How ready are manufacturers and AEC companies to embrace the cloud in engineering? AMC Bridge’s live webcast, hosted by Jim Brown, explores whether now is the right time to move toward cloud engineering software and data. Hear the panel of speakers share their deep experience and unique perspectives: Igor Tsinman, Co-founder and President of AMC Bridge,…

- Igor Tsinman, Co-founder and President of AMC Bridge,

- Oleg Shilovitsky, Co-founder and CEO of OpenBOM

- Marc Lind, Sr. Vice President, Strategy of Aras

- Lynn Allen, Global Technology Evangelist of Dassault Systèmes.

You can also watch the first of AMC Bridge's webcast series with Tech-Clarity here: How Software Enables Industrial Additive Manufacturing.

[post_title] => Embracing Cloud Engineering Software and Data (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-engineering-software-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10541

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 10531

[post_author] => 2

[post_date] => 2021-06-14 11:28:41

[post_date_gmt] => 2021-06-14 15:28:41

[post_content] => What do the experts say about cloud readiness in product innovation, engineering, and industrial software? What else can we learn about Siemens’ Paul Brown from his conversation with Tech-Clarity’s Jim Brown (no relation)? Tune into this episode of (Not Your Typical) Tech Interview, the show where we have a little fun by asking some important industry questions and then adding a few more to get to know our industry experts a little bit better. Want to find out what Paul's first computer was? His favorite browser? One of the answers might surprise you!

https://www.youtube.com/watch?v=5-4cmeZWS9M

For more information on cloud migration, please see the second video of this series, (Not Your Typical) Cloud Migration Interview with Schnitger Corp’s Monica Schnitger.

For more information on the engineering market's rapid shift to the cloud, please see the third video of this series, (Not Your Typical) Cloud Market Shift Interview with Allan Behrens.

For more information cloud perceptions, please see the fourth and final video of this series, (Not Your Typical) Cloud Perceptions Discussion with Siemens' Paul Brown.

Get more information about cloud readiness and Siemens' Cloud Solutions from Siemens Digital Industries Software. For related research, please check out our Cloud Advisor PLM Assessment.

You can also watch the first of AMC Bridge's webcast series with Tech-Clarity here: How Software Enables Industrial Additive Manufacturing.

[post_title] => Embracing Cloud Engineering Software and Data (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-engineering-software-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10541

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 10531

[post_author] => 2

[post_date] => 2021-06-14 11:28:41

[post_date_gmt] => 2021-06-14 15:28:41

[post_content] => What do the experts say about cloud readiness in product innovation, engineering, and industrial software? What else can we learn about Siemens’ Paul Brown from his conversation with Tech-Clarity’s Jim Brown (no relation)? Tune into this episode of (Not Your Typical) Tech Interview, the show where we have a little fun by asking some important industry questions and then adding a few more to get to know our industry experts a little bit better. Want to find out what Paul's first computer was? His favorite browser? One of the answers might surprise you!

https://www.youtube.com/watch?v=5-4cmeZWS9M

For more information on cloud migration, please see the second video of this series, (Not Your Typical) Cloud Migration Interview with Schnitger Corp’s Monica Schnitger.

For more information on the engineering market's rapid shift to the cloud, please see the third video of this series, (Not Your Typical) Cloud Market Shift Interview with Allan Behrens.

For more information cloud perceptions, please see the fourth and final video of this series, (Not Your Typical) Cloud Perceptions Discussion with Siemens' Paul Brown.

Get more information about cloud readiness and Siemens' Cloud Solutions from Siemens Digital Industries Software. For related research, please check out our Cloud Advisor PLM Assessment.

Transcript

Jim: Welcome to "Not Your Typical Industry Interview" where we ask industry experts some really important questions and then, throw some in that most people probably wouldn't ask them. Jim: Hi, this is Jim Brown, with Tech-Clarity, and welcome to the web show where we ask industry experts some questions that you might not think to ask. Today, I'm joined by Paul Brown, he is a long-time friend, industry friend, industry expert. He is a Senior Marketing Director at Siemens Digital Industry Software. Paul, welcome. Paul: Hi Jim! Good to talk to you! Jim: Today we're going to talk about how companies can tell that they're ready to move to the cloud for product innovation, product development, engineering, and other related industrial software. Are you ready to get started, Paul? And I’ve got to warn you, we've got a couple of little twists up our sleeve today. Jim: Paul, we've seen just a tremendous amount of increased interest in the cloud for engineering types of solutions, CAD, CAM, CAE, PLM, and other more digital solutions. What do you think are some of the key signs that a company is ready to make the transition to the cloud? Paul: Well, I think Jim, the big thing here now is when people are looking at the current environment and their need to collaborate, that's one of the big triggers. And once you start recognizing that you're working with other companies, you've got people working at home, remotely, if you can start... Once you start seeing that opportunity and that need to build up these communities of people together, that's when cloud technologies can really help you. And I think that that's one of those flags that says, "Actually really, you should be thinking hard about how can I bring this into my business." Jim: Paul, what's your favorite web browser? I'll go first. Mine's Chrome. Paul: Yeah, I'm using Chrome, I'll use Chrome pretty much all the time. Now and again, we get... There are things that pop up and say "This is better off in Edge," but I always try and I'll try it in Chrome first just to see... Jim: Well, are there any red flags that say a company maybe shouldn't be taking their product innovation and engineering software into the cloud? Paul: There is the obvious red flag, which everyone jumps to straight away, which is that I work on secure projects, I work military, I work... And obviously, that's one of those factors, that's the business environment you're working in. But the other red flag, and I think is more important, that companies can actually control themselves is having a plan as to what they want to achieve with the cloud. If they're just talking about, "Well, I'm going there because that's the current trend. Everyone is talking about cloud, I need to be on the cloud," that's not really a good business reason. You've got to have a goal and a business goal as to why you're going to benefit from the cloud. Otherwise, it's just change for change's sake, and that's never going to give you returns on investment that you want. Jim: What was your first personal computer? Paul: I guess my first personal computer, the one I had at home was, there was a company that was in the UK called Tiny. So that was my first home PC. And when I look at technology now and how we all are interconnected, if I think about it, my first real... The work PC, the one I first trained on CAD, that was, for those people that remember, there was a company called Digital Equipment Corporation a long, long time ago, and we had a micro, a VAX11750. We had to put it into a separate room, air-conditioned in our drawing office, it supported four workstations, and it cost the company by the time they got the four workstations plus the hardware, it cost the company about a million dollars for... Just for the hardware. And now we run technology on our laptops, on our phones, on our tablets, all connected through the web, running technologies, using cloud technologies in our own sort of personalized environment that we have without even thinking about it, and... So the change over the years. And I think the other thing is, I've always learned... I've now definitely, I'm a proponent of you never say never. I mean, I remember in the old days saying, you'd never run a CAD product on a laptop, those sorts of conversations that you used to have, and it's like everything is now... Becomes possible. Jim: Well, thanks so much for joining me. It's always a pleasure to talk to you both from a personal perspective, but from also a professional perspective. I always learn something new and love to share in your insights into the industry. Paul: Great. Thanks, Jim. Great to speak to you. And look forward to doing it again. Jim: Thanks for joining the web show where we asked industry experts mostly the wrong questions. We had a lot of fun today and certainly looking forward to more of these. If you'd like to learn more about product innovation, product development, engineering and other industrial software and how the cloud can really make that better, visit our sponsor, Siemens Digital Industry Software. [post_title] => NYT Cloud Readiness Tech Interview with Siemens’ Paul Brown (video) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => cloud-readiness-nyt-interview-one [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:29:24 [post_modified_gmt] => 2022-11-15 03:29:24 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10531 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [2] => WP_Post Object ( [ID] => 10513 [post_author] => 2 [post_date] => 2021-06-02 21:00:08 [post_date_gmt] => 2021-06-03 01:00:08 [post_content] => What are the core fundamentals that manufacturers need in their digital thread? What do they need in their PLM system to serve as their digital thread backbone? Read our eBook, The Seven Building Blocks of the Digital Thread, to learn more.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

For related research, read our original buyer's guide Choosing PLM for Digital Thread Initiatives.

What are the core fundamentals that manufacturers need in their digital thread? What do they need in their PLM system to serve as their digital thread backbone? Read our eBook, The Seven Building Blocks of the Digital Thread, to learn more.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

For related research, read our original buyer's guide Choosing PLM for Digital Thread Initiatives.

Table of Contents

- Introducing the Guide

- Why Digital Thread?

- Supporting the Digital Thread

- 1) Managing Engineering Data

- 2) BOMs, Configurations, and DMU

- 3) Production Planning

- 4) Part and Supplier Management

- 5) Product Traceability and Closed-Loop Quality

- 6) Enterprise Change

- 7) Secure Collaboration

- Implementation and Adoption

- Special Considerations

- Vendor Considerations

- Conclusions and Next Steps

- Acknowledgments

Executive Overview

The Digital Thread is Essential Over three-quarters of manufacturers view the digital thread as either important or critical to achieving their business strategy. These industrial companies view the digital thread as a fundamental way to improve performance and gain an advantage over their competitors. Our research, however, shows that only about one-quarter of companies have implemented a digital thread initiative. Having a comprehensive digital thread is moving from an advantage to a competitive necessity. But many companies struggle to define their needs and start an initiative. This guide introduces the top 7 fundamentals that manufacturers should consider to implement and support their digital thread, along with some key solution requirements to support them.

Why Digital Thread?

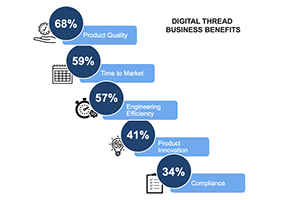

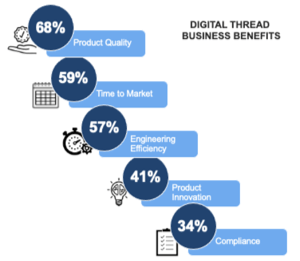

Business Benefits of the Digital Thread There are numerous definitions of the digital thread. Our research highlights two primary value drivers, streamlining engineering and creating digital continuity. More importantly, these factors are the means to significant business improvements. Benefits include improved quality, greater efficiency, lead-time reduction, enhanced innovation, and more. Specifically, our study shows that companies that have adopted a digital thread enable their technical resources to spend 10% more value-added time on innovation, design, and development work.

This value is the outcome of reduced handoffs and translations, a complete and cohesive data model, connected data, traceability, reuse, and better collaboration. This is why the digital thread is such a critical capability for manufacturers.

There are numerous definitions of the digital thread. Our research highlights two primary value drivers, streamlining engineering and creating digital continuity. More importantly, these factors are the means to significant business improvements. Benefits include improved quality, greater efficiency, lead-time reduction, enhanced innovation, and more. Specifically, our study shows that companies that have adopted a digital thread enable their technical resources to spend 10% more value-added time on innovation, design, and development work.

This value is the outcome of reduced handoffs and translations, a complete and cohesive data model, connected data, traceability, reuse, and better collaboration. This is why the digital thread is such a critical capability for manufacturers.

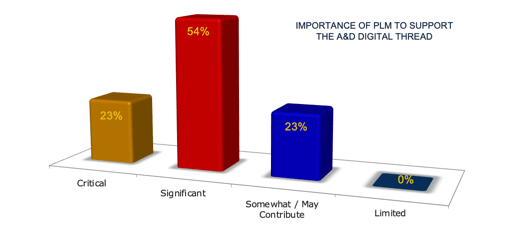

Conclusions and Next Steps

Achieving the Business Value of the Digital Thread The digital thread is crucial to business performance and competition for today’s manufacturer. We believe that those companies that adopt the efficiencies and traceability available from the digital thread have an opportunity to outperform their competitors. In fact, our research shows that Top Performers, those that outperform their competitors across key product development metrics, are almost two and one-half times as likely to have already implemented a digital thread initiative. Secure the Foundation of the Digital Thread with PLM The digital thread starts in Engineering and PLM is the foundation. Our survey finds that Top Performing companies are 2.4 times as likely to view PLM as critical to supporting the digital thread. PLM supports the basics of data management, processes, and collaboration that make up the seven foundational necessities of the digital thread. But PLM provides much more than that, supporting more advanced capabilities, integration, and technologies that will allow manufacturers to extend the value of their digital thread over time and continue to create competitive advantages. But they can start with the fundamentals and grow their capabilities – and value – over time. Get the Right PLM and Get Started As with any technology, it’s important to recognize the importance of not only software capabilities but also factors like implementation, adoption, vendor considerations, industry needs, and specific company needs. Most importantly, manufacturers should get started because the window where the digital thread provides an advantage is closing as basic digital thread maturity becomes the industry norm. *This summary is an abbreviated version of the research and does not contain the full content. Please visit our sponsor PTC for the full research (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Seven Building Blocks of the Digital Thread (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => digital-thread-fundamentals-book [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:28:22 [post_modified_gmt] => 2022-11-15 03:28:22 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10513 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [3] => WP_Post Object ( [ID] => 10507 [post_author] => 2574 [post_date] => 2021-05-24 09:55:29 [post_date_gmt] => 2021-05-24 13:55:29 [post_content] => Are your manufacturing workers safe? Many companies don’t know. Yet, the risk of not knowing workplace safety is high. The global COVID-19 pandemic has brought a new focus to the health and safety of onsite frontline employees. Those workers are in high demand, and part of knowing who is at risk comes down to their training, certifications, and qualifications. Another part is analyzing the types of issues that commonly arise in each work area and having preventive measures in place. A modern and proactive enterprise approach to health and safety software and processes is essential. For many companies, it’s quite different from the piecemeal and reactive processes currently in place. Watch this webinar with Tech-Clarity’s Julie Fraser and ComplianceQuest’s Michael Bower to learn more. Enjoy this important discussion about the rightful place of health and safety in your company’s strategy. Hear about ways to lower workplace safety and health risks. [post_title] => Could You Reduce your Manufacturing Workplace Safety Risks? (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => workplace-safety-webcast-10507-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10507

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 10472

[post_author] => 2

[post_date] => 2021-05-17 11:15:31

[post_date_gmt] => 2021-05-17 15:15:31

[post_content] => [caption id="attachment_10486" align="alignright" width="212"]

[post_title] => Could You Reduce your Manufacturing Workplace Safety Risks? (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => workplace-safety-webcast-10507-2

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10507

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 10472

[post_author] => 2

[post_date] => 2021-05-17 11:15:31

[post_date_gmt] => 2021-05-17 15:15:31

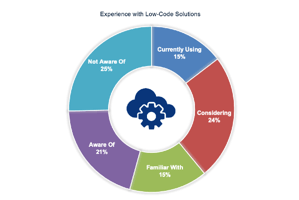

[post_content] => [caption id="attachment_10486" align="alignright" width="212"] Experience with low-code solutions[/caption]

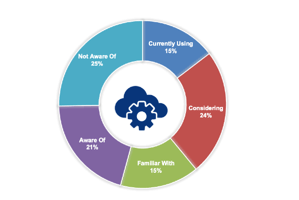

Some see low-code as a promising new technology, but is it really new? No. Is it promising for digital transformation? Our survey says yes.

Please enjoy the summary below or see Jim Brown's full guest post on the Siemen's blog to learn how the low-code technology "breakthrough" helps fill digital transformation gaps.

Digital Transformation Gaps

Digital transformation is creating new value for manufacturers. The digital revolution, whether under the banner of Industry 4.0, Smart Manufacturing, or some more overarching initiative, is a high priority to survive and thrive in the new normal. Even before the disruption from the recent pandemic, Tech-Clarity’s research on digital maturity in manufacturing shows that two-thirds of industrial companies viewed digitalization as either “important” or “critical” to achieving their business strategy.

Our recent survey, Filling Digital Transformation Gaps with Applications, shares that manufacturers’ digital initiatives create or uncover process, organizational, and technology gaps. They must overcome these “digital transformation gaps” to achieve their digitalization goals, such as driving internal efficiencies, creating new business models, or finding new revenue opportunities.

[caption id="attachment_10473" align="alignleft" width="157"]

Experience with low-code solutions[/caption]

Some see low-code as a promising new technology, but is it really new? No. Is it promising for digital transformation? Our survey says yes.

Please enjoy the summary below or see Jim Brown's full guest post on the Siemen's blog to learn how the low-code technology "breakthrough" helps fill digital transformation gaps.

Digital Transformation Gaps

Digital transformation is creating new value for manufacturers. The digital revolution, whether under the banner of Industry 4.0, Smart Manufacturing, or some more overarching initiative, is a high priority to survive and thrive in the new normal. Even before the disruption from the recent pandemic, Tech-Clarity’s research on digital maturity in manufacturing shows that two-thirds of industrial companies viewed digitalization as either “important” or “critical” to achieving their business strategy.

Our recent survey, Filling Digital Transformation Gaps with Applications, shares that manufacturers’ digital initiatives create or uncover process, organizational, and technology gaps. They must overcome these “digital transformation gaps” to achieve their digitalization goals, such as driving internal efficiencies, creating new business models, or finding new revenue opportunities.

[caption id="attachment_10473" align="alignleft" width="157"] Jim Brown in 2003 when the original article was published[/caption]

[caption id="attachment_10477" align="alignright" width="157"]

Jim Brown in 2003 when the original article was published[/caption]

[caption id="attachment_10477" align="alignright" width="157"] Jim Brown currently[/caption]

A "breakthrough" technology

Some see low-code as a promising new technology, but is it really? New technology? No. Despite the fact that a full 25% of industrial companies aren’t aware of it, it’s not new. The low-code approach has gone by different names, including model-based programming. In fact, I first wrote about it with Olin Thompson of Process ERP Partners in 2003 in a series of Technology Evaluation articles titled “What’s Wrong with Application Software.” In that we pointed out that “Early adopters are learning that Model Based Architectures create significant efficiencies throughout the application lifecycle.”

Take advantage of low-code to fill gaps

As we said over a decade ago “Model based architecture is … a tool that leverages existing applications and fills in the cracks that exist in your business processes.” That’s even more applicable today, given the higher demand – and value – of rapid application development in the digital era. It’s time for more manufacturers to adopt low-code in order to meet their critical digital transformation needs. Fortunately, it’s well suited to start small, prove the value, and grow. It’s time to get started.

For related commentary on how companies can fill IoT gaps with low-code applications, read the Fill IoT Gaps with Low-Code guest post.

[post_title] => The Low-Code Technology “Breakthrough” (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => low-code-breakthrough-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-09 20:48:30

[post_modified_gmt] => 2024-09-10 00:48:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10472

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 10464

[post_author] => 2574

[post_date] => 2021-05-13 19:38:28

[post_date_gmt] => 2021-05-13 23:38:28

[post_content] =>

Jim Brown currently[/caption]

A "breakthrough" technology

Some see low-code as a promising new technology, but is it really? New technology? No. Despite the fact that a full 25% of industrial companies aren’t aware of it, it’s not new. The low-code approach has gone by different names, including model-based programming. In fact, I first wrote about it with Olin Thompson of Process ERP Partners in 2003 in a series of Technology Evaluation articles titled “What’s Wrong with Application Software.” In that we pointed out that “Early adopters are learning that Model Based Architectures create significant efficiencies throughout the application lifecycle.”

Take advantage of low-code to fill gaps

As we said over a decade ago “Model based architecture is … a tool that leverages existing applications and fills in the cracks that exist in your business processes.” That’s even more applicable today, given the higher demand – and value – of rapid application development in the digital era. It’s time for more manufacturers to adopt low-code in order to meet their critical digital transformation needs. Fortunately, it’s well suited to start small, prove the value, and grow. It’s time to get started.

For related commentary on how companies can fill IoT gaps with low-code applications, read the Fill IoT Gaps with Low-Code guest post.

[post_title] => The Low-Code Technology “Breakthrough” (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => low-code-breakthrough-guest-post

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-09 20:48:30

[post_modified_gmt] => 2024-09-10 00:48:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10472

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 10464

[post_author] => 2574

[post_date] => 2021-05-13 19:38:28

[post_date_gmt] => 2021-05-13 23:38:28

[post_content] =>  Could your production operation be more productive? Sometimes it’s difficult to tell, despite having plenty of data. Sometimes, metrics like overall equipment effectiveness (OEE) don’t even help uncover the hidden factory. Yet, OEE can and should pinpoint opportunities.

Find out how to improve more reliably in this June 2021 webcast. Listen in to Tech-Clarity’s Julie Fraser, VP of Research for Operations and Manufacturing, and Nick Leeder, VP of Digital Transformation Solutions at PTC, as they discuss how digital continuous improvement (CI) programs can help your company succeed. Keep your bottlenecks productive. Build on and drill down into OEE to get real insights.

Hint: It’s all about speed. Get a glimpse into the hidden factory. Start thinking about how to uncover ways to boost productivity.

View the webcast on-demand here.

[post_title] => The Power in the Hidden Factory: Unlocking the Untapped Potential in Manufacturing Operations (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => hidden-factory-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10464

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 10432

[post_author] => 2572

[post_date] => 2021-05-05 17:12:39

[post_date_gmt] => 2021-05-05 21:12:39

[post_content] =>

Could your production operation be more productive? Sometimes it’s difficult to tell, despite having plenty of data. Sometimes, metrics like overall equipment effectiveness (OEE) don’t even help uncover the hidden factory. Yet, OEE can and should pinpoint opportunities.

Find out how to improve more reliably in this June 2021 webcast. Listen in to Tech-Clarity’s Julie Fraser, VP of Research for Operations and Manufacturing, and Nick Leeder, VP of Digital Transformation Solutions at PTC, as they discuss how digital continuous improvement (CI) programs can help your company succeed. Keep your bottlenecks productive. Build on and drill down into OEE to get real insights.

Hint: It’s all about speed. Get a glimpse into the hidden factory. Start thinking about how to uncover ways to boost productivity.

View the webcast on-demand here.

[post_title] => The Power in the Hidden Factory: Unlocking the Untapped Potential in Manufacturing Operations (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => hidden-factory-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10464

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 10432

[post_author] => 2572

[post_date] => 2021-05-05 17:12:39

[post_date_gmt] => 2021-05-05 21:12:39

[post_content] =>  With increasing demands for highly skilled operators, yet a shortage of workers with those skills, what can manufacturers do to boost manufacturing productivity?

With workforce shortages, market volatility, and rising costs plaguing most manufacturers, many are turning to new ways of operating, and digital transformation is playing a pivotal role. Digital work instructions can be a critical component of the strategy, but what should you look for in a solution? This buyer’s guide* defines what digital work instructions are, the challenges they solve, and the benefits a company can realize by adopting them. The guide then outlines nine capabilities to look for in a solution.

While this buyer’s guide was written before the COVID-19 pandemic, the challenges facing manufacturers have not gone away, and in fact, in many cases have gotten even worse. Due to the pandemic, factories may need to get by with limited staff, while also coping with new safety guidelines. They also need to adapt to severe supply chain disruptions. Consequently, this has created demand for greater agility and efficiency, which has accelerated digital transformation. Access this buyer’s guide to learn about how digital work instructions can help.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

With increasing demands for highly skilled operators, yet a shortage of workers with those skills, what can manufacturers do to boost manufacturing productivity?

With workforce shortages, market volatility, and rising costs plaguing most manufacturers, many are turning to new ways of operating, and digital transformation is playing a pivotal role. Digital work instructions can be a critical component of the strategy, but what should you look for in a solution? This buyer’s guide* defines what digital work instructions are, the challenges they solve, and the benefits a company can realize by adopting them. The guide then outlines nine capabilities to look for in a solution.

While this buyer’s guide was written before the COVID-19 pandemic, the challenges facing manufacturers have not gone away, and in fact, in many cases have gotten even worse. Due to the pandemic, factories may need to get by with limited staff, while also coping with new safety guidelines. They also need to adapt to severe supply chain disruptions. Consequently, this has created demand for greater agility and efficiency, which has accelerated digital transformation. Access this buyer’s guide to learn about how digital work instructions can help.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

Table of Contents

- Challenges Facing Manufacturers

- What Are Digital Work Instructions?

- Ten Ways Digital Work Instructions Help

- 1. Connectivity to Existing Systems

- 2. Single Point of Access

- 3. Traceability from Engineering to Manufacturing

- 4. Supports Roll out of New or Customized Products

- 5. Real-Time Process Control

- 6. Analytics to Optimize Work Instructions

- 7. Hardware Agnostic

- 8. User friendly and Easy to Adopt

- 9. Good Vendor Support

- Select the Right Solution for Your Needs

- Acknowledgments

What Are Digital Work Instructions?

Industrial Internet of Things (IIoT) The IIoT integrates many technologies in a factory. It can create a digital thread across the product lifecycle, enabling traceability to support greater efficiency, improve quality, and support regulatory compliance. For many, investments in IIoT will likely create a competitive advantage, especially during a downturn. There are many different approaches to start with IIoT adoption. One way is with digital work instructions. The Difference Between Digital and Electronic

While digital work instructions support going paperless, digital is not the same as electronic. While an electronic format such as a PDF offers the benefits of going paperless, it does not provide all of the benefits of going digital. A PDF is still a dumb document. The minute you create it, you break the digital thread. The document has no link to its source data, so as soon as there are changes, the PDF is outdated.

Digital Work Instructions

On the other hand, digital work instructions are smart and data-driven. They preserve the digital thread from the engineering data and connect it to the produced product. Digital work instructions dynamically guide operators as they work, providing instructions in a digestible way that is easy to follow. The software can pull data from multiple places, yet only show the operator what’s relevant to the current task, from a single screen. Work instructions are never out of date since they automatically update when there are changes. With connectivity, the software also captures what the operators do. This closed loop visibility validates that the instructions were executed properly and provides management with visibility, supporting continuous improvement.

The Difference Between Digital and Electronic

While digital work instructions support going paperless, digital is not the same as electronic. While an electronic format such as a PDF offers the benefits of going paperless, it does not provide all of the benefits of going digital. A PDF is still a dumb document. The minute you create it, you break the digital thread. The document has no link to its source data, so as soon as there are changes, the PDF is outdated.

Digital Work Instructions

On the other hand, digital work instructions are smart and data-driven. They preserve the digital thread from the engineering data and connect it to the produced product. Digital work instructions dynamically guide operators as they work, providing instructions in a digestible way that is easy to follow. The software can pull data from multiple places, yet only show the operator what’s relevant to the current task, from a single screen. Work instructions are never out of date since they automatically update when there are changes. With connectivity, the software also captures what the operators do. This closed loop visibility validates that the instructions were executed properly and provides management with visibility, supporting continuous improvement.

Select the Right Solution for Your Needs

Recommendations Based on industry experience and research for this report, Tech-Clarity has identified the following criteria to select the right solution for digital work instructions:- Connectivity to existing systems

- Single point of access

- Traceability from engineering to manufacturing

- Supports roll out of new products or customized products

- Real-time process control

- Analytics to optimize work instructions

- Hardware agnostic

- User friendly and easy to adopt

- Good vendor support

What role does software play in the maturation of additive manufacturing to industrial scale?

This live webcast, hosted by Jim Brown and Igor Tsinman, President of AMC Bridge, explores the symbiotic relationship between additive manufacturing technology and the software applications that work cohesively with them. The panel includes Igal Kaptsan - General Manager Software of GE Additive and Moritz Maier - Co-Funder & Co-CEO of ELISE.

What role does software play in the maturation of additive manufacturing to industrial scale?

This live webcast, hosted by Jim Brown and Igor Tsinman, President of AMC Bridge, explores the symbiotic relationship between additive manufacturing technology and the software applications that work cohesively with them. The panel includes Igal Kaptsan - General Manager Software of GE Additive and Moritz Maier - Co-Funder & Co-CEO of ELISE.

Register now to watch the May 13 webcast.

[post_title] => How Software Enables Industrial Additive Manufacturing (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => industrial-additive-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10420

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 10406

[post_author] => 2572

[post_date] => 2021-04-28 18:38:15

[post_date_gmt] => 2021-04-28 22:38:15

[post_content] =>

Register now to watch the May 13 webcast.

[post_title] => How Software Enables Industrial Additive Manufacturing (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => industrial-additive-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:05

[post_modified_gmt] => 2022-11-15 03:27:05

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10420

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 10406

[post_author] => 2572

[post_date] => 2021-04-28 18:38:15

[post_date_gmt] => 2021-04-28 22:38:15

[post_content] =>  What role should feature-based Product Line Engineering (PLE) play in a digital transformation strategy?

On May 11-12, 2021, Big Lever will be holding their Momentum 2021 Symposium and this question will be the underlying theme of the event.

Tech-Clarity’s Michelle Boucher will join the list of speakers and she will explore the question, why should business leaders care about PLE? Her talk will be at 1:45 EDT on Tuesday, May 11. You can register for the event here.

As products continue to grow in complexity, engineering jobs will only get harder. Digital transformation can help, and for many companies, this last year has dramatically accelerated adoption. With this growing adoption, what steps should you take to ensure you don’t fall behind your competition? Michelle’s talk will discuss how PLE fits into the digital transformation vision and the impact on the business. She will also explain how providing engineers with better solutions for PLE will help to execute a digital transformation strategy, while empowering your engineers to focus more on innovation and less on tedious tasks.

What role should feature-based Product Line Engineering (PLE) play in a digital transformation strategy?

On May 11-12, 2021, Big Lever will be holding their Momentum 2021 Symposium and this question will be the underlying theme of the event.

Tech-Clarity’s Michelle Boucher will join the list of speakers and she will explore the question, why should business leaders care about PLE? Her talk will be at 1:45 EDT on Tuesday, May 11. You can register for the event here.

As products continue to grow in complexity, engineering jobs will only get harder. Digital transformation can help, and for many companies, this last year has dramatically accelerated adoption. With this growing adoption, what steps should you take to ensure you don’t fall behind your competition? Michelle’s talk will discuss how PLE fits into the digital transformation vision and the impact on the business. She will also explain how providing engineers with better solutions for PLE will help to execute a digital transformation strategy, while empowering your engineers to focus more on innovation and less on tedious tasks.

About the Event

In addition to Michelle, other speakers will include:- David Long, President, Vitech: Beyond Digital: Bridging the Divides

- Dr. Bobbi Young, Systems Engineering Fellow, Raytheon: Digital Transformation: Composing Your Digital Future

- Dr. Charles Krueger, CEO, BigLever: Product Line Engineering in the New Digital Age

- Eric MacKnight, Staff Engineer, GE Aviation: General Electric Aviation’s Use of Product Line Engineering and Model-based Systems Engineering

- Panel Discussion

- Sandy Friedenthal, Co-lead for OMG SysML V2 Submission Team: Model-Based Systems Engineering (MBSE) and the Digital Transformation

- Rick Flores, Technical Fellow, General Motors & Halim Ragab, Engineering Specialist, General Motors: Application of PLE in MBSE for an AUTOSAR-based Digital Supply Chain

- Bill Schindel, President, ICTT System Sciences: The Forces of Modularity: Macro and Micro Patterns in the Innovation Ecosystem

- Rowland Darbin, INCOSE PLE Working Group Chair: INCOSE Product Line Engineering International Working Group Perspectives on Modern Feature-based PLE

- Dr. William Donaldson, President & Founder, Strategic Venture Planning: We need to talk: Enabling the Conversation Between Business and Engineering about Organizational Change for Digital Transformation, Digital Engineering, and PLE

- Roger McNicholas, VP, General Dynamics Mission Systems: Application of PLE to US Army Live Training

How can PLM enable medical device companies to streamline engineering and create digital continuity with a cohesive medical device digital thread? What should they look for in a PLM solution to improve closed-loop quality and patient outcomes while meeting complex, regional compliance demands?

This eBook takes a deeper dive into the data from our original, cross-industry digital thread study to better understand how the value and considerations for digital thread adoption apply to medical device manufacturers.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

How can PLM enable medical device companies to streamline engineering and create digital continuity with a cohesive medical device digital thread? What should they look for in a PLM solution to improve closed-loop quality and patient outcomes while meeting complex, regional compliance demands?

This eBook takes a deeper dive into the data from our original, cross-industry digital thread study to better understand how the value and considerations for digital thread adoption apply to medical device manufacturers.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

Table of Contents

- Introducing the Buyer's Guide

- The Digital Thread Imperative

- What to Look for to Streamline Engineering

- What to Look for to Closed-Loop Quality, Continuity

- Digital Thread Business Value

- Considerations by Role - Engineering

- Considerations by Role - Manufacturing

- Considerations by Role - Quality

- Considerations by Role - IT

- Considerations by Role - Service

- PLM is the Digital Thread Backbone

- Special Considerations - Emerging Technologies

- Implementation Considerations

- Vendor Considerations

- Conclusions and Next Steps

- About the Research

- Acknowledgments

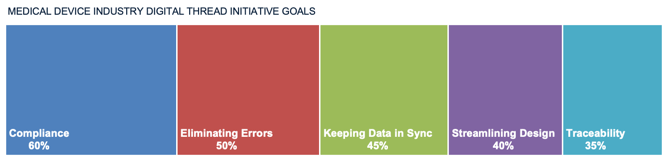

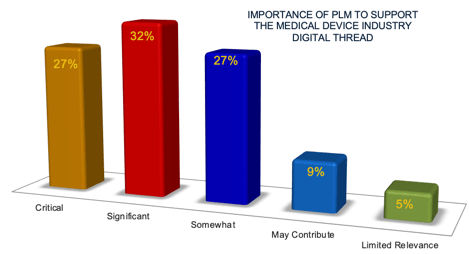

The Medical Device Digital Thread Imperative

Business Strategies Demand a Cohesive Digital Thread Over three-quarters of companies say that the digital thread is either important or critical to achieving their business strategy. About one-half of medical device manufacturers indicate they have already implemented a digital thread initiative, most likely to meet design control mandates such as Design History File (DHF) and Device Master Record (DMR) and rapidly changing, region-specific regulatory requirements such as EU Medical Device Regulation (MDR). Medical device manufacturers report a variety of important goals for their digital thread initiative (see chart). They are 30% more likely than other manufacturers to pursue compliance, for example seeking audit-ready data. They are investing in reducing errors and adverse events to improve patient outcomes, all while trying to control the cost of quality and compliance overhead. While definitions vary, medical device manufacturers are looking for quality, compliance, and streamlined engineering from the digital thread. Streamlined Engineering The digital thread streamlines design by allowing product development teams to share and reuse design data across the stages of innovation. Design continuity along the digital thread allows engineers to add their design information to a cohesive model, directly incorporating and extending design data from prior steps – allowing them to efficiently design for regulatory management. Continuity, Closed Loop Quality The digital thread ties product information, decisions, and history together in a structured, integrated way that captures product innovation and knowledge throughout the product lifecycle. It establishes traceability from early in the front end of innovation through development, manufacturing, service, and field operation. This continuity ensures data-driven handovers between departments and support for evolving global regulations, initiatives, and standards including the FDA’s Case for Quality (CfQ) and Quality System Regulation (QSR), ISO 13485, and the new EU MDR/EU IVDR.Conclusions and Next Steps

Invest in the Digital Thread Invest in the digital thread to streamline engineering and create digital continuity. Top Performers are 2.6 times as likely to view the digital thread as critical to supporting their business strategy. Extend the Thread across the Lifecycle Adopt a comprehensive scope that incorporates cross-departmental data. Top Performers are more likely to include manufacturing, quality, and service plans in the scope of their digital thread, and enrich it with actual data from the IoT. Leverage PLM as the Digital Medical Device Backbone for Closed-Loop Quality, Continuity, and Streamlined Engineering Adopt PLM to support the digital thread. Top Performing companies are 2.4 times as likely to view PLM as critical to supporting the digital thread and are much more likely to use PLM to support it.

Enjoy the Benefits

The digital thread provides significant, measurable benefits including improved quality, increased engineering efficiency, enhanced innovation, faster time to market, and better compliance. Top Performers gain even higher benefits than others. For example, these more successful product developers enable their technical resources to spend 27% more time, on average, on value-added activities than their poorer performing counterparts.

*This summary is an abbreviated version of the ebook and does not contain the full content. For the full research, please visit our sponsor PTC (registration required).

If you have difficulty obtaining a copy of the research, please contact us.

[post_title] => PLM for the Medical Device Digital Thread (buyer's guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-for-medical-device-digital-thread-survey-results

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:02

[post_modified_gmt] => 2022-11-15 03:28:02

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10369

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 10360

[post_author] => 2

[post_date] => 2021-04-16 12:49:56

[post_date_gmt] => 2021-04-16 16:49:56

[post_content] =>

Adopt PLM to support the digital thread. Top Performing companies are 2.4 times as likely to view PLM as critical to supporting the digital thread and are much more likely to use PLM to support it.

Enjoy the Benefits

The digital thread provides significant, measurable benefits including improved quality, increased engineering efficiency, enhanced innovation, faster time to market, and better compliance. Top Performers gain even higher benefits than others. For example, these more successful product developers enable their technical resources to spend 27% more time, on average, on value-added activities than their poorer performing counterparts.

*This summary is an abbreviated version of the ebook and does not contain the full content. For the full research, please visit our sponsor PTC (registration required).

If you have difficulty obtaining a copy of the research, please contact us.

[post_title] => PLM for the Medical Device Digital Thread (buyer's guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-for-medical-device-digital-thread-survey-results

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:02

[post_modified_gmt] => 2022-11-15 03:28:02

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10369

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 10360

[post_author] => 2

[post_date] => 2021-04-16 12:49:56

[post_date_gmt] => 2021-04-16 16:49:56

[post_content] =>  How can low-code help fill digital transformation gaps to help companies achieve the value of IoT opportunities? Jim Brown's guest post on Siemen's blog shows how companies can fill IoT gaps with low-code applications.

Below is a short summary, click here to read Jim Brown's full guest post on the Siemen's blog.

Digital Transformation Creates Opportunities

Today’s digital revolution is creating new opportunities for industrial companies. New business strategies powered by digital technologies are fundamentally changing the business landscape. Companies recognize they need to move quickly. As our Business Sustainability (and Survival) Strategies 2020 survey found, “Almost one-half of businesses (46%) have increased focus and/or accelerated digital transformation due to the pandemic.”

Digital Transformation Creates Gaps

Companies need to find ways to take advantage of the data and opportunities generated by the IoT. They need to figure out how to:

How can low-code help fill digital transformation gaps to help companies achieve the value of IoT opportunities? Jim Brown's guest post on Siemen's blog shows how companies can fill IoT gaps with low-code applications.

Below is a short summary, click here to read Jim Brown's full guest post on the Siemen's blog.

Digital Transformation Creates Opportunities

Today’s digital revolution is creating new opportunities for industrial companies. New business strategies powered by digital technologies are fundamentally changing the business landscape. Companies recognize they need to move quickly. As our Business Sustainability (and Survival) Strategies 2020 survey found, “Almost one-half of businesses (46%) have increased focus and/or accelerated digital transformation due to the pandemic.”

Digital Transformation Creates Gaps

Companies need to find ways to take advantage of the data and opportunities generated by the IoT. They need to figure out how to:

- Connect and communicate with equipment or products

- Monitor and analyze data and performance

- Notify and act on the findings

Digital transformation creates, exposes, and widens gaps in processes, organizational approaches, and systems. This leads 96% of industrial companies to say they need to create and implement new software more quickly. Addressing these application shortfalls is critical to long-term business success. Is developing applications with low-code the answer to filling the gaps? We surveyed over 300 manufacturers to find out.

Our new eBook, Filling Digital Transformation Gaps with Low-Code, looks at the challenges companies face today and how low-code development approaches can help.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

Digital transformation creates, exposes, and widens gaps in processes, organizational approaches, and systems. This leads 96% of industrial companies to say they need to create and implement new software more quickly. Addressing these application shortfalls is critical to long-term business success. Is developing applications with low-code the answer to filling the gaps? We surveyed over 300 manufacturers to find out.

Our new eBook, Filling Digital Transformation Gaps with Low-Code, looks at the challenges companies face today and how low-code development approaches can help.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

Table of Contents

- Digital Transformation Demands Development Agility

- Examining Digital Transformation Gaps

- Challenges

- Filling Digital Transformation Gaps

- IT Capabilities

- Exploring Low-Code Development

- Benefits

- Conclusions

- About the Research

- Acknowledgments

Digital Transformation

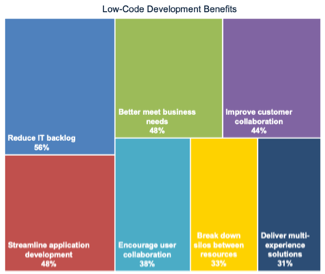

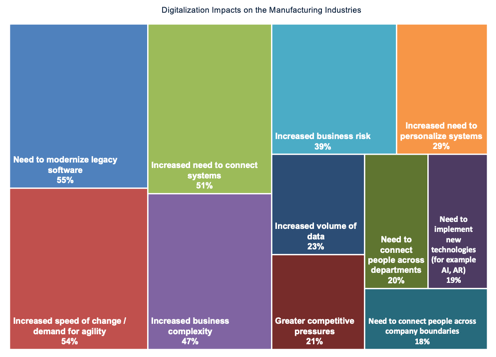

Digital Transformation Puts Pressure on Development Digital transformation is crucial to the success and profitability of today’s industrial companies. But transitioning to a digital business exposes shortfalls and creates gaps in most companies’ software ecosystems. Manufacturers must fill the gaps in their company’s processes, organizational approaches, and systems. Developing solutions to meet digital demands puts significant pressure on application development to do more – and do it faster! How can manufacturers improve the way they develop software applications to fill their digital transformation gaps and achieve their business strategies? We surveyed over 300 manufacturers to find out.Digital Transformation Demands Development Agility

Business Risk Survey respondents share that the digital transformation trend in manufacturing impacts companies in many ways. Digitalization creates business complexity and risk that challenge company viability. Our research shows that about three-quarters of companies shared that business risk and disruption increased for their market over the last five years, and a full one-half of companies with over 10,000 employees said that it had grown “significantly.” These risks demand rapid responses. Demand for Agility The most commonly reported business benefit is the flexibility to work anytime / anywhere, reported by two-thirds of participants. This is followed by ease of collaboration. This capability, along with the ability to have more integrated workflows as reported by about one-half of companies, allows OEMs and the supply chain to work together more efficiently and effectively. This is particularly important for Automotive companies given the global nature of their business, the need to be agile, and the integrated nature of the automotive value chain. Impact on Software Development Digital transformation’s impact on software needs is dramatic. It creates the need to update legacy solutions built for different times and increases the demand to integrate systems and people. It generates the need for new kinds of solutions, including personalized solutions that provide simpler, more focused “apps” that help users accomplish a task and the need to implement new technologies such as Artificial Intelligence (AI) and Augmented Reality (AR). Companies can’t expect to meet these demands if they continue developing solutions in the same way they have been.

Conclusions

Digital Transformation Gaps Manufacturers are keenly aware that digital transformation increases business complexity and risk. Digitalization increases the speed of change, demands more agility, and creates the need for more (and faster) software development. The vast majority of companies have gaps across the digital transformation initiatives they are pursuing. Few companies can fill these gaps very well. This disadvantage is partly due to technical challenges and partly due to their poor ability to collaborate with critical subject matter experts. Filling Gaps with Low-Code Companies must fill their gaps and they are doing so by both building and buying solutions. Low-code development provides them with the ability to build custom their solutions faster. It also enables companies to integrate and extend their COTS solutions more rapidly. Although still in early adoption, low-code development addresses companies’ technical challenges, creates development agility, and supports collaboration so manufacturers can efficiently modernize legacy systems and deploy new applications. The result is that manufacturers using low-code development are better able to fill their digital transformation gaps. We believe that low-code development is a critical capability to explore to drive overall digital transformation efforts. *This summary is an abbreviated version of the ebook and does not contain the full content. For the full research, please visit our sponsor Siemens (registration required). If you have difficulty obtaining a copy of the research, please contact us. [post_title] => Can Low-Code Fill Gaps in Digital Transformation (survey results) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => low-code-digital-transformation [to_ping] => [pinged] => [post_modified] => 2024-09-09 20:46:55 [post_modified_gmt] => 2024-09-10 00:46:55 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=10320 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [12] => WP_Post Object ( [ID] => 10309 [post_author] => 2574 [post_date] => 2021-03-08 19:30:42 [post_date_gmt] => 2021-03-09 00:30:42 [post_content] => Could deeper insights lower some manufacturing costs?

For years, continuous improvement programs have successfully lowered operating costs. Now, companies are using advanced analytics in manufacturing to find even more opportunities. This is not your father’s analytics. Rather, it correlates among different data sources, including IoT, to deliver fresh insights for confidently moving to reduce costs.

Julie Fraser's guest post on PTC’s blog outlines what advanced analytics is and the technologies that support it. Then it explores how advanced analytics can help save costs on asset maintenance and related production problems, reduce energy costs, and keep employees and communities safe. This short read will give you a new foundation to consider ways that advanced analytics in manufacturing might lower costs.

For related research, read Lower Six Manufacturing Costs with IoT. This eBook explores how advanced analytics works with other technologies to reduce costs in a manufacturing plant.

[post_title] => How Advanced Analytics in Manufacturing Can Lead to Cost Cuts (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => advanced-analytics-in-manufacturing

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:40

[post_modified_gmt] => 2022-11-15 03:25:40

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10309

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 10280

[post_author] => 2574

[post_date] => 2021-03-03 12:55:50

[post_date_gmt] => 2021-03-03 17:55:50

[post_content] =>

Could deeper insights lower some manufacturing costs?

For years, continuous improvement programs have successfully lowered operating costs. Now, companies are using advanced analytics in manufacturing to find even more opportunities. This is not your father’s analytics. Rather, it correlates among different data sources, including IoT, to deliver fresh insights for confidently moving to reduce costs.

Julie Fraser's guest post on PTC’s blog outlines what advanced analytics is and the technologies that support it. Then it explores how advanced analytics can help save costs on asset maintenance and related production problems, reduce energy costs, and keep employees and communities safe. This short read will give you a new foundation to consider ways that advanced analytics in manufacturing might lower costs.

For related research, read Lower Six Manufacturing Costs with IoT. This eBook explores how advanced analytics works with other technologies to reduce costs in a manufacturing plant.

[post_title] => How Advanced Analytics in Manufacturing Can Lead to Cost Cuts (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => advanced-analytics-in-manufacturing

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:40

[post_modified_gmt] => 2022-11-15 03:25:40

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10309

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 10280

[post_author] => 2574

[post_date] => 2021-03-03 12:55:50

[post_date_gmt] => 2021-03-03 17:55:50

[post_content] => Table of Contents

- Executive Overview

- Opportunity Brings Challenges

- Retooling to Lifecycle Management Strategies

- Identifying the Top Performers

- Business Capabilities Matter

- Top Performers Manage Product Data Better

- Organizing and Supporting People for Success

- Semiconductor’s Complex Technology Landscape

- Tech-Clarity PLM Value Maturity Model

- Digital Continuity from PLM

- How Semiconductor Companies Differ from Their Customers

- Conclusions

- Recommendations

- About the Author

- About the Research

- Acknowledgments

Overview

Gaining design wins and getting each product into the market profitably is a puzzle. Solving that puzzle repeatedly and reliably is an enterprise- and ecosystem-wide endeavor that requires retooling semiconductor innovation to support that scope. Some appear to have done that. We identified these companies as Top Performers: the companies with the best revenue, profit margin growth, and revenue from products less than two years old. They think and act more holistically. Top Performers have better capabilities for ecosystem collaboration and IP protection, waste less time in product development processes, and have faster time to market. These leaders accomplish their higher performance through better use of commercial technology, including PLM. They have better access to data and digital continuity. Top Performers also exhibit higher digital maturity, managing and sharing data across partners and disciplines. The Top Performers show a way forward for semiconductor, electronics, and high-tech companies.Conclusions

Every aspect of life increasingly depends on semiconductors and electronics to become smarter. Opportunity is growing. Yet to seize it, companies must retool innovation in not only product technology but also enterprise and ecosystem processes. Remember, success rests on achieving product quality, reliability, performance, innovativeness, and cost all at once. Beating the competition in all those ways is no small feat. Top Performers’ Holistic View What differentiates Top Performers from Others is how much they have done to ensure their business and product innovation work effectively. They are better at cross-functional and multi-partner processes than others. Rather than settling for trade-offs, they have developed capabilities to balance all the objectives. They can design successful innovative products while at the same time being efficient and protecting their IP. This balanced view and set of capabilities enable them to get to market faster and more confidently with lower operating costs.- managing their product data, whether BOMs, BOPs, simulation data, or IP

- digital continuity

- data access through the lifecycle

- using PDM or PLM technologies

- collaboration across their enterprise, ecosystem, and product lifecycle.

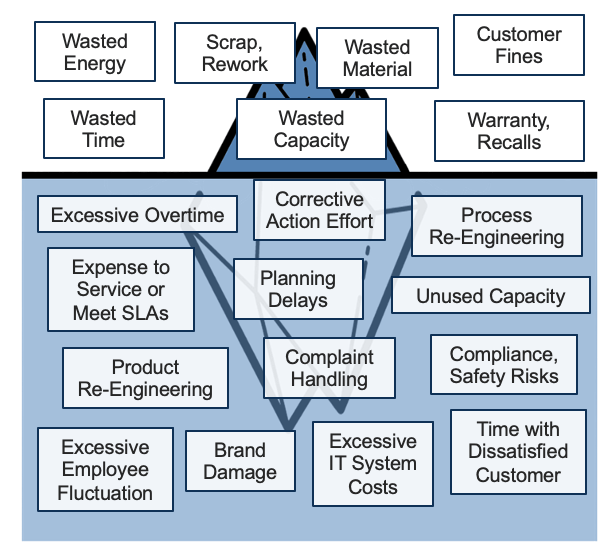

What does Poor Quality Really Cost?

Calculating the actual cost of quality problems is not straightforward. Some of the expenses are apparent, but many are not. Quality is important to customers and to business profitability. So, truly understanding the cost of quality warrants the effort. Fortunately, advanced manufacturing technologies can help analyze and understand expenses plus reduce quality problems and escapes.

Julie Fraser's guest post on PTC’s blog outlines some ways advanced manufacturing technologies can help avoid quality problems, spot patterns to improve processes, and improve team communication. Explore this to consider whether you’ve included all of the costs of poor quality and prevented them in your operation.

For related research, read Lower Six Manufacturing Costs with IoT to explore how new technologies can help keep manufacturing expenses in check.

[post_title] => What is the Cost of Poor Quality in Your Manufacturing Environment? (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cost-of-poor-quality-blog

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:39

[post_modified_gmt] => 2022-11-15 03:25:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10249

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 10222

[post_author] => 2574

[post_date] => 2021-02-16 09:08:02

[post_date_gmt] => 2021-02-16 14:08:02

[post_content] =>

What does Poor Quality Really Cost?

Calculating the actual cost of quality problems is not straightforward. Some of the expenses are apparent, but many are not. Quality is important to customers and to business profitability. So, truly understanding the cost of quality warrants the effort. Fortunately, advanced manufacturing technologies can help analyze and understand expenses plus reduce quality problems and escapes.

Julie Fraser's guest post on PTC’s blog outlines some ways advanced manufacturing technologies can help avoid quality problems, spot patterns to improve processes, and improve team communication. Explore this to consider whether you’ve included all of the costs of poor quality and prevented them in your operation.

For related research, read Lower Six Manufacturing Costs with IoT to explore how new technologies can help keep manufacturing expenses in check.

[post_title] => What is the Cost of Poor Quality in Your Manufacturing Environment? (guest post)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cost-of-poor-quality-blog

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:39

[post_modified_gmt] => 2022-11-15 03:25:39

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10249

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[15] => WP_Post Object

(

[ID] => 10222

[post_author] => 2574

[post_date] => 2021-02-16 09:08:02

[post_date_gmt] => 2021-02-16 14:08:02

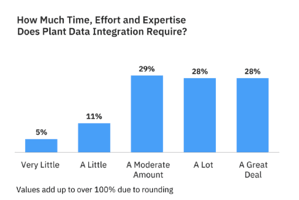

[post_content] =>  What current challenge have manufacturers been wrestling with for at least 35 years?

System integration. Getting manufacturing data to flow has always been a problem. And it still is.

Based on Tech-Clarity research The Manufacturing Data Challenge: Lessons from Top Performers, most of the 300 respondents’ companies need better ways to integrate IT and OT data. Consistency and context are essential to better data management.

Read Julie Fraser’s guest blog on the Critical Manufacturing site. The post points to just how essential – and possible – better and more integrated manufacturing data management is today.

[post_title] => Manufacturing Data: Can It Finally Flow? (guest blog)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-data-guest-blog

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:06

[post_modified_gmt] => 2022-11-15 03:26:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10222

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 10193

[post_author] => 2574

[post_date] => 2021-02-09 15:08:11

[post_date_gmt] => 2021-02-09 20:08:11

[post_content] =>

What current challenge have manufacturers been wrestling with for at least 35 years?

System integration. Getting manufacturing data to flow has always been a problem. And it still is.

Based on Tech-Clarity research The Manufacturing Data Challenge: Lessons from Top Performers, most of the 300 respondents’ companies need better ways to integrate IT and OT data. Consistency and context are essential to better data management.

Read Julie Fraser’s guest blog on the Critical Manufacturing site. The post points to just how essential – and possible – better and more integrated manufacturing data management is today.

[post_title] => Manufacturing Data: Can It Finally Flow? (guest blog)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-data-guest-blog

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:26:06

[post_modified_gmt] => 2022-11-15 03:26:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10222

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 10193

[post_author] => 2574

[post_date] => 2021-02-09 15:08:11

[post_date_gmt] => 2021-02-09 20:08:11

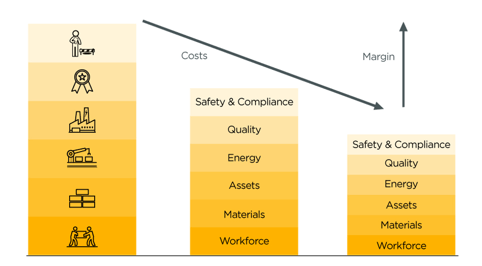

[post_content] =>  How can IoT and advanced technologies lower costs in manufacturing? Lower Six Manufacturing Costs with IoT explores how new technologies can help keep age-old manufacturing expenses in check. The report discusses how the Internet of Things (IoT) and related technologies for monitoring and using data can streamline processes and support people in making profitable decisions.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

How can IoT and advanced technologies lower costs in manufacturing? Lower Six Manufacturing Costs with IoT explores how new technologies can help keep age-old manufacturing expenses in check. The report discusses how the Internet of Things (IoT) and related technologies for monitoring and using data can streamline processes and support people in making profitable decisions.

Please enjoy the summary* below. Please visit our sponsor PTC for the full research (registration required).

Table of Contents

- Cost and Margin

- Workforce Productivity

- Material Costs

- Asset Costs

- Energy Costs

- Cost of Quality

- Safety and Compliance Costs

- Recommendations

- Acknowledgments

Cost and Margin

Age-old Manufacturing Challenges Margins matter. Ever since people began turning materials into higher-value goods and selling them for a living, lowering costs has been an objective for manufacturers. In the margin equation (simplified to income minus expenses), costs are often the easiest to control. For manufacturers, operating costs are a logical place to seek improvement. Manufacturing inherently has a set of input costs: workforce, materials, machinery, energy; lowering those costs improves operating margin. Problems with quality, safety, or compliance can add to the margin squeeze. Smarter Manufacturing to Lower Costs Each advancement in production methods and information technology has allowed better and less expensive production. Previous moves from artisans to steam power to mass production to control automation have each done this. Costs continue to drop with the transition to IT in operations and today’s IoT-connected distributed intelligence. Yet those savings require initial investments to create a smart connected factory. New technologies offer specific ways to reduce costs. We’ll show them in six primary areas:- Workforce productivity

- Materials

- Assets

- Energy

- Quality

- Safety & Compliance

Recommendations

Continuing Cost Reductions Cost improvements are crucial for manufacturers to remain profitable in the “new normal.” Fortunately, technologies for every level are now available to reduce operating costs across all six dimensions. Capabilities to bolster include sensing, monitoring, communicating, analyzing, predicting, and displaying operational data and performance indicators. As with previous generations of manufacturing technology, adding new technologies can create incremental – and sometimes dramatic – cost reductions. Some are one-time savings; many continue to reduce costs. Actions to Get Started While every company’s cost structure and situation is different, there are some things every manufacturer should do.- Examine operating costs and focus efforts on significant needs or easy-to-identify wastes.

- Add IoT sensors to gather more data where critical opportunities lurk.

- Provide workers with as much support as possible through work instructions and remote expert support on-line or through AR goggles.

- Use all data feeds available to monitor materials, processes, and equipment precisely.

- Assess energy and quality in detail and add guidance or monitoring to keep costs in line with revenues.

- Consider compliance and EH&S systems – are you still facing risks?

- Consider how new technologies in this paper will integrate with and leverage current automation and software systems.

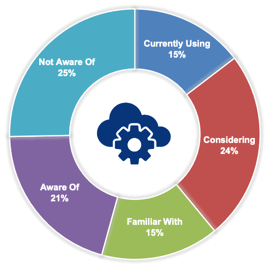

How can Aerospace and Defense (A&D) companies streamline collaboration and create digital continuity? What should they look for in a PLM system to support a cohesive digital thread, especially given that their IT systems were not designed for remote work during a pandemic?

This eBook takes a deeper dive into the data from our original, cross-industry study on the digital thread to better understand how the value and considerations for digital thread adoption apply to A&D companies.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

You can also watch our related digital thread webcast.

How can Aerospace and Defense (A&D) companies streamline collaboration and create digital continuity? What should they look for in a PLM system to support a cohesive digital thread, especially given that their IT systems were not designed for remote work during a pandemic?