What is needed for manufacturers to improve the maturity of BOM-related processes to help to manage complexity, improve efficiency, prevent mistakes, and enhance collaboration across departments and the supply chain? Read our buyer’s guide to find out. Please enjoy the summary below. Click here for the full report, thank you to our sponsor PTC. …

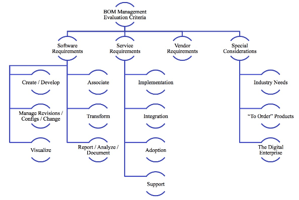

- Introducing the Buyer's Guide

- Diagnosing BOM Management Issues

- The BOM Management Status Quo

- The BOM Management Business Case

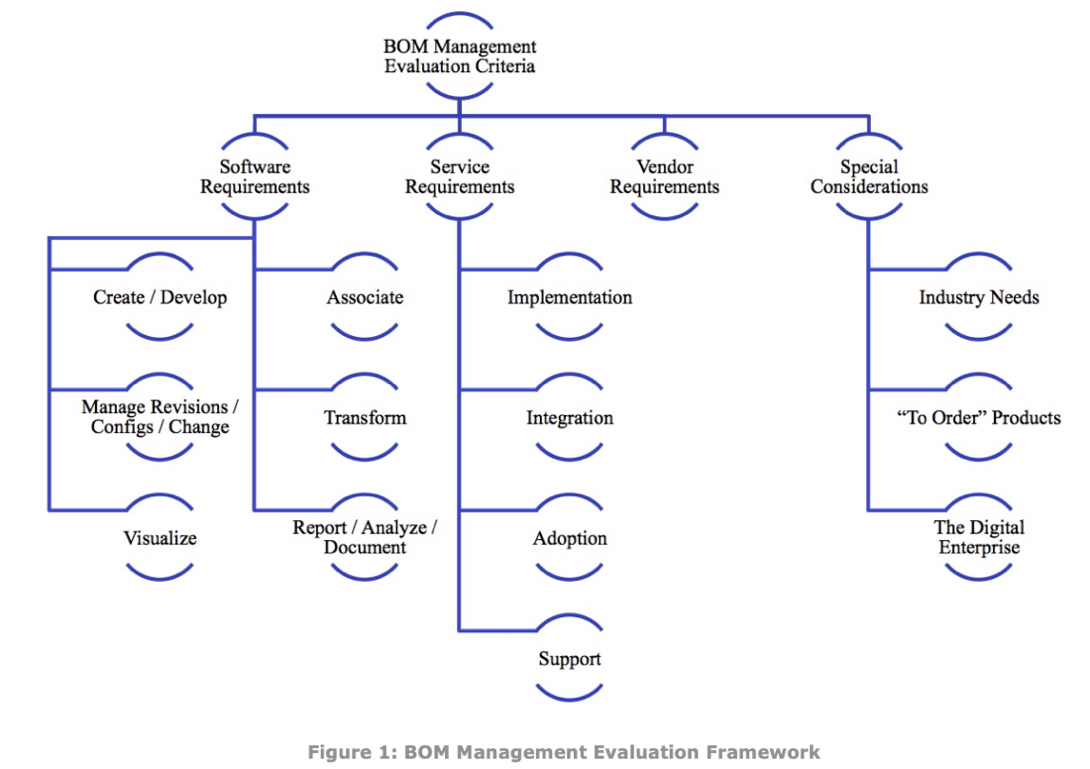

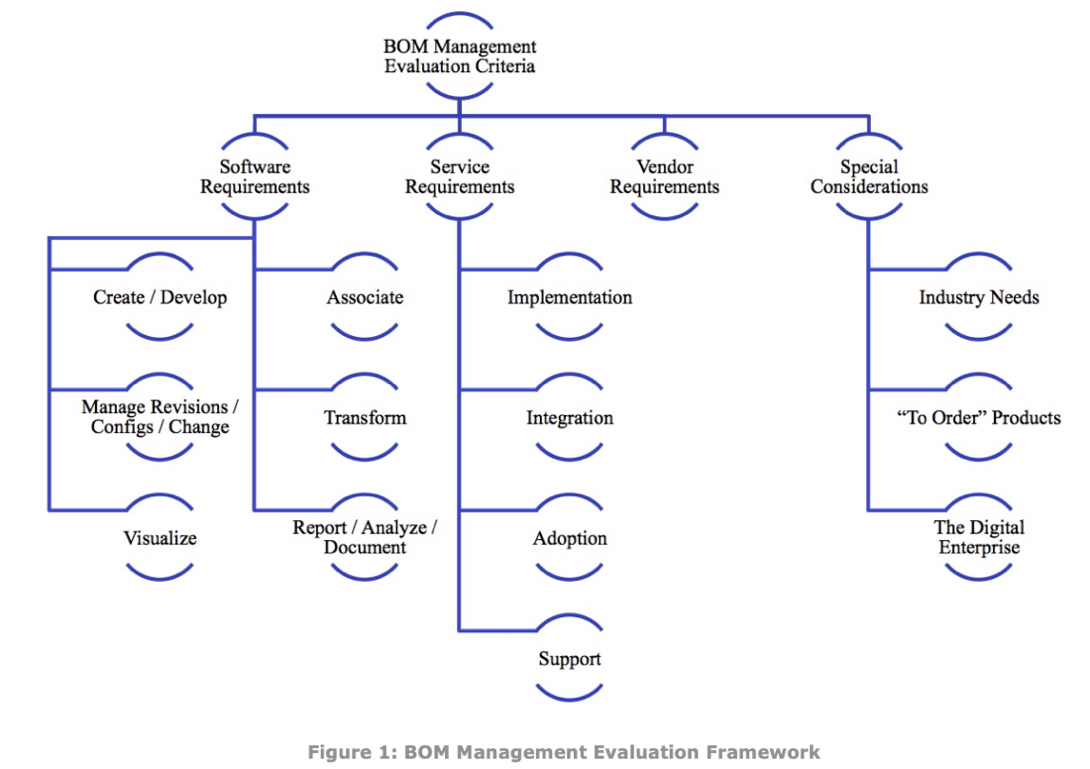

- Analyze BOM Management Solution Capabilities

- Assess Service Requirements

- Consider Vendor Requirements

- Special Considerations

- Prepare for the Digital Enterprise

- Conclusion

- Recommendations

- About the Author

- About the Research

- Acknowledgments

Introducing the Buyer's Guide

BOM Fundamentals Managing Bills of Material (BOMs) is a fundamental need for any manufacturer. Without effective control of product structures, companies struggle with inefficiency and errors. On the other hand, improving the maturity of BOM-related processes helps manage complexity, improve efficiency, prevent mistakes, and enhance collaboration across departments and the supply chain. Improving the maturity of BOM-related processes helps manage complexity, improve efficiency, prevent mistakes, and enhance collaboration across departments and the supply chain. The resulting benefits can be strategic, leading to increased agility and faster time to market that impact top-line financial performance. This Buyer's Guide is a reference tool for manufacturers selecting a system to improve the maturity of their BOM. It also shares that digital BOM management is critical to support digital transformation initiatives including the digital twin, the Internet of Things (IoT), Virtual Reality (VR), and Augmented Reality (AR). Diagnosing BOM Management Issues

Diagnosing BOM Management Issues

- Errors in manufacturing

- Poor first pass yield

- Ordering the wrong parts

- Delays due to part shortages

- Inability to confidently adopt engineering changes

- Slow time to full volume production

- Late identification of manufacturability or serviceability flaws

- Poor traceability

- Compliance issues or excess effort to comply

- Scrap and rework

- Slow review and approval processes

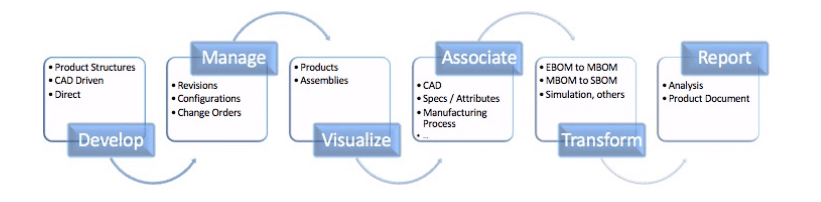

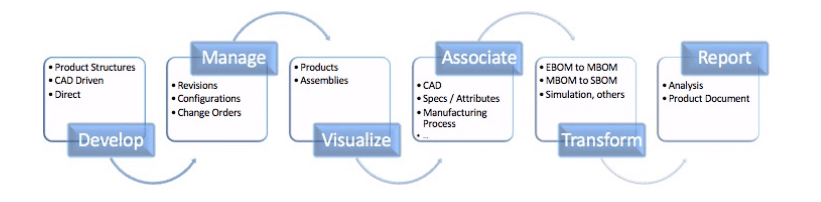

- Develop Product Structures

- Manage Revisions, Configurations, Change

- Visualize Products

- Associate Information

- Transform BOMs

- Report / Analyze / Document

It’s important to recognize that these requirements are in addition to the basic needs of managing product data, as most companies will extend their PDM or PLM environment to manage BOMs. These solutions provide platform capabilities such as access control and IP protection that serve as a critical foundation for effective BOM management.

It’s important to recognize that these requirements are in addition to the basic needs of managing product data, as most companies will extend their PDM or PLM environment to manage BOMs. These solutions provide platform capabilities such as access control and IP protection that serve as a critical foundation for effective BOM management.

Conclusion

Recommendations

Based on industry experience and research on this report, Tech-Clarity offers the following recommendations:- Think big, but remain agile and take BOM management improvements in steps

- Recognize the importance of accurate, complete, timely, and accessible product structures

- Know your needs

- Understand the value

- Look for functionality, but extend requirements to vendor and service

- Consider any special needs for your business, industry, or geography

- Build the foundation for the digital enterprise, recognizing that BOM management is a key enabler

- Get started

What do manufacturers need to know when they select a cloud Product Lifecycle Management (PLM) solution?

What do manufacturers need to know when they select a cloud Product Lifecycle Management (PLM) solution?

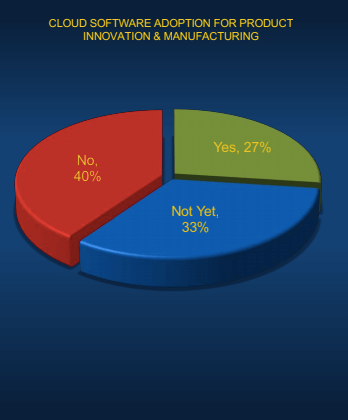

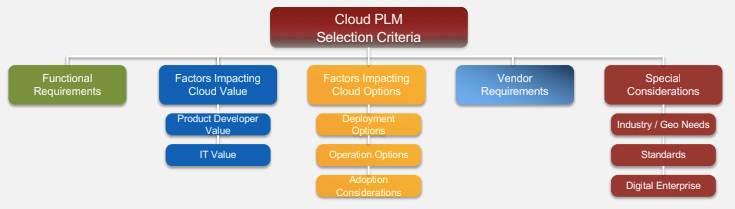

Although manufacturers have started to adopt cloud solutions for many aspects of their business, PLM has lagged behind. Our research shows that over one-half of manufacturers are considering cloud and about one-quarter already leverage the cloud support product innovation and manufacturing. Given the increased interest and adoption, we developed selection criteria to help companies navigate the options and choose the best-suited PLM cloud option for their business.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).Table of Contents

- Cloud PLM Adoption Increasing

- PLM Benefits and Business Value

- Increased Value/ROI of Cloud PLM

- Buyer's Considerations

- Choosing the Right PLM

- Considerations for Product Developers

- Considerations for IT

- Considerations for Adoption

- Review Deployment Options

- Evaluate Pricing Options

- Choose the Right Partner

- Special Considerations

- Conclusions and Recommendations

- Acknowledgments

Cloud PLM Adoption Increasing

A Solution First Approach

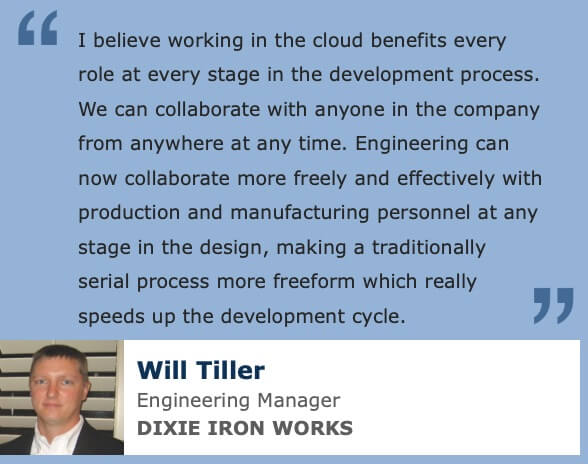

Cloud solutions are becoming more popular, yet PLM adoption in the cloud has been slower than other applications. The transition, however, is picking up pace. In fact, more companies are now asking, "why not the cloud?" instead of "why consider cloud?". We commend that companies pick their solution first and then choose their deployment option. This is effectively a "solution first" approach as opposed to a "cloud first" approach. We find that companies are just not willing to shortchange functionality in this crucial area. They recognize it's important to evaluate the functional capabilities of a PLM system to ensure they'll gain the significant top- and bottom-line benefits that PLM delivers.

PLM Benefits and Business Value

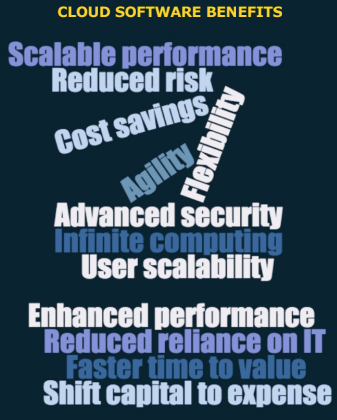

Product Lifecycle Management (PLM) spans multiple levels, offering value in multiple ways. PLM basics help manage products, parts, collaboration and release processes which leads to important benefits including increased productivity, preventing errors, reduced cost, improved quality, enhanced reliability, and more.

A Solution First Approach

Cloud solutions are becoming more popular, yet PLM adoption in the cloud has been slower than other applications. The transition, however, is picking up pace. In fact, more companies are now asking, "why not the cloud?" instead of "why consider cloud?". We commend that companies pick their solution first and then choose their deployment option. This is effectively a "solution first" approach as opposed to a "cloud first" approach. We find that companies are just not willing to shortchange functionality in this crucial area. They recognize it's important to evaluate the functional capabilities of a PLM system to ensure they'll gain the significant top- and bottom-line benefits that PLM delivers.

PLM Benefits and Business Value

Product Lifecycle Management (PLM) spans multiple levels, offering value in multiple ways. PLM basics help manage products, parts, collaboration and release processes which leads to important benefits including increased productivity, preventing errors, reduced cost, improved quality, enhanced reliability, and more.

Enterprise PLM expands that value by further helping companies develop, manufacture, and support their products. Our PLM Beyond Managing CAD study finds that expanded PLM use improves business performance, and that higher performing companies have more departments and third parties using PLM.

Get the Right PLM to Provide the Value

PLM drives tangible business value. This value is evolving and expanding quickly as companies pursue digital enterprise initiatives and expand the benefits to new business models capabilities. This value is available, but requires the right PLM system.

Enterprise PLM expands that value by further helping companies develop, manufacture, and support their products. Our PLM Beyond Managing CAD study finds that expanded PLM use improves business performance, and that higher performing companies have more departments and third parties using PLM.

Get the Right PLM to Provide the Value

PLM drives tangible business value. This value is evolving and expanding quickly as companies pursue digital enterprise initiatives and expand the benefits to new business models capabilities. This value is available, but requires the right PLM system.

Conclusions and Recommendations

The Cloud Offers Compelling Benefits The cloud makes the significant business value of PLM more accessible and reduces TCO for manufacturers. It offers new opportunities to enhance global reach and collaboration. But there are important things to consider when selecting a cloud PLM system, ranging from deployment options to considerations for certain industries and geographies. Recommendations for Cloud PLM Selection

To help companies research and analyze potential solutions based on company needs, including needs that help deliver benefits well into the future, Tech-Clarity offers the following recommendations:

Recommendations for Cloud PLM Selection

To help companies research and analyze potential solutions based on company needs, including needs that help deliver benefits well into the future, Tech-Clarity offers the following recommendations:

- Evaluate functional solution capabilities first, unless company standards mandate a deployment approach.

- After selecting the right functional solution, evaluate and select optimal deployment and pricing models that give your business the most benefit considering cost, risk, and time to achieve value.

- Consider the strategic value of cloud solutions for global deployments to support “design anywhere, build anywhere” strategies.

- Make sure to consider the future, including the transition to the digital enterprise. We believe that manufacturers that don’t digitalize will be at a competitive disadvantage.

- Narrow down solutions based on these high level criteria to create a smaller list of solutions to evaluate.

- Recognize that any solution selection process will require tradeoffs and understand which types of requirements are the most important to your company’s success and profitability

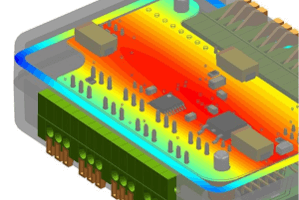

Is structural analysis enough or should design engineers use CFD too?

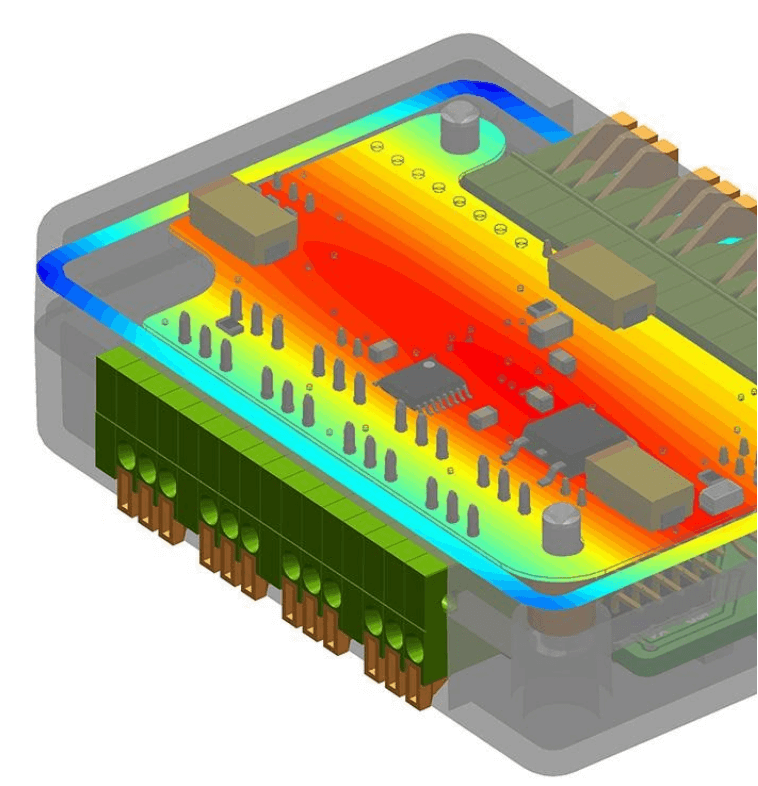

This guest post on the Siemens Solid Edge Blog explores this question. With product complexity increasing, it is harder than ever for engineers to make the right decision decisions. Complexity comes from the ever increasing amount of components, configurations, and electronics. Consequently, greater complexity has also increased the importance of understanding additional physics. For example, it's critical to understand the interactions of airflow around electronics so that they do not overheat. This is where Computational Fluid Dynamics (CFD) fits in.

CFD helps analyze airflow, among other fluids, and can help you uncover common problems that lead to failure, beyond what only structural analysis does. With this in mind, how else can it help design decisions?

This guest post discusses the many ways Computational Fluid Dynamics can help engineers design better products.

To learn more, view the related webinar.

[post_title] => Why Should You Use CFD?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => why-should-you-use-cfd-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-09 19:49:11

[post_modified_gmt] => 2024-01-10 00:49:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=9103

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 8998

[post_author] => 2574

[post_date] => 2020-06-01 10:12:28

[post_date_gmt] => 2020-06-01 14:12:28

[post_content] =>

Is structural analysis enough or should design engineers use CFD too?

This guest post on the Siemens Solid Edge Blog explores this question. With product complexity increasing, it is harder than ever for engineers to make the right decision decisions. Complexity comes from the ever increasing amount of components, configurations, and electronics. Consequently, greater complexity has also increased the importance of understanding additional physics. For example, it's critical to understand the interactions of airflow around electronics so that they do not overheat. This is where Computational Fluid Dynamics (CFD) fits in.

CFD helps analyze airflow, among other fluids, and can help you uncover common problems that lead to failure, beyond what only structural analysis does. With this in mind, how else can it help design decisions?

This guest post discusses the many ways Computational Fluid Dynamics can help engineers design better products.

To learn more, view the related webinar.

[post_title] => Why Should You Use CFD?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => why-should-you-use-cfd-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-09 19:49:11

[post_modified_gmt] => 2024-01-10 00:49:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=9103

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 8998

[post_author] => 2574

[post_date] => 2020-06-01 10:12:28

[post_date_gmt] => 2020-06-01 14:12:28

[post_content] =>  What step are many companies missing to ensure their Industry 4.0 initiatives succeed? Why Strategy Matters to Industry 4.0 Success discusses the importance of enterprise strategy. The right strategy makes even pilot projects more likely to live up to their potential. This eBook talks about how thinking big for enterprise transformation makes initiatives more pragmatic.

Please enjoy the summary* below. For the full research, please visit our sponsor, Critical Manufacturing (registration required).

What step are many companies missing to ensure their Industry 4.0 initiatives succeed? Why Strategy Matters to Industry 4.0 Success discusses the importance of enterprise strategy. The right strategy makes even pilot projects more likely to live up to their potential. This eBook talks about how thinking big for enterprise transformation makes initiatives more pragmatic.

Please enjoy the summary* below. For the full research, please visit our sponsor, Critical Manufacturing (registration required).

Table of Contents

- Making Industry 4.0 Pragmatic

- Industry 4.0 Transformative Benefits

- Making Industry 4.0 Approachable

- Why Disconnected Efforts are Insufficient

- Mindsets for Success

- Continuous Improvement for Industry 4.0

- Enterprise Needs

- Enterprise Technology

- Making it Scalable and Repeatable

- Build an Enterprise Industry 4.0 Approach

- Strategy to Accelerate Progress

Making Industry 4.0 Pragmatic

Small Steps Need Firm Ground in Strategy How can manufacturers take realistic steps to pursue Industry 4.0? The obvious answer is: get started with small projects. Yet, that may not be the best answer. Research shows that half of industrial internet of things (IIoT) projects are failing. It appears something is missing. According to research, that missing step is often setting an enterprise strategy for the transformation. Industry 4.0 is far broader than the manufacturing plant’s operations and processes. Every department plus the ecosystem of suppliers, distributors, and partners are involved. Only with an enterprise-level transformational strategy can manufacturers design, prioritize, and execute projects with assurance that they will build toward Industry 4.0. Companies must rely on what’s working, but also expand their view into the realm of what might be possible, even if it has not been to date.Strategy to Accelerate Progress

Foundation for the Future Strategy matters to Industry 4.0 success in several ways. Projects that have a clear context in strategy can deliver benefits not only locally, but roll out more widely and deliver enterprise benefits. Continuous Improvement (CI) progress can be smoother and more assured. With that clear strategic foundation, Industry 4.0 enables manufacturers to deliver higher value to their customers and markets now and into the future.

In short, Strategy Matters to Industry 4.0!

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available here.

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Why Strategy Matters to Industry 4.0 Success (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => strategy_matters_industry_4-0

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:20

[post_modified_gmt] => 2022-11-15 03:28:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8998

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 9009

[post_author] => 2

[post_date] => 2020-05-29 08:41:20

[post_date_gmt] => 2020-05-29 12:41:20

[post_content] =>

Strategy matters to Industry 4.0 success in several ways. Projects that have a clear context in strategy can deliver benefits not only locally, but roll out more widely and deliver enterprise benefits. Continuous Improvement (CI) progress can be smoother and more assured. With that clear strategic foundation, Industry 4.0 enables manufacturers to deliver higher value to their customers and markets now and into the future.

In short, Strategy Matters to Industry 4.0!

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available here.

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Why Strategy Matters to Industry 4.0 Success (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => strategy_matters_industry_4-0

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:20

[post_modified_gmt] => 2022-11-15 03:28:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8998

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 9009

[post_author] => 2

[post_date] => 2020-05-29 08:41:20

[post_date_gmt] => 2020-05-29 12:41:20

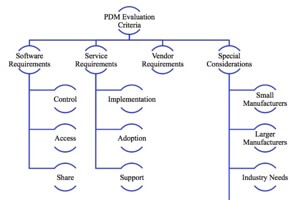

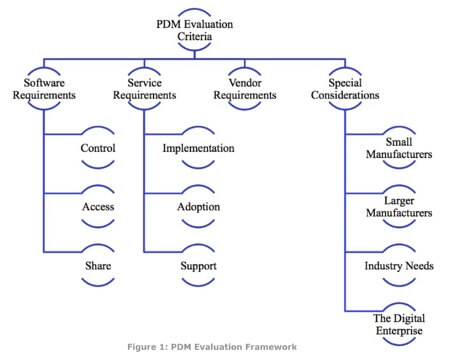

[post_content] =>  How can you choose the right PDM system for your business to make sure you achieve your productivity, product success, and profitability goals? The product data management (PDM) Buyer’s Guide is a reference tool to provide direction on what to look for when selecting a PDM system for your company. This guide is composed of four sections covering software functionality, service requirements, vendor attributes, and special company considerations.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

How can you choose the right PDM system for your business to make sure you achieve your productivity, product success, and profitability goals? The product data management (PDM) Buyer’s Guide is a reference tool to provide direction on what to look for when selecting a PDM system for your company. This guide is composed of four sections covering software functionality, service requirements, vendor attributes, and special company considerations.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

Table of Contents

- Introducing the PDM Buyer’s Guide

- The Product Data Management Imperative

- Analyze PDM Capabilities

- Assess Service Requirements

- Consider Vendor Requirements

- Identify Unique Company Needs

- Prepare for the Digital Enterprise

- Conclusion

- Recommendations

- About the Author

Introducing the Product Data Management Buyer’s Guide

Product Data Management (PDM) is an important tool to help manufacturers overcome the complexities of designing, developing, producing, and supporting today’s products and product development processes. Manual and ad-hoc approaches such as shared folders, Dropbox, and hard drives are simply not good solutions to manage critical, complex product information. These approaches may work for very small organizations, but quickly falter as organizations grow and must share information beyond a few core engineers. These techniques also fail to manage data relationships and complex file structures common to 3D CAD systems. PDM systems are purpose-built to address these issues. PDM is a structured, collaborative solution that helps manufacturers control, access, and share crucial product data. Selecting the right PDM system for your business has a large impact on productivity, product success, and profitability.- Getting files under control so people can find the right revision with confidence

- Making sure concurrent updates don’t overwrite each other to avoid “the last save wins” syndrome

- Making information easily accessible and consumable to teams outside of Engineering for reviews and downstream processes

- Safely sharing information with customers, partners, and the supply chain

- Ensuring intellectual property (IP) is captured and securely accessible regardless of who stored it

- Getting away from complicated shared drive structures that lead to errors

- Making sure people don’t manufacture or purchase against the wrong drawing

- Providing “one version of the truth” versus multiple copies of designs

Beyond these basics, there are special considerations for smaller companies and for the largest of enterprises. There are also special considerations for some industries. The guide addresses these and then goes beyond software functionality to focus on the entire experience of owning and operating the solution. The guide and associated checklists include product, infrastructure, implementation, service, and business requirements – all of which impact the benefits received and total cost of ownership (TCO) of PDM. The PDM Buyer’s Guide is not intended to provide an all-encompassing requirements list. Instead it covers the high points that manufacturers should look for in a PDM system. Think of this as a “PDM litmus test” to see if a solution is a good high-level fit for your business before spending significant time and effort analyzing detailed features and functions.

Beyond these basics, there are special considerations for smaller companies and for the largest of enterprises. There are also special considerations for some industries. The guide addresses these and then goes beyond software functionality to focus on the entire experience of owning and operating the solution. The guide and associated checklists include product, infrastructure, implementation, service, and business requirements – all of which impact the benefits received and total cost of ownership (TCO) of PDM. The PDM Buyer’s Guide is not intended to provide an all-encompassing requirements list. Instead it covers the high points that manufacturers should look for in a PDM system. Think of this as a “PDM litmus test” to see if a solution is a good high-level fit for your business before spending significant time and effort analyzing detailed features and functions.

Although the checklists focus only on PDM requirements, it’s important to consider more than your current needs when choosing a system. Many companies eventually want to grow beyond basic PDM to a more complete PDM system. These more advanced capabilities are covered in our Expanding Beyond Your Outgrown PDM System Buyer’s Guide.

Other companies may start with PDM and evolve through a maturity process to a more complete Product Lifecycle Management (PLM) environment. PLM extends the core PDM foundation to support more product development and engineering processes, manage a richer view of products, include more people in product development, and support processes further upstream and downstream from Engineering in the product lifecycle.

In addition, PDM is becoming the core 3D foundation for the digital enterprise, supporting advanced initiatives like the Internet of Things (IoT), model-based design (MBD), and three dimensional augmented / virtual reality. Modern PDM / PLM systems should enable a product digital twin that can serve as the central foundation on which to consolidate (or view) a variety of product-related data captured in systems across the enterprise. It’s important to consider these needs when selecting your software and ensure that your solution has the capability to expand with your growing needs.

Although the checklists focus only on PDM requirements, it’s important to consider more than your current needs when choosing a system. Many companies eventually want to grow beyond basic PDM to a more complete PDM system. These more advanced capabilities are covered in our Expanding Beyond Your Outgrown PDM System Buyer’s Guide.

Other companies may start with PDM and evolve through a maturity process to a more complete Product Lifecycle Management (PLM) environment. PLM extends the core PDM foundation to support more product development and engineering processes, manage a richer view of products, include more people in product development, and support processes further upstream and downstream from Engineering in the product lifecycle.

In addition, PDM is becoming the core 3D foundation for the digital enterprise, supporting advanced initiatives like the Internet of Things (IoT), model-based design (MBD), and three dimensional augmented / virtual reality. Modern PDM / PLM systems should enable a product digital twin that can serve as the central foundation on which to consolidate (or view) a variety of product-related data captured in systems across the enterprise. It’s important to consider these needs when selecting your software and ensure that your solution has the capability to expand with your growing needs.

Conclusion

PDM helps manufacturers address market complexity and improve business performance. As Tech-Clarity’s Managing Engineering Data concludes, “Product data management is the fundamental building block of any engineering software strategy and helps companies get the most out of their precious engineering resources.” When evaluating PDM, manufacturers need to take into account:- Product requirements

- Implementation, adoption, and support requirements

- Vendor / business requirements

- Special requirements based on company size (particularly for very small or very large organizations)

- Special considerations to meet industry needs

- Future requirements as business continues to digitalize

Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Identify and weigh PDM requirements based on company needs, company size, industry, and any unique company needs

- Use high level requirements such as the ones in this guide to evaluate solutions based on business fit before engaging in detailed evaluations

- Consider using more simple, commodity technical solutions like cloud or managed services solutions for smaller companies, companies that wish to move quickly, or those with limited IT resources

- Take user adoption into account, including simplified access and increased visualization for non-engineering resources

- Consider using more full-featured, scalable solutions for larger organizations that have more demanding process and scalability needs and can afford the IT resources required to support capabilities such as site synchronization

- Take into account long-term business and process growth needs including digitalization and IoT initiatives

- Consider the potential to expand to a more capable extended PDM or PLM system, but start small and get value along the way during implementation

Key take-aways

Many new applications for semiconductors in the smart, connected world also lead to exceptional pressures on both fabs and backend operations. Julie will discuss a few of the concepts that many semiconductor companies have not yet leveraged to full advantage. In this session, you will hear how digital twin, modern comprehensive MES with integrated scheduling and quality, and advanced analytics can accelerate operations’ improvement efforts. [post_title] => Its Time for Semiconductor to Smarten Up! (presentation) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => semiconductor-smarten-up-srl [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:26:26 [post_modified_gmt] => 2022-11-15 03:26:26 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=8976 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [6] => WP_Post Object ( [ID] => 8945 [post_author] => 2572 [post_date] => 2020-05-15 13:33:41 [post_date_gmt] => 2020-05-15 17:33:41 [post_content] => In the second part of this two-part blog series, Michelle Boucher continues to explore the question, should you consider an agile methodology to support new product development, beyond just software?

Proceeding from the first part, which explained what agile is and two reasons for using the agile methodology, the second part provides three more reasons to consider an agile methodology:

In the second part of this two-part blog series, Michelle Boucher continues to explore the question, should you consider an agile methodology to support new product development, beyond just software?

Proceeding from the first part, which explained what agile is and two reasons for using the agile methodology, the second part provides three more reasons to consider an agile methodology:

- Find Problems Sooner

- Tap into the Expertise of the Complete Team

- It Doesn’t Mean There Are No Requirements

Tech-Clarity's eBook, Designing Smart Products Smartly: Increase the Maturity of Your Development Processes, explores this question. The combination of mechanics, electronics and software into today’s smart products have made them more responsive, adaptable, interconnected and portable than ever before. Incidentally, with customers expecting this type of technology in their products, the growth of smart products will not abate. Though smart products can create opportunities, they also introduce new challenges and complexity. To overcome these challenges, companies need to mature their development processes. This eBook reveals the steps manufacturers can take to mature their processes for designing smart products.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

Tech-Clarity's eBook, Designing Smart Products Smartly: Increase the Maturity of Your Development Processes, explores this question. The combination of mechanics, electronics and software into today’s smart products have made them more responsive, adaptable, interconnected and portable than ever before. Incidentally, with customers expecting this type of technology in their products, the growth of smart products will not abate. Though smart products can create opportunities, they also introduce new challenges and complexity. To overcome these challenges, companies need to mature their development processes. This eBook reveals the steps manufacturers can take to mature their processes for designing smart products.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

Table of Contents

- Improve Smart Product Development Maturity

- Define the Target

- Plan the Product

- Validate Early and Often

- Design by Discipline and Validate to Interfaces

- Effectively Manage Change

- Enable an Integrated Lifecycle View

- Conclusions and Recommendations

- Acknowledgment

Improve Smart Product Development Maturity

The Opportunities for Smart Products Customers in nearly every industry find smart products compelling. It’s hard to compete with a car that drives and parks itself or a clothes washer that senses and adjusts to water conditions, fabric types, and dirt levels and schedules service when needed. Likewise, a medical device that monitors patient health and notifies a doctor when needed offers significant value. Benefits will increase even further as smart products become more aware and communicative as companies adopt strategies to support the Internet of Things (IoT) and technologies like 5G create even more opportunity for connectivity. But There Are Challenges

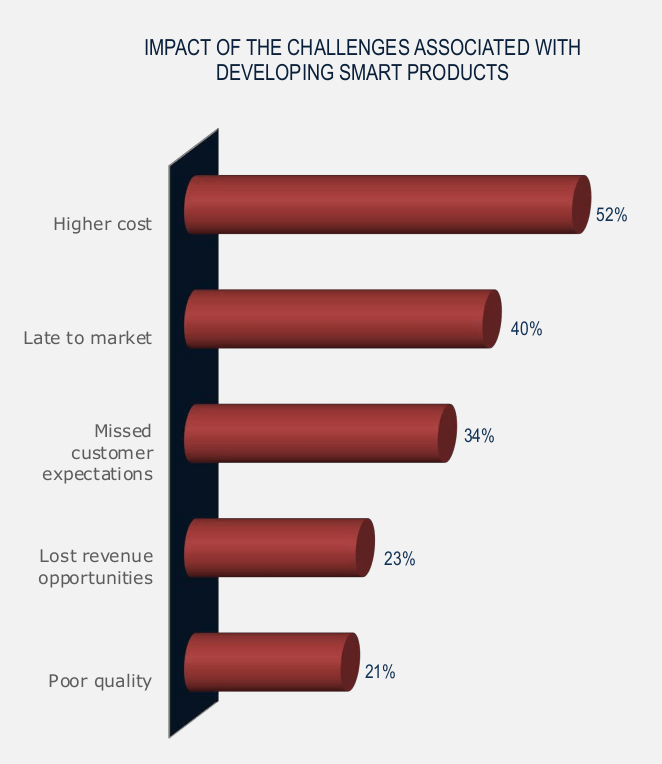

However, the advantages of smart products come at a cost. Developing complex, intelligent products brings inherent complexity. Multiple design disciplines must synchronize their work across different design life cycles. Multiple configuration options add even more complexity. Tech-Clarity research identifies several challenges created by increased complexity, but more importantly shows there can be significant, negative business impact (see graph). [1]

To overcome these challenges, companies need to raise the maturity of how they develop smart products. Fortunately, our research shows that better processes and enabling technology improve results through the use of a platform for integration, visibility, and traceability for smart product development. Digital transformation is a large piece of making these practices a success and enabling technologies such as the cloud, platforms, and modern design tools can make adoption easier. This paper outlines a number of tangible steps to improve the development of smart products with proven best practices, technology, and digital transformation.

But There Are Challenges

However, the advantages of smart products come at a cost. Developing complex, intelligent products brings inherent complexity. Multiple design disciplines must synchronize their work across different design life cycles. Multiple configuration options add even more complexity. Tech-Clarity research identifies several challenges created by increased complexity, but more importantly shows there can be significant, negative business impact (see graph). [1]

To overcome these challenges, companies need to raise the maturity of how they develop smart products. Fortunately, our research shows that better processes and enabling technology improve results through the use of a platform for integration, visibility, and traceability for smart product development. Digital transformation is a large piece of making these practices a success and enabling technologies such as the cloud, platforms, and modern design tools can make adoption easier. This paper outlines a number of tangible steps to improve the development of smart products with proven best practices, technology, and digital transformation.

Conclusions

Create a Competitive Advantage To beat competitors with smart innovations, companies must raise the maturity of their development processes and tools. This report suggests best practices for requirements management, systems design, simulation, interface management, and change management. There are others as well, but these processes are proven and can provide significant value today. In addition to best practices, companies should implement a lifecycle-oriented platform to enable a cohesive, transparent product development process across disciplines. These solutions allow companies to implement best practices to take advantage of the compelling benefits of smart products without suffering from costly, negative impacts to quality and time-to-market.

In addition to best practices, companies should implement a lifecycle-oriented platform to enable a cohesive, transparent product development process across disciplines. These solutions allow companies to implement best practices to take advantage of the compelling benefits of smart products without suffering from costly, negative impacts to quality and time-to-market.

Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Follow proven best practices for developing smart products:

- Create a single source of truth for requirements

- Plan the product starting with architecture and develop a system model

- Use multi-physics simulation early and often at both the system and component level to optimize and validate the design

- Develop a common product definition with interfaces

- Manage change by starting with an impact analysis across all disciplines

- Leverage product innovation platforms to create an integrated lifecycle view

- Implement the right tools to enable design, including simulation and systems design tools

- Leverage lifecycle-oriented systems to integrate the various processes, people, and deliverables required to efficiently develop high quality, smart products.

The introductory blog post of this two part series, defines the "waterfall" and "agile" methodologies. The post them reveals two of the five reasons to consider an agile methodology for your product development process:

The introductory blog post of this two part series, defines the "waterfall" and "agile" methodologies. The post them reveals two of the five reasons to consider an agile methodology for your product development process:

- Support Evolving Requirements

- Meet Customer Needs

What software tools do engineers need to support product design? Which capabilities will help engineers develop products that are higher quality, more personalized, more innovative, and lower in ownership cost?

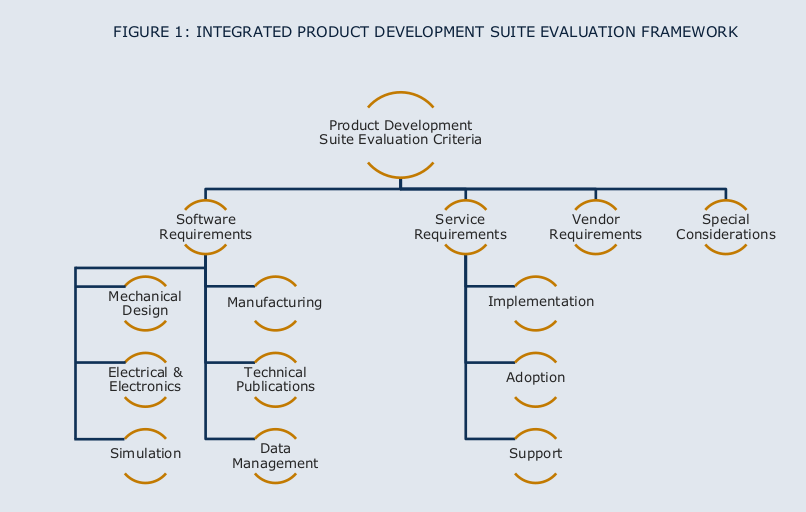

These are challenging tasks to achieve that are further complicated due to increasing product complexity, engineering changes, and multiple engineering disciplines. However, with the correct software solution, the challenges can be surmounted during product design. Tech-Clarity's Buyer's Guide for Engineers: How to Select Essential Tools for Product Design can do just that by providing guidance to help you choose the right solution for your company.

This guide is a starting point for tackling those challenges. It provides a high-level overview of requirements for a complete, integrated product design suite. Tech-Clarity’s buyer’s guides look beyond software requirements to the other elements that help companies get value from their solutions. Consequently, it includes criteria for implementation, adoption, service, and vendor selection. Further, each section contains a checklist to support your software evaluation efforts.

Please enjoy the summary* below. For the full eBook, please visit our sponsor Siemens (registration required).

What software tools do engineers need to support product design? Which capabilities will help engineers develop products that are higher quality, more personalized, more innovative, and lower in ownership cost?

These are challenging tasks to achieve that are further complicated due to increasing product complexity, engineering changes, and multiple engineering disciplines. However, with the correct software solution, the challenges can be surmounted during product design. Tech-Clarity's Buyer's Guide for Engineers: How to Select Essential Tools for Product Design can do just that by providing guidance to help you choose the right solution for your company.

This guide is a starting point for tackling those challenges. It provides a high-level overview of requirements for a complete, integrated product design suite. Tech-Clarity’s buyer’s guides look beyond software requirements to the other elements that help companies get value from their solutions. Consequently, it includes criteria for implementation, adoption, service, and vendor selection. Further, each section contains a checklist to support your software evaluation efforts.

Please enjoy the summary* below. For the full eBook, please visit our sponsor Siemens (registration required).

TABLE OF CONTENTS

- Executive Overview

- The Business Value of Investing in Engineering

- Support End-to-End Processes with an Integrated Solution

- Mechanical Design

- Electrical and Electronic Design

- Simulation

- Manufacturing

- Technical Publications

- Design Data Management

- Service Requirements

- Vendor Requirements

- Identify Unique Company Needs

- Conclusion

- Recommendations

- About the Author

- Acknowledgments

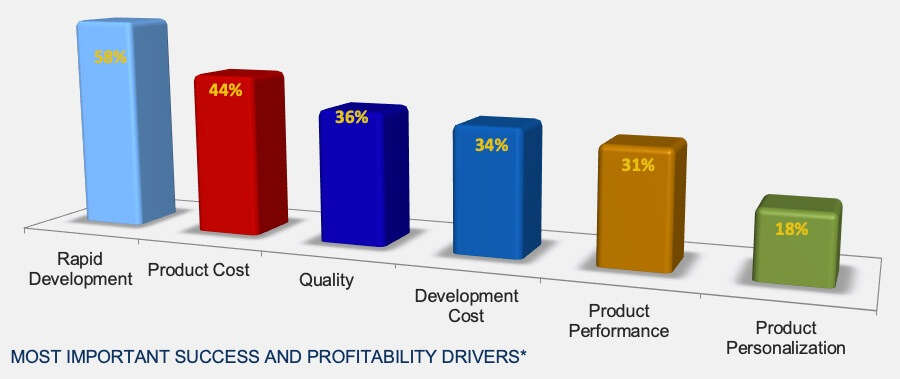

Executive Overview

Global competition, including low-cost providers, makes it hard to compete in today’s market. It is impossible to compete on price when competitors come from geographic regions with low employment costs. Consequently, companies must compete in other ways, such as with better, high quality products, more personalization, improved services, greater innovation, or lower cost of ownership. Achieving this requires improving efficiency, catching problems sooner, and making better decisions to lower product development costs and increase product quality. Consequently, teams must be agile enough to quickly respond to market shifts and customer demands. Products have to get to market as fast as possible to maximize the window of opportunity before low-cost providers can undercut prices with competing offerings.The Value of Digitalization

Efficiencies achieved through digitalization accelerate the development process and improve quality by creating a digital thread across the entire product development cycle. As a result, all information stays up to date, changes are propagated, and there is less risk of errors. However, it can be hard to know where to start, especially for a small or mid-size company. Smaller companies share many of the same challenges as larger companies, but lack the budget of a big OEM. The right software solution can help, but it must have the right capabilities, at an affordable price that will be manageable for a small company.Selecting the Right Solution

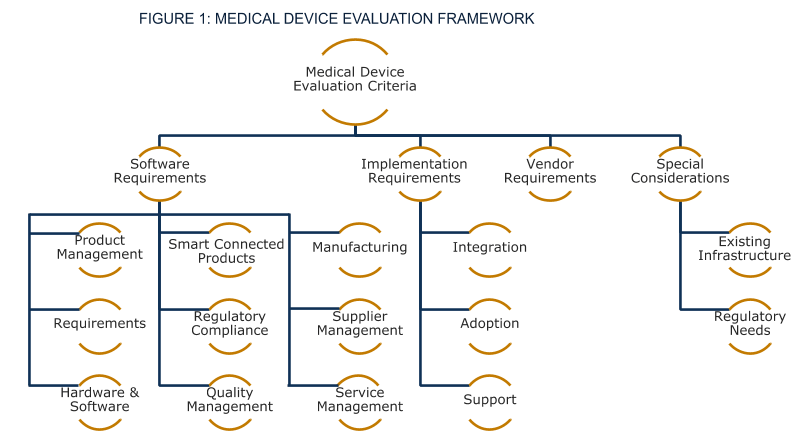

With so much to consider, how do you choose the right software solution to support your product life-cycle? This buyer’s guide serves as a guide to help you pick the right solution for your company. This guide covers requirements for a complete integrated product development suite. It has four major sections covering software functionality, service requirements, vendor attributes, and unique company considerations (Figure 1). Each section includes a checklist of key requirements to investigate when selecting software tools. This guide is not an all-encompassing requirements list. It provides a high-level overview. While the amount of embedded software in today’s products is growing, for the purposes of this guide, it was not considered part of the scope.

While the amount of embedded software in today’s products is growing, for the purposes of this guide, it was not considered part of the scope.

RECOMMENDATIONS

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

- Create a digital thread across your development process with an end-to-end integrated product development suite

- Consider solutions that support mechanical design, electrical design, simulation, manufacturing, technical publications, and design data management.

- Ensure you have traceability across the entire lifecycle of your product

- Do not compromise on ease of use

- Support collaboration across the development lifecycle

- Work off a single high-fidelity model to support your digitalization strategy and create a single source of truth

- Ensure your solution will have the support behind it to make it a success at your company.

- Select a vendor who will be a good partner.

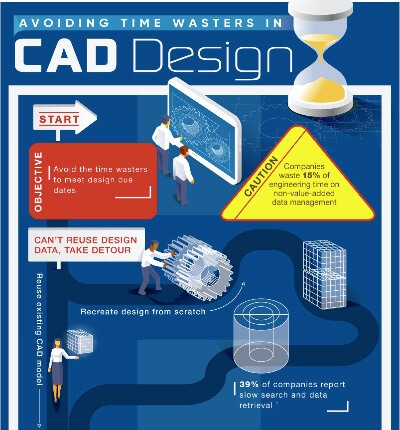

How can companies improve data management to avoid the five most common CAD design time wasters and win the engineering productivity challenge? Improving design data management maturity, enabled by PDM and PLM solutions, helps reduce non-value-added time and increase engineering productivity.

Please enjoy the summary* below. Please visit our sponsor Siemens for the full research (registration required).

Please also see the related Avoid Wasting Design Time infographic to learn more about CAD design time wasters.

How can companies improve data management to avoid the five most common CAD design time wasters and win the engineering productivity challenge? Improving design data management maturity, enabled by PDM and PLM solutions, helps reduce non-value-added time and increase engineering productivity.

Please enjoy the summary* below. Please visit our sponsor Siemens for the full research (registration required).

Please also see the related Avoid Wasting Design Time infographic to learn more about CAD design time wasters.

Table of Contents

- Reducing Non-Value-Added Time in CAD Design

- Engineers Don’t Have Time to Waste

- Time Waster 1 - Can’t Find and Reuse Data

- Time Waster 2 – Lost CAD Designs

- Time Waster 3 – Preparing Data for Others

- Time Waster 4 – Managing Complexity

- Time Waster 5 – Managing Change

- Conclusions and Next Steps

Engineers Don't Have Time to Waste

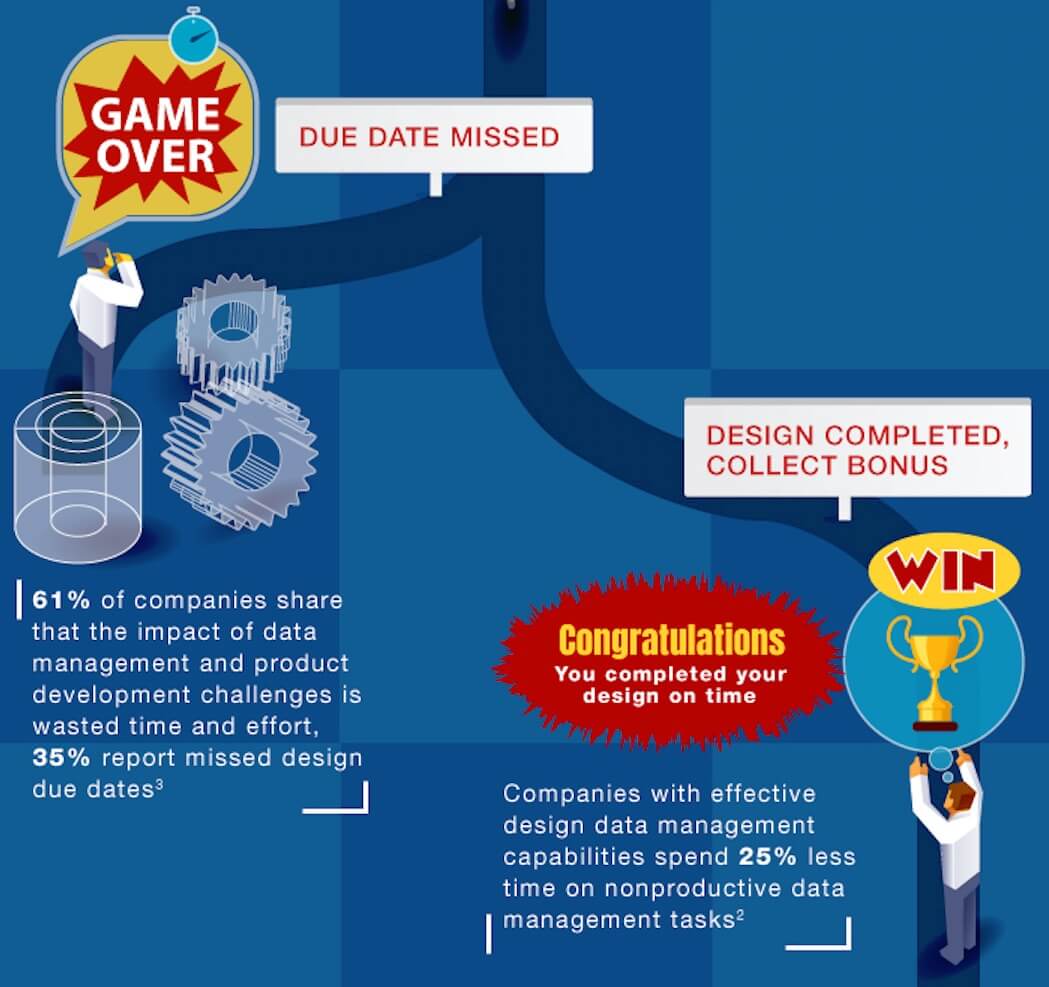

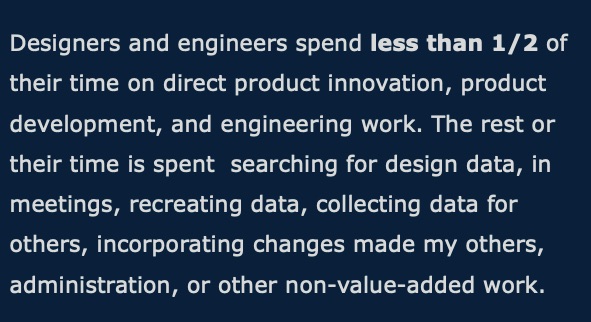

Too Much Spent Time on Non-Value-Added Data Management Product and product development complexity have increased while time-to-market goals have become more aggressive. The combination of these two trends puts a significant squeeze on the time available for engineers and designers to design and document their inventions. Unfortunately, companies waste an average of 15% of their engineers’ time on non-value-added data management tasks. Almost one-third of these companies spend over 25% of their engineers’ time this way. That’s one out of every four days wasted on data management efforts that could be better spent innovating. Design Data Management Maturity Relieves the Pressure What if companies could give that wasted time back to their technical personnel? That’s exactly what leading companies do. Our research shows that Top Performing companies – those that are better able to quickly and efficiently design high quality, innovative products – spend 25% less time on nonproductive data management tasks. What enables these companies to perform better than their competitors? These leaders are more likely to have adopted more mature data management capabilities1 and use more structured, collaborative data management solutions including Product Data Management (PDM) and Product Lifecycle Management (PLM). Let’s take a look at how these solutions help engineers avoid wasting precious design time by allowing them to control, access, and share design data.Conclusions and Next Steps

Avoid Time-Wasting Traps through Better Practices

The time-wasting events highlighted in this eBook are some of the most common issues we find in our research, but they are only a sample. The key to avoiding wasteful traps and gaining more productive design time is adopting mature design data management practices. With these better practices in place, companies are more likely to be able to meet their product development targets and win the CAD design challenge.

Put in Place the Right Design Data Management Technology

Mature design data management goes hand-in-hand with design data management technology. It’s essential for companies to control, access, and share CAD data effectively whether the system they choose is basic PDM or a more capable PLM system.

Get Started, Take Advantage of the Benefits

Companies that don’t have an effective PDM or PLM system in place are putting their design efficiency – and more – at risk. Rising complexity across product, product development, and other dimensions is increasing data management challenges, the potential for issues, and the need for design data management systems. Even for small teams, these systems provide structure and value that helps drive better design and business performance so companies can win at the CAD design game.

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Avoid 5 CAD Design Time Wasters (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cad-design-time-wasters

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:20

[post_modified_gmt] => 2022-11-15 03:28:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8874

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 8839

[post_author] => 2572

[post_date] => 2020-04-29 11:30:03

[post_date_gmt] => 2020-04-29 15:30:03

[post_content] =>

Avoid Time-Wasting Traps through Better Practices

The time-wasting events highlighted in this eBook are some of the most common issues we find in our research, but they are only a sample. The key to avoiding wasteful traps and gaining more productive design time is adopting mature design data management practices. With these better practices in place, companies are more likely to be able to meet their product development targets and win the CAD design challenge.

Put in Place the Right Design Data Management Technology

Mature design data management goes hand-in-hand with design data management technology. It’s essential for companies to control, access, and share CAD data effectively whether the system they choose is basic PDM or a more capable PLM system.

Get Started, Take Advantage of the Benefits

Companies that don’t have an effective PDM or PLM system in place are putting their design efficiency – and more – at risk. Rising complexity across product, product development, and other dimensions is increasing data management challenges, the potential for issues, and the need for design data management systems. Even for small teams, these systems provide structure and value that helps drive better design and business performance so companies can win at the CAD design game.

*This summary is an abbreviated version of the research and does not contain the full content. A link to download the full report is available above.

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Avoid 5 CAD Design Time Wasters (eBook)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cad-design-time-wasters

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:20

[post_modified_gmt] => 2022-11-15 03:28:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=8874

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 8839

[post_author] => 2572

[post_date] => 2020-04-29 11:30:03

[post_date_gmt] => 2020-04-29 15:30:03

[post_content] =>  What does it take for toolmakers to be competitive? What can mold makers do to improve their business?

Tech-Clarity's eBook, Breaking the Mold: How Toolmakers Are Transforming Operations to Stay Competitive explores these questions. The business of mold making is tough. Firstly, there is the time consuming bidding process where you need to provide an accurate, yet competitively priced bid and a realistic delivery date. However, many factors impact engineering and manufacturing, such as the quality of the part design, ability to manage cooling, and varied machining requirements. Significant effort is required and even small errors can significantly compromise profit margins. Despite the time and effort, mold makers, according to our survey respondents, only win 52% of the jobs they quote.

After winning the bid, a litany of further challenges await. Poor part designs, bottlenecks, complexity, changes, and more create obstacles to every business’s goal, profitability. How can toolmakers transform their operations to become more competitive and boost profitability? To answer this question, Tech-Clarity surveyed over 370 mold makers. This report reveals the results and provides recommendations to improve your business.

Please enjoy the summary* below. For the full report, please visit our sponsor Siemens (registration required).

What does it take for toolmakers to be competitive? What can mold makers do to improve their business?

Tech-Clarity's eBook, Breaking the Mold: How Toolmakers Are Transforming Operations to Stay Competitive explores these questions. The business of mold making is tough. Firstly, there is the time consuming bidding process where you need to provide an accurate, yet competitively priced bid and a realistic delivery date. However, many factors impact engineering and manufacturing, such as the quality of the part design, ability to manage cooling, and varied machining requirements. Significant effort is required and even small errors can significantly compromise profit margins. Despite the time and effort, mold makers, according to our survey respondents, only win 52% of the jobs they quote.

After winning the bid, a litany of further challenges await. Poor part designs, bottlenecks, complexity, changes, and more create obstacles to every business’s goal, profitability. How can toolmakers transform their operations to become more competitive and boost profitability? To answer this question, Tech-Clarity surveyed over 370 mold makers. This report reveals the results and provides recommendations to improve your business.

Please enjoy the summary* below. For the full report, please visit our sponsor Siemens (registration required).

TABLE OF CONTENTS

- What It Takes to Be Competitive

- Challenges that Hold Mold Makers Back

- Identifying Best Practices

- Strategies to Overcome the Challenges

- Challenges with the End-to-End Process

- Supporting the End-to-End Process

- Streamline Bidding

- Support Collaboration During Tool Design

- Ensure Quality by Verifying Manufacturability

- Optimize Cycle Time

- Automate Production Planning

- Support Quality Verification Processes

- Use an Integrated Solution

- Looking to the Future

- Recommendations and Conclusions

- About the Research

- Acknowledgments

What It Takes to Be Competitive

Objectives for Competitiveness

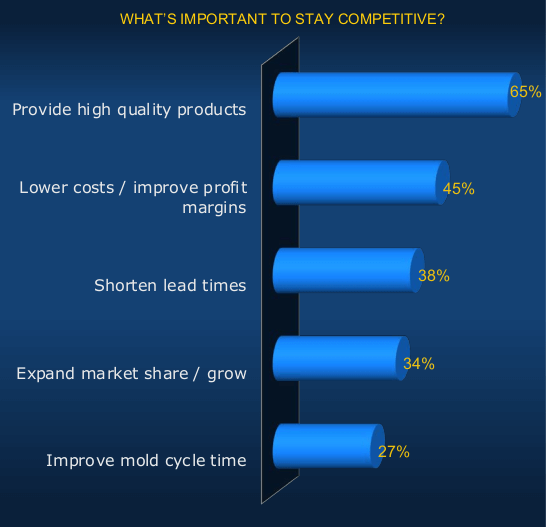

How can you become even more competitive? Where should you focus? The graph shows the top five areas. At a high level, it is about keeping customers happy.

Quality

Ensuring the quality of your molds and the resulting parts can help you stand out from other mold shops. It gives customers a reason to do business with you. High quality helps you earn their loyalty because they know they'll be able to rely on you. However, injection molding is so complex, it is hard to predict exactly what will happen, so having the right systems and processes in place will help you catch problems as early as possible to ensure quality.

Cost

Cost is also critical. If you can keep your costs low, you can afford to be price competitive without compromising your profit margins. However, as with quality, you need to catch potential problems as early as possible to avoid expensive mold rework. Efficiency will also help keep development costs down.

Speed

Efficiency also helps you meet delivery dates. Customers desire short lead times, so removing bottlenecks will help you win more bids. Shorter cycle times also help. Shaving just a couple of seconds off can save your customer tens or even hundreds of thousands of dollars. That’s certainly a reason for a customer to want to work with you!

Market Share and Cycle Time

The more customers you win over, the bigger your market share, which will boost your visibility and reputation to help you win even more business.

Objectives for Competitiveness

How can you become even more competitive? Where should you focus? The graph shows the top five areas. At a high level, it is about keeping customers happy.

Quality

Ensuring the quality of your molds and the resulting parts can help you stand out from other mold shops. It gives customers a reason to do business with you. High quality helps you earn their loyalty because they know they'll be able to rely on you. However, injection molding is so complex, it is hard to predict exactly what will happen, so having the right systems and processes in place will help you catch problems as early as possible to ensure quality.

Cost

Cost is also critical. If you can keep your costs low, you can afford to be price competitive without compromising your profit margins. However, as with quality, you need to catch potential problems as early as possible to avoid expensive mold rework. Efficiency will also help keep development costs down.

Speed

Efficiency also helps you meet delivery dates. Customers desire short lead times, so removing bottlenecks will help you win more bids. Shorter cycle times also help. Shaving just a couple of seconds off can save your customer tens or even hundreds of thousands of dollars. That’s certainly a reason for a customer to want to work with you!

Market Share and Cycle Time

The more customers you win over, the bigger your market share, which will boost your visibility and reputation to help you win even more business.

Conclusions

The Opportunity for Mold Makers Mold makers need to keep customers happy to stay competitive. Consequently, they need to ensure the quality of the mold, the parts it produces, manage costs, and meet delivery dates. Unfortunately, several challenges make meeting their objectives difficult. Global competition is fierce, skilled workers are hard to find, and margins continue to thin. To overcome this, Top Performing mold makers support an end-to-end process with better collaboration and improved hand-offs between the different phases of the group. When looking at the end-to-end process, most toolmakers struggle with process bottlenecks and managing changes. By creating a digital thread across the entire process, there is traceability across the complete life-cycle. Design details can then be reused from one phase to the next, saving time by avoiding duplication of efforts, improving quality by reducing risks for introducing human error, and saving costs by catching problems sooner.Recommendations

Recommendations and Next Steps Based on this research and our experience, we recommend that Automotive companies:

Based on this research and our experience, we recommend that Automotive companies:

- Streamline bidding

- Support collaboration during tool design

- Ensure quality by verifying manufacturability

- Optimize cycle time

- Automate production planning

- Support quality verification processes

- An integrated platform can help

Do your design tools hold product development back? With the pressures of global competition, and the never-ending struggle of bringing innovative, cost-effective products to market efficiently, a smooth product design process is paramount. Unfortunately, the vast majority of companies, 99%, report they experience design bottlenecks that hold them back, which consequently hurts their success and diminishes their profitability.

Tech-Clarity's research report, Empower Engineers with Cutting Edge Design Tools studied this further. The findings reveal an inherent deficiency in today’s design environments hurts collaboration across design teams, especially when they are geographically distributed or involve third-parties. On the other hand, modern infrastructures take advantage of the latest innovations to enable a smooth flow of information across locations and provide the competitive advantage businesses need to succeed.

By surveying 240 companies, Tech-Clarity has identified the primary sources of bottlenecks in the design process and their impacts on the company. A startling 99% reported that design bottlenecks can negatively affect the company in numerous ways, including delayed time-to-market, excess cost, and poor quality. This report explores these issues further and identifies how to solve the challenges associated with design bottlenecks.

Please enjoy the summary* below. For the full report, please visit our sponsor SOLIDWORKS (registration required).

Do your design tools hold product development back? With the pressures of global competition, and the never-ending struggle of bringing innovative, cost-effective products to market efficiently, a smooth product design process is paramount. Unfortunately, the vast majority of companies, 99%, report they experience design bottlenecks that hold them back, which consequently hurts their success and diminishes their profitability.

Tech-Clarity's research report, Empower Engineers with Cutting Edge Design Tools studied this further. The findings reveal an inherent deficiency in today’s design environments hurts collaboration across design teams, especially when they are geographically distributed or involve third-parties. On the other hand, modern infrastructures take advantage of the latest innovations to enable a smooth flow of information across locations and provide the competitive advantage businesses need to succeed.

By surveying 240 companies, Tech-Clarity has identified the primary sources of bottlenecks in the design process and their impacts on the company. A startling 99% reported that design bottlenecks can negatively affect the company in numerous ways, including delayed time-to-market, excess cost, and poor quality. This report explores these issues further and identifies how to solve the challenges associated with design bottlenecks.

Please enjoy the summary* below. For the full report, please visit our sponsor SOLIDWORKS (registration required).

TABLE OF CONTENTS

- The Reality of Today’s Product Development Environment

- Understand Collaboration Needs

- Silos Create a Barrier to Collaboration

- Understand Bottlenecks

- Impact of Bottlenecks

- Explore Solutions to Overcome Bottlenecks

- Use Technology to Solve the Problem

- CAD on the Cloud

- Do Not Underestimate Security Concerns with Existing Infrastructure

- Conclusions

- Recommendations

- About the Research

- Acknowledgments

The Reality of Today’s Product Development Environment

Staying Competitive

To successfully develop competitive products, companies must focus on a variety of factors, especially product performance, innovation, and quality. Achieving this falls on the shoulders of engineers, but juggling so many different requirements makes the job tough. To achieve these goals, product development teams must be empowered to make the best design decisions efficiently. However, several factors stand in the way.

Limitations of Product Development Environments

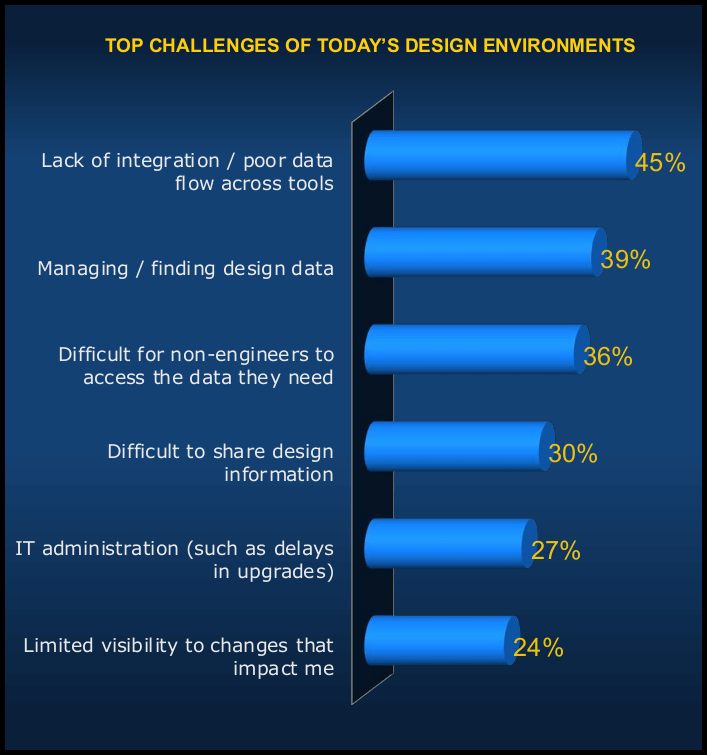

To identify factors that slow down engineers, we asked survey respondents about the top challenges of today's design environments (see graph). Due to all the criteria engineers must think about, they need access to a lot of information. Unfortunately, poor integration across tools makes it hard to find what they need. It also means it’s hard to know about changes that impact other parts of the design. Plus, design information tends to be in a format that is not easy to share nor easy to understand, especially for staff with less technical knowledge. This limits opportunity because when more people provide input, you can explore more ideas. More ideas lead to superior innovation and improvements in usability, quality, and manufacturability. IT limitations also create challenges. It takes time to maintain all the different software tools. Also, hardware investments are costly.

These problems are so widespread, surprisingly, only 5% do not experience challenges with today's design environments. In other words, 95% of companies suffer from design environment challenges that lead to design bottlenecks and collaboration problems. Let's explore these challenges further to understand their impacts.

Staying Competitive

To successfully develop competitive products, companies must focus on a variety of factors, especially product performance, innovation, and quality. Achieving this falls on the shoulders of engineers, but juggling so many different requirements makes the job tough. To achieve these goals, product development teams must be empowered to make the best design decisions efficiently. However, several factors stand in the way.

Limitations of Product Development Environments

To identify factors that slow down engineers, we asked survey respondents about the top challenges of today's design environments (see graph). Due to all the criteria engineers must think about, they need access to a lot of information. Unfortunately, poor integration across tools makes it hard to find what they need. It also means it’s hard to know about changes that impact other parts of the design. Plus, design information tends to be in a format that is not easy to share nor easy to understand, especially for staff with less technical knowledge. This limits opportunity because when more people provide input, you can explore more ideas. More ideas lead to superior innovation and improvements in usability, quality, and manufacturability. IT limitations also create challenges. It takes time to maintain all the different software tools. Also, hardware investments are costly.

These problems are so widespread, surprisingly, only 5% do not experience challenges with today's design environments. In other words, 95% of companies suffer from design environment challenges that lead to design bottlenecks and collaboration problems. Let's explore these challenges further to understand their impacts.

RECOMMENDATIONS

Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:

- Invest in product development to improve competitiveness and boost profitability.

- Understand how challenges in the design environment contribute to collaboration challenges and bottlenecks.

- Do not underestimate the business cost of collaboration challenges.

- Consider options that allow design data to be shared via a web browser and on any device as a way to improve collaboration.

- Consider a CAD solution on the cloud as a way to overcome design bottlenecks and improve collaboration.

- Do not underestimate security risks in your existing infrastructure. A cloud solution may offer greater security protection.

How can companies achieve faster product development and higher profitability using the cloud? Join Jim Brown on an exciting webcast as he shares four key takeaways from his recent survey of over 300 companies. Jim will be joined by an Onshape founder who will share how Onshape customers take advantage of the cloud to improve product development performance.

Register for Onshape sponsored webcast now. (registration required)

Please also see our related survey results eBook, Accelerating Product Development in the Cloud.

How can companies achieve faster product development and higher profitability using the cloud? Join Jim Brown on an exciting webcast as he shares four key takeaways from his recent survey of over 300 companies. Jim will be joined by an Onshape founder who will share how Onshape customers take advantage of the cloud to improve product development performance.

Register for Onshape sponsored webcast now. (registration required)

Please also see our related survey results eBook, Accelerating Product Development in the Cloud.

Webcast Announcement

The Cloud: 4 Takeaways from New Research The need to innovate quickly to better respond to market and customer needs is more important than ever. Tech-Clarity surveyed more than 300 companies that design and/or manufacture products across a wide range of industries to find out how the cloud can help manufacturers improve their product development to drive higher levels of profitability. In this webinar, you will learn how cloud-native tools enable companies to reduce time wastage and production delays caused by product development challenges. Tech-Clarity’s research lead and an Onshape co-founder will provide some commentary and expand on the more surprising results. [post_title] => Faster Product Development on the Cloud (webcast) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => faster-product-development [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:01 [post_modified_gmt] => 2022-11-15 03:27:01 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=8812 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [14] => WP_Post Object ( [ID] => 8776 [post_author] => 2572 [post_date] => 2020-04-21 11:30:19 [post_date_gmt] => 2020-04-21 15:30:19 [post_content] => How can a company better utilize engineers’ time?

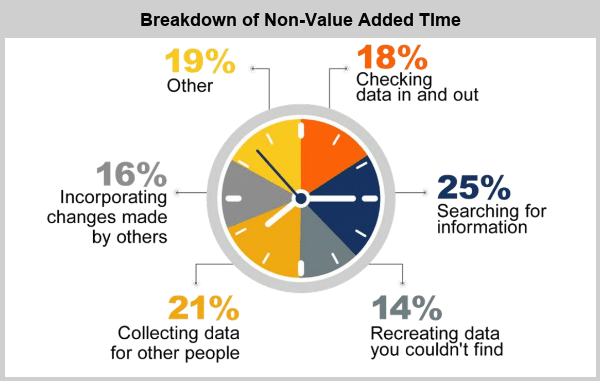

Today's market is hyper competitive; it is hard to stand out. To be successful, companies must empower their engineering teams to focus on product innovation, quality, performance and cost. Balancing those key criteria is challenging enough, but made even more challenging as engineers report they waste a third of their time on non-value added work. Tech-Clarity’s How-To Guide: Avoid Non-Value Added Work For Engineers explores how to overcome this challenge. Based on a survey of nearly 250 manufacturers, the report reveals best practices for managing data, communicating engineering changes, and collaborating with internal and external members of the development team. Together, these practices will help engineers focus more of their effort on making products more competitive.

Please enjoy the summary* below. For the full report, please visit our sponsor Dassault Systèmes (registration required).

How can a company better utilize engineers’ time?

Today's market is hyper competitive; it is hard to stand out. To be successful, companies must empower their engineering teams to focus on product innovation, quality, performance and cost. Balancing those key criteria is challenging enough, but made even more challenging as engineers report they waste a third of their time on non-value added work. Tech-Clarity’s How-To Guide: Avoid Non-Value Added Work For Engineers explores how to overcome this challenge. Based on a survey of nearly 250 manufacturers, the report reveals best practices for managing data, communicating engineering changes, and collaborating with internal and external members of the development team. Together, these practices will help engineers focus more of their effort on making products more competitive.

Please enjoy the summary* below. For the full report, please visit our sponsor Dassault Systèmes (registration required).

TABLE OF CONTENTS

- Identify Bottlenecks

- Assess Non-Value Added Time

- Business Value of Eliminating Non-Value Added Work

- Recognize the Time Required for Check-ins

- Outdated Information Impacts Engineering Changes

- The Impact of Outdated Information on Collaboration

- Identifying the Top Performers

- Technology As a Collaboration Solution

- Consider the Security Risks of Email

- The Benefits of Real-Time Data Updates

- Recommendations

- About the Research

Executive Overview

Engineering Is Key to Competitive Differentiation Today's market is so competitive; it is hard to stand out. To be successful companies must empower their engineering teams to differentiate products on innovation, quality, performance, and cost. While balancing all those criteria can be a challenge, it is made even harder as engineers report they waste a third of their time on non-value added work. Even worse, 20 % of their time is spent working with outdated information, leading to more wasted effort and rework. One way companies can improve this situation is to provide engineers with real-time access to design data, in the right context. The result should be increased engineering bandwidth so engineers can focus more effort on making products more competitive.

Determining Best Practices

To determine best practices for accessing design information, Tech-Clarity analyzed survey responses from nearly 250 manufacturers to understand how they manage data, communicate engineering changes, and collaborate with both internal and external members of the development team.

The research shows that companies who are most successful, Top Performers, are nearly 2-times more likely to maintain up-to-date models. PDM/PLM makes these real-time updates possible.

What Can You Learn from This Research?

% of their time is spent working with outdated information, leading to more wasted effort and rework. One way companies can improve this situation is to provide engineers with real-time access to design data, in the right context. The result should be increased engineering bandwidth so engineers can focus more effort on making products more competitive.

Determining Best Practices

To determine best practices for accessing design information, Tech-Clarity analyzed survey responses from nearly 250 manufacturers to understand how they manage data, communicate engineering changes, and collaborate with both internal and external members of the development team.

The research shows that companies who are most successful, Top Performers, are nearly 2-times more likely to maintain up-to-date models. PDM/PLM makes these real-time updates possible.

What Can You Learn from This Research?

This report explores best practices for streamlining access to design data in real-time. It also exposes some challenges manufacturers should be aware of as they strive to maintain a competitive edge in today's complex and cutthroat environment. The report also reveals how manufacturers can plan for a design environment that will prepare them for long-term competitiveness.

This report explores best practices for streamlining access to design data in real-time. It also exposes some challenges manufacturers should be aware of as they strive to maintain a competitive edge in today's complex and cutthroat environment. The report also reveals how manufacturers can plan for a design environment that will prepare them for long-term competitiveness.

RECOMMENDATIONS

Next Steps Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Understand how engineers spend their time and improve processes to minimize time wasted on non-value added work

- Consider solutions such as PLM or PDM to centralize design information and support change management and collaboration

- Evaluate options to design in the context of the assembly to improve collaboration and understand the impact of changes

- Consider real-time updates to keep CAD data up-to-date while minimizing or eliminating check-in times

- Establish means for secure, real-time collaboration with third parties to minimize delays in getting updated CAD data from them

What should you think about when selecting a software solution to support the development of medical devices while considering the Case for Quality and the EU MDR?

Tech-Clarity’s Medical Device Manufacturers' Software Selection Guide helps manufacturers identify the right buying criteria for software solutions to support developing, producing, and servicing medical devices. The guide also includes additional considerations for utilizing the Internet of Things (IoT) and other technological advancements such as augmented reality (AR) and 3D printing. Unique needs for medical device companies are also taken into account in the buyer’s guide, including regulatory compliance and support for the FDA’s Case for Quality and the European Union Medical Design Regulation (EU MDR).

Tech-Clarity’s Buyer’s Guides go beyond software functionality to provide a framework of requirements that impact implementation success and long-term ROI, including:

What should you think about when selecting a software solution to support the development of medical devices while considering the Case for Quality and the EU MDR?

Tech-Clarity’s Medical Device Manufacturers' Software Selection Guide helps manufacturers identify the right buying criteria for software solutions to support developing, producing, and servicing medical devices. The guide also includes additional considerations for utilizing the Internet of Things (IoT) and other technological advancements such as augmented reality (AR) and 3D printing. Unique needs for medical device companies are also taken into account in the buyer’s guide, including regulatory compliance and support for the FDA’s Case for Quality and the European Union Medical Design Regulation (EU MDR).