I had the opportunity to visit Graphisoft’s Budapest headquarters for their recent Building Together | Connect event. I left the event with several key takeaways: They showed significant progress and alignment around their strategic vision to integrate AEC design processes across disciplines They delivered on a variety of enhancement requests for their existing customer base…

- They showed significant progress and alignment around their strategic vision to integrate AEC design processes across disciplines

- They delivered on a variety of enhancement requests for their existing customer base

- They demonstrated a product roadmap process that provides transparency and advanced insights while balancing strategic and tactical enhancements

Graphisoft shared its strategy and pointed to significant progress that will help integrate the work of its traditional architect customer base with others. At the event, they shared the release of the MEP Modeler in Archicad and new capabilities in DDScad. They plan to continue to add MEP / structural capabilities with every release. They also demonstrated enhancements to BIMcloud and BIMx that help support collaboration and interoperability to support industry initiatives and standards, including open BIM.

As a reflection of their integrated approach, they merged their product release announcements into one instead of individual announcements for Archicad, DDScad, BIMcloud, and BIMx. That might seem subtle, but it’s a meaningful statement about the importance of integration and evidence of a more integral product planning process and mindset.

Delivering on Customer Requests

The launch event was open to customers and Graphisoft paid clear attention to enhancements that make life better for existing customers. Graphisoft confirmed that “architects will always be at the center of our thinking,” even as they extend capabilities for multidisciplinary teams. These announcements are not the type that excite the market, but they are the tactical improvements that customers love. Some examples included integrated design option management to prevent the need to make numerous copies of a model, improved attribute management, smart distance guides, streamlined manufacturing library import, advanced model compare, and enhanced search. Graphisoft experts explained each of these in detail, and although the customer audience was remote, I could imagine their pleased responses. Graphisoft also added improved documentation for single-line drawings, which will likely make certain customers happy and also make Archicad more attractive in North America. It appears Graphisoft delivered some real value to existing customers with this release.

New Roadmapping Process

As mentioned, the announcement shared enhancements to help Graphisoft deliver on its vision but also showed strong evidence that they are listening to their customers. I met with the head of product management, Sylwester Pawluk, and Ghaleb Khadra from professional services to understand their product planning approach for the release. The plan included a mix of strategic additions like one-click LCA and tactical customer enhancements. What’s new, I’m told, is that Graphisoft has adopted a transparent roadmap so customers know what to expect. They also implemented a new technology preview process to share the enhancements with customers in advance and gained a very positive reaction to the release from their pre-release preview process.

Graphisoft now offers a live roadmap on its website, and this release shows that they delivered on their promises. In addition to solid roadmap items, Graphisoft shared research initiatives they’re focused on, including AI assistance, parametrics, and augmented / virtual reality. We expect to see results from these added to their roadmap over time. Again, Graphisoft is showing transparency and gaining credibility by announcing what they’re working on and adding it to the roadmap as they become confident of when and how they’ll upgrade their capabilities.

Final Thoughts

It’s great to see progress on both vision and customer-oriented enhancements. We’re excited about Graphisoft’s vision to offer a more integrated AEC solution while supporting existing architect customers. To do this, we expect to see continued investment in their existing solutions. We also believe we will see Graphisoft leverage more capabilities from across parent company, Nemetschek, to fulfill their vision and bring more value to their customers. AEC software is a dynamic market with significant opportunities for vendors and the industry. We look forward to seeing what Graphisoft delivers next.

Thank you to CEO Huw Roberts, Ron Close, Julianna Gulden, and the Graphisoft events team for inviting me to join such a well-organized, informative event. Further thanks to Sylwester Pawluk and Ghaleb Khadra for sharing product strategy and progress.

For more information about integrating design processes, see the survey results from our The State of Collaborative Design in AEC study.

[post_title] => Graphisoft Delivers New Capabilities, Progress on Integrated Design Vision

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => graphisoft-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-14 16:23:20

[post_modified_gmt] => 2023-12-14 21:23:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18831

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 18742

[post_author] => 2574

[post_date] => 2023-10-17 09:00:05

[post_date_gmt] => 2023-10-17 13:00:05

[post_content] =>

Graphisoft shared its strategy and pointed to significant progress that will help integrate the work of its traditional architect customer base with others. At the event, they shared the release of the MEP Modeler in Archicad and new capabilities in DDScad. They plan to continue to add MEP / structural capabilities with every release. They also demonstrated enhancements to BIMcloud and BIMx that help support collaboration and interoperability to support industry initiatives and standards, including open BIM.

As a reflection of their integrated approach, they merged their product release announcements into one instead of individual announcements for Archicad, DDScad, BIMcloud, and BIMx. That might seem subtle, but it’s a meaningful statement about the importance of integration and evidence of a more integral product planning process and mindset.

Delivering on Customer Requests

The launch event was open to customers and Graphisoft paid clear attention to enhancements that make life better for existing customers. Graphisoft confirmed that “architects will always be at the center of our thinking,” even as they extend capabilities for multidisciplinary teams. These announcements are not the type that excite the market, but they are the tactical improvements that customers love. Some examples included integrated design option management to prevent the need to make numerous copies of a model, improved attribute management, smart distance guides, streamlined manufacturing library import, advanced model compare, and enhanced search. Graphisoft experts explained each of these in detail, and although the customer audience was remote, I could imagine their pleased responses. Graphisoft also added improved documentation for single-line drawings, which will likely make certain customers happy and also make Archicad more attractive in North America. It appears Graphisoft delivered some real value to existing customers with this release.

New Roadmapping Process

As mentioned, the announcement shared enhancements to help Graphisoft deliver on its vision but also showed strong evidence that they are listening to their customers. I met with the head of product management, Sylwester Pawluk, and Ghaleb Khadra from professional services to understand their product planning approach for the release. The plan included a mix of strategic additions like one-click LCA and tactical customer enhancements. What’s new, I’m told, is that Graphisoft has adopted a transparent roadmap so customers know what to expect. They also implemented a new technology preview process to share the enhancements with customers in advance and gained a very positive reaction to the release from their pre-release preview process.

Graphisoft now offers a live roadmap on its website, and this release shows that they delivered on their promises. In addition to solid roadmap items, Graphisoft shared research initiatives they’re focused on, including AI assistance, parametrics, and augmented / virtual reality. We expect to see results from these added to their roadmap over time. Again, Graphisoft is showing transparency and gaining credibility by announcing what they’re working on and adding it to the roadmap as they become confident of when and how they’ll upgrade their capabilities.

Final Thoughts

It’s great to see progress on both vision and customer-oriented enhancements. We’re excited about Graphisoft’s vision to offer a more integrated AEC solution while supporting existing architect customers. To do this, we expect to see continued investment in their existing solutions. We also believe we will see Graphisoft leverage more capabilities from across parent company, Nemetschek, to fulfill their vision and bring more value to their customers. AEC software is a dynamic market with significant opportunities for vendors and the industry. We look forward to seeing what Graphisoft delivers next.

Thank you to CEO Huw Roberts, Ron Close, Julianna Gulden, and the Graphisoft events team for inviting me to join such a well-organized, informative event. Further thanks to Sylwester Pawluk and Ghaleb Khadra for sharing product strategy and progress.

For more information about integrating design processes, see the survey results from our The State of Collaborative Design in AEC study.

[post_title] => Graphisoft Delivers New Capabilities, Progress on Integrated Design Vision

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => graphisoft-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-14 16:23:20

[post_modified_gmt] => 2023-12-14 21:23:20

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18831

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 18742

[post_author] => 2574

[post_date] => 2023-10-17 09:00:05

[post_date_gmt] => 2023-10-17 13:00:05

[post_content] =>  How do you manage a semiconductor production facility? Most people in the chip industry would say: with semiconductor MES. With its complex processes and products that cannot be clearly seen with the naked human eye, the semiconductor industry began broadly adopting MES in the 1980s and 1990s.

And therein lies the problem. The systems that many semiconductor professionals know - and some still use - are completely outdated. This guest blog post by Julie Fraser points out that just as the semiconductor industry has changed radically, so has the software available to support it. She argues it is time for redefining semiconductor MES.

The new definition encompasses many new changes in four categories:

How do you manage a semiconductor production facility? Most people in the chip industry would say: with semiconductor MES. With its complex processes and products that cannot be clearly seen with the naked human eye, the semiconductor industry began broadly adopting MES in the 1980s and 1990s.

And therein lies the problem. The systems that many semiconductor professionals know - and some still use - are completely outdated. This guest blog post by Julie Fraser points out that just as the semiconductor industry has changed radically, so has the software available to support it. She argues it is time for redefining semiconductor MES.

The new definition encompasses many new changes in four categories:

- Functionality

- Integration and data availability

- Configuration and scalability

- Solution partner experience

What is the most important way a company can help supply chain resilience so it has a positive impact on the business? What are Top-Performing companies doing differently than others? How important are autonomous systems and artificial intelligence (AI)? What does the transformation of supply chain planning entail?

Read this new survey-based eBook to find out more about what really matters most to resilience. Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

What is the most important way a company can help supply chain resilience so it has a positive impact on the business? What are Top-Performing companies doing differently than others? How important are autonomous systems and artificial intelligence (AI)? What does the transformation of supply chain planning entail?

Read this new survey-based eBook to find out more about what really matters most to resilience. Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

Table of Contents

- Executive Summary

- Supply Chain Challenges Persist

- Supply Chain Resilience

- Resilience: Improving Business Results

- Factors in Positive Supply Chain Impact

- Visibility into Production

- Visibility into Product Changes

- People in the Planning Process

- Technology Hurdles

- Integrating Software Applications

- Technologies for Planning

- AI and Autonomous Support

- Plan Cadence and Structure

- Investing in Resilience

- Drivers for Resilience

- Benefits from Investing

- Redefining Planning Scope

- Recommendations

- About the Research

- Acknowledgments

Executive Summary

Transforming to Succeed

Every manufacturer has suffered supply chain challenges in the past few years. Thus, supply chain resilience is top of mind but takes work to achieve. What needs to change is typically the scope and focus of planning.

This research shows that transforming and expanding the thinking, team, and processes to achieve resilience in planning can have significant business benefits.

Top Performers’ View

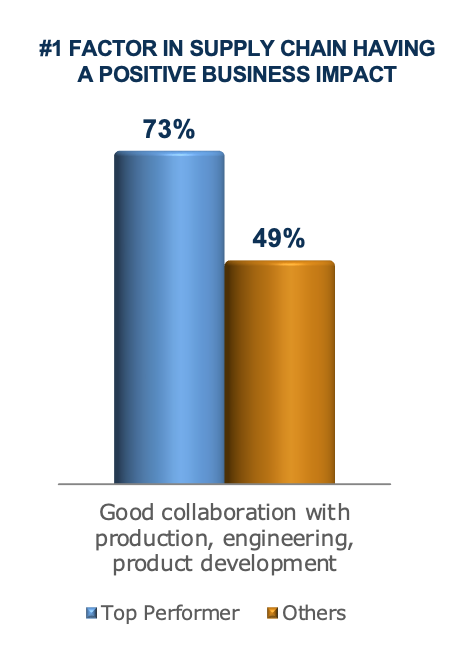

In this survey of 229 manufacturers, Top Performers show the way. These Top Performers are defined by superior performance on business metrics around new products, revenue, profit, and time to market.

Best Practices

Top Performers’ planning is far more likely to involve the entire organization and its data. Not just sourcing, planning, scheduling, and logistics from the supply chain discipline but also product design, process engineering, and manufacturing. The involvement of these disciplines in planning is the #1 factor for Top Performers’ supply chains positively impacting the business. Top Performers are significantly more likely to cite this factor, so it’s a differentiator in what they do. (See chart)

Resilience is an Attainable Initiative

The good news is that internal collaboration and visibility to data from internal manufacturing and engineering groups is a resilience initiative any company can undertake. To succeed with such a program, manufacturers need software that supports a broad-based planning process transformation. Capabilities such as a common data platform and multi-discipline collaboration are crucial to success.

Investing Delivers Benefits

Companies that invest in transformation for resilience are seeing the benefits. This research shows that the longer you invest, the more likely you are to see benefits. Top Performers provide a blueprint for where to focus investment, who to involve, and what to expect from this transformation

Transforming to Succeed

Every manufacturer has suffered supply chain challenges in the past few years. Thus, supply chain resilience is top of mind but takes work to achieve. What needs to change is typically the scope and focus of planning.

This research shows that transforming and expanding the thinking, team, and processes to achieve resilience in planning can have significant business benefits.

Top Performers’ View

In this survey of 229 manufacturers, Top Performers show the way. These Top Performers are defined by superior performance on business metrics around new products, revenue, profit, and time to market.

Best Practices

Top Performers’ planning is far more likely to involve the entire organization and its data. Not just sourcing, planning, scheduling, and logistics from the supply chain discipline but also product design, process engineering, and manufacturing. The involvement of these disciplines in planning is the #1 factor for Top Performers’ supply chains positively impacting the business. Top Performers are significantly more likely to cite this factor, so it’s a differentiator in what they do. (See chart)

Resilience is an Attainable Initiative

The good news is that internal collaboration and visibility to data from internal manufacturing and engineering groups is a resilience initiative any company can undertake. To succeed with such a program, manufacturers need software that supports a broad-based planning process transformation. Capabilities such as a common data platform and multi-discipline collaboration are crucial to success.

Investing Delivers Benefits

Companies that invest in transformation for resilience are seeing the benefits. This research shows that the longer you invest, the more likely you are to see benefits. Top Performers provide a blueprint for where to focus investment, who to involve, and what to expect from this transformation

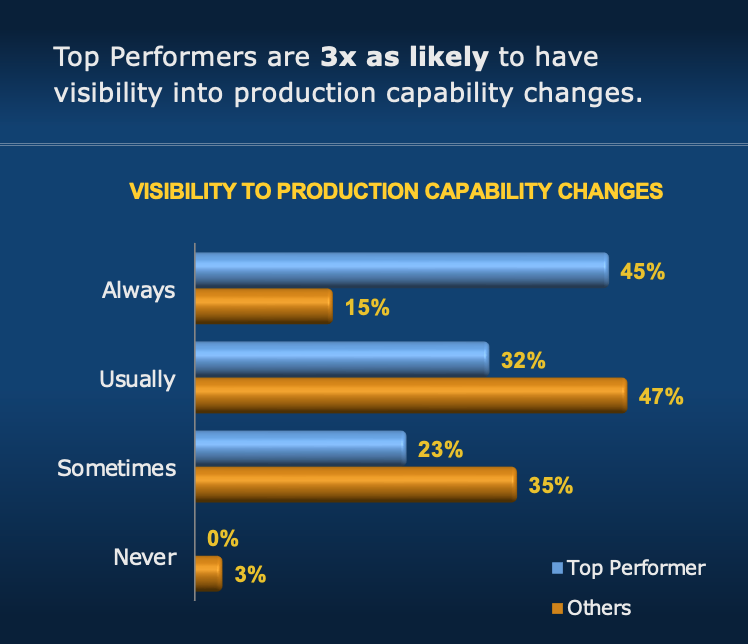

Visibility into Production

Capabilities Change

After collaboration, visibility is the next most important factor in achieving positive supply chain impacts on the business. Manufacturers typically have continuous improvement programs that regularly boost production capabilities. Every time there is such a change, the basis of the supply chain plans should shift.

Hole in the Center

While manufacturing or “make” sits at the center of the supply chain, many companies do not have good visibility into production. The plant floor has often been described as a “black hole” for information flow: it goes in but does not come out readily.

Challenges Seeing Manufacturing Clearly

Capabilities Change

After collaboration, visibility is the next most important factor in achieving positive supply chain impacts on the business. Manufacturers typically have continuous improvement programs that regularly boost production capabilities. Every time there is such a change, the basis of the supply chain plans should shift.

Hole in the Center

While manufacturing or “make” sits at the center of the supply chain, many companies do not have good visibility into production. The plant floor has often been described as a “black hole” for information flow: it goes in but does not come out readily.

Challenges Seeing Manufacturing Clearly

- People: Plant floor people have wanted their systems separate to ensure maximum uptime to support ongoing production.

- Process: Production can change minute-to-minute, so understanding what’s relevant and creating a pipeline appropriate to each planning cadence is dynamic.

- Technology: Separate systems with incompatible data formats and levels of granularity or detail abound in plants. Adding appropriate context for production data to be useful in supply chain planning is a common challenge, along with the need for a uniform data platform.

Redefining Planning Scope

Breadth of Operations For resilience, supply chain planning must transform and expand to ALL operations. Aligning within supply chain based on every aspect, from product specs to production capabilities, is crucial. That means integration of this data must be complete and as seamless as possible. Processes also need to involve all of these disciplines fully. Collaboration What appears to make the most difference in supply chain resilience is involving the right people. Collaboration between supply chain, manufacturing engineering, production operations, and product design is a top priority for resilience. Planning processes must be inclusive; ideally, technology will support this effort. Technology Support Scope Many companies will need to make technology investments to plan based on this scope. Based on these survey results, manufacturers need visibility, data access and normalization, and an enterprise collaboration platform. Digital twins of the supply chain, products, and production processes that enable the virtual and real to stay in sync even through extreme volatility could play a significant role *This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Transformation for Supply Chain Resilience [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => supply-chain-resilience [to_ping] => [pinged] => [post_modified] => 2023-12-19 16:58:16 [post_modified_gmt] => 2023-12-19 21:58:16 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18749 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [3] => WP_Post Object ( [ID] => 18729 [post_author] => 2 [post_date] => 2023-10-05 14:09:32 [post_date_gmt] => 2023-10-05 18:09:32 [post_content] => Julie Fraser and I are enthusiastic about the potential for manufacturers to get more from their data following a briefing with enterprise search company Sinequa. Sinequa is tailoring their search applications to directly support manufacturers who want more holistic, integrated intelligence about their products and their business. Being able to find and connect data across disparate systems is always a challenge, but even more important is what you do with it once you find it. Sinequa can integrate with a variety of systems to ingest, enrich, index, and present valuable manufacturing data in the proper context. For example, a Sinequa application could collect and display the various elements of a product digital thread from data spread across underlying systems like PLM, QMS, and ERP. Sinequa also leverages AI to help users “converse” with the content. For example, they leverage large language models to surface and contextualize both structured and unstructured information about products that a typical employee would not have access to, or perhaps know existed, from related systems. It’s important to note here that Sinequa has developed a mature security model so users will not be presented with information they do not have permission to access. These capabilities have the potential to provide a much richer, more holistic view of manufacturing data. This view can help manufacturers better understand their products and business and ultimately make better decisions. They’ve developed applications for a very compelling set of customers, including Alstom, Airbus, Northrop Grumman, and NASA, that they’ve helped with information-intensive processes like maintenance and support, among others. We’re excited to see their progress and how the manufacturing community receives the application templates they’re developing. It will also be interesting to see how they partner with PLM vendors and potentially expand to operational data like MES. We’re excited to learn more. Thank you, Xavier Pornain, Laurent Fanichet, Michael Finocchiaro, and John Lenker, for explaining your vision and progress.

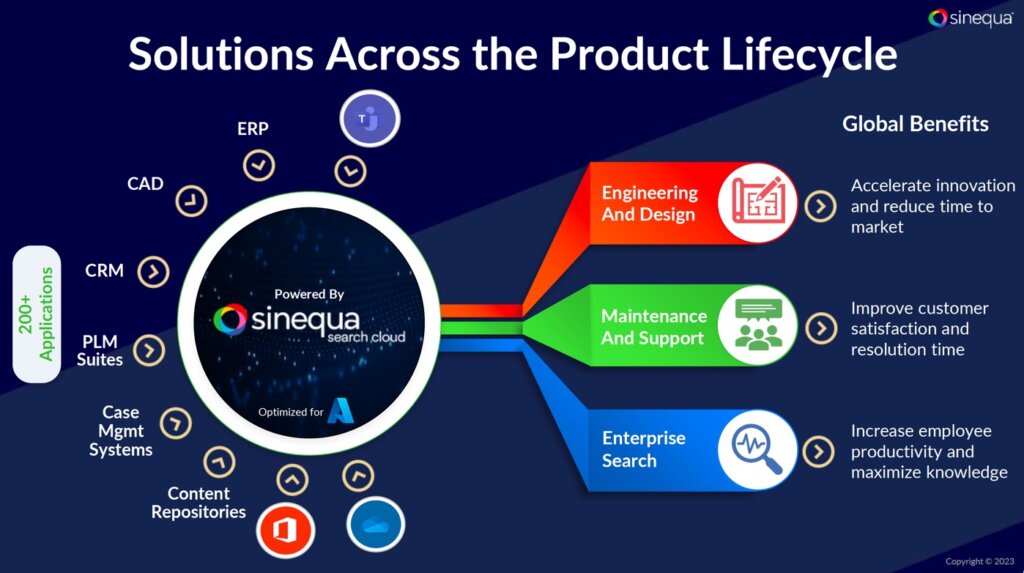

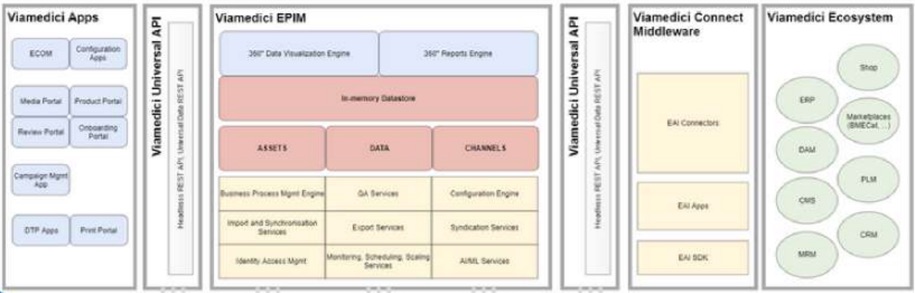

[post_title] => Sinequa Brings Enterprise Search to Product and Manufacturing Data [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => enterprise-search-sinequa-insight [to_ping] => [pinged] => [post_modified] => 2023-10-05 14:10:40 [post_modified_gmt] => 2023-10-05 18:10:40 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18729 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 18722 [post_author] => 2 [post_date] => 2023-10-03 09:18:58 [post_date_gmt] => 2023-10-03 13:18:58 [post_content] => We had an interesting update from Viamedici, a company we’ve been following that digitalizes product management and product marketing for manufacturers. They offer a multi-domain MDM platform that started in the manufacturing industry and has now expanded to multichannel distributors and retailers. Viamedici quickly achieved a strong footprint in this vertical by acquiring another PIM vendor and upgrading all clients to their platform. Their customers use their platform to collect, cleanse, and share digital data from product design, development, marketing, and supplier data. Many of their customers also use their DAM solution, although others integrate with a complementary or existing solution. They also offer an interesting, model-based CPQ system to handle configured / personalized products or support a guided selling and guided buying model. We’re intrigued by their offering and the potential it has to provide an integrated, cloud platform for MDM, PIM, DAM, and CPQ. Thank you for the update Juergen Mueller and Sven Litke, and it was nice to meet some of the rest of the team.

[post_title] => Viamedici Integrates MDM, PIM, DAM, and CPQ on the Cloud [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => viamedici-insight [to_ping] => [pinged] => [post_modified] => 2023-10-03 09:19:45 [post_modified_gmt] => 2023-10-03 13:19:45 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18722 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [5] => WP_Post Object ( [ID] => 18707 [post_author] => 2574 [post_date] => 2023-10-03 09:00:17 [post_date_gmt] => 2023-10-03 13:00:17 [post_content] => Many companies are talking about environmental sustainability – and GE Digital is aiming to embed it in customers’ operations. Jim Brown and I recently got an update from Ben Whiteman on their progress toward that end. The problems they want to solve are:

- operationalizing environmental sustainability goals

- breaking siloes between operations and sustainability

- providing process context to optimize resources more fully

[post_title] => GE Aims to Operationalize Sustainability

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => operationalize-sustainability

[to_ping] =>

[pinged] =>

[post_modified] => 2023-10-11 11:51:12

[post_modified_gmt] => 2023-10-11 15:51:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18707

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 18704

[post_author] => 2

[post_date] => 2023-09-26 15:35:39

[post_date_gmt] => 2023-09-26 19:35:39

[post_content] => What’s the right amount of PLM for small to midsized manufacturers? We had a briefing with Office PLM to understand their offering. I spoke with Philip Thurman and he explained that Office PLM has all of the features a PLM system needs, but is affordable and installs in a couple of hours. I’m sure we could all have a long discussion about what features PLM “should” have, but what I saw meets what we call “Extended PLM” that goes beyond managing CAD to cover core revision, BOM, configuration, and engineering change functionality with a configurable workflow. They have a goal to simplify PLM and I suspect that their scope hits the sweet spot for a lot of manufacturers that don’t have time to implement a more complex application. Their integration with SOLIDWORKS and should also appeal to many smaller manufacturers. They offer a lot of educational information about PLM as well to help get their customers up to speed. Smaller manufacturers and suppliers should include Office PLM in their research if they’re looking for a lightweight PLM system. Thank you Philip for taking the time to get me up to speed on Office PLM. I look forward to learning more.

[post_title] => GE Aims to Operationalize Sustainability

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => operationalize-sustainability

[to_ping] =>

[pinged] =>

[post_modified] => 2023-10-11 11:51:12

[post_modified_gmt] => 2023-10-11 15:51:12

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18707

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 18704

[post_author] => 2

[post_date] => 2023-09-26 15:35:39

[post_date_gmt] => 2023-09-26 19:35:39

[post_content] => What’s the right amount of PLM for small to midsized manufacturers? We had a briefing with Office PLM to understand their offering. I spoke with Philip Thurman and he explained that Office PLM has all of the features a PLM system needs, but is affordable and installs in a couple of hours. I’m sure we could all have a long discussion about what features PLM “should” have, but what I saw meets what we call “Extended PLM” that goes beyond managing CAD to cover core revision, BOM, configuration, and engineering change functionality with a configurable workflow. They have a goal to simplify PLM and I suspect that their scope hits the sweet spot for a lot of manufacturers that don’t have time to implement a more complex application. Their integration with SOLIDWORKS and should also appeal to many smaller manufacturers. They offer a lot of educational information about PLM as well to help get their customers up to speed. Smaller manufacturers and suppliers should include Office PLM in their research if they’re looking for a lightweight PLM system. Thank you Philip for taking the time to get me up to speed on Office PLM. I look forward to learning more.

[post_title] => Is Office PLM Right for Small to Midsize Manufacturers? [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => office-plm [to_ping] => [pinged] => [post_modified] => 2023-10-02 14:10:40 [post_modified_gmt] => 2023-10-02 18:10:40 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18704 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [7] => WP_Post Object ( [ID] => 18680 [post_author] => 2 [post_date] => 2023-09-21 10:00:59 [post_date_gmt] => 2023-09-21 14:00:59 [post_content] =>

Michelle Boucher and I joined a group of industry analysts for an annual visit to Dassault Systèmes headquarters for an update on their business performance, product progress, and corporate strategy. This year did not disappoint. We had a lot of great conversations with company leadership and heard some really interesting updates. I’m going to try to condense our experience down to a number of key areas and follow that with a list of interesting things you may want to learn more about.

In summary, my observations are that:

Michelle Boucher and I joined a group of industry analysts for an annual visit to Dassault Systèmes headquarters for an update on their business performance, product progress, and corporate strategy. This year did not disappoint. We had a lot of great conversations with company leadership and heard some really interesting updates. I’m going to try to condense our experience down to a number of key areas and follow that with a list of interesting things you may want to learn more about.

In summary, my observations are that:

- The Dassault Systèmes business is strong and well positioned for the future

- They are making significant investment, and progress, on their cloud transition

- They are invested in sustainability, focusing on both direct and indirect impacts

- They are exploring an interesting new line of services called XaaS, or Experience as a Service, that have the potential to change the way capabilities like the digital twin are delivered

Some final thoughts. I won’t do them all justice here, but follow our research for more.

Business Process Management Dassault Systèmes is moving beyond features and experiences to business processes. Highlights here are a new BPM offering and the plan to offer business experiences that customers can purchased from a marketplace. Director of Strategy & Transformation Vincent Merlino shared that the use of no-code, low-code platform for business experiences will add flexibility to allow the platform to support a broader array of industries and user types. Industrial Metaverse I’ll keep this short, but I will say that the augmented reality experience 3DS shared with us in a local museum was one of the first AR experiences I’ve seen that looks like it will provide significant value while still being within reach of smaller manufacturers. The example shared a virtual twin of a factory and examined placing new equipment. Whether you call it the metaverse or something else, there is something important happening here as technologies converge. PLM Updates 3DS is clearly continuing to invest in ENOVIA. Some examples shared by ENVIA CEO Stéphane Declee and VP Philippe Bartissol include the new BPM solution, a supplier portal PartSupply, and quite a few interesting integrated / distributed collaboration examples. Analytics NETVIBES-EXALEAD CEO Morgan Zimmermann shared some of the increased focus on analytics and some really interesting case studies, including an exciting case study we first learned about during an earlier ENOVIA-NETVIBES analyst event (), Morgan shared another example of a virtual twin that correlates and synchronizes data from different systems on the virtual twin, created a dashboard of information from Primavera, SAP, CRM, and other systems overlaid on the physical model and supports a workflow to identify and trace an issue in the platform without resorting to email. Artificial Intelligence Patrick Johnson, Senior VP of Research and Science, shared a number of practical examples of AI. There we very little hype. They just shared that they are already using it and have plans for more. Watch this space. Model Based Systems Engineering CATIA CEO Olivier Sappin shared 3DS’ continued focus on MBSE to support the industry transformation to highly automated system of systems. He shared a virtual twin for cyber systems experience that started at mission definition, defined the system of Systems Architecture, and realized it with multi-discipline Engineering (including automation). Progress in AEC VP Remi Dornier gave us on update on the vision they shared last year to componentize and modernize architecture, engineering, and construction. He shared working examples that show they are further exploring and realizing their vision. Batteries Managing Director Reza Sadedhi shared some significant work they are doing around battery cells, starting from scientific principles and simulation, creating a digital twin of the battery cell. There was more shared and there are things I didn’t mention, but this is all I have room to share at the moment. Thank you Joe Horine, Orenella De Angelis, and Kurt Chen for hosting us and thank you to all of the 3DS execs who took time out of their schedule to meet with us. For related insights, Michelle Boucher and Jim Brown share their updates on ENOVIA and NETVIBES Transitioning to a Business Platform, Michelle Boucher highlights key takeaways from 3DEXPERIENCE World 2021, and take a look back to read how Dassault Systèmes has made significant progress on their 3DExperience Vision from 2017. [post_title] => Dassault Systèmes Shares Growth and Strategy at Analyst Day 2023 [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => dassault-systems-business [to_ping] => [pinged] => [post_modified] => 2023-12-15 15:41:17 [post_modified_gmt] => 2023-12-15 20:41:17 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18680 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 18656 [post_author] => 2 [post_date] => 2023-09-20 09:00:05 [post_date_gmt] => 2023-09-20 13:00:05 [post_content] => How do companies prioritize the business strategies that drive their long-term success? What’s driving their strategy as they face constantly shifting global market disruptions? How do they balance initiatives like digital transformation, ESG, developing their workforce, and adopting new business models to ensure business sustainability in 2023 and beyond?

Read our 5th annual survey to see how executive strategies have changed as companies face shifting global market disruptions.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

For related research, please read our prior survey results from the past five years: Strategies for Business Sustainability 2022, Business Sustainability and Transformation Strategies 2021, Business Sustainability and Survival 2020, and Executive Strategies for Long-Term Business Success 2019.

How do companies prioritize the business strategies that drive their long-term success? What’s driving their strategy as they face constantly shifting global market disruptions? How do they balance initiatives like digital transformation, ESG, developing their workforce, and adopting new business models to ensure business sustainability in 2023 and beyond?

Read our 5th annual survey to see how executive strategies have changed as companies face shifting global market disruptions.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

For related research, please read our prior survey results from the past five years: Strategies for Business Sustainability 2022, Business Sustainability and Transformation Strategies 2021, Business Sustainability and Survival 2020, and Executive Strategies for Long-Term Business Success 2019.

Table of Contents

- Disruptions Vary, But Risk is Constant

- Preparing for Success

- Strategy and Initiative Drivers Have Shifted

- ESG Pressure Comes from Many Angles

- Holistic Business Sustainability

- Putting Strategy into Action

- Technology is Key to Business Sustainability

- Technology Drivers Significant Business Benefits

- Conclusions and Recommendations

- About the Research

- Acknowledgments

A Time to Create Agility and Improve Sustainability

No Major Shocks, But Risk Remains The past decade confronted businesses with a constant barrage of disruptions, including natural catastrophes and human-created disasters. Although the business environment is still turbulent, industry faced fewer significant new events since our survey in 2022. Our fifth annual survey, though, shows that risks remain. Although the percentage saying business risk and disruption has increased "significantly" dropped 27% from the prior year, about three-quarters of responding companies still say it has grown over the last five years. Despite the lack of new shocks, companies in 2023 report that they still struggle with supply chain challenges, the fallout of COVID, and the impact of armed conflict. They also face lingering economic uncertainty despite relaxing global recession fears. Moreover, while it's not new, the threat from climate change is coming to fruition, and predicted impacts appear to be ahead of schedule. In 2022, the world's oceans were the hottest in history and exceeded the 2021 recorded maximum, and experts warn that "this year's United in Science report shows climate impacts heading into uncharted territory of destruction." Events like Canada's 2023 wildfires are constant reminders of climate change impacts and are becoming more common. Time to Continue Transformation and Drive Sustainability Our surveys on long-term business success show that companies responded to prior disruptions by accelerating technology adoption to increase agility and become more resilient. Now is the time for companies to continue with digital transformation to prepare for future inevitable disruptions and continuously improve efficiency in the face of continued economic uncertainty. At the same time, they must act on sustainability initiatives that are becoming critical to both human experience and continued economic success. Given the landscape, how are companies prioritizing the essential pillars of long-term business sustainability to ensure business success in 2023 and beyond?

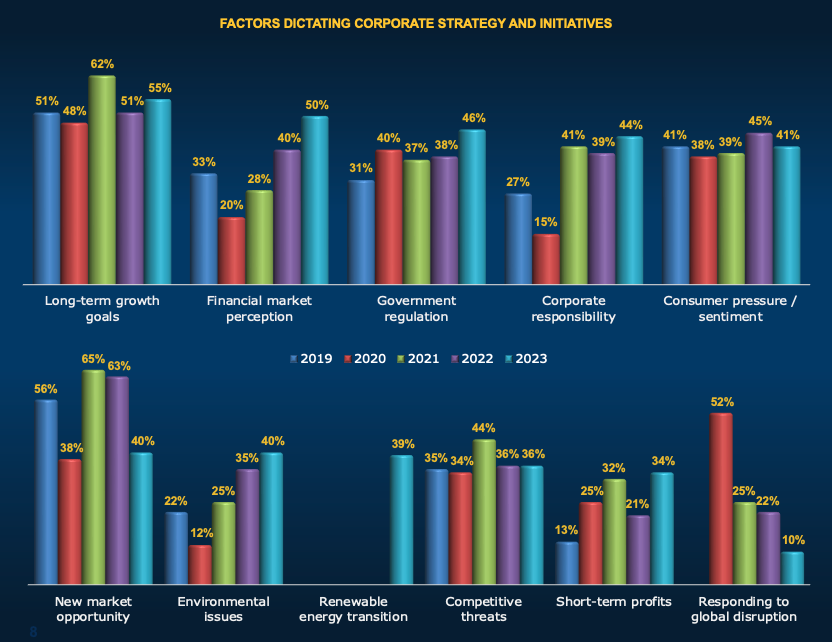

Strategy and Initiative Drivers Have Shifted

A Period of (Relative) Stability Responding to global disruption dropped as a strategy driver from 52% of companies in 2020 to 10% in 2023, the lowest point since COVID began impacting global markets (see next page). This is a strong indicator that disruption may have eased off, at least so far this year. Instead, companies appear to be back on track with ambitious strategies for business sustainability. Long-term growth goals are about the same and remain the most common strategy driver. Growth goals have been a constant from the beginning of this research series, and now financial market perception has grown from a low of 20% in 2020 to one-half of companies this year. ESG becomes a Larger Factor Other factors that influence corporate strategy and initiatives have shifted. Respondents now report that strategic plans are more driven by financial market perception and ESG factors. This is very different from the "survival mode" companies faced in 2020, where essential initiatives like environmental sustainability were pushed to the side. In fact, almost one-half of respondents report that government regulation drives their strategy this year, growing by 48% since 2019. We expect that these regulations are largely focused on greenhouse gas emissions and other environmental mandates. Other ESG business pressures are becoming more prevalent as well. Environmental issues were reported 83% more frequently as a strategy driver than in 2019 and have continued to climb since a low in 2020. In addition, 44% report corporate responsibility drives strategy, growing 63% since 2019, reflecting an additional ESG-related factor being considered more frequently in strategy decisions. New Focus on New Energy This year, we began tracking how the transition to new energy drives strategy and found that over one-third report it as a driver. We believe government regulation will add to existing transformation pressures such as cost and scarcity and spur more direct activity in this area. At the same time, government investment in new energy initiatives will also likely influence corporate direction. These drivers will further ESG efforts both directly and indirectly.

Technology is Key to Business Sustainability

Technology Critical to Business Success and Profitability The second factor we investigated in detail is technology. Technology plays a crucial role in supporting the pillars and driving long-term success and profitability. To demonstrate this, a full 87% percent share that technology is important to business success, and 30% say it's critical. Technology plays a crucial role in supporting each of the pillars of long-term success. About three-quarters of companies share that technology is critical or important to five of the seven pillars, and about two-thirds report it's important to the others. Reaching ESG Goals Demands Technical Support Perhaps one of the more surprising findings is technology's high importance in supporting ESG. Companies now recognize that they need to take a systematic approach to environmental sustainability. Making sustainable decisions and green reporting require a tremendous amount of data from across the business and the supply chain. Technology is vital to capturing information and reporting on sustainability, but also to developing the insights needed to improve it. ESG technology is full of innovation. From our experience, companies are not finding a single application for ESG. They are applying existing technologies to make more sustainable choices in everything from product and service innovation to business execution. Technology is Crucial to Transformation Technology is also seen as most important to digital transformation and product / service innovation and agility. Each of these is reported as "critical" by one-third of companies. The speed and scope of innovation demand a broad array of information and collaboration across disciplines. Technology Supports Business Sustainability Technology adoption continues to play a role in preparing for and responding to disruption, providing companies the agility they need to identify and react to issues. Technology alone doesn't achieve these goals, but the key finding is that modern businesses can't survive into the future without adopting technology to support them in the digital age.Conclusions and Recommendations

Disruption is Lower, but Remain Vigilant

Risk and disruption continue to grow, but significant disruption may have leveled off (for now). Although the most common disruptions today are the supply chain and financial market, our research shows that the problems companies face vary. Businesses should anticipate ongoing disruption and the need to develop agility and resilience. Global business means companies are constantly at risk, it's simply the reality.

Take the Long View

It's essential to prepare for disruption but stay focused on long-term business needs. Company success drivers are optimistic and show a belief in the long view, including long-term profits, innovation, and transformation. Disruptions come and go. As companies mitigate risk by becoming ever more agile and responsive, they must also stay focused on the enduring fundamentals of business success, such as customer relationships and long-term profits, while digitally transforming to stay relevant for the long term. At the same time, they must also attract and develop the workforce of the future.

Stay Focused on Sustainability

Companies are taking a balanced approach and continue to focus across the pillars of business sustainability. But the world has changed, and strategic drivers have shifted to put more emphasis on financial markets and the environment. One of the most significant increases in attention is ESG. Environmental and social responsibility are becoming increasingly critical to long-term business success. Companies must continue to drive their internal green initiatives while satisfying regulatory demands. Fortunately, regulations are beginning to reflect environmental imperatives and create a level playing field that supports both business and the environment.

Adopt Technology to Drive Long-Term Success

Our research clearly shows that technology plays a crucial role in driving long-term company profitability and sustainability and achieving value across the pillars of business sustainability. It also delivers significant business value. Companies must continue their digital transformation, adopting new business models and technologies, to achieve long-term business success.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Business Strategies for Long-Term Success

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => business-strategies-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2024-12-18 17:11:55

[post_modified_gmt] => 2024-12-18 22:11:55

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18656

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 18640

[post_author] => 2

[post_date] => 2023-09-19 09:00:24

[post_date_gmt] => 2023-09-19 13:00:24

[post_content] =>

Disruption is Lower, but Remain Vigilant

Risk and disruption continue to grow, but significant disruption may have leveled off (for now). Although the most common disruptions today are the supply chain and financial market, our research shows that the problems companies face vary. Businesses should anticipate ongoing disruption and the need to develop agility and resilience. Global business means companies are constantly at risk, it's simply the reality.

Take the Long View

It's essential to prepare for disruption but stay focused on long-term business needs. Company success drivers are optimistic and show a belief in the long view, including long-term profits, innovation, and transformation. Disruptions come and go. As companies mitigate risk by becoming ever more agile and responsive, they must also stay focused on the enduring fundamentals of business success, such as customer relationships and long-term profits, while digitally transforming to stay relevant for the long term. At the same time, they must also attract and develop the workforce of the future.

Stay Focused on Sustainability

Companies are taking a balanced approach and continue to focus across the pillars of business sustainability. But the world has changed, and strategic drivers have shifted to put more emphasis on financial markets and the environment. One of the most significant increases in attention is ESG. Environmental and social responsibility are becoming increasingly critical to long-term business success. Companies must continue to drive their internal green initiatives while satisfying regulatory demands. Fortunately, regulations are beginning to reflect environmental imperatives and create a level playing field that supports both business and the environment.

Adopt Technology to Drive Long-Term Success

Our research clearly shows that technology plays a crucial role in driving long-term company profitability and sustainability and achieving value across the pillars of business sustainability. It also delivers significant business value. Companies must continue their digital transformation, adopting new business models and technologies, to achieve long-term business success.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Business Strategies for Long-Term Success

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => business-strategies-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2024-12-18 17:11:55

[post_modified_gmt] => 2024-12-18 22:11:55

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18656

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 18640

[post_author] => 2

[post_date] => 2023-09-19 09:00:24

[post_date_gmt] => 2023-09-19 13:00:24

[post_content] =>  How can auto manufacturers improve process design performance in the face of increased complexity? We surveyed over 150 people involved with manufacturing engineering and found that modernizing processes and technology drives higher automotive manufacturing engineering productivity and performance. These improvements are crucial to profitability in the transportation and mobility industry as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

For related research, please read our Transforming Manufacturing in the Transportation Industry eBook.

How can auto manufacturers improve process design performance in the face of increased complexity? We surveyed over 150 people involved with manufacturing engineering and found that modernizing processes and technology drives higher automotive manufacturing engineering productivity and performance. These improvements are crucial to profitability in the transportation and mobility industry as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

For related research, please read our Transforming Manufacturing in the Transportation Industry eBook.

Table of Contents

- Improve Manufacturing Engineering to Increase Profitability

- Address Process Designer Challenges

- Recognize the Opportunity

- Quantify the Potential

- Identify Performance Drivers

- Find Issues Earlier in Design

- Use more 3D and Simulation

- Use More Advanced Ways to Support 3D / Simulation

- Leverage More Integrated Solutions

- Use More Advanced Communication and Collaboration

- Top Performers Show the Way

- Recommendations and Next Steps

- About the Research

- Acknowledgments

Improve Manufacturing Engineering Performance

Improve Performance in the Face of Complexity How can manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability in the transportation and mobility industry as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity. Modernize Manufacturing Engineering Survey results show that Top Performers in manufacturing engineering have increased maturity in the way they plan, validate, and communicate manufacturing operations. These leading companies waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. They accomplish this through best practices, including:- More advanced collaboration and communication methods

- Increased use of 3D and simulation to plan and validate manufacturing operations with virtual, digital twins

Improve Manufacturing Engineering to Increase Profitability

Product Profitability Relies on Speed, Cost, and Quality Developing profitable products in today’s transportation and mobility industry is challenging. Manufacturers have to move quickly to out-innovate their competitors without sacrificing product cost and quality. Our research1 shows that achieving product development success relies on meeting a combination of targets. According to this prior survey, the top business success and profitability drivers include faster product development, lower product cost, and increased product quality. Each of these goals is challenging, and transportation and mobility companies need to meet them simultaneously. Manufacturing Engineering’s Contribution With that in mind, we investigated the role manufacturing planning plays in achieving these product development goals. Respondents indicate that efficiency, quality, and cost most drive product success and profitability. The two most commonly reported items, manufacturing engineering efficiency and first time quality, are valuable on their own. But it’s important to recognize that both impact the time it takes a product to reach the market. The third most commonly reported factor, manufacturing cost, directly impacts product profitability. These make improving manufacturing engineering efficiency and performance strategic.Address Process Design Challenges

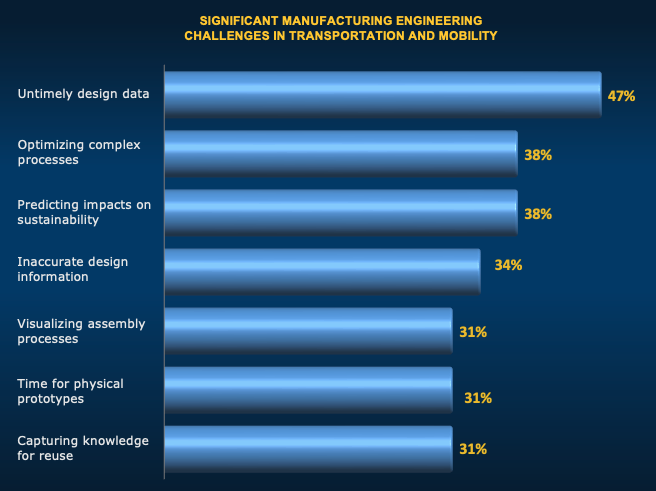

Manufacturing Engineers Face Increased Complexity Manufacturing is more complex than ever. Complexity has increased in three areas; products, manufacturing processes, and markets. Today’s products are going through a dramatic transformation to electrification. The shift from internal combustion engines to electric drivetrains adds complexity and demands significant changes to design and manufacturing processes. Today’s production environment may include new processes such as battery cell production or industrial additive manufacturing. Finally, transportation and mobility supply chains are shifting production and reshoring as the industry is trying to cope with supply disruption. Despite these, manufacturing engineers need to decrease cycle times and improve quality. Challenges Reflect Lack of Information and Ability to Optimize

Manufacturing engineers must overcome significant challenges to design and validate production processes. The most commonly reported challenge is untimely product design data. This hampers accurate, timely process design because planners can’t access trusted product details in time to optimize production plans and provide feedback on manufacturability. They also share challenges optimizing complex processes, which is likely becoming more complicated due to vehicle electrification.

In addition, respondents report challenges predicting the impact of their decisions on sustainability, inaccurate design information, visualizing assembly processes, and the time required to build prototypes.

Challenges Reflect Lack of Information and Ability to Optimize

Manufacturing engineers must overcome significant challenges to design and validate production processes. The most commonly reported challenge is untimely product design data. This hampers accurate, timely process design because planners can’t access trusted product details in time to optimize production plans and provide feedback on manufacturability. They also share challenges optimizing complex processes, which is likely becoming more complicated due to vehicle electrification.

In addition, respondents report challenges predicting the impact of their decisions on sustainability, inaccurate design information, visualizing assembly processes, and the time required to build prototypes.

Top Performers Show the Way

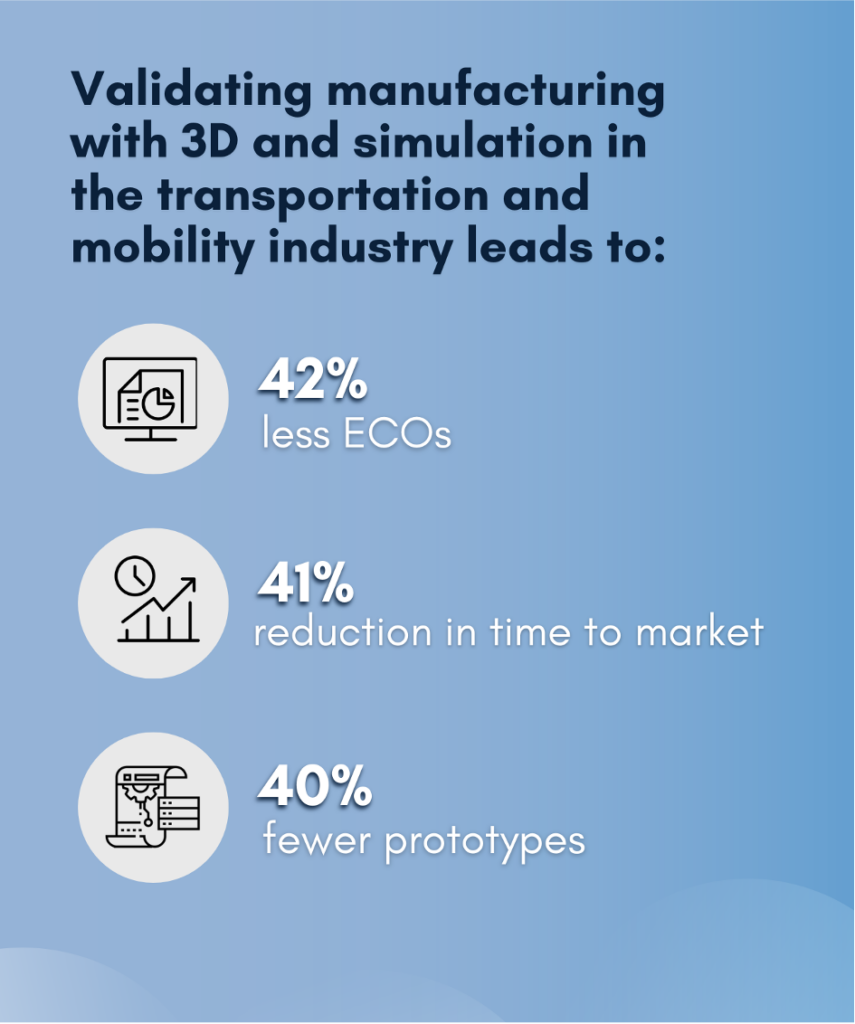

Top Performers Have Transformed The Top Performers, those with higher performance in time to full production, quality, efficiency, cost, ergonomics, and worker safety, have adopted more advanced approaches to manufacturing engineering. The data shows that these companies have adopted best practices, including more advanced collaboration, 3D, and simulation. In addition, they leverage more integrated solutions for manufacturing engineering. Top Performers Prove the Value The Top Performers’ better practices correlate with better manufacturing engineering results. As reported earlier, the leading companies are more likely to find physical issues in product design where they can fix them without considerable rework. Researchers also analyzed benchmark data on the amount of non-value-added time companies spend in manufacturing engineering, the cost of physical prototypes, and the average number of physical prototypes required for a product. Top Performers showed advantages in all of these statistics. Researchers found, for example, that Top Performers spend 17% less time on non-value-added manufacturing engineering work. Further, they spend over 50% less on physical prototypes than Others through a combination of fewer and less expensive prototypes. However, these cost savings are only a portion of the potential value available from transforming manufacturing engineering because they don’t include any other savings or revenue improvement from improved time to market. Conclusion

Conclusion

Based on the benchmark results, researchers concluded that transforming manufacturing engineering with increased use of 3D and simulation to plan, validate, and communicate manufacturing operations leads to measurably better manufacturing engineering performance.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Transforming Manufacturing in the Transportation Industry

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => automotive-manufacturing-engineering

[to_ping] =>

[pinged] =>

[post_modified] => 2024-01-30 13:55:22

[post_modified_gmt] => 2024-01-30 18:55:22

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18640

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 18915

[post_author] => 2574

[post_date] => 2023-09-18 10:00:11

[post_date_gmt] => 2023-09-18 14:00:11

[post_content] =>  Artificial intelligence holds the promise of entirely new insights for better decision-making. However, is it doing that in your company today? Manufacturers have long suffered from discipline-specific or “siloes” of data and information. Increasingly, those siloes have their own specific AI or analytics.

September 27, day 3 of Smart Manufacturing Now, Julie Fraser will facilitate the discussion. Attendees were asked to bring their questions, thoughts, and experiences for this interactive short-version of the MESA Smart Manufacturing Community Supply Chain Group discussion.

Note that the Smart Manufacturing Community had these mini-sessions each day of the conference:

Monday 9/25 was Smart Manufacturing, Robotics, and Internal Logistics for Smart Connected Factory

Tuesday 9/26 New Capabilities in Manufacturing Operations Software

Thursday 9/28 Design for Manufacturing with Digital Thread and Digital Twin.

[post_title] => Getting Beyond Siloes of AI for Supply Chain Decisions

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => siloes-of-ai

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-07 18:26:30

[post_modified_gmt] => 2023-12-07 23:26:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18915

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 18621

[post_author] => 2

[post_date] => 2023-09-13 10:12:35

[post_date_gmt] => 2023-09-13 14:12:35

[post_content] =>

Artificial intelligence holds the promise of entirely new insights for better decision-making. However, is it doing that in your company today? Manufacturers have long suffered from discipline-specific or “siloes” of data and information. Increasingly, those siloes have their own specific AI or analytics.

September 27, day 3 of Smart Manufacturing Now, Julie Fraser will facilitate the discussion. Attendees were asked to bring their questions, thoughts, and experiences for this interactive short-version of the MESA Smart Manufacturing Community Supply Chain Group discussion.

Note that the Smart Manufacturing Community had these mini-sessions each day of the conference:

Monday 9/25 was Smart Manufacturing, Robotics, and Internal Logistics for Smart Connected Factory

Tuesday 9/26 New Capabilities in Manufacturing Operations Software

Thursday 9/28 Design for Manufacturing with Digital Thread and Digital Twin.

[post_title] => Getting Beyond Siloes of AI for Supply Chain Decisions

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => siloes-of-ai

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-07 18:26:30

[post_modified_gmt] => 2023-12-07 23:26:30

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18915

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 18621

[post_author] => 2

[post_date] => 2023-09-13 10:12:35

[post_date_gmt] => 2023-09-13 14:12:35

[post_content] => Takeaways from Hexagon Live 2023

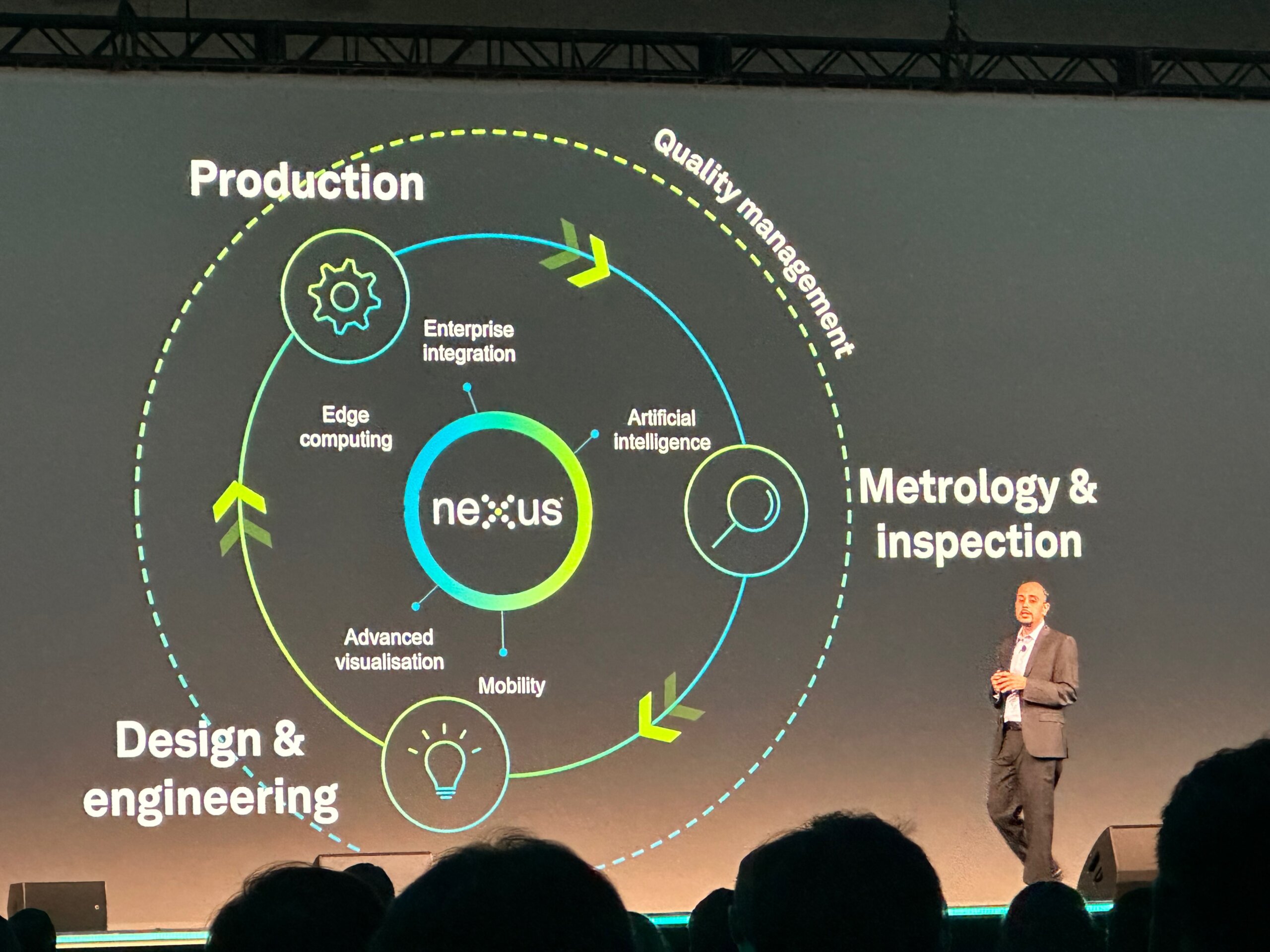

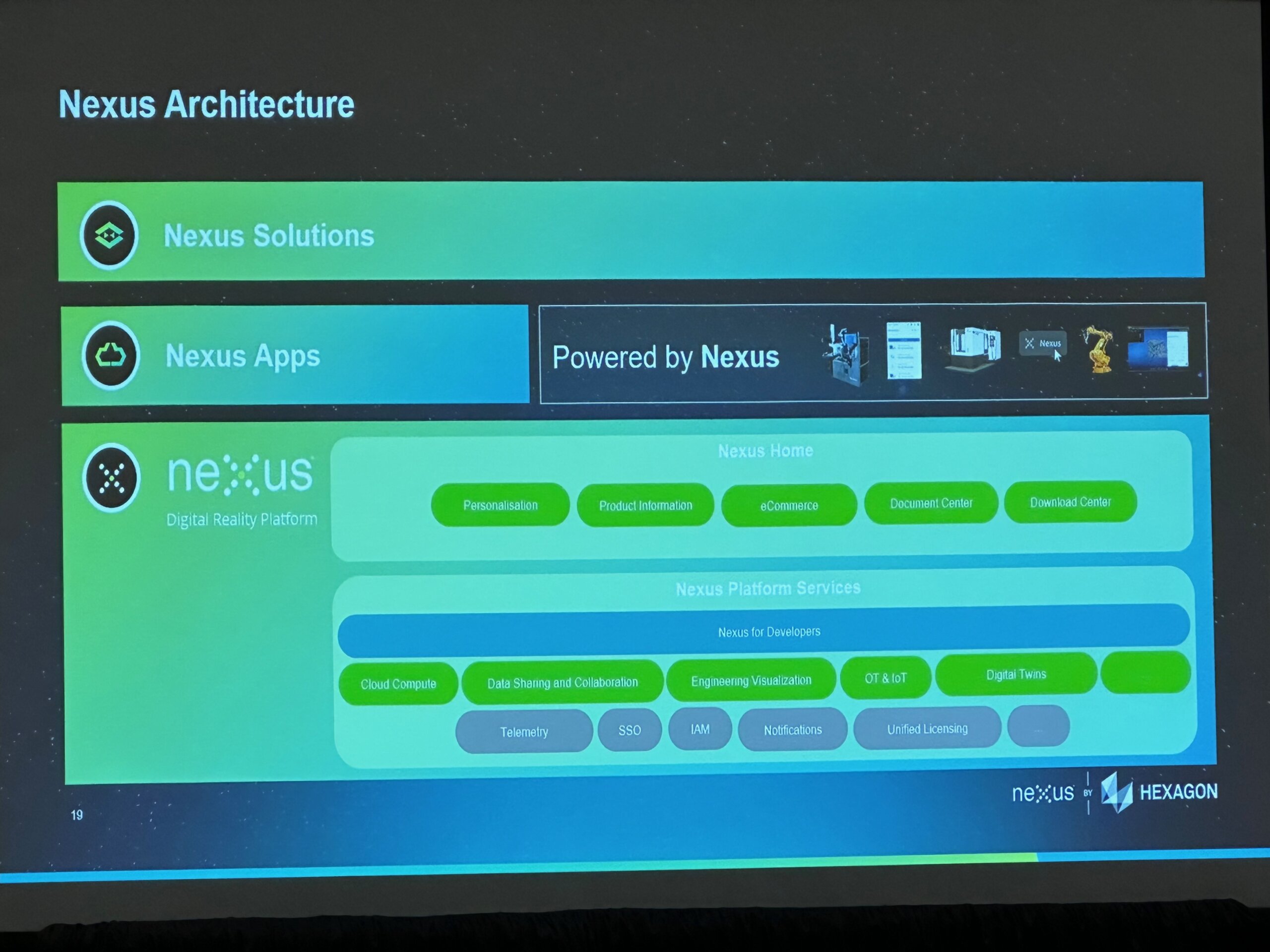

I attended my first Hexagon Live user conference this year. It was a well-attended, high-energy, polished event. I have to say, the content reminded me of my first conversation with Hexagon at a COFES industry conference a few years ago where I was overwhelmed with the scope and depth of their offerings. Hexagon covers a number of key solutions areas with their portfolio, including Design & Engineering, Production, and Metrology offerings that span both software and hardware. Some recent additions include quality management (QMS), connected worker, and asset performance management (APM). We feel there is strong potential for synergy across these areas as manufacturers face a convergence of technologies that demand integrated solutions. Because of this, others in our analyst team including Michelle Boucher (engineering practices research) and Julie Fraser (operations and manufacturing research) are also keenly interested in Hexagon’s progress. Ironically, perhaps, the theme for COFES and my presentation the year I got to know Hexagon focused on technology convergence and how it impacts the engineering software industry. Vision and Platform President and CEO Paolo Guglielmini shared the Hexagon vision to deliver “digital twins of everything to improve and optimize at scale.” That’s a big goal. But Hexagon has a lot of solutions to apply toward that vision, having made over 170 acquisitions over the past 12 years. They plan to bring those together to create the “smart digital reality” that merges physical and virtual realities via the digital twin. This requires a lot of convergence and solution integration spanning both Hexagon products and the broader manufacturing and engineering software ecosystem. That’s where their new Nexus platform comes in, intended to be the platform to connect from the shop floor to the top floor. Hexagon launched Nexus earlier this year to support discrete manufacturing but has eyes on expanding to more industry segments. Nexus

I’m going to focus on Nexus because it’s new, it’s so important to the Hexagon vision, and it was one of my biggest takeaways from the conference. Why is it so important?

Nexus

I’m going to focus on Nexus because it’s new, it’s so important to the Hexagon vision, and it was one of my biggest takeaways from the conference. Why is it so important?

- It’s an opportunity for convergence

- It provides an opportunity for Hexagon partners

- It is the path to Hexagon’s future technology

- It’s a gateway to what we might expect from the industrial metaverse

Two significant partners, NVIDIA and Microsoft, are already involved with Nexus. Jensen Huang, Founder and CEO of long-term partner NVIDIA, shared his vision for how Nexus and their Omniverse platform will work together to provide the benefits of AI to the industrial metaverse. Microsoft’s VP of Customer Innovation, Andy Pratt, shared how Nexus will support digital twins. It’s clear that a lot of thought has already been put into these partnerships around Nexus.

Beyond these larger partners, Hexagon announced Nexus for Developers at the conference. This capability provides APIs, SDKs, templates, and training that allow partners to build native apps, custom workflows, and “powered by Nexus communities.” They shared that their partner Altium was the first to pilot Nexus for Developers by creating a new solution for the electronics industry.

By opening up the platform, Hexagon provides partners (and customers) the opportunity to innovate and do more with their solutions than Hexagon can offer on their own.

Path to the Future

Nexus is a significant part of Hexagon’s future technology plans and they are using it to build the next generation of their applications and create a path to the cloud. They’ve already launched a number of apps and are in the process of introducing more. In addition, they are developing more platform capabilities that can be leveraged by both Nexus and partner applications. There is more detail here than I can cover, I encourage you to look at their roadmap to learn more as it is growing rapidly.

One of the important things to recognize about Nexus is that it’s not a replacement for existing systems. EVP and Nexus GM Stephen Graham explained that Nexus is intended to complement enterprise systems. It’s focused more on agility than control and works more as a system of engagement as compared to a typical system of record (like PLM). Nexus will bring automation and enable new feedback loops that will make processes more automated, efficient, and flexible. It will enhance current solutions by adding AI and visualization and support integration across solutions. This allows Hexagon to leverage their current solutions more effectively while they build out future offerings. The introduction of systems of engagement is an exciting new trend that we’re following closely, and Hexagon looks well aligned to help customers get more from their systems of record.

Industrial Metaverse

There is a lot of hype around the industrial metaverse. Beyond all of the hype, there is also value. With Nexus, Hexagon’s solutions offer the ability to connect real-world performance from the physical world with the digital twin. Their goal is to leverage simulation and AI to improve designs and the real world. Beyond that, Nexus has a goal to automate decisions in real-time to increase value by acting in the real world. This is an area that we look forward to learning more about. Look for more autonomy from Hexagon and Nexus in the future.

It’s also an area where partner collaboration, for example with NVIDIA, offers the potential for a lot of future innovation. For example, VP of Omniverse & Simulation Technology for NVIDIA Rev Lebaredian explained how companies can combine and simulate designs earlier to save money, reduce waste, and increase sustainability. He shared an example where companies with complex factories could bring together digital twins of a variety of assets, such as buildings, conveyors, robotics, and other equipment from different suppliers to simulate and find problems earlier. The potential is compelling.

Wrapping Up

Nexus is a significant new direction for Hexagon. It’s still relatively early, but their vision is strong and they’ve demonstrated real progress.

There was a lot more to the conference, but I hope this is a start in understanding what’s new with Hexagon. Thank you Robin Wolstenhome and Fiona Batchelor for your help coordinating schedules and customer discussions as I navigated my first Hexagon Live experience, and to countless Hexagon leaders who helped me learn more about Hexagon and their solutions.

Two significant partners, NVIDIA and Microsoft, are already involved with Nexus. Jensen Huang, Founder and CEO of long-term partner NVIDIA, shared his vision for how Nexus and their Omniverse platform will work together to provide the benefits of AI to the industrial metaverse. Microsoft’s VP of Customer Innovation, Andy Pratt, shared how Nexus will support digital twins. It’s clear that a lot of thought has already been put into these partnerships around Nexus.

Beyond these larger partners, Hexagon announced Nexus for Developers at the conference. This capability provides APIs, SDKs, templates, and training that allow partners to build native apps, custom workflows, and “powered by Nexus communities.” They shared that their partner Altium was the first to pilot Nexus for Developers by creating a new solution for the electronics industry.

By opening up the platform, Hexagon provides partners (and customers) the opportunity to innovate and do more with their solutions than Hexagon can offer on their own.

Path to the Future

Nexus is a significant part of Hexagon’s future technology plans and they are using it to build the next generation of their applications and create a path to the cloud. They’ve already launched a number of apps and are in the process of introducing more. In addition, they are developing more platform capabilities that can be leveraged by both Nexus and partner applications. There is more detail here than I can cover, I encourage you to look at their roadmap to learn more as it is growing rapidly.

One of the important things to recognize about Nexus is that it’s not a replacement for existing systems. EVP and Nexus GM Stephen Graham explained that Nexus is intended to complement enterprise systems. It’s focused more on agility than control and works more as a system of engagement as compared to a typical system of record (like PLM). Nexus will bring automation and enable new feedback loops that will make processes more automated, efficient, and flexible. It will enhance current solutions by adding AI and visualization and support integration across solutions. This allows Hexagon to leverage their current solutions more effectively while they build out future offerings. The introduction of systems of engagement is an exciting new trend that we’re following closely, and Hexagon looks well aligned to help customers get more from their systems of record.

Industrial Metaverse

There is a lot of hype around the industrial metaverse. Beyond all of the hype, there is also value. With Nexus, Hexagon’s solutions offer the ability to connect real-world performance from the physical world with the digital twin. Their goal is to leverage simulation and AI to improve designs and the real world. Beyond that, Nexus has a goal to automate decisions in real-time to increase value by acting in the real world. This is an area that we look forward to learning more about. Look for more autonomy from Hexagon and Nexus in the future.

It’s also an area where partner collaboration, for example with NVIDIA, offers the potential for a lot of future innovation. For example, VP of Omniverse & Simulation Technology for NVIDIA Rev Lebaredian explained how companies can combine and simulate designs earlier to save money, reduce waste, and increase sustainability. He shared an example where companies with complex factories could bring together digital twins of a variety of assets, such as buildings, conveyors, robotics, and other equipment from different suppliers to simulate and find problems earlier. The potential is compelling.

Wrapping Up

Nexus is a significant new direction for Hexagon. It’s still relatively early, but their vision is strong and they’ve demonstrated real progress.

There was a lot more to the conference, but I hope this is a start in understanding what’s new with Hexagon. Thank you Robin Wolstenhome and Fiona Batchelor for your help coordinating schedules and customer discussions as I navigated my first Hexagon Live experience, and to countless Hexagon leaders who helped me learn more about Hexagon and their solutions.

You can read our initial reaction to the Nexus announcement here.

[post_title] => Takeaways from Hexagon Live 2023 [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => hexagon-live [to_ping] => [pinged] => [post_modified] => 2023-10-24 09:20:14 [post_modified_gmt] => 2023-10-24 13:20:14 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18621 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [12] => WP_Post Object ( [ID] => 18598 [post_author] => 2 [post_date] => 2023-09-13 09:00:35 [post_date_gmt] => 2023-09-13 13:00:35 [post_content] => How can machine builders improve the way they work with the companies that use their products to create more collaborative, mutually valuable relationships? This eBook explores five practical steps manufacturers can take to improve machine builder – operator collaboration and increase value for both themselves and the customers operating their machines.

Please enjoy the summary below and visit our sponsor Siemens to learn more about digital manufacturing solutions machine builders. You can also download the full eBook to learn more.

For related research, please read prior eBooks, The Machine Builder Digital Twin, Increasing Equipment Design Velocity, and Increasing Performance Engineering Performance.

How can machine builders improve the way they work with the companies that use their products to create more collaborative, mutually valuable relationships? This eBook explores five practical steps manufacturers can take to improve machine builder – operator collaboration and increase value for both themselves and the customers operating their machines.

Please enjoy the summary below and visit our sponsor Siemens to learn more about digital manufacturing solutions machine builders. You can also download the full eBook to learn more.