solutions including cloud-based file sharing or very basic data management applications. They know they can’t afford the errors and inefficiency inherent to informal data and process management, but can’t afford a large time, resource, and financial investment to fix their problems. Unfortunately simple solutions like web file sharing, while very attractive, fall short of their real needs, don’t help them improve their business the way they need to, and don’t leave them room to grow in the future. They need to find the “sweet spot” of a solution that helps them get started quickly with the basics of controlling, managing, and sharing product data but provides the features they need to be successful now and into the future.

Please enjoy the summary below, or click the report or title to download the full PDF from our sponsor, Dassault Systèmes (free of charge, registration required).

Watch the related webinar on demand on the Dassault Systèmes site (free of charge, registration required).

Midsize Companies are Stuck In-Between

Leading high-tech companies are driving breakthrough innovation and growing rapidly. But developing today’s high-tech products is increasingly complex. It requires systems-level thinking, collaboration across disciplines – and lightning speed. Midsize companies have to overcome this complexity and work closely with their supply chains to meet rapidly changing market demands and compete with their larger competitors. Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may try to control, access, and share product data with relatively simple Product Data Management (PDM) tools, larger companies rely on full-featured PLM systems that help automate processes and share data across global supply chains.

Midsize companies may find themselves in-between because:

Product Lifecycle Management (PLM) software can help. It drives better product development performance by managing product-related data, processes, and projects. While smaller companies may try to control, access, and share product data with relatively simple Product Data Management (PDM) tools, larger companies rely on full-featured PLM systems that help automate processes and share data across global supply chains.

Midsize companies may find themselves in-between because:

- Product and organizational complexity drive them beyond basic PDM capabilities

- A full-featured PLM implementation may feel out of reach

Get Started with the Right PLM Solution

Core PLM can quickly add value to midsized high-tech companies by helping them combat complexity, improve productivity, and innovate faster to meet market needs. Recognize the potential value of a fully featured PLM with all of the bells and whistles, but be honest with yourself about how much time and effort your company can afford to get there (at least right away). Don’t take on too much. Start with the basics and get value quickly, but recognize the shortcomings of simple file sharing solutions that fall short for the complex, multi-discipline products and product development environments common to midsize high-tech companies. Look for a solution that allows you to design in the context of your products in real time, but also in the context of processes and product development projects. In addition, look for PLM that incorporates automation including automatic project updates to keep engineers focused on innovation instead of managing files. Finally, make sure to leave your company room to grow as your business and business needs grow, using the initial implementation as a foundation for greater improvements. *This summary is an abbreviated version of the eBook and does not contain the full content. A link to download the full eBook is available above. If you have difficulty obtaining a copy of the research, please contact us using the "Contact" link below. [post_title] => Finding PLM to Fit Mid-Sized High-Tech Companies (ebook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => plm-midsize-ht [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:04 [post_modified_gmt] => 2022-11-15 03:28:04 [post_content_filtered] => [post_parent] => 0 [guid] => http://tech-clarity.com/?p=6177 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 2 [filter] => raw ) [12] => WP_Post Object ( [ID] => 6216 [post_author] => 2572 [post_date] => 2017-07-18 22:28:54 [post_date_gmt] => 2017-07-19 02:28:54 [post_content] => The How-to Guide to Transitioning from 2D CAD to 3D CAD shares best practices for moving from 2D to 3D. The guide shares the reasons you should consider going from 2D to 3D, common challenges to avoid, and benefits enjoyed by other companies who gone to 3D. The guide then shares advice to make your switch from 2D to 3D CAD a success. The recommendations were developed by analyzing the responses of Top Performing companies and comparing them to Average Performing companies.

This eBook is one in a series of three:

The How-to Guide to Transitioning from 2D CAD to 3D CAD shares best practices for moving from 2D to 3D. The guide shares the reasons you should consider going from 2D to 3D, common challenges to avoid, and benefits enjoyed by other companies who gone to 3D. The guide then shares advice to make your switch from 2D to 3D CAD a success. The recommendations were developed by analyzing the responses of Top Performing companies and comparing them to Average Performing companies.

This eBook is one in a series of three:

- Transitioning from 2D CAD to 3D CAD

- Migrating from 3D CAD to a new 3D CAD

- Adopting model-based definition (MBD)

Why Change from 2D to 3D?

While 2D offers a lot of simplicity, going to 3D CAD can offer multiple benefits:- Find problems earlier during design by checking for interferences.

- Identify quality problems and improve performance by conducting virtual tests.

- Evaluate more design iterations to arrive at a more innovative solution.

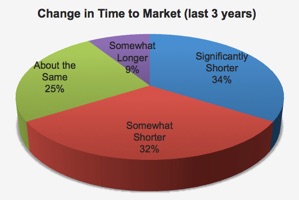

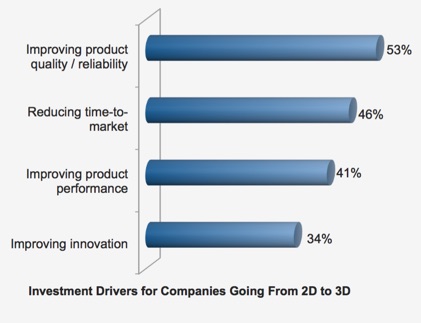

The graph shows what's driving engineering investments at companies who have gone from 2D to 3D. What's interesting is that these drivers are all benefits that can be realized by going to 3D CAD.

The graph shows what's driving engineering investments at companies who have gone from 2D to 3D. What's interesting is that these drivers are all benefits that can be realized by going to 3D CAD.

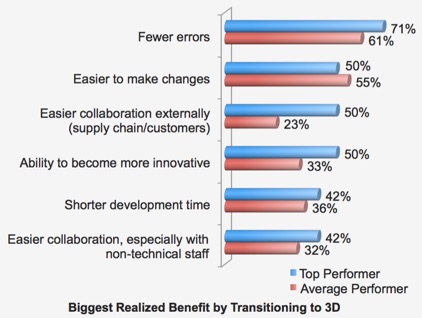

Benefits of Transitioning to 3D

The most exciting part of the results is the number of benefits companies enjoy by transitioning to 3D CAD. Regardless of performance, companies report many benefits, but Top Performers experience even more. Both groups report fewer errors and easier changes. However, Top Performers seem to use their CAD tool more strategically. In addition to using it as a design tool, they also view it as a helpful collaboration tool. Consequently, they get more feedback on the design, and can take advantage of the collective expertise of the product team. This creates more opportunities to catch problems and improve quality and performance. Innovation is another area where they see more value. Top Performers use their 3D tool to evaluate multiple iterations to ultimately arrive at a more innovative design. Again, the result will be better quality and performance, which in turn means happier customers and more revenue opportunity.

The takeaway is that Top Performers are more successful at meeting the goals that drove their investment in the first place.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Best Practices for Going from 2D to 3D CAD (eBook, survey findings)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 2d-to-3d

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:35

[post_modified_gmt] => 2022-11-15 03:28:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6216

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 6195

[post_author] => 2

[post_date] => 2017-07-13 14:04:22

[post_date_gmt] => 2017-07-13 18:04:22

[post_content] =>

Innovation is another area where they see more value. Top Performers use their 3D tool to evaluate multiple iterations to ultimately arrive at a more innovative design. Again, the result will be better quality and performance, which in turn means happier customers and more revenue opportunity.

The takeaway is that Top Performers are more successful at meeting the goals that drove their investment in the first place.

*This summary is an abbreviated version of the report and does not contain the full content. A link to download the full report is available above. If you have difficulty obtaining a copy of the report, please contact us using the "Contact" link below.

[post_title] => Best Practices for Going from 2D to 3D CAD (eBook, survey findings)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 2d-to-3d

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:35

[post_modified_gmt] => 2022-11-15 03:28:35

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6216

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 6195

[post_author] => 2

[post_date] => 2017-07-13 14:04:22

[post_date_gmt] => 2017-07-13 18:04:22

[post_content] =>  The Reducing Cost of Quality in CPG report shares perspectives from a survey of over 175 CPG companies to determine how Top Performers manage consumer packaged goods quality. The research finds that these leading companies are able to achieve better quality results with lower internal costs. The report analyzes their processes, organizational structures, and enabling technology to determine how they can get better quality results without placing a financial burden on the business.

Click here to read the full report, thank you to our sponsor Dassault Systèmes.

The Reducing Cost of Quality in CPG report shares perspectives from a survey of over 175 CPG companies to determine how Top Performers manage consumer packaged goods quality. The research finds that these leading companies are able to achieve better quality results with lower internal costs. The report analyzes their processes, organizational structures, and enabling technology to determine how they can get better quality results without placing a financial burden on the business.

Click here to read the full report, thank you to our sponsor Dassault Systèmes.

Executive Overview

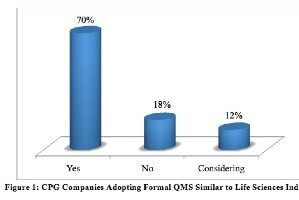

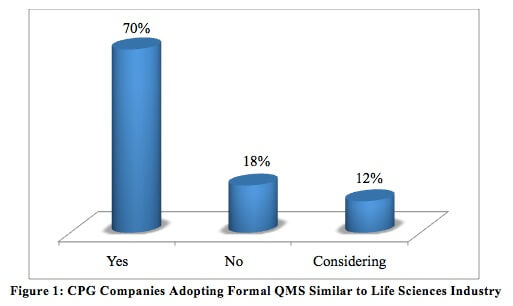

Quality management is critical to the success and profitability of a Consumer Packaged Goods (CPG) company. According to Tech-Clarity research, Successful Products Begin and End with the Customer, over three-quarters of CPG Companies say higher quality is required to drive competitive differentiation. It’s also clearly important to deliver customer satisfaction, safety, regulatory compliance, corporate responsibility, and overall company profitability. To better understand how they address this crucial need, we surveyed over 175 CPG companies and examined their quality management challenges, processes, organizational structure, technology use, and performance. We found that these businesses face significant quality management issues. We also discovered that they’re taking action. Specifically, about two-thirds of CPG companies are going beyond what’s currently required by adopting formal quality management processes and systems such as those used in the pharmaceutical and life sciences industry.

A key finding of the study is that while companies are able to avoid significant negative quality impacts relatively well, many suffer from excessive internal costs related to quality challenges. Based on these findings, we believe that CPG companies are mitigating quality risk through “brute force” quality management that adds significant operational cost. Top Performers, however, achieve better quality results at lower cost. How do they do this? The survey shows that they take different approaches to managing quality. Specifically, they are more likely to:

To better understand how they address this crucial need, we surveyed over 175 CPG companies and examined their quality management challenges, processes, organizational structure, technology use, and performance. We found that these businesses face significant quality management issues. We also discovered that they’re taking action. Specifically, about two-thirds of CPG companies are going beyond what’s currently required by adopting formal quality management processes and systems such as those used in the pharmaceutical and life sciences industry.

A key finding of the study is that while companies are able to avoid significant negative quality impacts relatively well, many suffer from excessive internal costs related to quality challenges. Based on these findings, we believe that CPG companies are mitigating quality risk through “brute force” quality management that adds significant operational cost. Top Performers, however, achieve better quality results at lower cost. How do they do this? The survey shows that they take different approaches to managing quality. Specifically, they are more likely to:

- Take a more integrated approach to quality along geographic, organizational, and product lifecycle dimensions

- Adopt a more digital approach to managing quality, relying less solely on paper and isolated electronic documents

- Enable quality management with more automation and advanced technology, including automated data collection, analytics, and product documentation automation

- Use more integrated solutions to manage quality and pursue a platform approach to quality solutions

Table of Contents

- Executive Overview

- The Quality Imperative

- Managing Quality Carries Enterprise-Level Challenges

- Quality and Mistakes Avoided with Brute Force

- What Sets Apart Top Performers in Quality?

- Top Performers Take a More Integrated Approach to Quality

- Top Performers Extend Data and Processes to More Functions

- Top Performers Use More Automation, Advanced Technology

- Top Performers Enable Quality Digitally

- Top Performers Enable Quality with a Platform Approach

- Conclusion

- Recommendations

- About the Author

- About the Research

- About the Sponsor

Conclusion

Quality Management is crucial for CPG companies, but they face significant challenges. Although CPG companies report they are relatively effective at preventing significant issues, they face excess Quality Management related costs. Top Performers, on the other hand, are able to achieve better quality results from both quality and cost perspectives. They appear to have broken out of the paradigm of “better quality or lower cost, choose one.” They do this by taking a more holistic approach to quality, using more advanced tools like analytics, and leveraging more automation. Beyond the individual tools they use to manage quality, Top Performers take a much more integrated approach to organization, processes, and systems. They are more likely to have integrated data and processes, integrated systems, and pursue a platform approach for Quality Management. Our conclusion is that an integrated, digital approach to Quality Management in the CPG industry drives better business results from both quality and cost perspectives.Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Take a holistic view and approach to quality

- Move away from brute force Quality Management practices

- Adopt automation for more current, trusted data

- Adopt advanced tools like analytics to improve quality

- Move to a digital approach

- Integrate quality systems

- Leverage a platform of solutions to enable more holistic, integrated quality to improve quality without increasing cost, or reduce cost and maintain quality

This eBook takes a look at the cloud opportunity for PLM from the vendor perspective. It highlights the fact that although customers are rewarded with lower complexity and risk by moving to the cloud, vendors often face higher complexity and risk. It reviews the options ISVs have to move existing solutions to the cloud and points out business, operational, and technical issues to consider.

Please enjoy the summary below (free of charge, no registration required).

To download the full eBook, please visit our sponsor NuoDB (free of charge, registration required).

This eBook takes a look at the cloud opportunity for PLM from the vendor perspective. It highlights the fact that although customers are rewarded with lower complexity and risk by moving to the cloud, vendors often face higher complexity and risk. It reviews the options ISVs have to move existing solutions to the cloud and points out business, operational, and technical issues to consider.

Please enjoy the summary below (free of charge, no registration required).

To download the full eBook, please visit our sponsor NuoDB (free of charge, registration required).

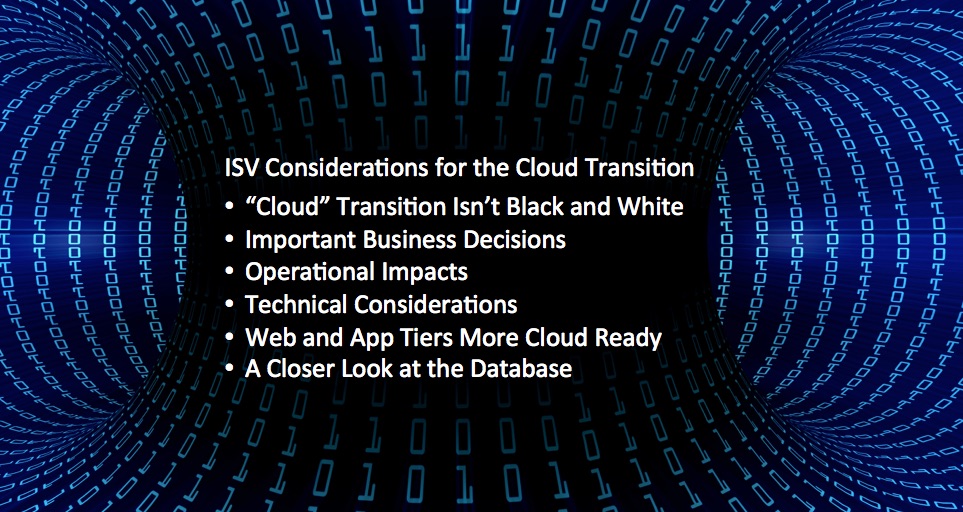

The Cloud Opportunity for PLM

Cloud solutions offer companies a range of compelling benefits including lower cost, scalability, ease of implementation, and reduced need for IT resources. Most companies are taking advantage of some cloud applications at this point, and it’s becoming a de facto architecture for some. That makes it an important option for independent software vendors (ISVs) to offer.

Cloud adoption in Product Lifecycle Management (PLM) has been slower, at least partially due to limited demand from conservative customers. But initial concerns have given way to rational requirements and audits. This is creating a growing competitive need in PLM, and even the largest, traditional vendors are making strides.

Overall, cloud solutions offer lower implementation and cost risk for customers. But that same can’t be said for software vendors who find themselves facing a significant architectural transition. Many PLM vendors are already rearchitecting toward a “platform” approach, making it a natural time to shift architectures. The technical considerations can be significant, but it’s not just a technical journey. There are implications to processes and organization as well. This eBook isn’t intended to provide all of the answers, just to make sure you’re asking the right questions.

Cloud solutions offer companies a range of compelling benefits including lower cost, scalability, ease of implementation, and reduced need for IT resources. Most companies are taking advantage of some cloud applications at this point, and it’s becoming a de facto architecture for some. That makes it an important option for independent software vendors (ISVs) to offer.

Cloud adoption in Product Lifecycle Management (PLM) has been slower, at least partially due to limited demand from conservative customers. But initial concerns have given way to rational requirements and audits. This is creating a growing competitive need in PLM, and even the largest, traditional vendors are making strides.

Overall, cloud solutions offer lower implementation and cost risk for customers. But that same can’t be said for software vendors who find themselves facing a significant architectural transition. Many PLM vendors are already rearchitecting toward a “platform” approach, making it a natural time to shift architectures. The technical considerations can be significant, but it’s not just a technical journey. There are implications to processes and organization as well. This eBook isn’t intended to provide all of the answers, just to make sure you’re asking the right questions.

Conclusion and Recommendations

For PLM, the move to the cloud has begun. Whether a vendor is moving all of their applications to the cloud, some of them, or offering a hybrid solution, it’s an evolution that requires a lot of decisions. After all, shifts in computing infrastructure and paradigms have historically resulted in major disruption for vendors, leading to major shifts in the competitive landscape as new players emerge and older players fade into the sunset. PLM vendors can, and are, making the transition to the cloud. They key considerations in this eBook are a guide to help identify the implications of the change. PLM vendors considering shifting to the cloud should:- Recognize that the cloud opportunity for customers is compelling

- Understand the impacts on them as an ISV

- Develop a strategy – even if it’s not to move solutions to the cloud

- Create a business plan to support the strategy and educate customers and investors about it

- Understand and address likely operational impacts, considering a DevOps approach

- Recognize and address technical issues

- Look for an architecture that provides cloud benefits to customers as well as the ISV (scalability, lower total cost of ownership) and room to grow over time

- Don’t underestimate the role of the database. Look for a DBMS aligned to your business needs and don’t force your business or application to radically change to fit the choice

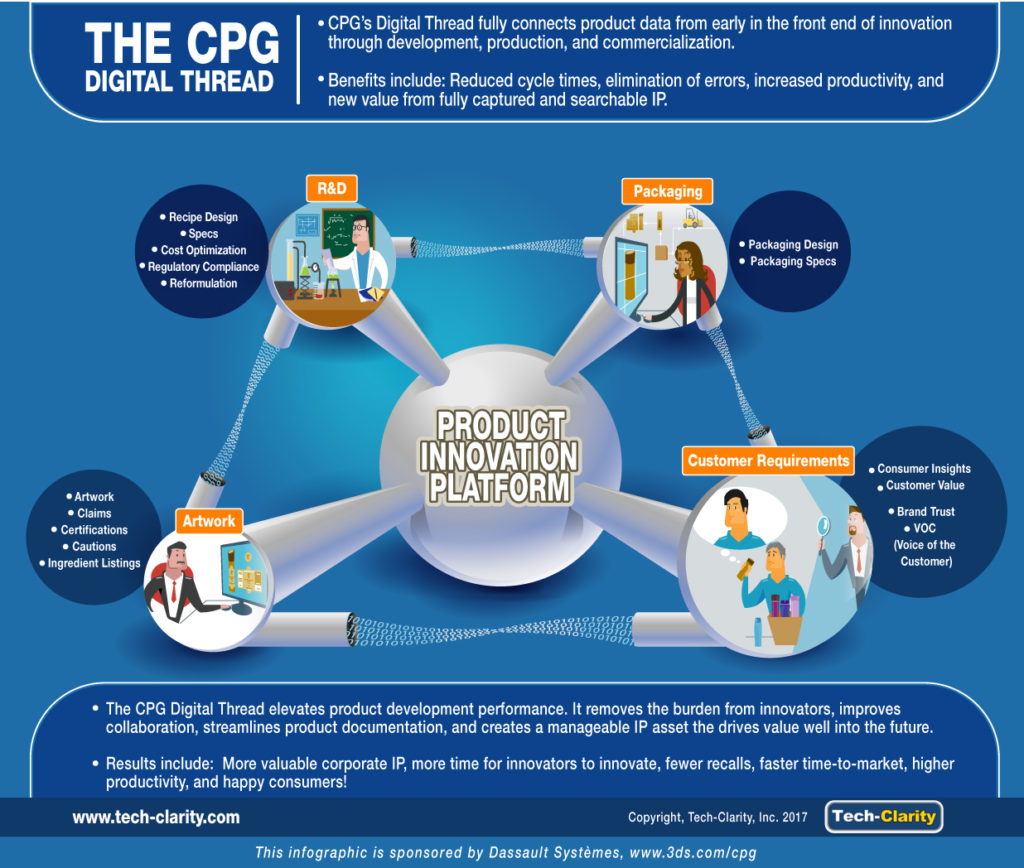

Click the image for a closer look!

To learn more, please see The CPG Digital Thread Overview (free of charge, no registration required) or download the full The CPG Digital Thread eBook from our sponsor Dassault Systèmes (free or charge, registration required). [post_title] => The CPG Digital Thread (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cpg-thread-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:08

[post_modified_gmt] => 2022-11-15 03:26:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6151

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 6133

[post_author] => 2

[post_date] => 2017-06-07 08:27:12

[post_date_gmt] => 2017-06-07 12:27:12

[post_content] => Join Tech-Clarity's Jim Brown on this webinar sharing recent survey results from almost 200 Consumer Packaged Goods companies, delving into their quality issue and how top performing CPG companies achieve better quality without suffering from excess internal cost. Learn the process, organizational, and technology approaches that Top Performers leverage to overcome their challenges and drive cost-effective quality.

This Business Review Webinars event is brought to you by Dassault Systèmes BIOVIA.

[post_title] => The CPG Digital Thread (infographic)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cpg-thread-infographic

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:08

[post_modified_gmt] => 2022-11-15 03:26:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6151

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 6133

[post_author] => 2

[post_date] => 2017-06-07 08:27:12

[post_date_gmt] => 2017-06-07 12:27:12

[post_content] => Join Tech-Clarity's Jim Brown on this webinar sharing recent survey results from almost 200 Consumer Packaged Goods companies, delving into their quality issue and how top performing CPG companies achieve better quality without suffering from excess internal cost. Learn the process, organizational, and technology approaches that Top Performers leverage to overcome their challenges and drive cost-effective quality.

This Business Review Webinars event is brought to you by Dassault Systèmes BIOVIA.

Watch the webcast on demand now (free of charge, registration required).

All registrants will get a free copy of the paper resulting from the survey, Top CPG Performers Move Beyond "Brute Force" to Drive Quality and Compliance.

[post_title] => Cost Effective Quality in CPG (webcast, survey results)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => managing-quality-cpg-survey-results-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:45

[post_modified_gmt] => 2022-11-15 03:26:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6133

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 6140

[post_author] => 2572

[post_date] => 2017-06-06 16:37:36

[post_date_gmt] => 2017-06-06 20:37:36

[post_content] =>

Watch the webcast on demand now (free of charge, registration required).

All registrants will get a free copy of the paper resulting from the survey, Top CPG Performers Move Beyond "Brute Force" to Drive Quality and Compliance.

[post_title] => Cost Effective Quality in CPG (webcast, survey results)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => managing-quality-cpg-survey-results-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:45

[post_modified_gmt] => 2022-11-15 03:26:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6133

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 6140

[post_author] => 2572

[post_date] => 2017-06-06 16:37:36

[post_date_gmt] => 2017-06-06 20:37:36

[post_content] => Hear Michelle Boucher's interview with David Wolf from PTC on medical devices. They focused on key topics for medical device companies, including the Case for Quality.

During the discussion, Michelle shared research on medical device industry trends. She also discussed the implications for the Case for Quality and offered advice to efficiently manage regulatory compliance. Throughout the discussion, she asked David Wolf for his thought's and how PTC is supporting key trends in the medical device industry. Access the recording from this event as well as other health care webcasts and content here. [post_title] => Live Interview - Achieve the Case for Quality (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical_device_novartis

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:51

[post_modified_gmt] => 2022-11-15 03:26:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6140

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 6123

[post_author] => 2

[post_date] => 2017-06-05 12:47:32

[post_date_gmt] => 2017-06-05 16:47:32

[post_content] =>

[post_title] => Live Interview - Achieve the Case for Quality (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => medical_device_novartis

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:51

[post_modified_gmt] => 2022-11-15 03:26:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6140

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[18] => WP_Post Object

(

[ID] => 6123

[post_author] => 2

[post_date] => 2017-06-05 12:47:32

[post_date_gmt] => 2017-06-05 16:47:32

[post_content] =>  This eBook shares survey results analyzing companies' ability to hit new product development (NPD) targets, then offers seven practical tips identified by the research as best practice processes, organization, and technology leveraged by the top performing product developers. The research provides recommendations to companies based on the approaches taken by the Top Performers, those that are able to outperform their competitors in revenue growth, margin expansion, and delivering innovative products to market.

Please enjoy the summary below.

For the full report, please visit our sponsor Autodesk (free of charge, registration required).

Investigating How to Win at NPDI

This eBook shares survey results analyzing companies' ability to hit new product development (NPD) targets, then offers seven practical tips identified by the research as best practice processes, organization, and technology leveraged by the top performing product developers. The research provides recommendations to companies based on the approaches taken by the Top Performers, those that are able to outperform their competitors in revenue growth, margin expansion, and delivering innovative products to market.

Please enjoy the summary below.

For the full report, please visit our sponsor Autodesk (free of charge, registration required).

Investigating How to Win at NPDI

Beating the competition at new product development and introduction (NPDI) is critical to a company’s success and profitability. It’s also a major challenge loaded with obstacles, targets, and tradeoffs. Common best practices, like gated processes and cross-departmental teams, are designed to help. But are those too commonplace to provide a competitive advantage? What really drives better market performance?

Tech-Clarity surveyed over 150 companies to find out. We analyzed responding companies’ processes, organization, and enabling technology to see what sets those with higher revenue growth, margin expansion, and portfolio innovation – the Top Performers – apart from the rest. We identified seven things that those companies do differently than their lower-performing competitors – the Others. Have they found a better way to develop products and beat the competition?

Seven Things Top Product Developers do Differently

Beating the competition at new product development and introduction (NPDI) is critical to a company’s success and profitability. It’s also a major challenge loaded with obstacles, targets, and tradeoffs. Common best practices, like gated processes and cross-departmental teams, are designed to help. But are those too commonplace to provide a competitive advantage? What really drives better market performance?

Tech-Clarity surveyed over 150 companies to find out. We analyzed responding companies’ processes, organization, and enabling technology to see what sets those with higher revenue growth, margin expansion, and portfolio innovation – the Top Performers – apart from the rest. We identified seven things that those companies do differently than their lower-performing competitors – the Others. Have they found a better way to develop products and beat the competition?

Seven Things Top Product Developers do Differently

- Focus on market speed

- Compete on innovation at multiple levels

- Plan for success with better portfolio processes and requirements

- Go beyond product excellence to market excellence

- Adhere to their product development process

- Adopt a more integrated, holistic view of NPDI

- Enable innovators with more collaborative, agile systems

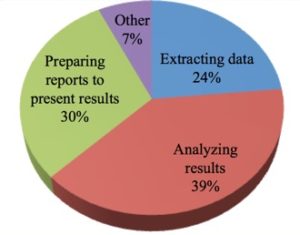

Listen to Michelle Boucher share best practices to improve the efficiency of simulation postprocessing. During this webinar, Shawn Wasserman, simulation editor at ENGINEERING.com, joined Michelle.

This webinar reveals:

Listen to Michelle Boucher share best practices to improve the efficiency of simulation postprocessing. During this webinar, Shawn Wasserman, simulation editor at ENGINEERING.com, joined Michelle.

This webinar reveals:

- Common challenges during the postprocessing phase

- Best practices to overcome those postprocessing challenges

- Case studies demonstrating the benefits of efficient postprocessing

[post_title] => Solving the Bottlenecks of Simulation: Postprocessing (Webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => simulation_postprocessing

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:45

[post_modified_gmt] => 2022-11-15 03:26:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6105

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 6159

[post_author] => 2572

[post_date] => 2017-10-23 11:30:05

[post_date_gmt] => 2017-10-23 15:30:05

[post_content] =>

[post_title] => Solving the Bottlenecks of Simulation: Postprocessing (Webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => simulation_postprocessing

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:45

[post_modified_gmt] => 2022-11-15 03:26:45

[post_content_filtered] =>

[post_parent] => 0

[guid] => http://tech-clarity.com/?p=6105

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

)

[post_count] => 20

[current_post] => -1

[before_loop] => 1

[in_the_loop] =>

[post] => WP_Post Object

(

[ID] => 6159

[post_author] => 2572

[post_date] => 2017-10-23 11:30:05

[post_date_gmt] => 2017-10-23 15:30:05

[post_content] =>  Composite Trends in the A&D Industry: Identifying Opportunities to Save Cost and Time reveals survey findings on design and manufacturing trends for composites in the Aerospace & Defense industry. The research examines two areas that can be a source for bottlenecks when working with composites: springback and manufacturing planning. The report details best practices to minimize or avoid distortions due to springback. It also looks at ways to streamline manufacturing planning while reducing errors and supporting changing.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required) thanks to our sponsor Siemens PLM.

Composite Trends in the A&D Industry: Identifying Opportunities to Save Cost and Time reveals survey findings on design and manufacturing trends for composites in the Aerospace & Defense industry. The research examines two areas that can be a source for bottlenecks when working with composites: springback and manufacturing planning. The report details best practices to minimize or avoid distortions due to springback. It also looks at ways to streamline manufacturing planning while reducing errors and supporting changing.

Please enjoy the summary below, or click the report to download a PDF overview (free of charge, no registration required) thanks to our sponsor Siemens PLM.

Executive Overview

Composites have become increasingly important to the Aerospace and Defense (A&D) industry. In fact, Tech-Clarity’s Composite State of the Market study, found that A&D companies overwhelmingly turn to composites to help with light weighting so that they can improve performance and realize better fuel economy. The study also found that while composites offer significant benefits, the expense of the material means companies should look at ways to get better insight. This way they can make better decisions during design to produce better composite parts. This is especially important to the A&D industry, which is under significant pressure to manage costs. To further examine the use of composites in the A&D industry, Tech-Clarity surveyed 181 A&D manufacturers. The study examines two areas that can be a source for bottlenecks when working with composites: springback and manufacturing planning. Springback can cause significant issues for A&D companies. Springback is a manufacturing defect that can occur while the composite part is curing. Due to shrinkage, the material can deviate from the original molded shape. When this happens, the part is out of tolerance. Depending on how severe the distortion is, manufacturers have to spend extra time correcting the part to get it within tolerance so that they can assemble it. In a worst case scenario, they may even have to scrap the part. This results in a lot of wasted time and excess cost. The good news is that companies who have adopted best practices for composites are much less likely to experience springback. One of those best practices includes using design guidelines. Another best practice involves communicating ply level design information by providing direct access to the composite data in the engineering model. Manufacturing planning is another important part of producing quality composite parts. With composites, it is especially crucial to produce parts exactly as designed. Even a slight deviation in fiber orientation significantly impacts part strength. By following manufacturing planning best practices you are more likely to produce composite parts as-designed. Best practices involve leveraging an accurate engineering model. In addition, manufacturers should look at ways to automate changes to avoid wasted time manually reworking manufacturing plans. This report examines design and manufacturing trends in the use of composites in the A&D industry. It also offers advice to overcome common problems to help A&D companies lower costTable of Contents

- Executive Overview

- Understanding Springback

- Corrective Actions for Springback

- Identifying the Top Performers

- Avoiding Springback

- Planning for Manufacturing

- Don’t Overlook the Time Impact of Changes

- Considering Programming Trends

- Conclusion

- Recommendations

- About the Author

- About the Research

- Copyright Notice

Conclusion