Supply Chain Collaboration

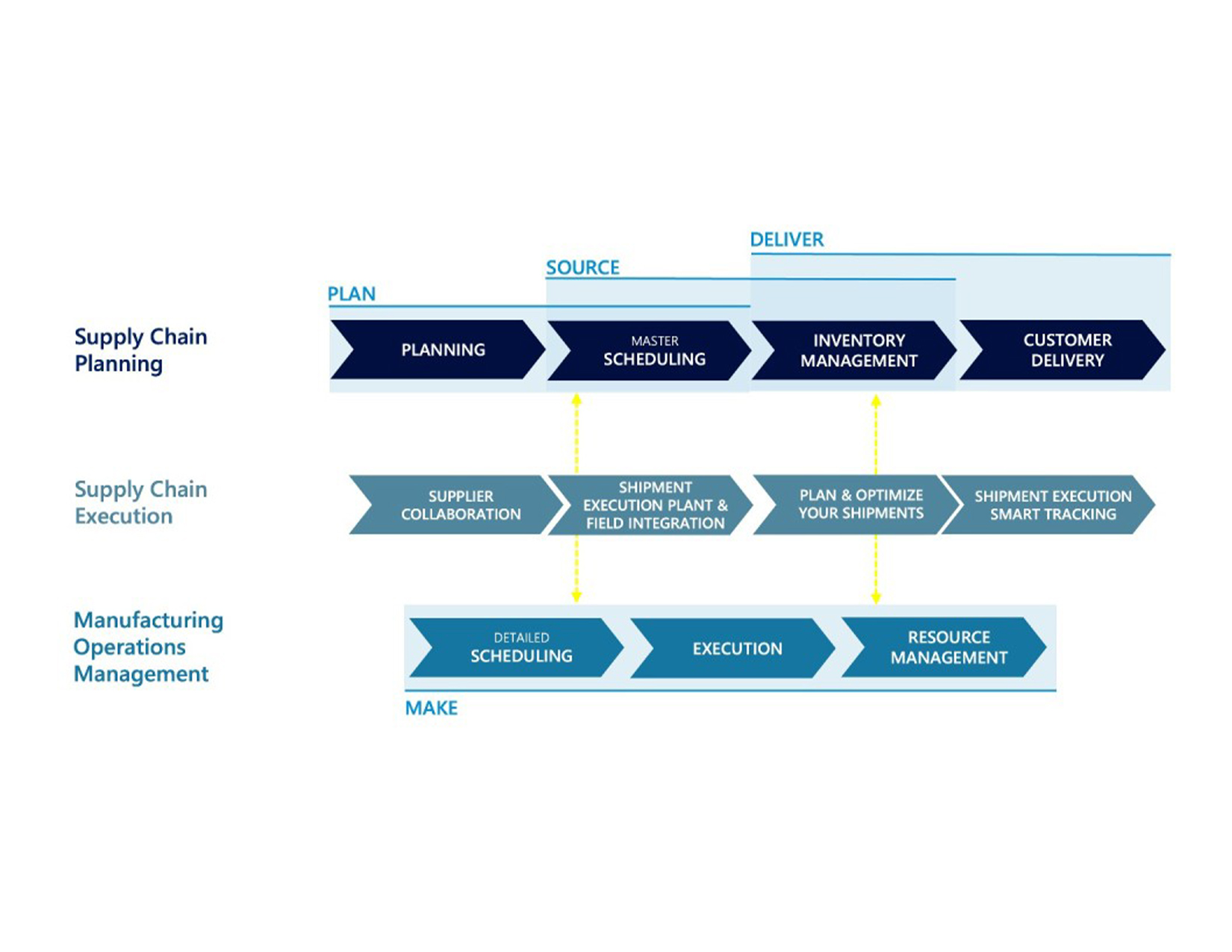

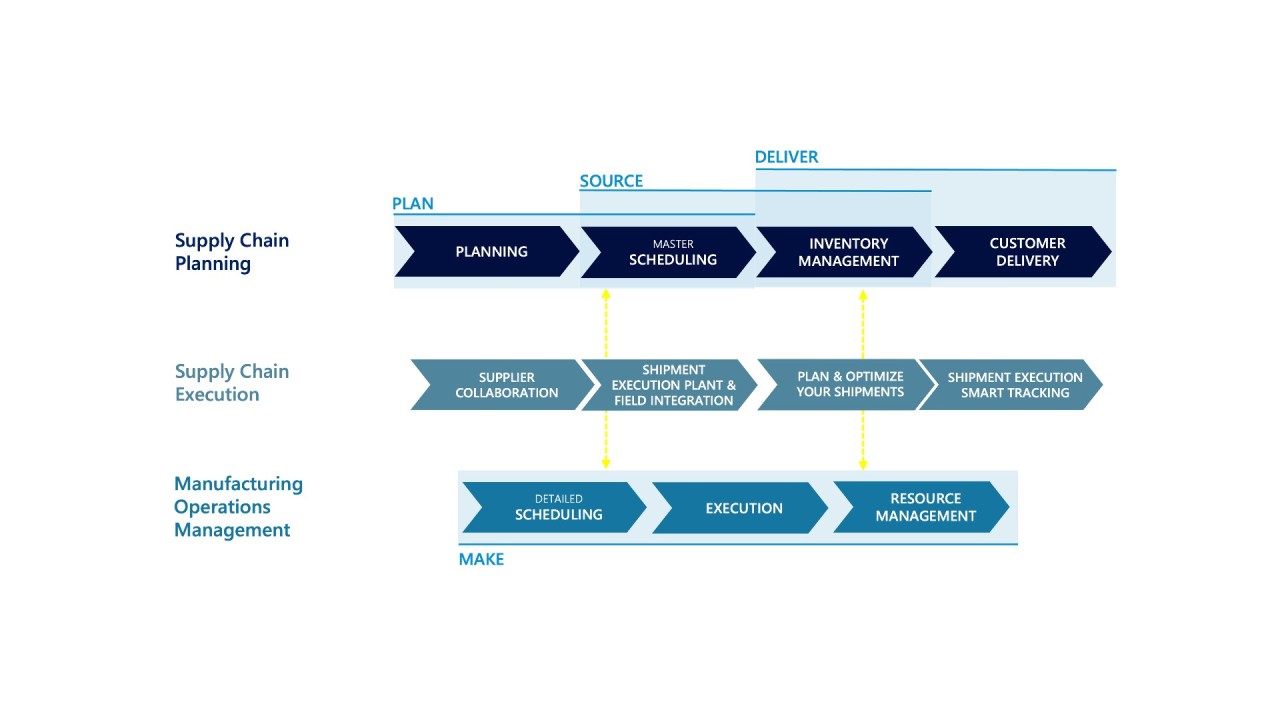

Supply chain planning and execution and manufacturing operations have often been separate groups with disconnected software applications. Yet they are all part of one supply chain, one flow of data and materials (plan-source-make-deliver). sedApta Group offers software to gain visibility, collaboration, and orchestration across all of those areas.

We caught up with sedApta just as their relationship with Elisa IndustrIQ shifted from being a partner to becoming part of the company. We see that as a good move. It should afford sedApta opportunities to expand globally, bolster AI, and extend and deepen functionality such as warehouse management by leveraging sister companies. The acquisition builds out supply chain capabilities for Elisa, which is actively acquiring companies for a comprehensive and modular set of manufacturing software.

Origins and Leadership

It turns out that MES pioneer Giorgio Cuttica was sedApta’s CEO, nurturing another fascinating software company in the operations space! (We met him as he brought Orsi, now Siemens Simatic IT MES, into the global market.) In 2014, he found a successful planning and scheduling product in Italy and modernized it.

With Giorgio’s manufacturing operations and MES background, the company saw the need for tighter working between supply chain planning, manufacturing operations, and supply chain execution. Particularly as uncertainty has grown in supply chains worldwide, this integration is increasingly important.

Now that the acquisition is final, Elisa has named Benedetta Cuttica CEO. She was formerly the CTO and has deep roots in the sedApta software.

Broad Scope of Natively-Integrated Functions

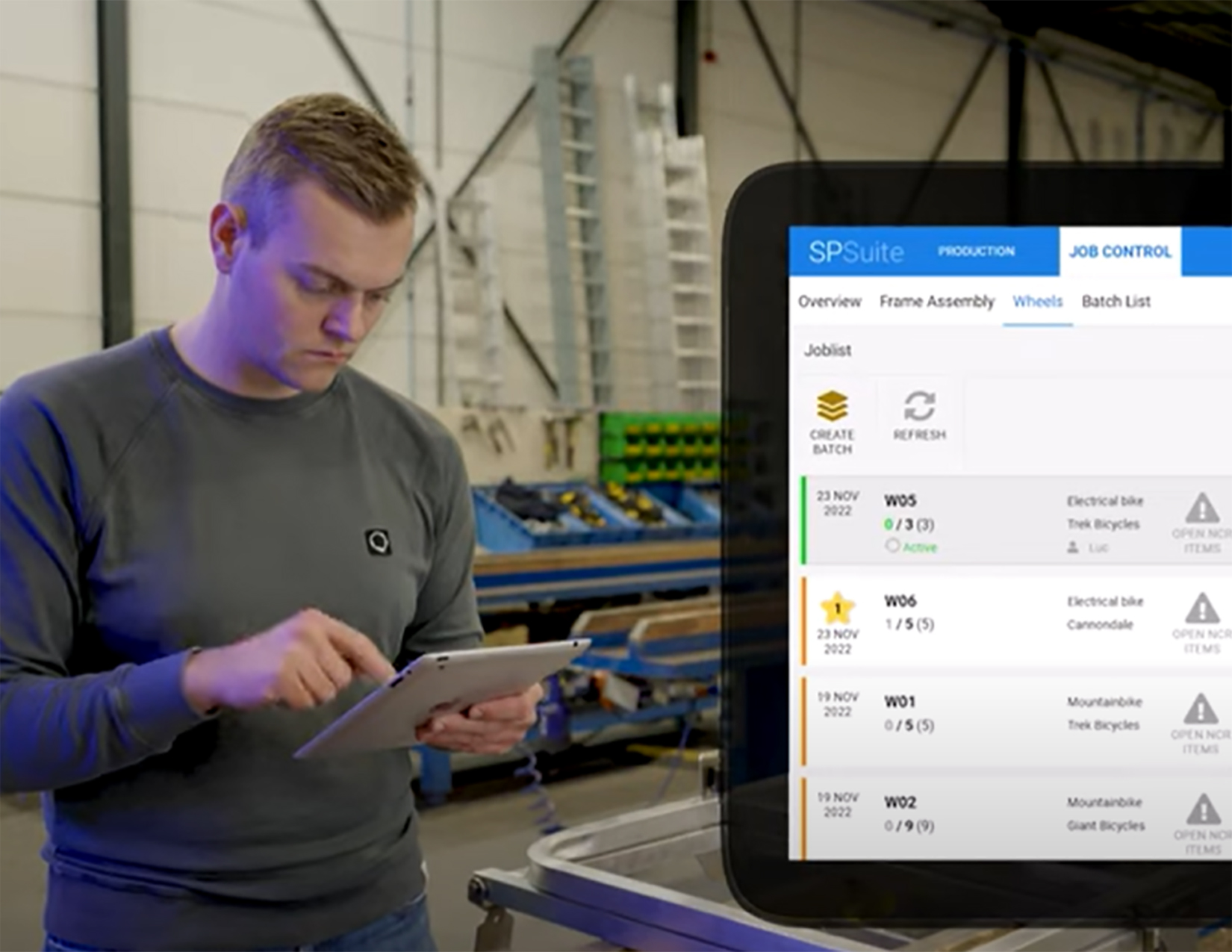

sedApta’s concept is that planning must be more integrated with what’s happening in manufacturing, distribution centers, and transportation, and it must all be aligned with customer and market demand. We agree that’s important and has historically been difficult for companies to achieve.

sedApta has invested heavily in R&D over the past 10 years. While other companies have been acquiring, sedApta has built out a comprehensive suite with native integration and a shared data lake. This delivers some significant benefits for collaboration and orchestration. In addition to expanding the overall set of modules and functionality, they have also created industry-specific functionality with libraries and best practices.

Some differentiating capabilities in sedApta’s integrated suite include a simulation-based control tower, a supplier portal for reporting progress collaboratively, multi-plant planning and production visibility, volume and operations planning (V&OP) that extends beyond traditional sales data of S&OP, and a process digital twin developed in collaboration with Elisa.

Customers Served

Different industries have different supply chain issues. sedApta’s vertical focus and libraries are:

- discrete manufacturing

- food and beverage

- fashion and luxury goods

- process manufacturing

Food and beverage tends to be short-term around promotions and large retail customers; fashion is driven by short seasons and outsourced production. Discrete and process may be more stable. Within those, they have often served both final OEMs and suppliers to them, so the focus shifts from long-term supply and demand planning to short-term, reactive planning.

The sedApta solution is well suited to middle-market companies with revenue between $200M and $3 billion. These companies may not be interested in investing in some of the other well-known supply chain software suites designed and priced for large enterprises. sedApta has also invested heavily in ERP integration to ensure data flows smoothly.

[caption id="" align="alignnone" width="2232"] sedApta's architecture is modern and comprehensive with a data lake that can accommodate real-time data, AI/ML, and bricks web interface.[/caption]

sedApta's architecture is modern and comprehensive with a data lake that can accommodate real-time data, AI/ML, and bricks web interface.[/caption]

Special Tech Touches

sedApta has a composable web interface it calls bricks, all on a shared database. Once they create an integration or a user interface, customers can reuse it. The control tower is built with bricks, for example.

Open interfaces enable the software to use variables from external sources. This is crucial for many industries’ supply chains where supplier and customer data, weather feeds, and economic sustainability data can greatly impact the accuracy of forecasts and market signals. This can also enable sustainability data to ensure compliance and traceability.

AI is laced into nearly every product. Algorithms have always been the core of supply chain planning and scheduling, but now some of that logic is readable to explain why the system made the decisions or created the sequences it did. The Elisa Bot is a copilot to improve the planning cycle. A demand-sensing solution will improve longer-term forecasting.

Extending the Reach

sedApta has many partners. Some are global implementation partners, such as KPMG working in the Caribbean and Asia. Others, such as Sage X3, white-label parts of the product suite. The company also has some resellers.

Under new parent Elisa, sedApta’s reach will extend beyond its roots in Europe. While its customers have sites outside Europe using sedApta today, it will now build go-to-market capabilities.

Thank you, Duncan Chapple, for setting up the meeting, and Pietro Cuttica for taking the time to update me on sedApta! I’m excited to follow your supply chain progress as part of Elisa IndustrIQ!

[post_title] => The Game of Avoiding Wasted Time in CAD Design

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => non-value-added-time-in-cad-design

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-19 09:55:27

[post_modified_gmt] => 2024-11-19 14:55:27

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20933

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 21004

[post_author] => 2574

[post_date] => 2024-11-18 10:00:24

[post_date_gmt] => 2024-11-18 15:00:24

[post_content] =>

[post_title] => The Game of Avoiding Wasted Time in CAD Design

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => non-value-added-time-in-cad-design

[to_ping] =>

[pinged] =>

[post_modified] => 2024-11-19 09:55:27

[post_modified_gmt] => 2024-11-19 14:55:27

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20933

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 21004

[post_author] => 2574

[post_date] => 2024-11-18 10:00:24

[post_date_gmt] => 2024-11-18 15:00:24

[post_content] =>

In the latest episode of

In the latest episode of  Addressing Pain Points

Addressing Pain Points Small engineering teams have many of the same challenges as larger ones, but have fewer resources to address them. How can small design teams manage product development complexity through better collaboration and design data management and the cloud to meet their design targets?

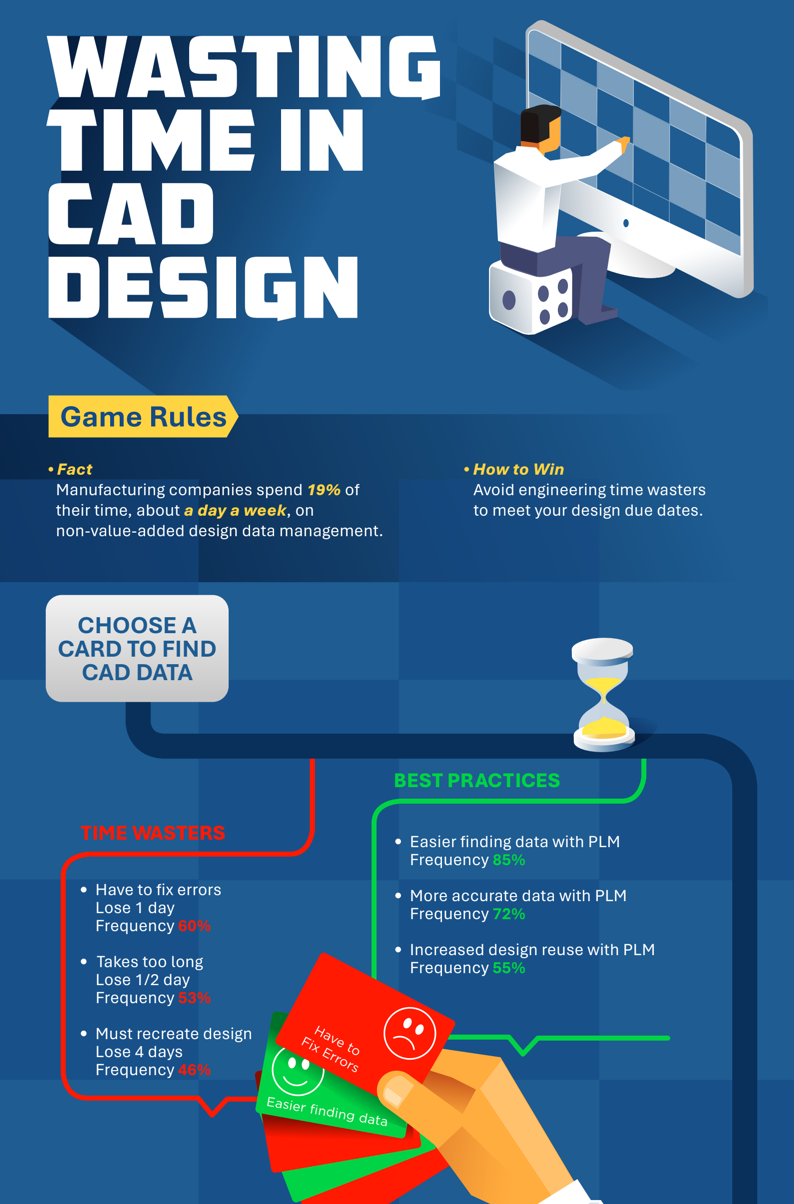

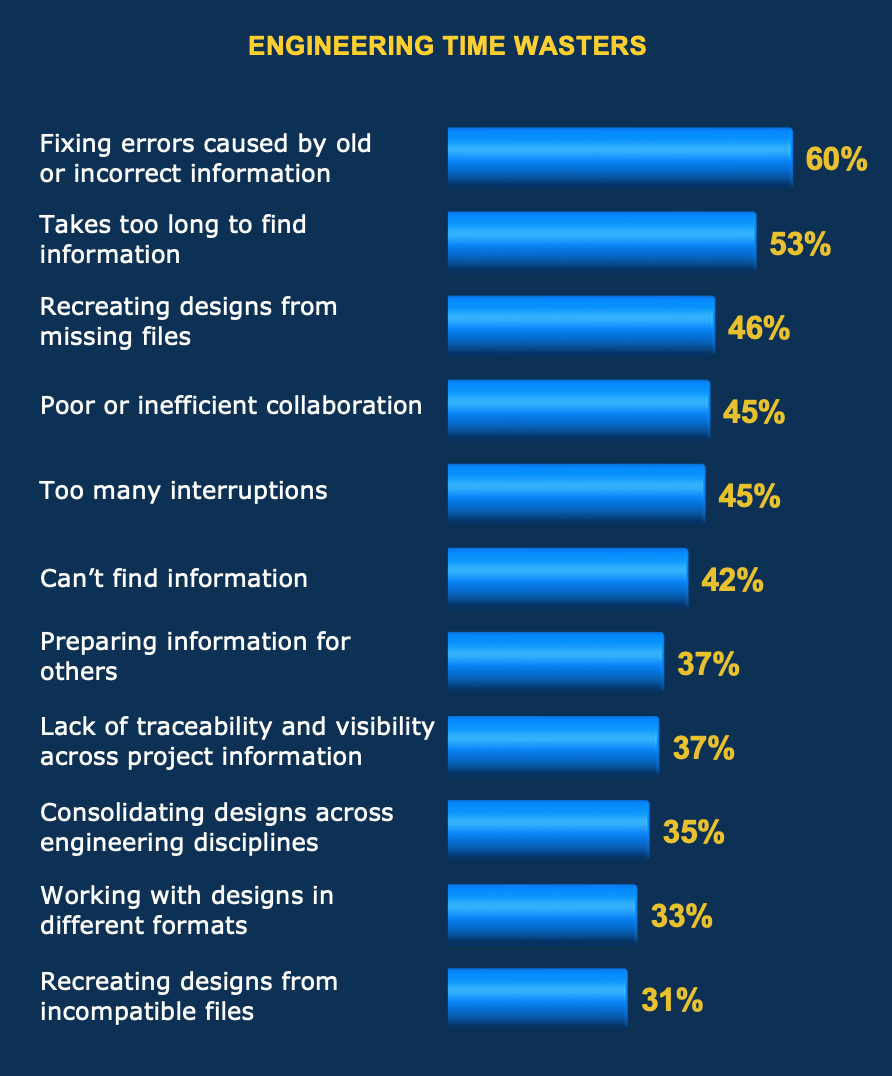

Small engineering teams have many of the same challenges as larger ones, but have fewer resources to address them. How can small design teams manage product development complexity through better collaboration and design data management and the cloud to meet their design targets? Wasted Engineering Time

Wasted Engineering Time

Implement PLM

Implement PLM

What can startups in the new space industry do to rise above the status quo and win the new space race? How can they overcome technical and value chain complexity to meet project deadlines, costs, quality, performance, and reliability by operationalizing collaboration?

What can startups in the new space industry do to rise above the status quo and win the new space race? How can they overcome technical and value chain complexity to meet project deadlines, costs, quality, performance, and reliability by operationalizing collaboration?  The Business of Space is Hard

The Business of Space is Hard

Collaborate in a Complex, Multi-CAD Environment

Collaborate in a Complex, Multi-CAD Environment

The time to get started is now. Succeeding in the space industry is challenging, demanding both technical and business savvy. Space startups need to be fast, innovative, accurate, and nimble to beat the competition. The current product development status quo is not sufficient.

The time to get started is now. Succeeding in the space industry is challenging, demanding both technical and business savvy. Space startups need to be fast, innovative, accurate, and nimble to beat the competition. The current product development status quo is not sufficient.  I’ve had the chance to speak with

I’ve had the chance to speak with  Managing the Configuration Lifecycle

Managing the Configuration Lifecycle

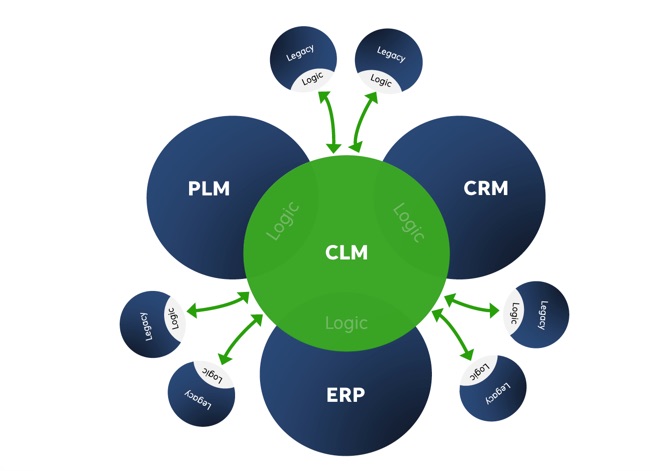

Configit can be implemented in a variety of ways depending on what the manufacturer needs, including acting as a component in an existing product configuration system ecosystem or as a more comprehensive solution. It can also be adopted in a broader CLM approach to coordinate configuration across the lifecycle, but there are options to start small to solve more focused problems and grow over time. Modeling and implementation are part of the implementation strategy, where Configit brings a methodology and not just technology. Their implementations also tend to integrate across multiple systems that contain information that either feeds or receives crucial configuration data, including close ties with Product Lifecycle Management (PLM).

Configit can be implemented in a variety of ways depending on what the manufacturer needs, including acting as a component in an existing product configuration system ecosystem or as a more comprehensive solution. It can also be adopted in a broader CLM approach to coordinate configuration across the lifecycle, but there are options to start small to solve more focused problems and grow over time. Modeling and implementation are part of the implementation strategy, where Configit brings a methodology and not just technology. Their implementations also tend to integrate across multiple systems that contain information that either feeds or receives crucial configuration data, including close ties with Product Lifecycle Management (PLM).

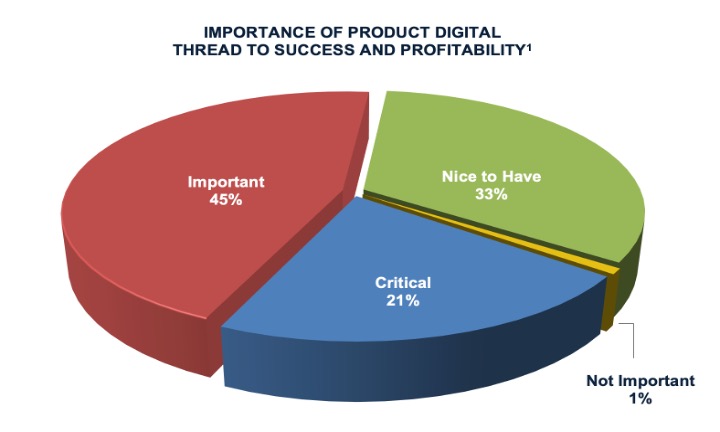

What value does the product digital thread offer manufacturers? How important is integrating data and systems across the digital thread to achieving that value? We set out to better understand the value of product digital thread integration and how top performing companies overcome implementation, operation, and maintenance challenges to achieve it. Did we find the magic bullet to effective product digital integration? The answer may surprise you.

What value does the product digital thread offer manufacturers? How important is integrating data and systems across the digital thread to achieving that value? We set out to better understand the value of product digital thread integration and how top performing companies overcome implementation, operation, and maintenance challenges to achieve it. Did we find the magic bullet to effective product digital integration? The answer may surprise you.  Challenges Impacting the Maintenance Lifecycle

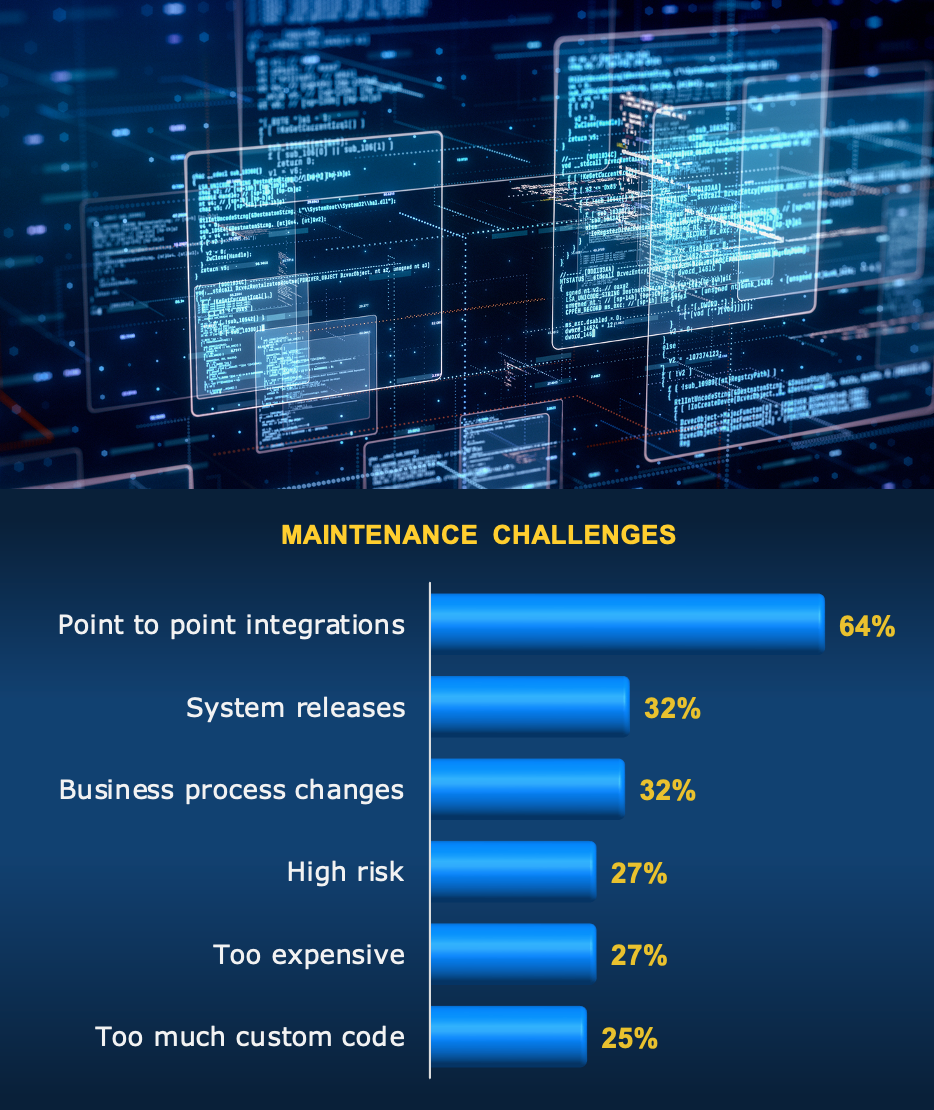

Implementing integration across data and applications along the digital thread is only the first step. Integration requires care and feeding to keep it running. It's important to acknowledge that, like the products they manufacture, integration involves many moving parts, at least metaphorically. Manufacturers report that managing change is difficult, including both keeping up with releases for different systems and adjusting as business processes change.

Manufacturers also point to challenges related to continued cost and business risk in the maintenance phase. Additionally, about one-half reported that integration challenges disrupt operationsand that validating integration consumes about 25% of systems upgrade efforts. There is clearly room for improvement, and it's no surprise that manufacturers lack the integration they need.

Maintenance Challenges Vary by Approach

Some integration approaches lead to more maintenance difficulties than others. For example, about two-thirds of companies report "point to point" integration as a top challenge, and about one-quarter report that too much custom code is an issue. These approaches are more prone to require manual updates when underlying systems or processes change. We'll look at manufacturers' approaches to integrate their product digital threads shortly.

Challenges Impacting the Maintenance Lifecycle

Implementing integration across data and applications along the digital thread is only the first step. Integration requires care and feeding to keep it running. It's important to acknowledge that, like the products they manufacture, integration involves many moving parts, at least metaphorically. Manufacturers report that managing change is difficult, including both keeping up with releases for different systems and adjusting as business processes change.

Manufacturers also point to challenges related to continued cost and business risk in the maintenance phase. Additionally, about one-half reported that integration challenges disrupt operationsand that validating integration consumes about 25% of systems upgrade efforts. There is clearly room for improvement, and it's no surprise that manufacturers lack the integration they need.

Maintenance Challenges Vary by Approach

Some integration approaches lead to more maintenance difficulties than others. For example, about two-thirds of companies report "point to point" integration as a top challenge, and about one-quarter report that too much custom code is an issue. These approaches are more prone to require manual updates when underlying systems or processes change. We'll look at manufacturers' approaches to integrate their product digital threads shortly.

The product digital thread is very important or critical to business success and profitability. Manufacturers are turning to the digital thread for a variety of significant business benefits, including product quality, better decision-making, engineering efficiency, product development speed, and product traceability.

The Product Digital Thread Requires Assembly

The product digital thread doesn't come in a single system. It lies across an ecosystem of applications and data sources. Manufacturers recognize the importance of integration to achieve their business goals.

Integration is Challenging

Product data is complex and requires technical and business expertise to interpret its meaning and the contextual relationships that make up the product digital thread. The current state of integration leads to data problems and challenges in implementation, operation, and maintenance. These challenges make it harder for manufacturers to achieve their product digital thread goals.

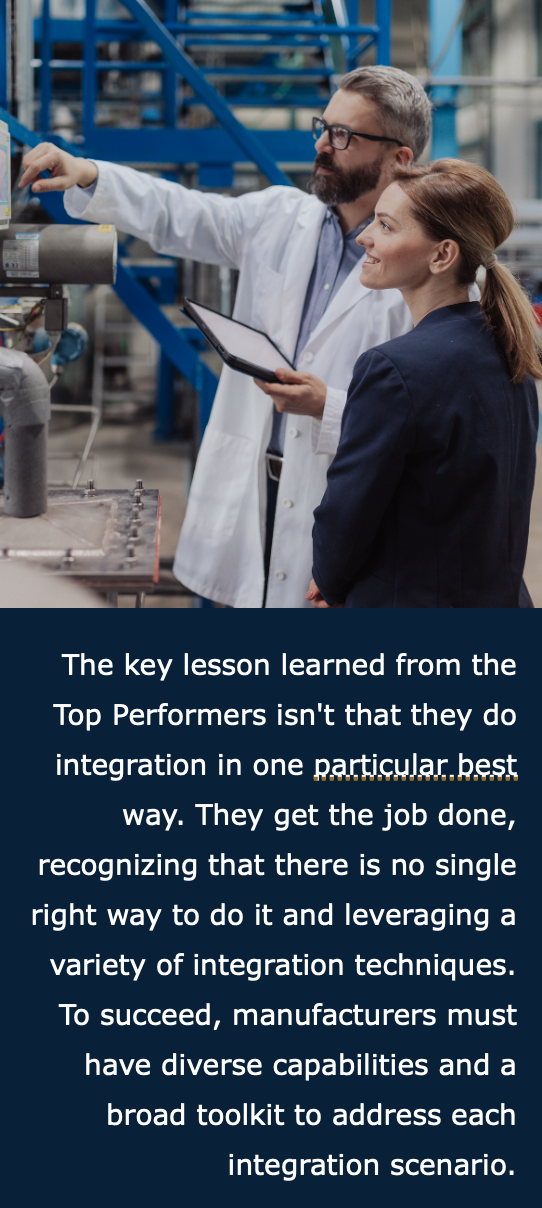

Develop Top Performing Integration Capabilities

The Top Performers, those with better integration capabilities, have accomplished more significant and more enterprise-wide integration. At the same time, they face fewer challenges in all phases of the integration lifecycle, including:

The product digital thread is very important or critical to business success and profitability. Manufacturers are turning to the digital thread for a variety of significant business benefits, including product quality, better decision-making, engineering efficiency, product development speed, and product traceability.

The Product Digital Thread Requires Assembly

The product digital thread doesn't come in a single system. It lies across an ecosystem of applications and data sources. Manufacturers recognize the importance of integration to achieve their business goals.

Integration is Challenging

Product data is complex and requires technical and business expertise to interpret its meaning and the contextual relationships that make up the product digital thread. The current state of integration leads to data problems and challenges in implementation, operation, and maintenance. These challenges make it harder for manufacturers to achieve their product digital thread goals.

Develop Top Performing Integration Capabilities

The Top Performers, those with better integration capabilities, have accomplished more significant and more enterprise-wide integration. At the same time, they face fewer challenges in all phases of the integration lifecycle, including:

Is it time to rethink the role of PLM in managing the digital thread? Should we evolve beyond the idea of “a single source of truth” and pursue digital thread orchestration to integrate product data and processes, recognizing that the data will span multiple systems? Our latest eBook addresses these questions and more.

Click here for the

Is it time to rethink the role of PLM in managing the digital thread? Should we evolve beyond the idea of “a single source of truth” and pursue digital thread orchestration to integrate product data and processes, recognizing that the data will span multiple systems? Our latest eBook addresses these questions and more.

Click here for the

Recognize the False Hope

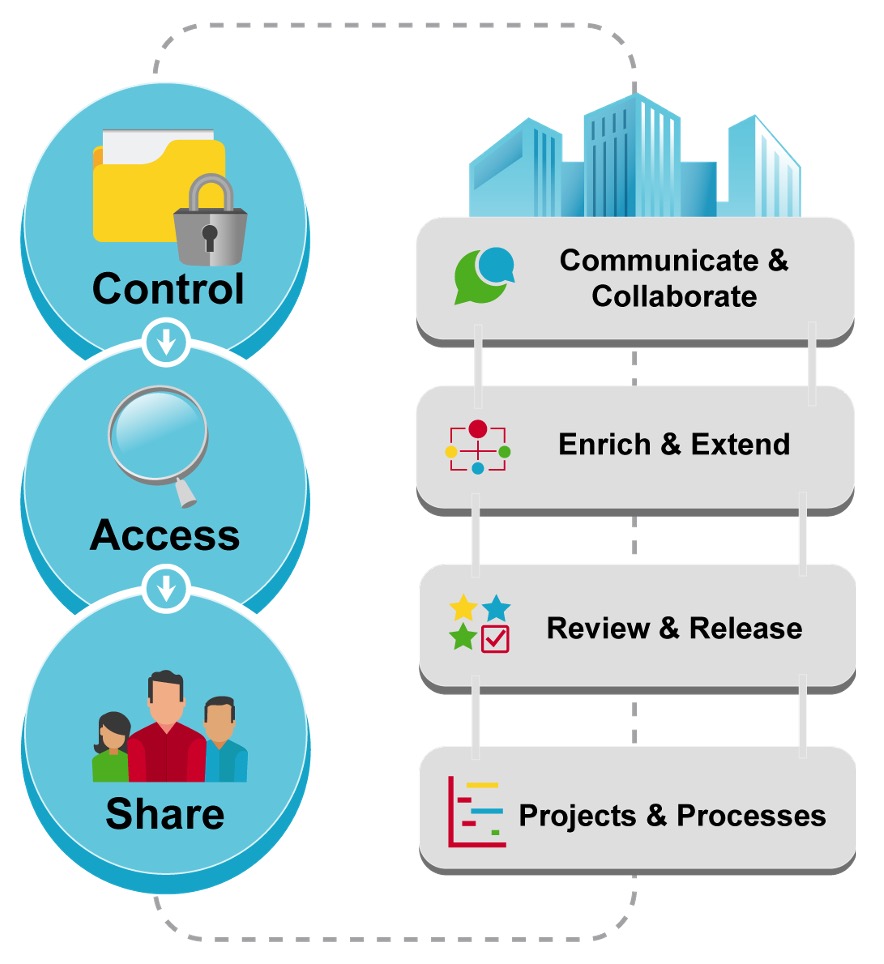

Let’s face it, the digital thread is now too detailed and complex to be contained in a single system. Individual workgroups and disciplines require specialty design and engineering tools including one or more mechanical CAD (MCAD), electrical CAD (ECAD), and software development kit (SDK) solutions. Beyond these, specialists need best-in-class tools to design and analyze chips, digital communication protocols, interfaces, heat transfer, magnetic interference, and other intricacies of today’s software- and electronics-drive devices.

Each of the tools engineers use creates valuable data. They develop too much detailed information, in varied formats, with their own individual lifecycles, to manage centrally. Instead, engineering teams may consider workgroup orchestration and design data management and centralize only the results. “The PCBAs we design have rich component information, but in the ERP world they are a BOM line item because we manufacture out of house,” says the R&D Director. “But we need to have that information available because we need visibility to the high value components on the board to be able to manage things like component shortages.”

Centralize Selectively for Control

Not all detailed data needs to be centralized and managed, but some information should be centrally available in order to manage change and release management. Take software development as an example. PLM should be concerned with released software but few would suggest it controls software sprints. Instead, PLM can manage the big picture so that device engineers, developers, and manufacturing resources are kept aware of progress and how changes impact different disciplines.

Recognize the False Hope

Let’s face it, the digital thread is now too detailed and complex to be contained in a single system. Individual workgroups and disciplines require specialty design and engineering tools including one or more mechanical CAD (MCAD), electrical CAD (ECAD), and software development kit (SDK) solutions. Beyond these, specialists need best-in-class tools to design and analyze chips, digital communication protocols, interfaces, heat transfer, magnetic interference, and other intricacies of today’s software- and electronics-drive devices.

Each of the tools engineers use creates valuable data. They develop too much detailed information, in varied formats, with their own individual lifecycles, to manage centrally. Instead, engineering teams may consider workgroup orchestration and design data management and centralize only the results. “The PCBAs we design have rich component information, but in the ERP world they are a BOM line item because we manufacture out of house,” says the R&D Director. “But we need to have that information available because we need visibility to the high value components on the board to be able to manage things like component shortages.”

Centralize Selectively for Control

Not all detailed data needs to be centralized and managed, but some information should be centrally available in order to manage change and release management. Take software development as an example. PLM should be concerned with released software but few would suggest it controls software sprints. Instead, PLM can manage the big picture so that device engineers, developers, and manufacturing resources are kept aware of progress and how changes impact different disciplines.

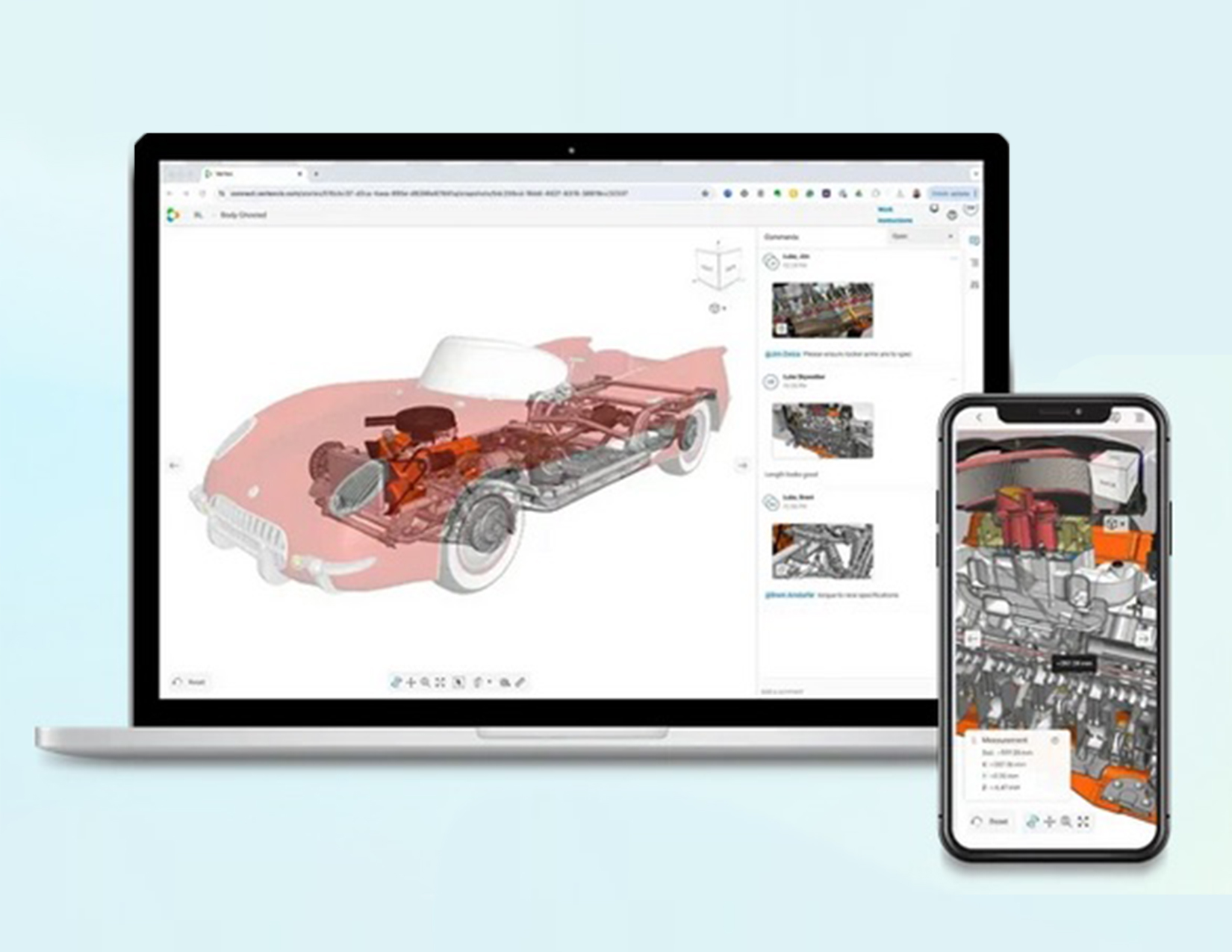

Leverage PLM to Enable Rich Collaboration

When PLM is used as an orchestration tool, it has the right data and context to allow engineers and others to collaborate in the context of their product development projects, products, and releases. PLM can act as the place where designs from multiple disciplines come together. Centralizing the right data allows design teams to review the implications of their designs in the context of other designers and design disciplines, and a place to work through conflicts and optimize system performance.

PLM can also keep engineers informed of design changes that impact their work. For example, they could get an alert of a changed design through PLM or in a separate tool like Slack. This way, individuals within workgroups, across workgroups, and across the supply chain can be kept in the loop on changes they need to be informed about. PLM should also provide a forum for designers to share their feedback with each other and store that feedback for future reference, for example, for the next revision of the product.

Multidiscipline Collaboration Example

The Director of R&D for the electronic device supplier we interviewed for this research shares an applicable example. “When a PCBA is ready for a revision, it goes to PLM. That’s where the mechanical and electrical designs come together,” explains. “Then our MCAD picks up the PCBA and creates a joint view in our PLM and makes sure the dimensions of the fiberglass work.” Viewing design data in context helps companies uncover clashes or disconnects early to prevent integration mistakes across mechanical, electrical, and software components. It can also help Manufacturing see changes to design files and can provide feedback quickly if there is an issue that impacts manufacturability.

Leverage PLM to Enable Rich Collaboration

When PLM is used as an orchestration tool, it has the right data and context to allow engineers and others to collaborate in the context of their product development projects, products, and releases. PLM can act as the place where designs from multiple disciplines come together. Centralizing the right data allows design teams to review the implications of their designs in the context of other designers and design disciplines, and a place to work through conflicts and optimize system performance.

PLM can also keep engineers informed of design changes that impact their work. For example, they could get an alert of a changed design through PLM or in a separate tool like Slack. This way, individuals within workgroups, across workgroups, and across the supply chain can be kept in the loop on changes they need to be informed about. PLM should also provide a forum for designers to share their feedback with each other and store that feedback for future reference, for example, for the next revision of the product.

Multidiscipline Collaboration Example

The Director of R&D for the electronic device supplier we interviewed for this research shares an applicable example. “When a PCBA is ready for a revision, it goes to PLM. That’s where the mechanical and electrical designs come together,” explains. “Then our MCAD picks up the PCBA and creates a joint view in our PLM and makes sure the dimensions of the fiberglass work.” Viewing design data in context helps companies uncover clashes or disconnects early to prevent integration mistakes across mechanical, electrical, and software components. It can also help Manufacturing see changes to design files and can provide feedback quickly if there is an issue that impacts manufacturability.

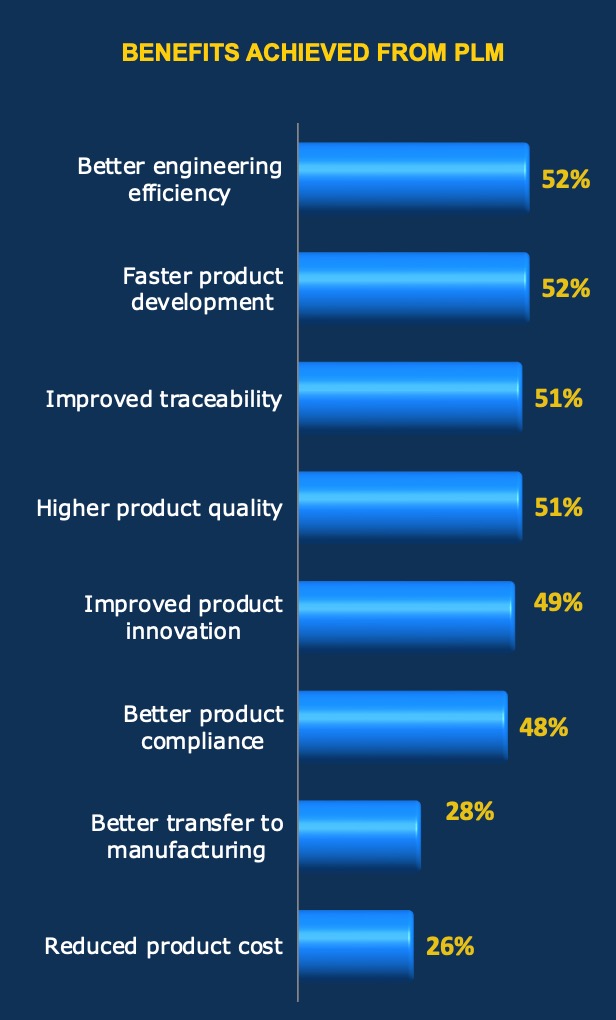

PLM can serve as a system for orchestration, but let’s not forget it provides value on its own. PLM has expanded in multiple dimensions and although today’s PLM offerings can’t do everything for everyone, they provide extensive functionality that adds value to the business. Our research shows that PLM delivers significant operational value by streamlining the flow of information and processes. “We implemented automation in PLM that reduces tedious, unproductive tasks. Our engineers are more productive,” explains the VP of Engineering for the modular office device manufacturer. “We now have a much better single point of truth with PLM integrated, which makes implementing changes clearer. We likely could not have been successful on some projects without it.”

Take Advantage of PLM’s Business Value

These operational improvements lead to both top-line and bottom-line business benefits. These benefits are only extended as PLM plays a broader orchestration role. The Director of R&D for the electronic device supplier shares an example of both operational and business benefits by allowing them to make better decisions based on the data they need. “Designers can look for a component by searching ERP data for a part to see if it has been used to prevent duplication. We can also better manage the component lifecycle, for example, discovering an end-of-life component, doing a where-used, and assessing whether to make a last-time buy to avoid an expensive R&D board redesign.” Our research confirms the business value, with over one-half of companies reporting faster product development, a similar number achieving better innovation, and one-half sharing PLM improves product quality.

Look Beyond Centralization to Orchestration

It’s time to take advantage of PLM’s operational and business value but also recognize the need for PLM to adopt a new role to orchestrate the digital thread across a diverse ecosystem of tools. The R&D Director for the device supplier sums it up nicely, “When you have multiple teams and multiple tools, you need a PLM tool to create a central view of components and processes in the digital thread.”

Click here for the

PLM can serve as a system for orchestration, but let’s not forget it provides value on its own. PLM has expanded in multiple dimensions and although today’s PLM offerings can’t do everything for everyone, they provide extensive functionality that adds value to the business. Our research shows that PLM delivers significant operational value by streamlining the flow of information and processes. “We implemented automation in PLM that reduces tedious, unproductive tasks. Our engineers are more productive,” explains the VP of Engineering for the modular office device manufacturer. “We now have a much better single point of truth with PLM integrated, which makes implementing changes clearer. We likely could not have been successful on some projects without it.”

Take Advantage of PLM’s Business Value

These operational improvements lead to both top-line and bottom-line business benefits. These benefits are only extended as PLM plays a broader orchestration role. The Director of R&D for the electronic device supplier shares an example of both operational and business benefits by allowing them to make better decisions based on the data they need. “Designers can look for a component by searching ERP data for a part to see if it has been used to prevent duplication. We can also better manage the component lifecycle, for example, discovering an end-of-life component, doing a where-used, and assessing whether to make a last-time buy to avoid an expensive R&D board redesign.” Our research confirms the business value, with over one-half of companies reporting faster product development, a similar number achieving better innovation, and one-half sharing PLM improves product quality.

Look Beyond Centralization to Orchestration

It’s time to take advantage of PLM’s operational and business value but also recognize the need for PLM to adopt a new role to orchestrate the digital thread across a diverse ecosystem of tools. The R&D Director for the device supplier sums it up nicely, “When you have multiple teams and multiple tools, you need a PLM tool to create a central view of components and processes in the digital thread.”

Click here for the

How can process manufacturers, who are traditionally undersupported by PLM offerings, manage their digital threads and bridge the gaps from formulas, to process, to plant, to the supply chain? Where can recipe-driven companies, including those in chemicals, food & beverage, cosmetics, oil & gas, and other related “process industry” companies, turn for PLM?

How can process manufacturers, who are traditionally undersupported by PLM offerings, manage their digital threads and bridge the gaps from formulas, to process, to plant, to the supply chain? Where can recipe-driven companies, including those in chemicals, food & beverage, cosmetics, oil & gas, and other related “process industry” companies, turn for PLM?  System Fundamentals

These capabilities can add significant value to the process industry digital thread. There are other fundamental PLM capabilities that translate well to process industry PLM, such as user and role management, granular security models, workflow management, cloud deployment, and more. Ideally, these are created as services that can be adapted and reused to support and digitally transform the process industries.

System Fundamentals

These capabilities can add significant value to the process industry digital thread. There are other fundamental PLM capabilities that translate well to process industry PLM, such as user and role management, granular security models, workflow management, cloud deployment, and more. Ideally, these are created as services that can be adapted and reused to support and digitally transform the process industries.

Manufacturers of all kinds can gain significant business value from a trusted digital thread managed by PLM. However, traditional PLM systems were not designed to meet unique process industry needs, let alone specific needs for industries like chemicals or food and beverage.

Traditional PLM capabilities, on the other hand, can support packaging design and BOMs, which follow a discrete model. These systems can also manage the digital thread and digital twin of plants and plant assets.

Look for Flexibility and Adaptability

How do you expand a solution from an 80% fit to a fully capable solution without impacting maintainability and the ability to upgrade? Consider that it might be easier to get from a 60% fit with a solution built on a low-code architecture so you don't create technical debt.

One way to pursue PLM for the process industries is to adopt PLM basics and use low-code to replicate, modify, and augment it to fill the process industry disconnects. This approach offers the fundamentals of PLM for both recipe- and BOM-centric needs in a way that doesn't create unmanageable technical debt.

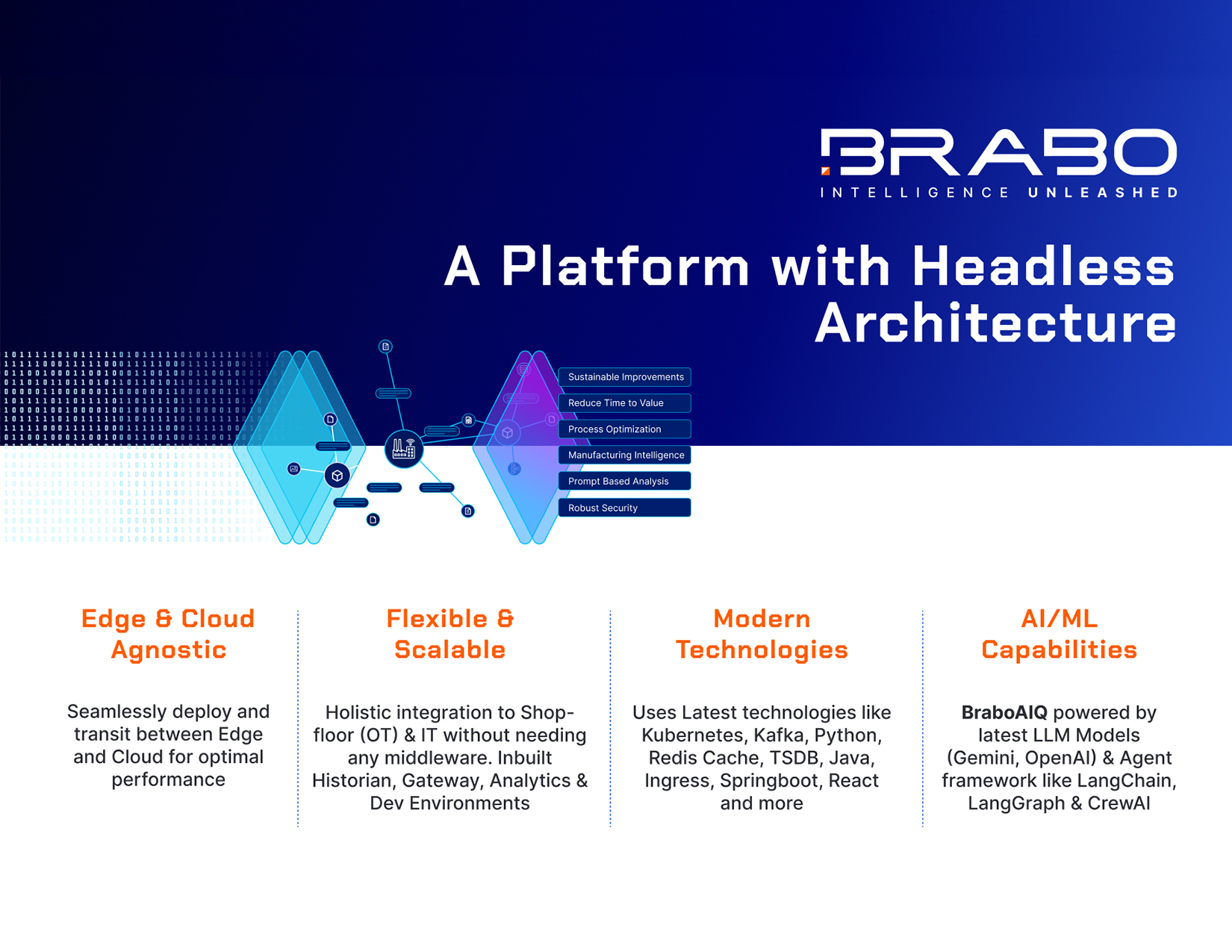

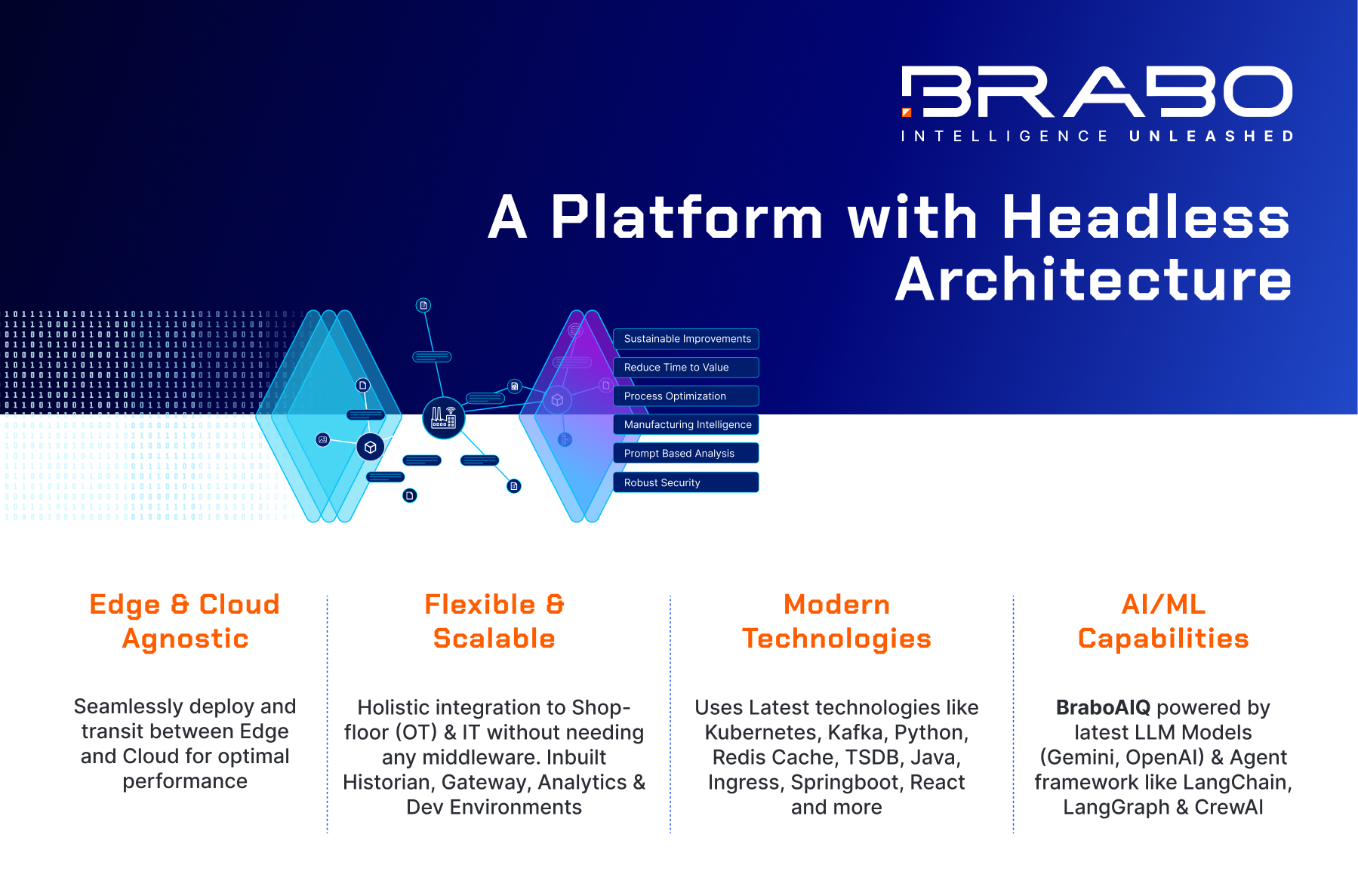

Get the Right Architecture

When looking at a system to support the process industries, it's essential to consider the architecture of the solution in addition to the capabilities. For example, is it open? Easily integrated? Available on the cloud? Does it offer low-code to make it flexible and maintainable? These are important considerations to get the right combination of capabilities for today and the ability to future-proof the system to support the business of the future.

Gain Business Value

Ultimately, the purpose of selecting and implementing a PLM system is growing business value through higher revenue, greater agility, lower cost, better quality, and increased compliance. PLM delivers proven value, but it's critical for PLM to support the uniqueness of the digital thread in the process industry.

Manufacturers of all kinds can gain significant business value from a trusted digital thread managed by PLM. However, traditional PLM systems were not designed to meet unique process industry needs, let alone specific needs for industries like chemicals or food and beverage.

Traditional PLM capabilities, on the other hand, can support packaging design and BOMs, which follow a discrete model. These systems can also manage the digital thread and digital twin of plants and plant assets.

Look for Flexibility and Adaptability

How do you expand a solution from an 80% fit to a fully capable solution without impacting maintainability and the ability to upgrade? Consider that it might be easier to get from a 60% fit with a solution built on a low-code architecture so you don't create technical debt.

One way to pursue PLM for the process industries is to adopt PLM basics and use low-code to replicate, modify, and augment it to fill the process industry disconnects. This approach offers the fundamentals of PLM for both recipe- and BOM-centric needs in a way that doesn't create unmanageable technical debt.

Get the Right Architecture

When looking at a system to support the process industries, it's essential to consider the architecture of the solution in addition to the capabilities. For example, is it open? Easily integrated? Available on the cloud? Does it offer low-code to make it flexible and maintainable? These are important considerations to get the right combination of capabilities for today and the ability to future-proof the system to support the business of the future.

Gain Business Value

Ultimately, the purpose of selecting and implementing a PLM system is growing business value through higher revenue, greater agility, lower cost, better quality, and increased compliance. PLM delivers proven value, but it's critical for PLM to support the uniqueness of the digital thread in the process industry.

[post_title] => Digitalizing the Factory Lifecycle

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => factory-lifecycle-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-26 11:54:01

[post_modified_gmt] => 2024-09-26 15:54:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20613

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 20596

[post_author] => 2574

[post_date] => 2024-09-06 09:00:30

[post_date_gmt] => 2024-09-06 13:00:30

[post_content] =>

[post_title] => Digitalizing the Factory Lifecycle

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => factory-lifecycle-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2024-09-26 11:54:01

[post_modified_gmt] => 2024-09-26 15:54:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20613

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 20596

[post_author] => 2574

[post_date] => 2024-09-06 09:00:30

[post_date_gmt] => 2024-09-06 13:00:30

[post_content] =>