How can a comprehensive manufacturing software suite that works across batch, hybrid, and complex discrete industries hosted on cloud, edge, or on-prem deliver more value? GE Vernova’s answer is to improve central data management, embed more AI, and enable customers to unlock capacity through detailed scheduling. The GE Vernova's Proficy® Software & Services Suite update for 2025 introduces the Proficy Data Hub. The company also recently acquired long-time partner ROB-EX A/S for detailed and finite scheduling.

New Data Hub with AI

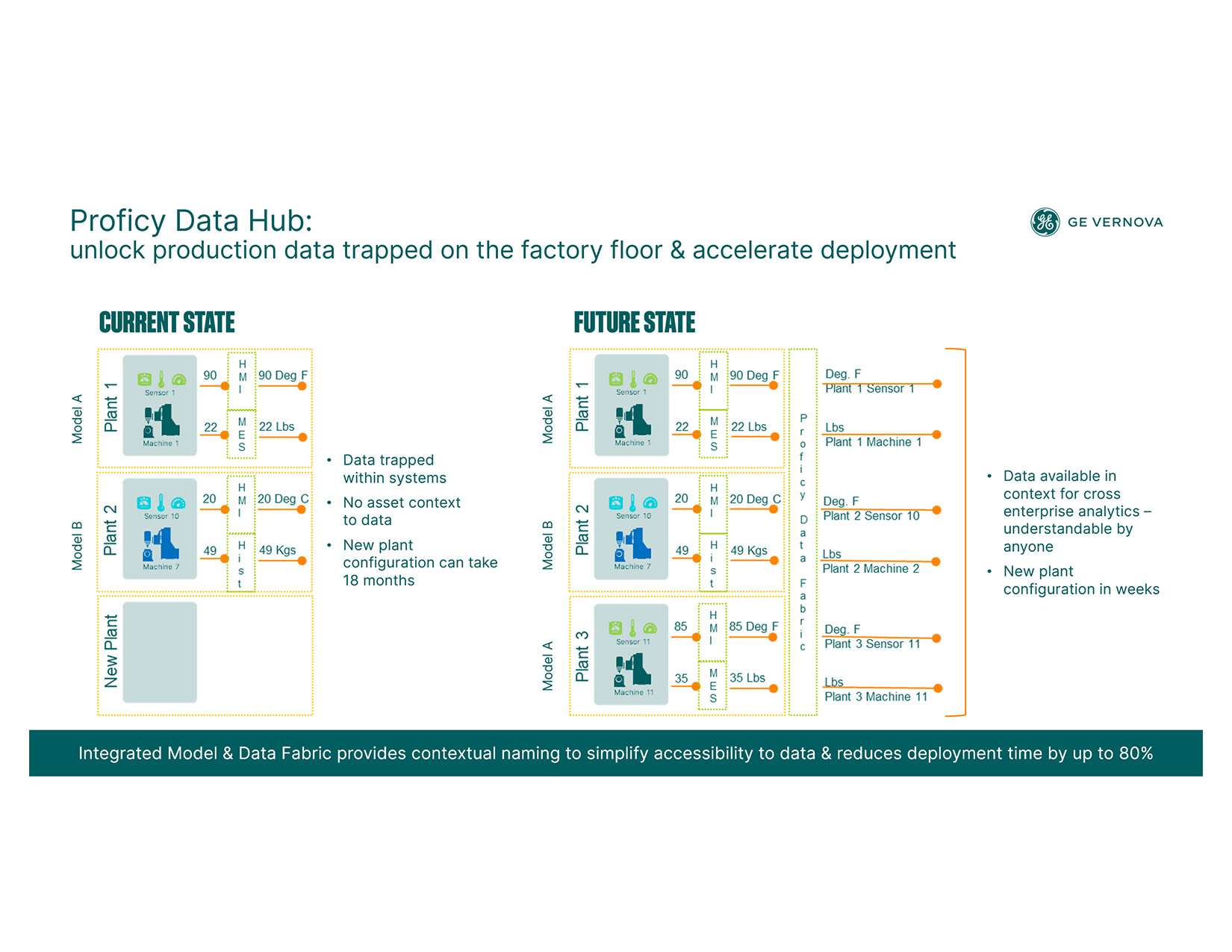

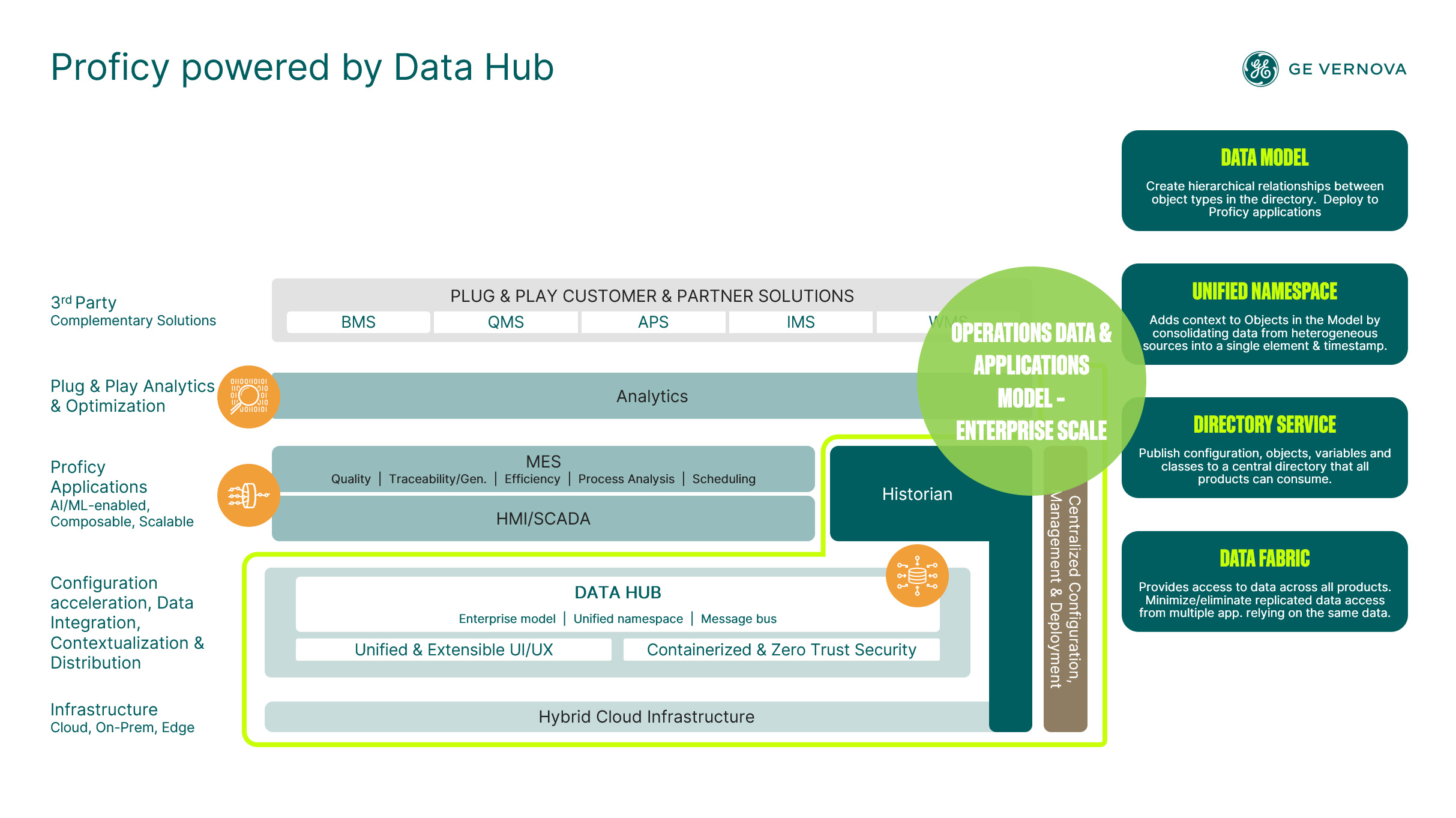

The big news in the Proficy 2025 announcement is the Proficy Data Hub. This coherent Unified Name Space (UNS)-style addition simplifies data access. It incorporates a single UNS-style data model plus uses the data fabric concept to streamline access to data in any system of record to put into context in that data model. The company estimates it can reduce deployment time by up to 80%, and this will be validated in early test cases.

Data Hub provides natural language access and context to any data in one or multiple plants. As IT/OT convergence continues, the data challenges can be overwhelming, and the Data Hub sets out to address those. Using natural language queries (read AI), customers can more easily find the data they need.

The central, consistent Data Hub can support enterprise-wide consistency and governance. The previously released Proficy Operations Hub helps domain experts design visual user experiences with low-code/no-code and includes analysis widgets. Together, the Operations and Data Hubs can help configure any Proficy software for each customer’s (and each role’s) needs and deploy across one or many plants. It can also support coherent data viewing and analysis.

ROB-EX Scheduler Acquisition

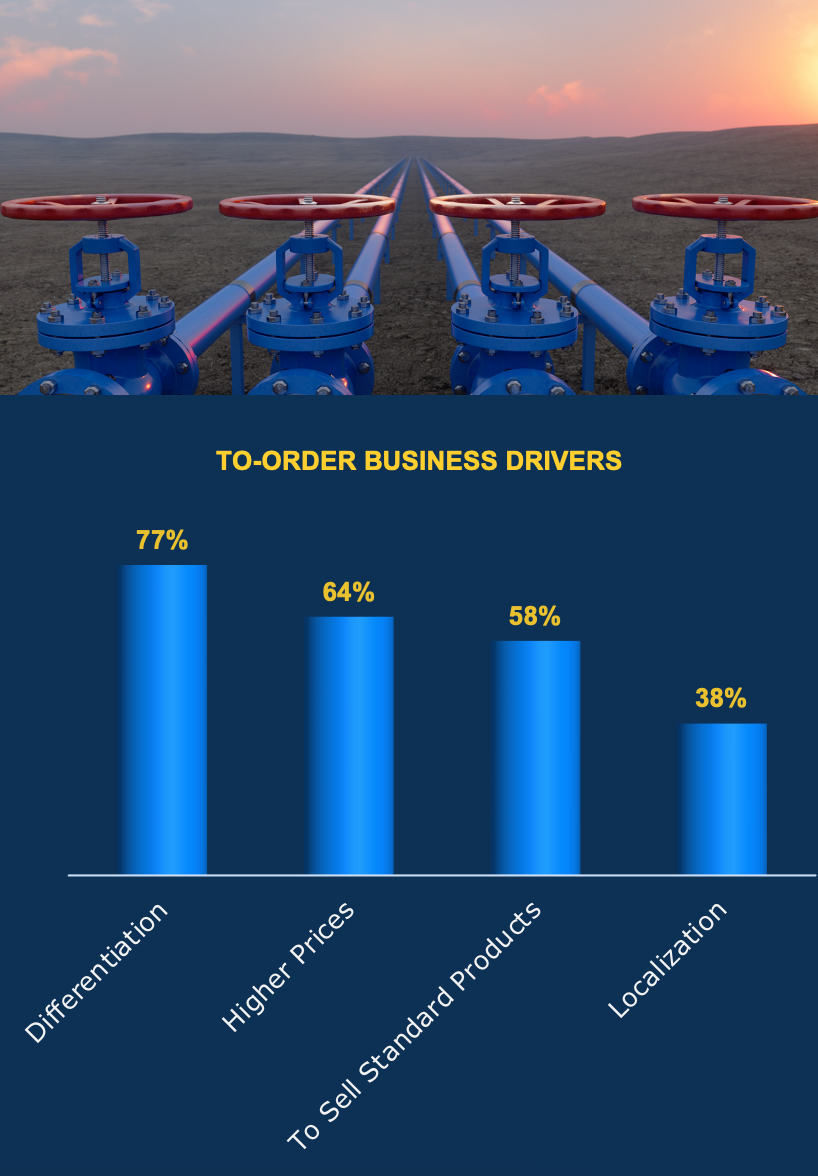

In addition to the Proficy Suite's organic growth, GE Vernova signed an agreement in December to acquire scheduling company ROB-EX. The ROB-EX scheduler has been offered as part of the Proficy Suite for over a decade.

In our view, MES and Scheduling need each other to be fully effective and deliver maximum value. Together, they can not only guide and plan but also optimize production. The benefits of an MES-APS combination may include on-time delivery, cost, quality, and asset and resource utilization. Sequencing matters to many types of operations, and ROB-EX boasts customers in discrete, process, and project manufacturing.

As a part of the same company, we expect to see tighter integration and synchronized innovation, as we have for the rest of the Proficy suite. In the future, we expect to see more scheduling interaction with MES and the Data Hub, HMI/SCADA, and CSense analytics.

AI and Analytics

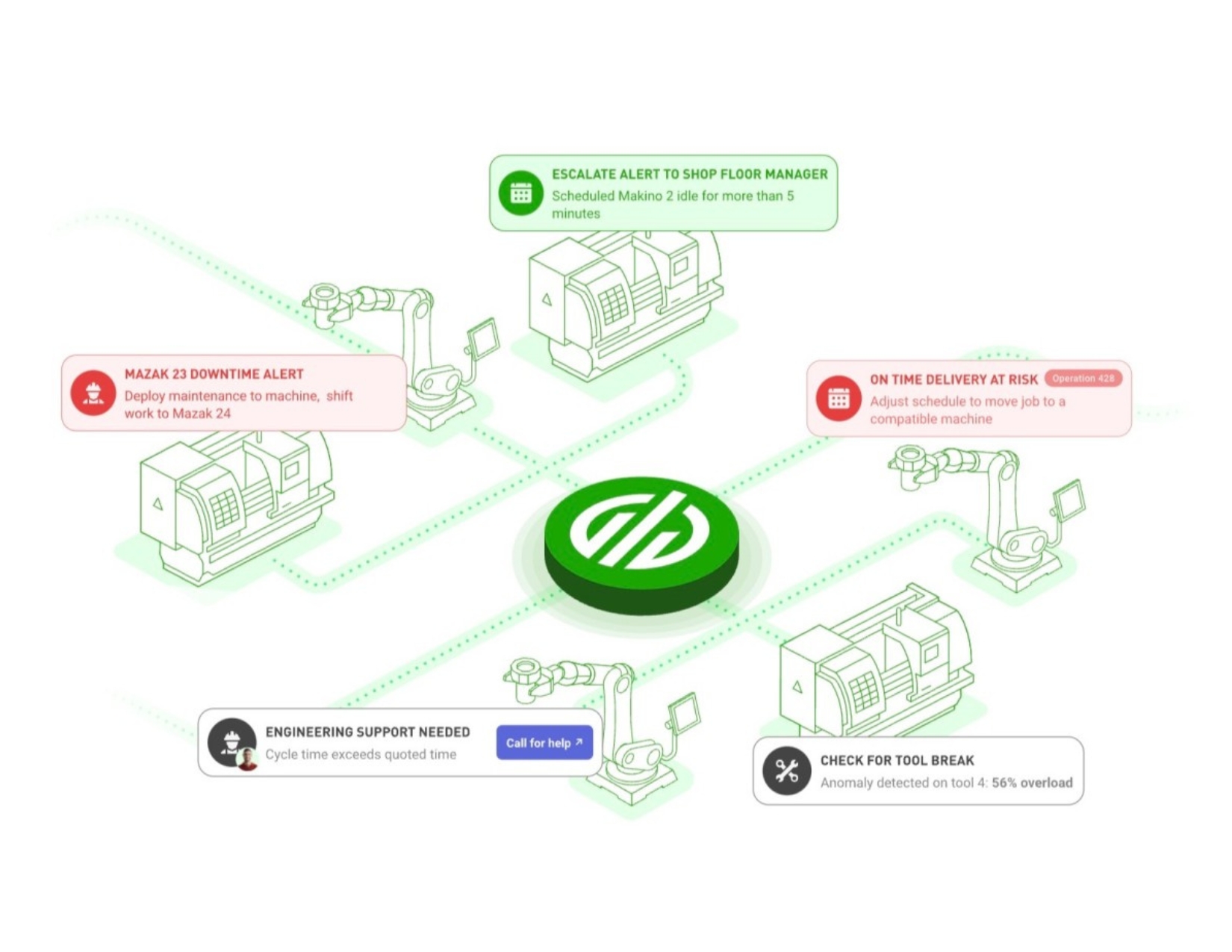

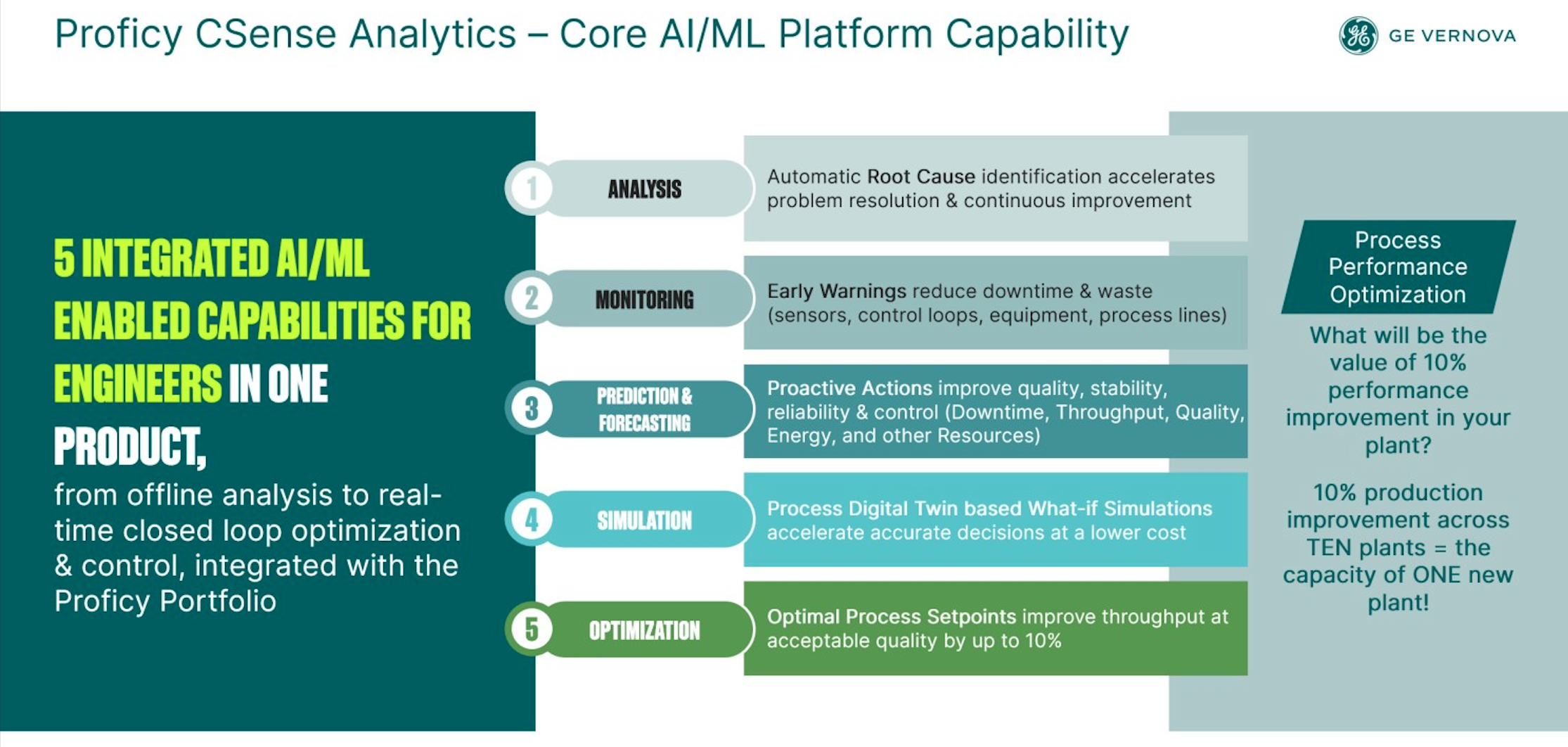

CSense, the Proficy Suite ML-based analytics platform, is not new. It has long provided analysis, monitoring, prediction and forecasting, simulation, and optimization. However, GE Vernova has added more models for common problems customers face to enable customers to do more, even if their team is not fully trained to leverage modern AI technologies.

For example, there’s now a downtime prediction model and alarm pattern recognition in the SCADA. Customers have their own issue-specific models, too. For example, a major automotive manufacturer uses a model for weld quality, and one of the world’s largest forest products company uses a model for chipboard press optimization.

At their recent Users conference in Lisbon, GE Vernova demonstrated pilots of how GenAI could be used in three ways in Proficy:

- The system can automatically add new elements based on widgets to visual screens in the Operations Hub.

- For example, generating output using natural language to build instances of a known machine type.

- Natural language queries using a GraphQL database on top of the Smart Factory MES.

Proficy Suite Keeps Improving

All of this is on top of strengthening based on strategic moves from the past few years. Proficy has become a much more integrated and flexible suite to deploy over the past several years. We see particular value in adding Data Hub to support:

- Operations Hub, which was the Predix IIoT platform

- Proficy Sustainability Insights, which already leverages Proficy data on W.A.G.E.S. (water, air, gas, electric, steam) use

- Mixing cloud and on-premise Historian, HMI/SCADA, and MES

- Creating data flows that include non-Proficy software

- Rolling out across multiple plants to improve enterprise visibility and control

Thank you, Stephen Pavlosky, for updating us on the 2025 Proficy improvements. We look forward to hearing Proficy news as it comes!

Thank you, Stephen Pavlosky, for updating us on the 2025 Proficy improvements. We look forward to hearing Proficy news as it comes!

We also heard that the biggest push this year is Datahub, which syncs data from other sources using a no-code data integration approach. We believe this is a critical element to support their mission, but we didn’t get into much detail about that as of yet.

We also heard that the biggest push this year is Datahub, which syncs data from other sources using a no-code data integration approach. We believe this is a critical element to support their mission, but we didn’t get into much detail about that as of yet.