How well is collaboration working in the AEC industry? We surveyed 393 people whose companies design, engineer, or construct the built environment to find out about collaborative design in AEC, including multidisciplinary design and BIM. Please enjoy the summary* below. For the full research, please visit our sponsor Graphisoft (registration required). Table of Contents Profitability…

- Profitability Demands Compelling Yet Efficient Design

- Communication and Complexity are Top Challenges

- Design Complexity is Growing

- Complexity Requires Multidisciplinary Collaboration

- Current Collaboration Has Room to Improve

- Importance of Design Integration

- Integration Approaches are Insufficient

- BIM as a Solution for Design Integration

- BIM is Maturing to Become the System of Record

- Importance of Design Integration Approaches

- Companies are Adopting Multidisciplinary Design

- Multidisciplinary Design Provides Valuable Benefits

- Perspectives on Multidisciplinary Design

- Multidisciplinary Design Faces Challenges

- Challenges Lead to Business Impacts

- Value of a Single BIM Authoring Environment

- Views on a Single BIM Authoring Environment

- IPD is Growing and Requires Multidisciplinary Design

- Fear of Trading off Capabilities

- Conclusions

- About the Research

- Acknowledgments

Executive Summary

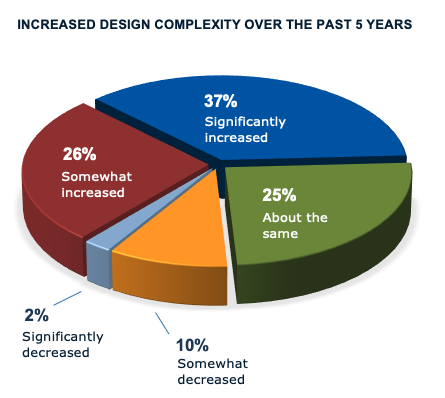

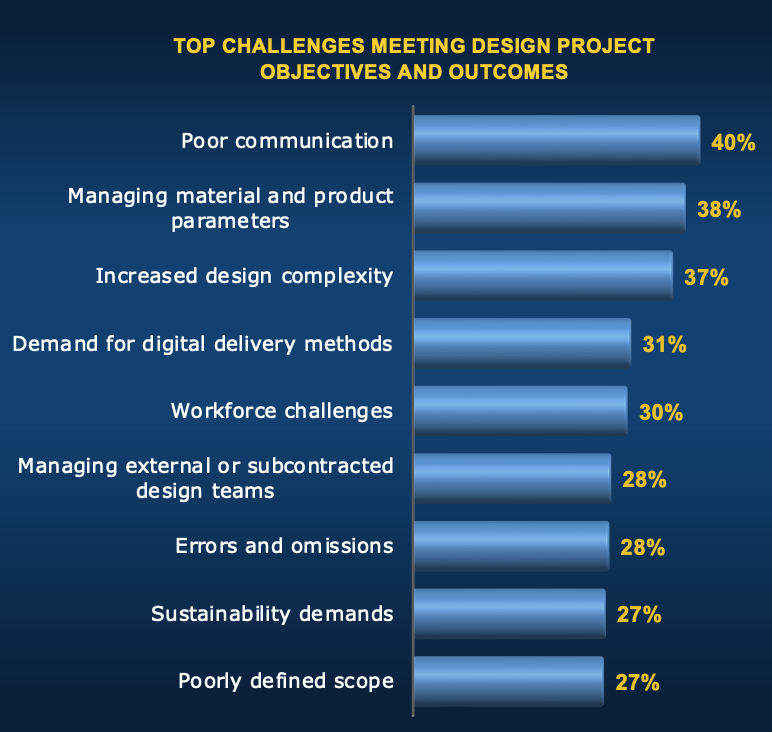

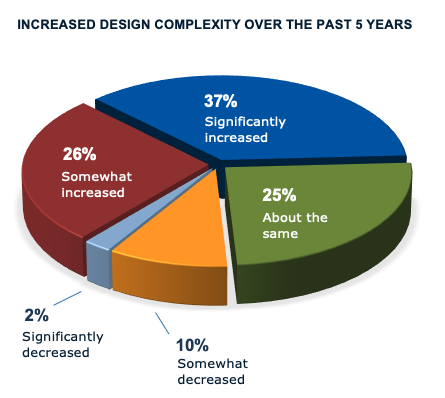

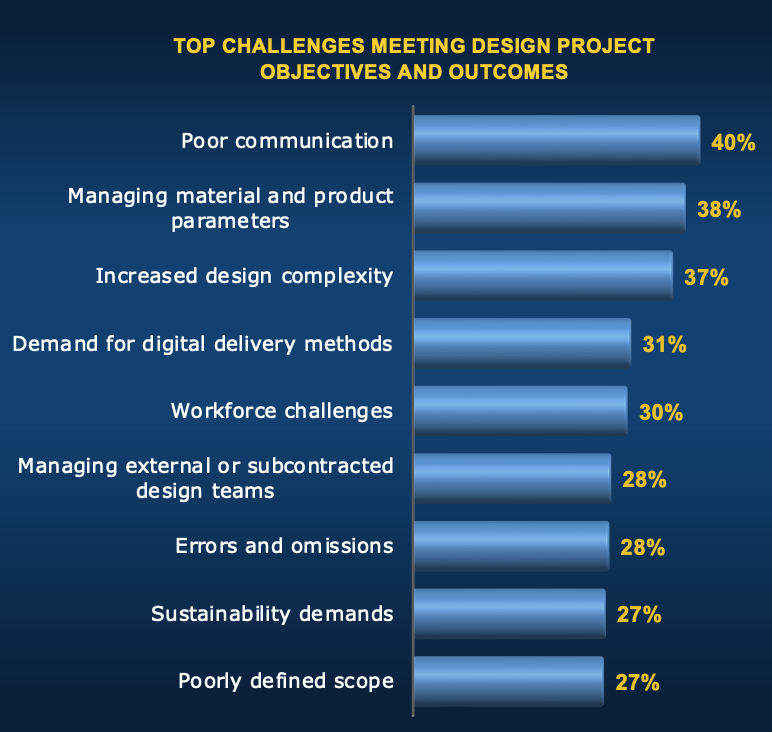

Collaboration Design in AEC Our survey investigated the current state of collaboration and multidisciplinary design in the AEC community. The research focused on current approaches to collaboration, the readiness to adopt advanced design tools, and how these factors impact project success and profitability. The study focused primarily on the design and design coordination phase of the full built-project lifecycle and does not significantly include the experience of the construction community. About three-quarters (72%) of the research respondents are architects and the vast majority of companies offer architectural and/or engineering services. The study shows that architects must design concepts with strong aesthetics and build their company reputation while also recognizing the need to meet practical project objectives like project cost and schedule. Unfortunately, poor communication and increased design complexity, which emerged as two of the most common challenges to meeting project objectives and outcomes, make this difficult. Beyond this, almost two-thirds of survey respondents report that design complexity has increased over the last five years.

Insufficient Collaboration and Design Integration Approaches

Designers recognize that working collaboratively across disciplines helps manage increased design complexity. However, the most common forms of collaboration include email, in-person meetings, PDFs, and hard-copy sheets. These methods are inefficient and error-prone. In addition, despite the fact that about two-thirds of respondents report that design integration across disciplines is critical or important to project success, the design integration approaches they typically use, like collecting 2D or printed documents, are also insufficient.

The study shows that architects must design concepts with strong aesthetics and build their company reputation while also recognizing the need to meet practical project objectives like project cost and schedule. Unfortunately, poor communication and increased design complexity, which emerged as two of the most common challenges to meeting project objectives and outcomes, make this difficult. Beyond this, almost two-thirds of survey respondents report that design complexity has increased over the last five years.

Insufficient Collaboration and Design Integration Approaches

Designers recognize that working collaboratively across disciplines helps manage increased design complexity. However, the most common forms of collaboration include email, in-person meetings, PDFs, and hard-copy sheets. These methods are inefficient and error-prone. In addition, despite the fact that about two-thirds of respondents report that design integration across disciplines is critical or important to project success, the design integration approaches they typically use, like collecting 2D or printed documents, are also insufficient.

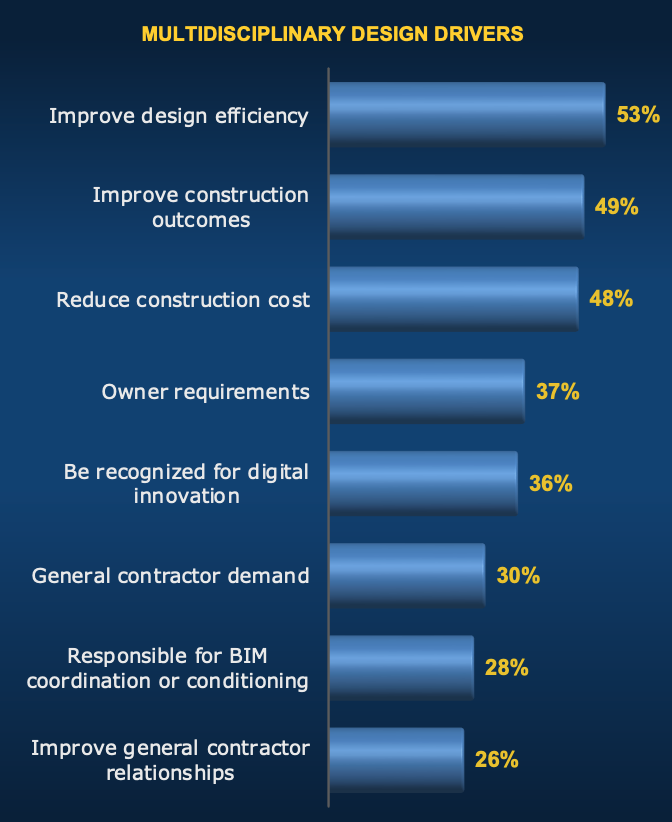

The Multidisciplinary Design Opportunity

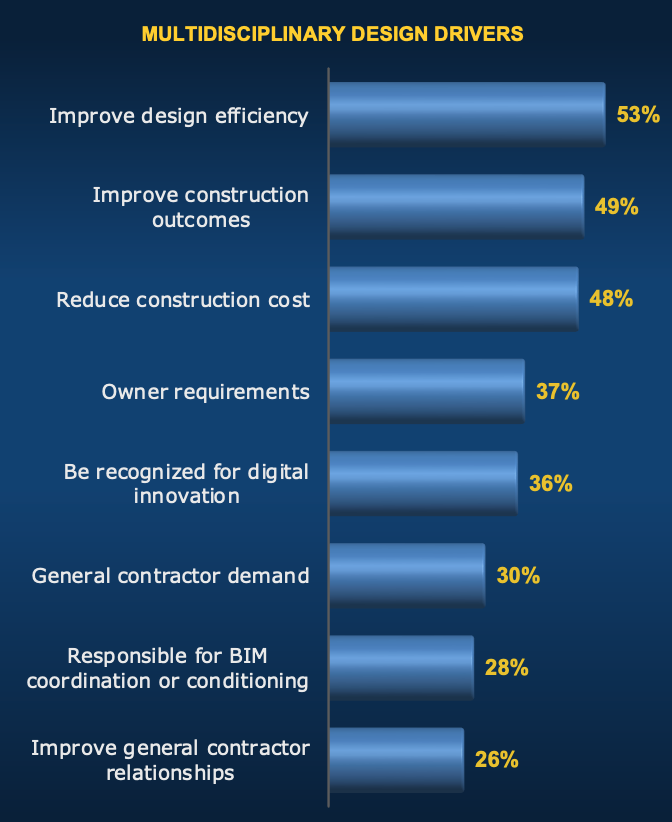

Although the AEC industry faces increased complexity, the design and construction community has been hesitant to adopt new technologies and integrated data platforms. Our research shows, however, that surveyed companies are exploring and migrating to multidisciplinary design to drive efficiency, improve project outcomes, and reduce cost (among other drivers).

Multidisciplinary design marries the efforts of different disciplines into a cohesive process. This increases efficiency and provides impact visibility to designers. They can assess the impacts of choices on a design's cost, more efficiently deal with clashes and geometric constraints, and better tackle complexity driven by code upgrades, material improvements, and energy performance.

The Multidisciplinary Design Transition

The study finds that full multidisciplinary design adoption is still relatively low in the architecture and engineering community, with only 22% of respondents using it on all projects. But about two-thirds of respondents have a positive perception of this methodology, and over one-half of companies are using it on at least some projects.

Although there are barriers to adoption, including organizational, technical, and business concerns, companies report valuable benefits. Over two-thirds of companies who have adopted multidisciplinary design for all projects report more complete designs and fewer errors and omissions. About one-half report increased efficiency and improved constructability. The opportunities are compelling and available. The eBook shares the full details of our findings.

The Multidisciplinary Design Opportunity

Although the AEC industry faces increased complexity, the design and construction community has been hesitant to adopt new technologies and integrated data platforms. Our research shows, however, that surveyed companies are exploring and migrating to multidisciplinary design to drive efficiency, improve project outcomes, and reduce cost (among other drivers).

Multidisciplinary design marries the efforts of different disciplines into a cohesive process. This increases efficiency and provides impact visibility to designers. They can assess the impacts of choices on a design's cost, more efficiently deal with clashes and geometric constraints, and better tackle complexity driven by code upgrades, material improvements, and energy performance.

The Multidisciplinary Design Transition

The study finds that full multidisciplinary design adoption is still relatively low in the architecture and engineering community, with only 22% of respondents using it on all projects. But about two-thirds of respondents have a positive perception of this methodology, and over one-half of companies are using it on at least some projects.

Although there are barriers to adoption, including organizational, technical, and business concerns, companies report valuable benefits. Over two-thirds of companies who have adopted multidisciplinary design for all projects report more complete designs and fewer errors and omissions. About one-half report increased efficiency and improved constructability. The opportunities are compelling and available. The eBook shares the full details of our findings.

Conclusions

Communication is the Biggest Challenge The design and construction industry is highly fragmented. Companies range in size and the cross-section of industry segments they serve. Project

participants often span regional, country, language, and cultural boundaries. Multiple disciplines rarely share common offices, which only exacerbates the challenge of communication. With increasing project complexity and shrinking access to well-trained resources, communication is strained. The industry must uncover ways to become more effective.

Greater Collaboration is the Key

Architecture and engineering companies must increase their ability to effectively collaborate across design disciplines. Traditional collaboration approaches are insufficient. Fortunately, there are proven benefits to digitally integrating designs across disciplines. Typical integration methods must also improve, and the data demonstrates that the AEC design community is moving towards more enhanced collaboration workflows leveraging tools based on BIM. The role of BIM is also maturing to be a system of record. Although the domains of design are vast, our research concludes that companies are exploring and migrating to multidisciplinary design to drive better project outcomes and profitability.

Multidisciplinary Design Remains Novel in the Maturity Cycle

Full multidisciplinary design adoption is still relatively low, but those adopting it are achieving significant benefits. The overall perception of multidisciplinary design and BIM is positive, yet it faces a number of challenges. Most companies are not willing to trade off significant design functionality for those benefits. We expect to see greater adoption of multidisciplinary design as systems mature, but also expect that companies must maintain an open approach to BIM tools to accommodate an environment consisting of multiple authoring tools.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Graphisoft (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => The State of Collaborative Design in AEC

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => collaborative-design-in-aec

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-14 16:18:24

[post_modified_gmt] => 2023-12-14 21:18:24

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18059

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 18011

[post_author] => 2

[post_date] => 2023-03-27 10:00:38

[post_date_gmt] => 2023-03-27 14:00:38

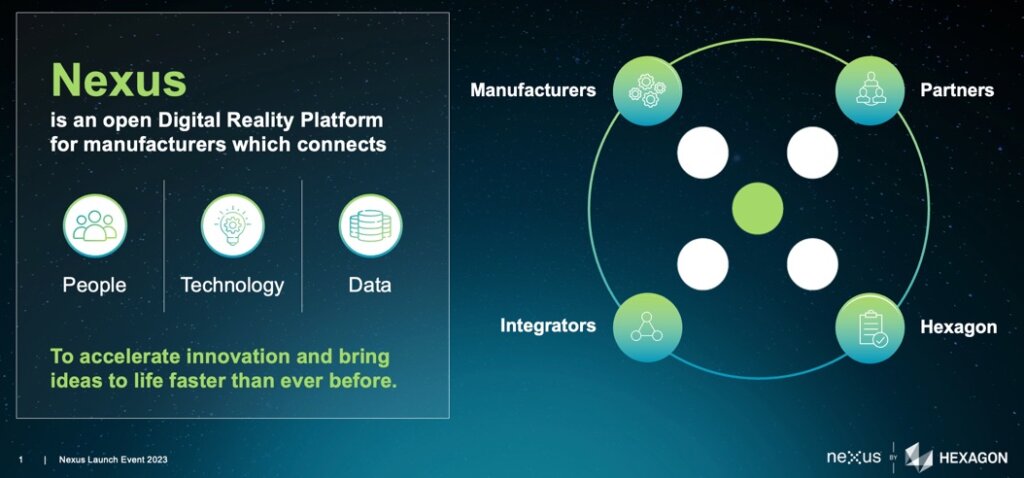

[post_content] => We spoke with Hexagon following a recent event launching their Nexus platform. Hexagon already offers a wide range of solutions supporting the product lifecycle, including design and engineering; production; and metrology and inspection portfolios from its Manufacturing Intelligence division and others including the newly acquired Enterprise Asset Management (EAM) and quality management (QMS, ETQ) solutions. This release gives Hexagon a platform to connect across their solutions, and solutions from others, to execute and automate workflows that cross application boundaries.

They’re taking a data-centric approach to connecting heterogeneous solutions, providing contextual data to streamline across steps in the process and create a common digital thread. Hexagon is calling Nexus a “digital reality platform.” They compare it with a digital twin. They say it’s different, though, because it is connected in near-real-time with products and machines to integrate information support automation in addition to user-driven tasks. In their words, Nexus “connects applications, hardware, and anything creating data in a democratized manner.”

An example we explored during our call was an electronics designer changing a printed circuit board in their PCB design tool that would share the relevant change with a mechanical designer in the CAD tool. In addition, they pointed out it could autonomously run a simulation in the cloud to validate the resulting change, for example heat exchange. The example helped me grasp the fact that Nexus is intended to share data directly between different applications and tools, not just pass the information to the next user in a traditional workflow. That level of data integration is highly valuable.

The platform provides central services like visualization and analytics and will be offered as Nexus Platform Services. In addition, they’re busy developing Nexus Applications on the platform, including several announced in the launch event and a roadmap of solutions in development. They will also provide partners with the ability to develop applications for Nexus and plan to create an active ecosystem of applications and services offered through Nexus. In the future, they intend to open application development to customers so they can create their own connected workflows.

Hexagon has a wealth of solutions for manufacturers, and now has a platform and strategy that will allow customers to get the most out of them in a connected, data-centric, cloud-based platform. Thank you Stephen Graham and Robin Wolstenholme for taking the time to provide more detail and answer our questions, Michelle Boucher, Julie Fraser, and I appreciated and enjoyed it.

The design and construction industry is highly fragmented. Companies range in size and the cross-section of industry segments they serve. Project

participants often span regional, country, language, and cultural boundaries. Multiple disciplines rarely share common offices, which only exacerbates the challenge of communication. With increasing project complexity and shrinking access to well-trained resources, communication is strained. The industry must uncover ways to become more effective.

Greater Collaboration is the Key

Architecture and engineering companies must increase their ability to effectively collaborate across design disciplines. Traditional collaboration approaches are insufficient. Fortunately, there are proven benefits to digitally integrating designs across disciplines. Typical integration methods must also improve, and the data demonstrates that the AEC design community is moving towards more enhanced collaboration workflows leveraging tools based on BIM. The role of BIM is also maturing to be a system of record. Although the domains of design are vast, our research concludes that companies are exploring and migrating to multidisciplinary design to drive better project outcomes and profitability.

Multidisciplinary Design Remains Novel in the Maturity Cycle

Full multidisciplinary design adoption is still relatively low, but those adopting it are achieving significant benefits. The overall perception of multidisciplinary design and BIM is positive, yet it faces a number of challenges. Most companies are not willing to trade off significant design functionality for those benefits. We expect to see greater adoption of multidisciplinary design as systems mature, but also expect that companies must maintain an open approach to BIM tools to accommodate an environment consisting of multiple authoring tools.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Graphisoft (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => The State of Collaborative Design in AEC

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => collaborative-design-in-aec

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-14 16:18:24

[post_modified_gmt] => 2023-12-14 21:18:24

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18059

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 18011

[post_author] => 2

[post_date] => 2023-03-27 10:00:38

[post_date_gmt] => 2023-03-27 14:00:38

[post_content] => We spoke with Hexagon following a recent event launching their Nexus platform. Hexagon already offers a wide range of solutions supporting the product lifecycle, including design and engineering; production; and metrology and inspection portfolios from its Manufacturing Intelligence division and others including the newly acquired Enterprise Asset Management (EAM) and quality management (QMS, ETQ) solutions. This release gives Hexagon a platform to connect across their solutions, and solutions from others, to execute and automate workflows that cross application boundaries.

They’re taking a data-centric approach to connecting heterogeneous solutions, providing contextual data to streamline across steps in the process and create a common digital thread. Hexagon is calling Nexus a “digital reality platform.” They compare it with a digital twin. They say it’s different, though, because it is connected in near-real-time with products and machines to integrate information support automation in addition to user-driven tasks. In their words, Nexus “connects applications, hardware, and anything creating data in a democratized manner.”

An example we explored during our call was an electronics designer changing a printed circuit board in their PCB design tool that would share the relevant change with a mechanical designer in the CAD tool. In addition, they pointed out it could autonomously run a simulation in the cloud to validate the resulting change, for example heat exchange. The example helped me grasp the fact that Nexus is intended to share data directly between different applications and tools, not just pass the information to the next user in a traditional workflow. That level of data integration is highly valuable.

The platform provides central services like visualization and analytics and will be offered as Nexus Platform Services. In addition, they’re busy developing Nexus Applications on the platform, including several announced in the launch event and a roadmap of solutions in development. They will also provide partners with the ability to develop applications for Nexus and plan to create an active ecosystem of applications and services offered through Nexus. In the future, they intend to open application development to customers so they can create their own connected workflows.

Hexagon has a wealth of solutions for manufacturers, and now has a platform and strategy that will allow customers to get the most out of them in a connected, data-centric, cloud-based platform. Thank you Stephen Graham and Robin Wolstenholme for taking the time to provide more detail and answer our questions, Michelle Boucher, Julie Fraser, and I appreciated and enjoyed it.

[post_title] => Hexagon Launches Digital Reality Platform, Nexus (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-reality-platform-hexagon-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-27 14:15:51

[post_modified_gmt] => 2023-03-27 18:15:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18011

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 18019

[post_author] => 2574

[post_date] => 2023-03-24 09:30:46

[post_date_gmt] => 2023-03-24 13:30:46

[post_content] => What are some keys to success with Industry 4.0? And what does mindfulness have to do with it? Listen to this fireside chat with Julie Fraser, hosted by the Industry 4.0 Club’s Mike Ungar and Mike Yost to start thinking about your ecosystem for success.

An ecosystem is the environment in which a variety of compatible organisms - or organizations - coexist. Some elements go together and some do not. For Industry 4.0, each player must review fit and ability to support each other over a longer period of time. Rather than thinking of vendors and customers, moving to view each other as partners is a start.

What does that entail? How can manufacturers identify partners that will truly partner and support them? What can the solution providers do to bolster their customer-partners’ success?

In this video, you’ll get to hear what Julie and the two Mikes think and have seen. You’ll also hear about a trend that’s beyond the “talking about” stage and into the “take action” stage this year. Industry 4.0 technologies will support this earth-level ecosystem issue. Julie also takes some questions from the LinkedIn Live audience.

Thank you, Industry 4.0 Club, for the opportunity to have a conversation on all of this!

[post_title] => Hexagon Launches Digital Reality Platform, Nexus (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-reality-platform-hexagon-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-27 14:15:51

[post_modified_gmt] => 2023-03-27 18:15:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18011

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 18019

[post_author] => 2574

[post_date] => 2023-03-24 09:30:46

[post_date_gmt] => 2023-03-24 13:30:46

[post_content] => What are some keys to success with Industry 4.0? And what does mindfulness have to do with it? Listen to this fireside chat with Julie Fraser, hosted by the Industry 4.0 Club’s Mike Ungar and Mike Yost to start thinking about your ecosystem for success.

An ecosystem is the environment in which a variety of compatible organisms - or organizations - coexist. Some elements go together and some do not. For Industry 4.0, each player must review fit and ability to support each other over a longer period of time. Rather than thinking of vendors and customers, moving to view each other as partners is a start.

What does that entail? How can manufacturers identify partners that will truly partner and support them? What can the solution providers do to bolster their customer-partners’ success?

In this video, you’ll get to hear what Julie and the two Mikes think and have seen. You’ll also hear about a trend that’s beyond the “talking about” stage and into the “take action” stage this year. Industry 4.0 technologies will support this earth-level ecosystem issue. Julie also takes some questions from the LinkedIn Live audience.

Thank you, Industry 4.0 Club, for the opportunity to have a conversation on all of this!

[post_title] => An Ecosystem Enabling Manufacturers and Industry 4.0 Providers to Flourish with Julie Fraser

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ecosystem-for-industry-4-0

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-28 14:12:15

[post_modified_gmt] => 2023-03-28 18:12:15

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18019

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 18001

[post_author] => 2574

[post_date] => 2023-03-21 09:30:11

[post_date_gmt] => 2023-03-21 13:30:11

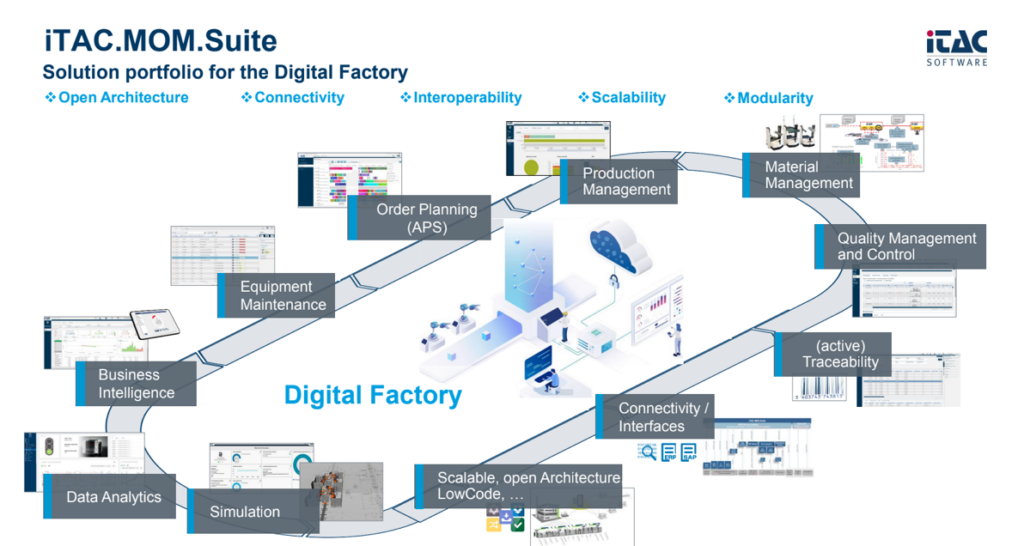

[post_content] => I recently got an update briefing from iTAC Software AG, which was eye-opening. It appears you can now get deep out-of-the-box MES/MOM functionality plus low-code ways to extend the software. This company has offered #MES for many years but has recently expanded on many fronts.

The original company philosophy of bidirectional integration with equipment has served iTAC well in its core discrete industry segments. That’s been strengthened by adding Cogiscan to the iTAC group. Customers have advanced in their ability to be agile and respond to change also, as the group also includes DUALIS GmbH IT Solution advanced planning and scheduling.

Some of the newer functionality is compelling.

[post_title] => An Ecosystem Enabling Manufacturers and Industry 4.0 Providers to Flourish with Julie Fraser

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ecosystem-for-industry-4-0

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-28 14:12:15

[post_modified_gmt] => 2023-03-28 18:12:15

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18019

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 18001

[post_author] => 2574

[post_date] => 2023-03-21 09:30:11

[post_date_gmt] => 2023-03-21 13:30:11

[post_content] => I recently got an update briefing from iTAC Software AG, which was eye-opening. It appears you can now get deep out-of-the-box MES/MOM functionality plus low-code ways to extend the software. This company has offered #MES for many years but has recently expanded on many fronts.

The original company philosophy of bidirectional integration with equipment has served iTAC well in its core discrete industry segments. That’s been strengthened by adding Cogiscan to the iTAC group. Customers have advanced in their ability to be agile and respond to change also, as the group also includes DUALIS GmbH IT Solution advanced planning and scheduling.

Some of the newer functionality is compelling.

- Plant floor logistics with two-way communication to AGVs and AIVs is much-needed in the increasingly automated plant floors iTAC serves.

- Data analytics are designed to work with iTAC’s #IIoT or other IoT platforms. The IIoT.Edge and SMT. Edge products offer AI-based analytics at the edge using algorithms iTAC offers but are also open for customers to develop or use their own algorithms.

[post_title] => iTAC MES/MOM Adds Low-Code, Logistics, and Edge Analytics (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => itac-mes-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-24 14:03:49

[post_modified_gmt] => 2023-03-24 18:03:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18001

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 17975

[post_author] => 2

[post_date] => 2023-03-16 09:00:55

[post_date_gmt] => 2023-03-16 13:00:55

[post_content] =>

[post_title] => iTAC MES/MOM Adds Low-Code, Logistics, and Edge Analytics (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => itac-mes-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-24 14:03:49

[post_modified_gmt] => 2023-03-24 18:03:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18001

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 17975

[post_author] => 2

[post_date] => 2023-03-16 09:00:55

[post_date_gmt] => 2023-03-16 13:00:55

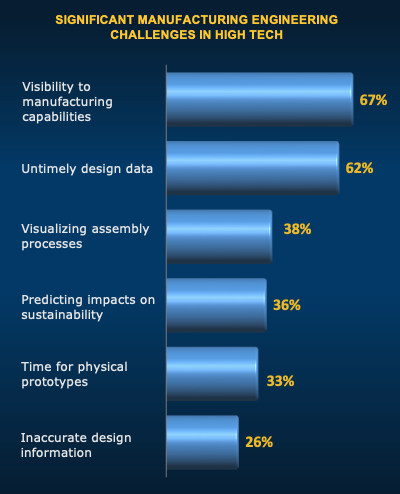

[post_content] =>  How can high tech manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability as customers demand high quality, personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity.

Unfortunately, high tech companies face challenges in process design as products, manufacturing processes, including:

How can high tech manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability as customers demand high quality, personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity.

Unfortunately, high tech companies face challenges in process design as products, manufacturing processes, including:

- Visibility to manufacturing capabilities

- Untimely design data

- Visualizing assembly processes

- Predicting impacts on sustainability

Table of Contents

- Improve Manufacturing Engineering to Increase Profitability

- Address Process Designer Challenges

- Recognize the Opportunity

- Quantify the Potential

- Identify Performance Drivers

- Find Issues Earlier in Design

- Use more 3D and Simulation

- Leverage More Integrated Solutions

- Use More Advanced Communication and Collaboration

- Top Performers Show the Way

- Recommendations and Next Steps

- About the Research

- Acknowledgments

Improve Manufacturing Engineering Performance

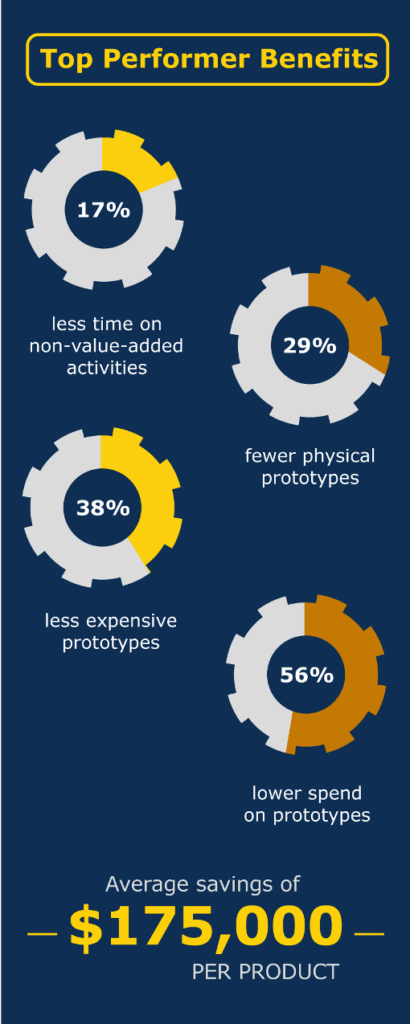

Improve Performance in the Face of Complexity How can high tech manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity. Modernize Manufacturing Engineering Survey results show that Top Performers (see definition in eBook) in manufacturing engineering have increased maturity in the way they plan, validate, and communicate manufacturing operations. These leading companies waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. They accomplish this through best practices, including:- More advanced collaboration and communication methods

- Increased use of 3D and simulation to plan and validate manufacturing operations with virtual, digital twins

Recognize the Opportunity

Manufacturing Engineering is Ready for an Upgrade It’s time for change. Manufacturers must digitalize production planning to reduce cycle times, increase efficiently, and deliver quality. High tech companies need to adopt new techniques to validate manufacturing earlier in the process, in parallel with product design. Current Processes can be Improved

There is significant room for improvement. The majority of companies validate process plans with time-consuming and expensive physical prototyping. Physical prototypes bring abstract designs into the real world so engineers can identify issues and improvement opportunities. Most companies also use spreadsheets, which are prone to errors and file-based so they are not conducive to collaboration. These approaches lead to late discoveries and expensive process validation.

Leverage Visual Approaches

Trading physical prototypes for digital validation reduces time and cost. A significant number of companies already use some form of virtual representations. Static visualizations can help engineers see an issue in the digital world before committing to a physical prototype or manufacturing equipment.

Adopt Simulation

Beyond static images, virtual simulation helps designers go beyond “seeing” to virtually experiencing the production process. While only about one-quarter use either 2D or 3D simulation, it’s a promising technology and a potential for significant planning and validation improvement.

Current Processes can be Improved

There is significant room for improvement. The majority of companies validate process plans with time-consuming and expensive physical prototyping. Physical prototypes bring abstract designs into the real world so engineers can identify issues and improvement opportunities. Most companies also use spreadsheets, which are prone to errors and file-based so they are not conducive to collaboration. These approaches lead to late discoveries and expensive process validation.

Leverage Visual Approaches

Trading physical prototypes for digital validation reduces time and cost. A significant number of companies already use some form of virtual representations. Static visualizations can help engineers see an issue in the digital world before committing to a physical prototype or manufacturing equipment.

Adopt Simulation

Beyond static images, virtual simulation helps designers go beyond “seeing” to virtually experiencing the production process. While only about one-quarter use either 2D or 3D simulation, it’s a promising technology and a potential for significant planning and validation improvement.

Recommendations and Next Steps

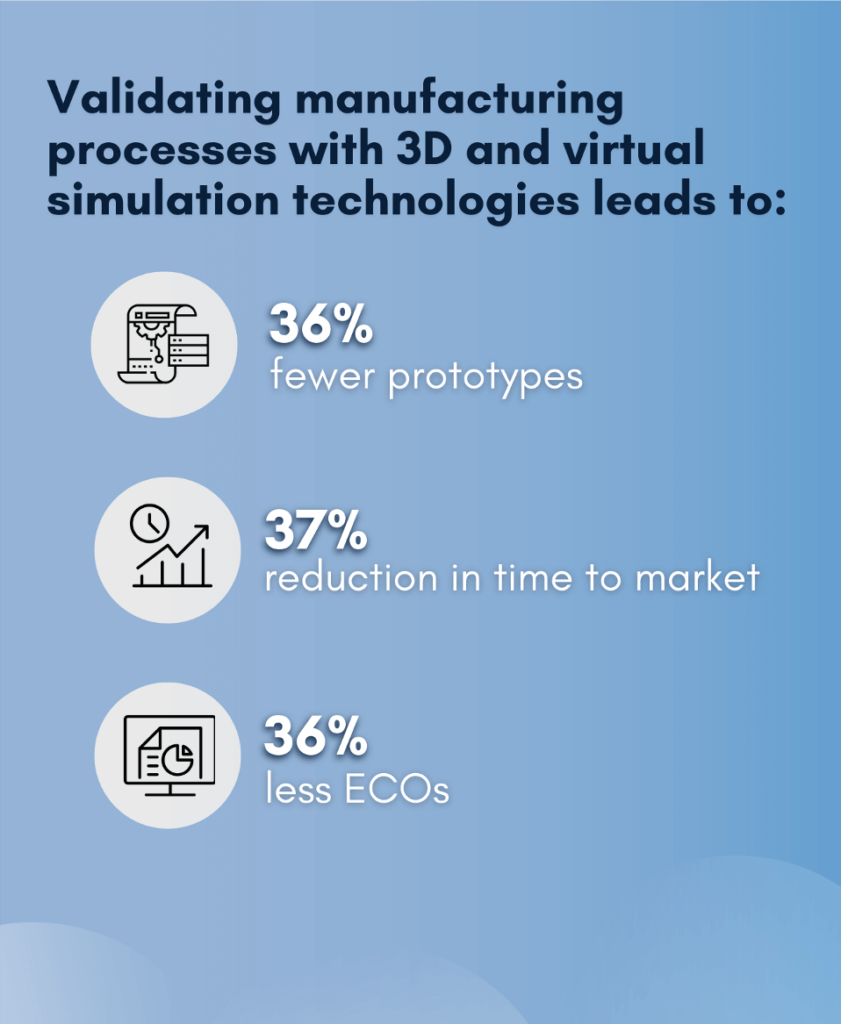

Make a Strategic Improvement Today’s product, manufacturing process, and market complexity demand new ways of working. The Top Performers are transforming manufacturing engineering through digitalization, better collaboration, 3D, and simulation allowing them to overcome efficiency, quality, and cost challenges. Using virtual, digital twins offers manufacturing engineers both the ability to improve their own performance and a strategic opportunity to increase overall product development profitability. These leaders spend 17% less time on non-value-added activities in manufacturing engineering, directly reducing development cycle times. Improve Time to Market Survey respondents report that they can reduce time to market by 37% by using 3D and simulation to plan and validate manufacturing operations. This is done, in part, by increasing efficiency, reducing time-consuming physical prototyping, and lowering rework by finding issues sooner in product development. This is critical in the high tech industry where time to market drives market share and products have such short lifecycles. Reduce Cost Survey respondents share that they can eliminate 36% of their prototypes by increasing manufacturing engineering maturity, leading to significant cost savings per product. They do this by shifting validation and issue identification sooner in the product development process so they need fewer physical prototypes. Increase Quality

Responding companies also indicate that they can reduce ECOs by over one-third. They do this by improving manufacturing process design using virtual technologies. Top Performers are more likely to find physical manufacturing issues in a virtual model than Others who are more likely to discover them in physical prototypes and actual production.

Get Started

It’s time to improve manufacturing engineering productivity and performance. Companies can follow the lead of the Top Performers to increase maturity in how they plan, validate, and communicate manufacturing plans. To increase maturity, manufacturers should adopt the best practices of the Top Performers, including using integrated solutions such as 3D and simulation for manufacturing engineering.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Transforming High Tech Manufacturing Engineering

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => high-tech-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-30 13:57:06

[post_modified_gmt] => 2024-01-30 18:57:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17975

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 17918

[post_author] => 2

[post_date] => 2023-03-14 09:00:18

[post_date_gmt] => 2023-03-14 13:00:18

[post_content] =>

Increase Quality

Responding companies also indicate that they can reduce ECOs by over one-third. They do this by improving manufacturing process design using virtual technologies. Top Performers are more likely to find physical manufacturing issues in a virtual model than Others who are more likely to discover them in physical prototypes and actual production.

Get Started

It’s time to improve manufacturing engineering productivity and performance. Companies can follow the lead of the Top Performers to increase maturity in how they plan, validate, and communicate manufacturing plans. To increase maturity, manufacturers should adopt the best practices of the Top Performers, including using integrated solutions such as 3D and simulation for manufacturing engineering.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Transforming High Tech Manufacturing Engineering

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => high-tech-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-30 13:57:06

[post_modified_gmt] => 2024-01-30 18:57:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17975

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 17918

[post_author] => 2

[post_date] => 2023-03-14 09:00:18

[post_date_gmt] => 2023-03-14 13:00:18

[post_content] =>  Why is effective bill of material management critical to digital transformation? What should you look for in a BOM management solution? Our white paper serves as a reference tool for manufacturers selecting a system to improve the maturity of their BOM management practices.

Please enjoy the summary* below. For the full buyer's guide please visit our sponsor, PTC (registration required).

This white paper is an update to our original buyer's guide published in 2020.

Why is effective bill of material management critical to digital transformation? What should you look for in a BOM management solution? Our white paper serves as a reference tool for manufacturers selecting a system to improve the maturity of their BOM management practices.

Please enjoy the summary* below. For the full buyer's guide please visit our sponsor, PTC (registration required).

This white paper is an update to our original buyer's guide published in 2020.

Table of Contents

- Introducing the Buyer's Guide

- Diagnosing BOM Management Issues

- The BOM Management Status Quo

- The BOM Management Business Case

- Analyze BOM Management Solution Capabilities

- Assess Service Requirements

- Consider Vendor Requirements

- Special Considerations

- Conclusions

- Recommendations

- Acknowledgments

- About the Author

Introducing the Buyer's Guide

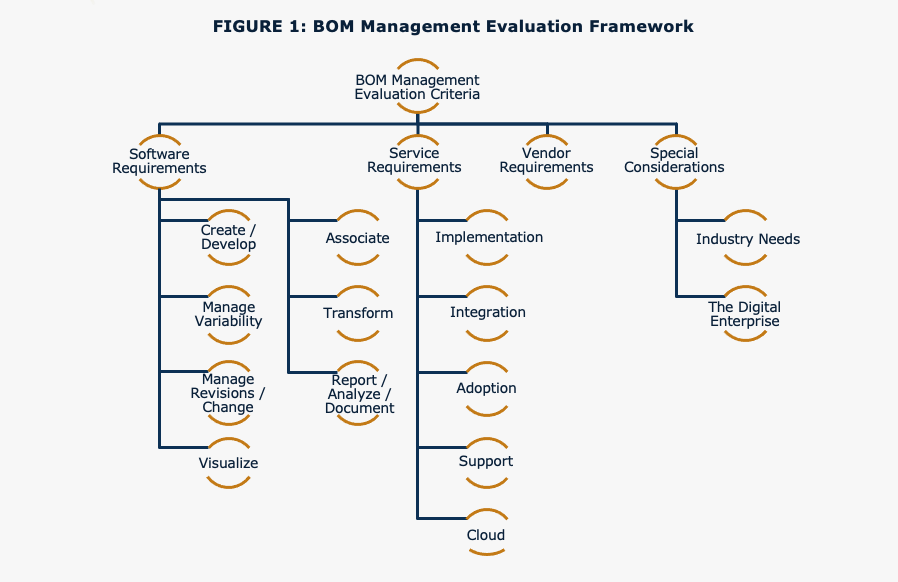

Managing Bills of Material (BOMs) is a fundamental need for any manufacturer. Without effective control of product structures, companies struggle with inefficiency and errors. On the other hand, improving the maturity of BOM-related processes helps manage complexity, increase product personalization, improve efficiency, prevent mistakes, and enhance collaboration across departments and the supply chain. The resulting benefits can be strategic, leading to increased innovation, agility, and faster time to market that impact top-line financial performance. BOM management is now essential as the foundation for the digital enterprise and serves as the backbone of the digital twin. Effective BOM management is also critical for manufacturers to confidently change products to adapt to market challenges like chip shortages and supply chain disruption. This Buyer’s Guide is a reference tool for manufacturers selecting a system to improve the maturity of their BOM management practices. The guide is composed of sections covering software, service, and vendor requirements, along with some special considerations. These are all important factors that impact implementation success and ROI.

Each of these sections includes a checklist with key requirements to investigate when selecting software to enable and improve BOM management. The guide also touches on special considerations for companies to keep an eye on by industry. It also shows how digital BOM management plays a critical role in supporting digital transformation initiatives, including the digital twin, digital thread service transformation, Industry 4.0, and more.

This Buyer’s Guide is a reference tool for manufacturers selecting a system to improve the maturity of their BOM management practices. The guide is composed of sections covering software, service, and vendor requirements, along with some special considerations. These are all important factors that impact implementation success and ROI.

Each of these sections includes a checklist with key requirements to investigate when selecting software to enable and improve BOM management. The guide also touches on special considerations for companies to keep an eye on by industry. It also shows how digital BOM management plays a critical role in supporting digital transformation initiatives, including the digital twin, digital thread service transformation, Industry 4.0, and more.

Analyzing BOM Management Solution Capabilities

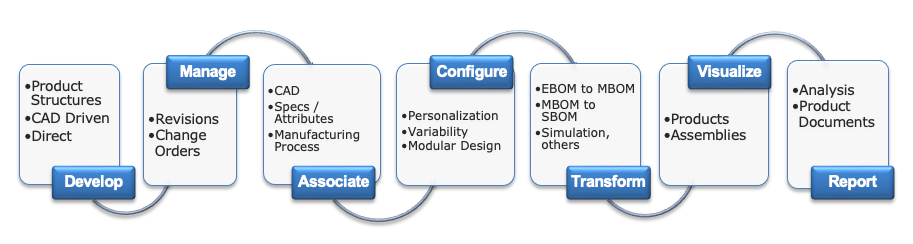

Perhaps the most obvious place to start when evaluating new software solutions is functionality. This section covers multiple types and uses of product structures, including Engineering BOMs (EBOM), Manufacturing BOMs (MBOM), Service BOMs (SBOM), and others such as those used for simulation or compliance analysis. For the purposes of this analysis, we’ve broken BOM management into seven main focus areas:- Developing product structures

- Managing revisions and change

- Supporting product variability

- Associating information

- Transforming BOMs

- Visualizing products

- Reporting, analyzing, documenting

- Controlling and securing product-related data

- Quickly finding and reusing information

- Sharing product knowledge with other departments (and beyond enterprise boundaries)

Clearly, a user should be able to enter a BOM manually from a screen by selecting a combination of materials, components, or lower-level assemblies. Systems should also be able to accept and validate an input file, for example, a spreadsheet or XML file, to import / upload BOMs from another system or in a “mass load” scenario. Finally, the system should be able to develop BOMs from underlying engineering tools for efficiency and to prevent manual transcription errors, also known as the “bottom-up” approach.

Of these, the most complex scenario is the bottoms up creation from a Computer Aided Design (CAD) tool. This scenario requires the BOM management solution to digitally interpret the contents of the CAD structure. CAD systems typically contain a lot of information about a product, making good CAD integration a primary need.

Clearly, a user should be able to enter a BOM manually from a screen by selecting a combination of materials, components, or lower-level assemblies. Systems should also be able to accept and validate an input file, for example, a spreadsheet or XML file, to import / upload BOMs from another system or in a “mass load” scenario. Finally, the system should be able to develop BOMs from underlying engineering tools for efficiency and to prevent manual transcription errors, also known as the “bottom-up” approach.

Of these, the most complex scenario is the bottoms up creation from a Computer Aided Design (CAD) tool. This scenario requires the BOM management solution to digitally interpret the contents of the CAD structure. CAD systems typically contain a lot of information about a product, making good CAD integration a primary need.

Conclusion

BOM management helps manage complexity and streamline operations. It provides an important, foundational element that serves as the backbone for all engineering, manufacturing, and service activity. An accessible, trusted source of product structure information is valuable and improves traceability and control. Effective BOM management provides enterprise-level benefits, improving business performance and alleviating disconnects across the business. The net result is efficiency and cost gains combined with revenue improvement from better collaboration and faster time to market, making BOM management an essential operational tool and a key driver of improved profitability. Supporting BOM management at the enterprise level requires the right solution. Companies should develop a requirements list that helps encourage a holistic decision encompassing software functionality, service-related needs, vendor requirements, and any special considerations based on their industry, size, and product strategy. Finally, the plan should look beyond current needs to support the digital future where the Digital Twin, Digital Thread, AR, VR, and IoT rely on sound BOM information.Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Think big, but remain agile and take BOM management improvement in steps

- Recognize the importance of accurate, complete, timely, and accessible product structures

- Develop a comprehensive, multidiscipline, and multi-CAD BOM management capability

- Look for functionality, but extend requirements to vendor and service considerations

- Look for a Cloud / SaaS solution to reduce risk, ease adoption, and ensure vendor market competitiveness

- Consider any special needs for your business, industry, or geography

- Provide the foundation for the digital enterprise to compete today and into the future

- Get started

Product Updates in Onshape

David also shared an overview of some of their key product releases over the last year, including: PCB Studio: Supports concurrent ECAD and MCAD design.- Render Studio: Offers photorealistic imagery

- Onshape Simulation: Gives design engineers easy access to structural analysis during design

- Frames: Enables quick design of structural frames

- Variables Studios: Provides a way to define and modify common variables across parts and assemblies

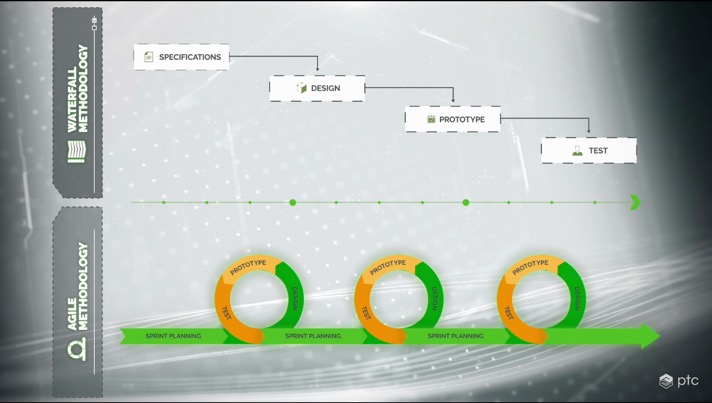

Agile Product Development

Jon Hirschtick shared his perspective as well. He stressed that they see much interest from companies looking to apply the Agile Methodology they use for software development to hardware (see graphic below). He cited trends driving this interest include:- Product development tools have evolved

- The new generation workforce wants to work in a more agile way

- The pace of change is so significant, companies need new methodologies to allow them to quickly adapt and pivot

Simulation in Onshape

I believe their approach to simulation could also be a key enabler for Agile. With it, design engineers do not have to worry about translating or meshing their model, and the software already understands assembly constraints. Consequently, design engineers, including those unfamiliar with simulation, can apply loads and view the results. Our research consistently shows that the activities involved with preprocessing, particularly defining the mesh, are one of the biggest bottlenecks for design engineers’ use of simulation. Onshape’s approach automates much of this, making it easier to adopt. Since Onshape Simulation is cloud-based, the processing is done on the cloud, without slowing down the engineer’s workstation. Another engineer can pull up the model and make changes, and the engineers can work together to evaluate the results. With this approach, the potential for supporting the Agile Methodology during short sprints of design, prototype, and test looks very powerful. I look forward to seeing the new developments in 2023. Thanks to Coray Thibaut de Maisieres and the Onshape team for putting on a great event. [post_title] => Onshape Live 23 Reveals Significant Progress

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => onshape-live-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 12:39:02

[post_modified_gmt] => 2023-12-15 17:39:02

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17946

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 17938

[post_author] => 2574

[post_date] => 2023-03-08 09:00:52

[post_date_gmt] => 2023-03-08 14:00:52

[post_content] => There is more exciting news from GE Digital on its newest Proficy MES version. In a previous discussion, we learned that all of the GE Smart Factory Portfolio are becoming available not only on-premises but also on cloud or hybrid. As a fully-hosted managed service for MES-as-a-Service, MES can always be up to date with improvements from lean or continuous improvement (CI) efforts. GE claims up to 30% lower total cost of ownership (TCO) and reduced maintenance while improving security.

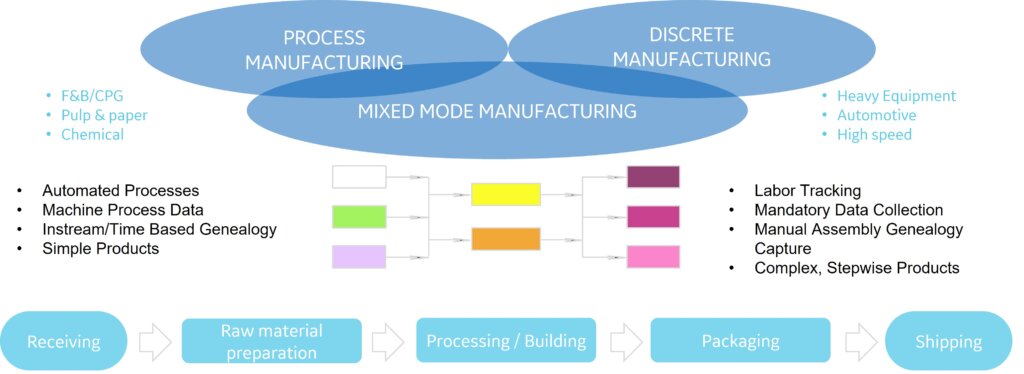

The composable architecture now supports OEE, production, and quality management. With cloud hosting, smaller manufacturers can also deploy MES effectively. Another aspect of this release that supports quick results and lasting value is the dozens of out-of-the-box configured screens. These are ready to support production, quality, and performance measurement workflows in process, discrete, and mixed-mode environments.

No-code capabilities also enable customers to tailor the MES to their specific needs. This can be crucial in supporting frontline workers’ adoption of MES. The quality module also offers a way for operators to comment on issues as they arise.

All of these enhancements are to an MES that is already deep and broad. Progress toward the cloud in manufacturing software is continuing. GE offers that option for those who want it, but also on-premise and hybrid for those maintaining those environments. Thank you, Sumit Pal, for sharing this with us!

[post_title] => Onshape Live 23 Reveals Significant Progress

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => onshape-live-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 12:39:02

[post_modified_gmt] => 2023-12-15 17:39:02

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17946

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 17938

[post_author] => 2574

[post_date] => 2023-03-08 09:00:52

[post_date_gmt] => 2023-03-08 14:00:52

[post_content] => There is more exciting news from GE Digital on its newest Proficy MES version. In a previous discussion, we learned that all of the GE Smart Factory Portfolio are becoming available not only on-premises but also on cloud or hybrid. As a fully-hosted managed service for MES-as-a-Service, MES can always be up to date with improvements from lean or continuous improvement (CI) efforts. GE claims up to 30% lower total cost of ownership (TCO) and reduced maintenance while improving security.

The composable architecture now supports OEE, production, and quality management. With cloud hosting, smaller manufacturers can also deploy MES effectively. Another aspect of this release that supports quick results and lasting value is the dozens of out-of-the-box configured screens. These are ready to support production, quality, and performance measurement workflows in process, discrete, and mixed-mode environments.

No-code capabilities also enable customers to tailor the MES to their specific needs. This can be crucial in supporting frontline workers’ adoption of MES. The quality module also offers a way for operators to comment on issues as they arise.

All of these enhancements are to an MES that is already deep and broad. Progress toward the cloud in manufacturing software is continuing. GE offers that option for those who want it, but also on-premise and hybrid for those maintaining those environments. Thank you, Sumit Pal, for sharing this with us!

[post_title] => GE Enhances Cloud MES for TCO, Flexibility (Insight) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cloud-mes-insight [to_ping] => [pinged] => [post_modified] => 2023-03-13 15:54:34 [post_modified_gmt] => 2023-03-13 19:54:34 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=17938 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 17895 [post_author] => 2 [post_date] => 2023-02-23 09:00:57 [post_date_gmt] => 2023-02-23 14:00:57 [post_content] =>

How can manufacturers overcome their product data gaps to improve new product introduction and drive product profitability? Jim Brown joined Propel’s Converged Live webinar, The Product Information Disconnect: How Collaboration Drives Business Value and Customer Loyalty, to preview his latest research on the product information disconnect and how to solve it.

View the webinar on demand to hear Jim Brown and Propel's Mark Boles and Tom Shoemaker in this open conversation to:

How can manufacturers overcome their product data gaps to improve new product introduction and drive product profitability? Jim Brown joined Propel’s Converged Live webinar, The Product Information Disconnect: How Collaboration Drives Business Value and Customer Loyalty, to preview his latest research on the product information disconnect and how to solve it.

View the webinar on demand to hear Jim Brown and Propel's Mark Boles and Tom Shoemaker in this open conversation to:

- Learn how disconnected data and processes derail product introduction, leaving time and money on the table

- Find out how using a single digital thread delivers accurate information every time, from design to commercialization

- Discover the fastest, most accurate way to launch quality products across every channel

Image Source: CoLab

[post_title] => Update on CoLab as the Design Engagement System (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => design-engagement-system-colab

[to_ping] =>

[pinged] =>

[post_modified] => 2023-02-14 11:55:47

[post_modified_gmt] => 2023-02-14 16:55:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17877

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 17857

[post_author] => 2

[post_date] => 2023-02-09 10:00:40

[post_date_gmt] => 2023-02-09 15:00:40

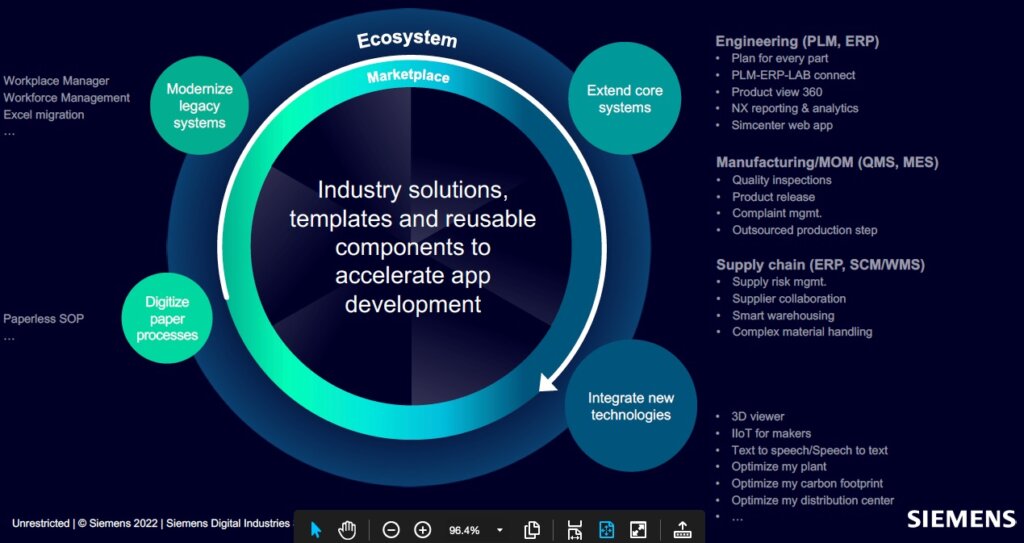

[post_content] => We just learned a lot in an interesting update briefing on Mendix from Siemens. Jim Brown was introduced to #lowcode almost 20 years ago and was excited about the potential when Siemens acquired Mendix. They’ve kept their promise and let Mendix compete in their traditional industries, such as financial services and insurance. They’re also using it themselves across Siemens, sharing that they’ve now adopted Mendix in 11 business and operating units. My update, though, was on the progress Siemens has made in applying Mendix to industrial applications. As I wrote in “Filling Digital Transformation Gaps with Low-Code,” there’s a huge need for new applications to meet industry40, IoT, IIoT, and digital transformation needs. Lowcode creates development agility and supports collaboration so manufacturers can efficiently modernize legacy systems and deploy new applications. Mendix’s ability to deploy in multiple places like, mobile devices and at the edge, helps make that achievable.

In addition to general lowcode enhancements, Siemens has made a lot of progress applying lowcode to their Xcelerator portfolio. They’ve introduced new capabilities and templates to make it easier for customers to extend, integrate, and customize Xcelerator applications. Some interesting general capabilities the provide for lowcode developers come from AWS including text-to-speech. But they’ve also created industry solutions that help industrial companies jumpstart solutions for functions like supply risk management, complaint management, carbon footprint optimization, and more.

The last part of the update was very exciting. They shared that they embedded Mendix into the Opcenter backbone so customers can personalize and extend user experiences - including operator dashboards and screens – based on standard, OOTB templates. The solution is released in January. They shared some examples including Mendix templates for quality Inspection, smart warehouse, workforce management, and field service. This allows customers to adopt existing MES capabilities and rapidly tailor them using lowcode. Mendix capabilities also allow manufacturers to run Opcenter in an offline mode.

All this represents both a big investment and significant proofpoint of Siemens’ integration of Mendix into their core business. Thank you Subba Rao, Shaun Ennis, and Jon Heidorn for taking the time to share the updates.

Image Source: CoLab

[post_title] => Update on CoLab as the Design Engagement System (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => design-engagement-system-colab

[to_ping] =>

[pinged] =>

[post_modified] => 2023-02-14 11:55:47

[post_modified_gmt] => 2023-02-14 16:55:47

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17877

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 17857

[post_author] => 2

[post_date] => 2023-02-09 10:00:40

[post_date_gmt] => 2023-02-09 15:00:40

[post_content] => We just learned a lot in an interesting update briefing on Mendix from Siemens. Jim Brown was introduced to #lowcode almost 20 years ago and was excited about the potential when Siemens acquired Mendix. They’ve kept their promise and let Mendix compete in their traditional industries, such as financial services and insurance. They’re also using it themselves across Siemens, sharing that they’ve now adopted Mendix in 11 business and operating units. My update, though, was on the progress Siemens has made in applying Mendix to industrial applications. As I wrote in “Filling Digital Transformation Gaps with Low-Code,” there’s a huge need for new applications to meet industry40, IoT, IIoT, and digital transformation needs. Lowcode creates development agility and supports collaboration so manufacturers can efficiently modernize legacy systems and deploy new applications. Mendix’s ability to deploy in multiple places like, mobile devices and at the edge, helps make that achievable.

In addition to general lowcode enhancements, Siemens has made a lot of progress applying lowcode to their Xcelerator portfolio. They’ve introduced new capabilities and templates to make it easier for customers to extend, integrate, and customize Xcelerator applications. Some interesting general capabilities the provide for lowcode developers come from AWS including text-to-speech. But they’ve also created industry solutions that help industrial companies jumpstart solutions for functions like supply risk management, complaint management, carbon footprint optimization, and more.

The last part of the update was very exciting. They shared that they embedded Mendix into the Opcenter backbone so customers can personalize and extend user experiences - including operator dashboards and screens – based on standard, OOTB templates. The solution is released in January. They shared some examples including Mendix templates for quality Inspection, smart warehouse, workforce management, and field service. This allows customers to adopt existing MES capabilities and rapidly tailor them using lowcode. Mendix capabilities also allow manufacturers to run Opcenter in an offline mode.

All this represents both a big investment and significant proofpoint of Siemens’ integration of Mendix into their core business. Thank you Subba Rao, Shaun Ennis, and Jon Heidorn for taking the time to share the updates.

[post_title] => Siemens Shows Progress with Mendix Lowcode for Industrial Applications (insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => siemens-mendix-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-07 10:51:00

[post_modified_gmt] => 2023-03-07 15:51:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17857

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 17806

[post_author] => 2

[post_date] => 2023-02-07 09:00:11

[post_date_gmt] => 2023-02-07 14:00:11

[post_content] =>

[post_title] => Siemens Shows Progress with Mendix Lowcode for Industrial Applications (insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => siemens-mendix-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-03-07 10:51:00

[post_modified_gmt] => 2023-03-07 15:51:00

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17857

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 17806

[post_author] => 2

[post_date] => 2023-02-07 09:00:11

[post_date_gmt] => 2023-02-07 14:00:11

[post_content] =>  How can manufacturers improve manufacturing engineering performance despite increased complexity? We surveyed 177 people involved in manufacturing engineering to find out. The results show that the leaders in manufacturing engineering have increased maturity in the way they plan, validate, and communicate manufacturing operations. These Top Performers waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. The eBook shares the best practices they use to do it.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

How can manufacturers improve manufacturing engineering performance despite increased complexity? We surveyed 177 people involved in manufacturing engineering to find out. The results show that the leaders in manufacturing engineering have increased maturity in the way they plan, validate, and communicate manufacturing operations. These Top Performers waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. The eBook shares the best practices they use to do it.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

Table of Contents

- Improve Manufacturing Engineering to Increase Profitability

- Address Process Designer Challenges

- Recognize the Opportunity

- Quantify the Potential

- Identify Performance Drivers

- Find Issues Earlier in Design

- Use more 3D and Simulation

- Use More Advanced Ways to Support 3D / Simulation

- Leverage More Integrated Solutions

- Use More Advanced Communication and Collaboration

- Quantify the Improvement

- Recommendations and Next Steps

- About the Research

- Acknowledgments

Improve Manufacturing Engineering Performance

Improve Performance in the Face of Complexity How can manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity. Modernize Manufacturing Engineering Survey results show that Top Performers (see definition in full eBook) in manufacturing engineering have increased maturity in the way they plan, validate, and communicate manufacturing operations. These leading companies waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. They accomplish this through best practices, including:- More advanced collaboration and communication methods

- Increased use of 3D and simulation to plan and validate manufacturing operations with virtual, digital twins

Recognize the Opportunity

Manufacturing Engineering is Ready for an Upgrade It’s time for change. Manufacturers must digitalize production planning to reduce cycle times, increase efficiently, and deliver quality. Companies need to adopt new techniques to validate manufacturing earlier in the process, in parallel with product design. Current Processes can be Improved

There is significant room for improvement. The majority of companies validate process plans with time-consuming and expensive physical prototyping. Physical prototypes bring abstract designs into the real world so engineers can identify issues and improvement opportunities. Most companies also use spreadsheets, which are prone to errors and file-based so they are not conducive to collaboration. These approaches lead to late discoveries and expensive process validation.

Leverage Visual Approaches

Trading physical prototypes for digital validation reduces time and cost. A significant number of companies already use some form of virtual representations. Static visualizations can help engineers see an issue in the digital world before committing to a physical prototype or manufacturing equipment.

Adopt Simulation

Beyond static images, virtual simulation helps designers go beyond “seeing” to virtually experiencing the production process. While only about one-quarter use either 2D or 3D simulation, it’s a promising technology and a potential for significant planning and validation improvement.

Current Processes can be Improved

There is significant room for improvement. The majority of companies validate process plans with time-consuming and expensive physical prototyping. Physical prototypes bring abstract designs into the real world so engineers can identify issues and improvement opportunities. Most companies also use spreadsheets, which are prone to errors and file-based so they are not conducive to collaboration. These approaches lead to late discoveries and expensive process validation.

Leverage Visual Approaches

Trading physical prototypes for digital validation reduces time and cost. A significant number of companies already use some form of virtual representations. Static visualizations can help engineers see an issue in the digital world before committing to a physical prototype or manufacturing equipment.

Adopt Simulation

Beyond static images, virtual simulation helps designers go beyond “seeing” to virtually experiencing the production process. While only about one-quarter use either 2D or 3D simulation, it’s a promising technology and a potential for significant planning and validation improvement.

Recommendations and Next Steps

Make a Strategic Improvement Today’s product, manufacturing process, and market complexity demand new ways of working. The Top Performers are transforming manufacturing engineering through digitalization, better collaboration, 3D, and simulation allowing them to overcome efficiency, quality, and cost challenges. Using virtual, digital twins offers manufacturing engineers both the ability to improve their own performance and a strategic opportunity to increase overall product development profitability. These leaders spend 17% less time on non-value-added activities in manufacturing engineering, directly reducing development cycle times. Improve Time to Market Survey respondents report that they can reduce time to market by 37% by using 3D and simulation to plan and validate manufacturing operations. This is done, in part, by increasing efficiency, reducing time-consuming physical prototyping, and lowering rework by finding issues sooner in product development. Reduce Cost Survey respondents share that they can eliminate 36% of their prototypes by increasing maturity, leading to significant cost savings per product. They do this by shifting validation and issue identification sooner in the product development process so they need fewer physical prototypes. Increase Quality Responding companies also indicate that they can reduce ECOs by over one-third. They do this by improving manufacturing process design using virtual technologies. Top Performers are more likely to find physical manufacturing issues in a virtual model than Others who are more likely to discover them in physical prototypes and actual production. Get Started It’s time to improve manufacturing engineering productivity and performance. Companies can follow the lead of the Top Performers to increase maturity in how they plan, validate, and communicate manufacturing plans. To increase maturity, manufacturers should adopt the best practices of the Top Performers, including using integrated solutions such as 3D and simulation for manufacturing engineering. *This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Transforming Manufacturing Engineering [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => transforming-manufacturing-engineering [to_ping] => [pinged] => [post_modified] => 2024-01-30 13:57:29 [post_modified_gmt] => 2024-01-30 18:57:29 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=17806 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [12] => WP_Post Object ( [ID] => 17625 [post_author] => 2 [post_date] => 2023-02-03 09:30:18 [post_date_gmt] => 2023-02-03 14:30:18 [post_content] => This Tech-Clarity TV episode helps manufacturers decide how to get started with Product Lifecycle Management. The animated video offers advice for companies to determine what kind of PLM best fits their business, basic PDM or a more capable PLM system. It shares the how PDM helps and how PLM extends those capabilities to add more business value. Thank you Siemens for sponsoring this educational video. Watch this episode about choosing between PLM options and more educational videos on the Tech-Clarity YouTube channel. [embed]https://youtu.be/sgL6jE0StCU[/embed] For related content, watch our other episode Getting Started with PLM and The Payback of PLM. Transcript Finding the right way to manage your product data can be a challenge. Product lifecycle management software, PLM, can help. But how do you choose the right path forward? Let’s get some clarity. First you have to choose what kind of PLM solution fits your business. Unmanaged or manually managed environments are inefficient and lead to mistakes. Basic product data management, PDM, can help. PDM helps keep engineers organized and efficient, collaborate better, and avoid costly errors. But why stop there? PLM goes beyond basic PDM to manage processes and projects in addition to data. Let's take a closer look at how PLM helps manage product data and puts your company on the path to do much more. PLM helps companies keep revisions and configurations under control and prevents overwriting files. It helps engineers work better, even if they're in different locations, and it helps designers coordinate activities across departments and the supply chain, even if they use different CAD tools. PLM provides the capabilities people across the business need to control, access, and share product data in a way that's accessible to smaller companies. Thanks for watching. Click to learn more from our sponsor, watch more Tech Clarity TV, or subscribe. [post_title] => Choosing Your Path to PLM [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => path-to-plm-animation [to_ping] => [pinged] => [post_modified] => 2023-12-15 15:26:54 [post_modified_gmt] => 2023-12-15 20:26:54 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=17625 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [13] => WP_Post Object ( [ID] => 17798 [post_author] => 2574 [post_date] => 2023-02-02 11:13:32 [post_date_gmt] => 2023-02-02 16:13:32 [post_content] => As a production metrics maven, I’m energized by a recent briefing for Jim Brown and me with Edge2Web, Inc. about their expansion to a second platform and first foray into applications. Now its low-code IoT tools Director and Flow Server run both on Siemens Digital Industries Software MindSphere and Amazon Web Services (AWS). This opens new horizons for customers that have selected the AWS IoT platform for both user-facing and back-end smart factory software development. Their new Factory Insights manufacturing intelligence and OEE application sits on Amazon Web Services’ IoT SiteWise. The OT data it ingests is in an open platform, accessible to many tools and ready for integration. Built on Edge2Web’s proven low-code tools for IoT, this dashboard and scorecard-oriented application has value out of the box. It is also highly configurable and extensible to match the process, terminology, and priorities of each plant. While it is early days, we suspect the manufacturers who select Factory Insights are likely to have an easier time scaling out from a proof of concept to full enterprise-wide use. I also love that a free sandbox version is available for people to get a feel for setting up performance monitoring in Factory Insights. Thank you, Fred Holahan, for taking the time to update us on this exciting development!

[post_title] => Edge2Web Moves from Tools to Manufacturing Intelligence Application on AWS (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-intelligence-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-02-02 11:14:05

[post_modified_gmt] => 2023-02-02 16:14:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17798

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 17787

[post_author] => 2

[post_date] => 2023-02-01 09:00:46

[post_date_gmt] => 2023-02-01 14:00:46

[post_content] =>

[post_title] => Edge2Web Moves from Tools to Manufacturing Intelligence Application on AWS (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-intelligence-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-02-02 11:14:05

[post_modified_gmt] => 2023-02-02 16:14:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17798

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 17787

[post_author] => 2

[post_date] => 2023-02-01 09:00:46

[post_date_gmt] => 2023-02-01 14:00:46

[post_content] =>  How can PLM, traditionally an engineering-centric solution, drive innovation, agility, and operational excellence throughout the entire product lifecycle? Attend this webinar to learn how the right PLM can help manufacturers focus on the big picture, not just engineering, to develop profitable products. Hear from: