In these competitive times, continuous improvement is crucial, but it’s not always easy to pinpoint where the biggest benefits lie. How can you prioritize manufacturing improvement opportunities to ensure maximum value to the business? This Buyer’s Guide points to an array of software characteristics to support such decisions. You need digital means to support greater…

- Evaluation Criteria

- Urgency to Improve Manufacturing Productivity

- Current Situation

- Prioritizing Manufacturing Productivity Opportunities

- Functionality for Prioritizing Opportunities

- Analytics for Clear Action

- Technology Considerations

- Evaluating Software Partners

- Implementation Factors

- Software Investment Priorities

- Maximum Value for Productivity Projects

- Recommendations

- Acknowledgments

Urgency to Improve Manufacturing Productivity

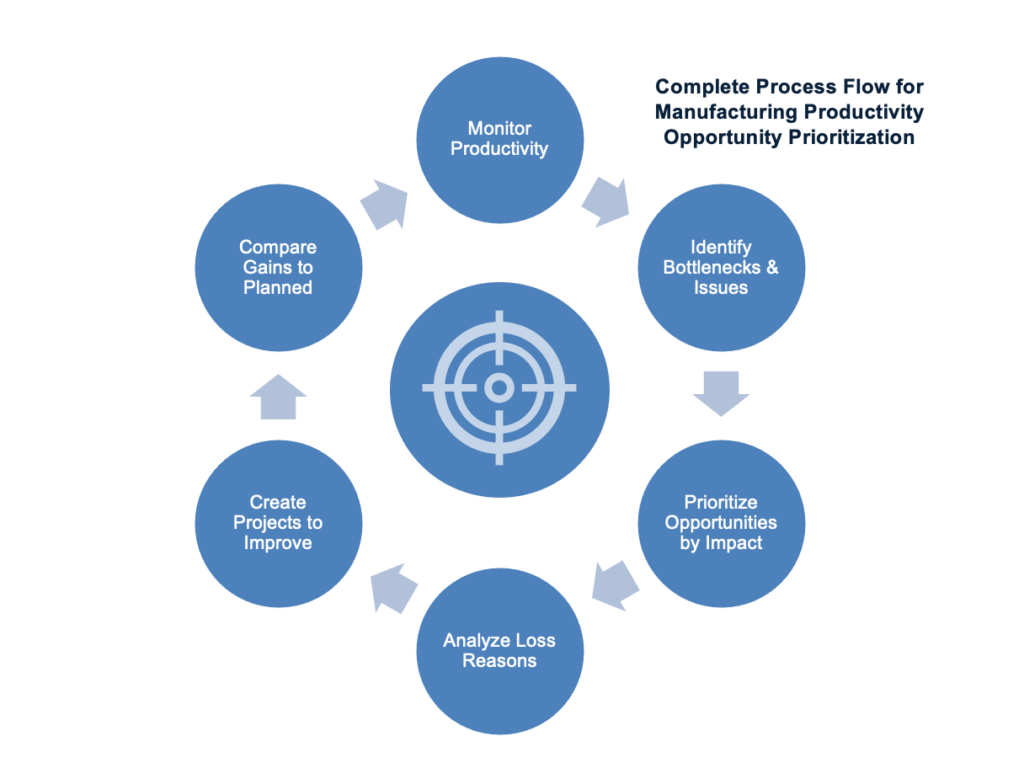

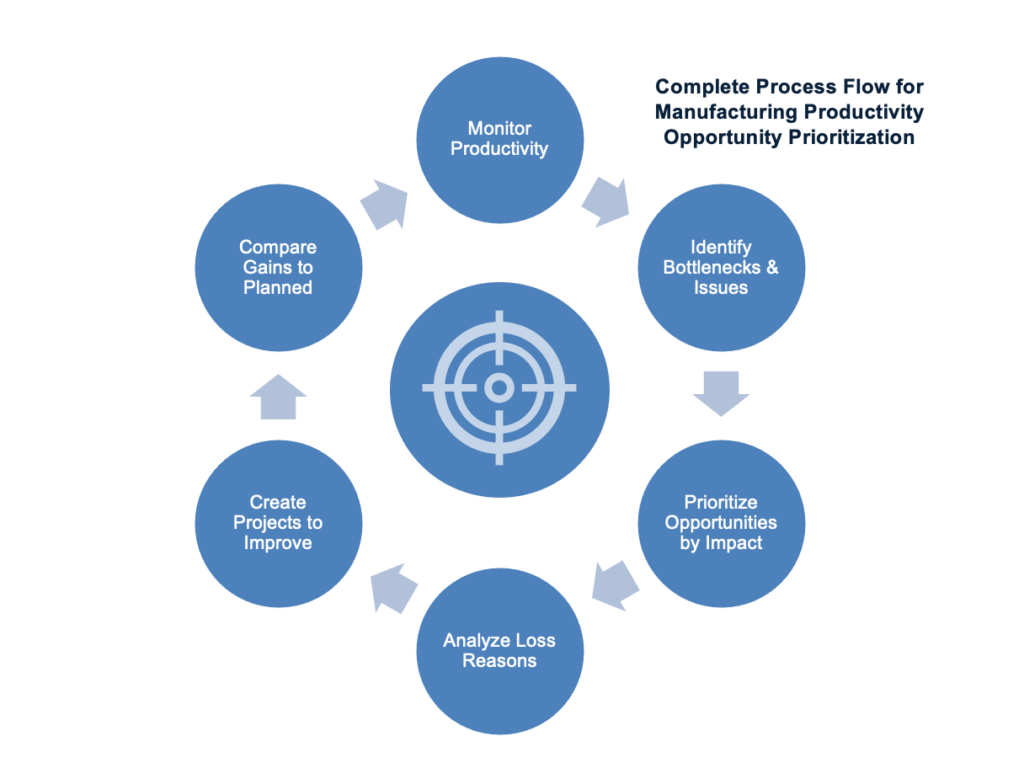

Staying Competitive Most manufacturers are in competitive markets with supply chain challenges. With so much out of the company’s control, it’s vital to leverage production resources such as facilities, equipment, people, materials, and tools effectively. Today’s environment of great uncertainty makes this more complex and crucial to success. Needs Expand with the Move to the Digital Enterprise Productivity is all about minimizing losses – and time is the obvious way to measure those losses. The impacts of lost time are not just on the production operation itself. Time losses can be quantified in terms of impact on profit and customer service. Capacity-constrained companies can sell as much as they can make, so it’s a top-line issue for revenues. For these companies, it also determines when they can promise and deliver orders to customers.Even when not capacity constrained, time losses can impact costs and customer satisfaction. In some cases, companies could lower materials, assets, energy, quality, compliance, and payroll costs. Continuous Improvement Yet, calculating where to focus to stem those time losses is not straightforward since many sources of waste contribute to throughput and productivity losses. Continuous Improvement (CI) is a common process manufacturers use to identify and eliminate waste to improve performance. It may be called Lean, Six Sigma, Operational Excellence, or other names. In these trying times, CI programs can feed success – particularly if they have balanced characteristics and digital support.Prioritizing Manufacturing Productivity Opportunities

Helping Focus As the term prioritizing suggests, what is new here is that the software is not just measuring performance but ranking opportunities for improvement. By seeking prioritization, you get support to focus resources and attention, which can be challenging with traditional manufacturing intelligence, OEE, or dashboard software. Readying for Action In addition to prioritizing opportunities, seek out software that provides a reason drill-down for each problem. This ability to deliver deeper insights into root causes can transform challenges into opportunities One Application, Many Roles Seek a software system that can support multiple user profiles:- Executives and Managers for comparing plants, products, and investment in CI programs

- CI leads for plotting priorities and tracking progress

- Supervisors for focusing on how to improve in their area

- Operators and Technicians to focus, buy in, and see what’s working and how much time they can save

This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor PTC (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Confidently Prioritize Manufacturing Improvement Opportunities

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => prioritize-manufacturing-improvement

[to_ping] =>

[pinged] =>

[post_modified] => 2024-05-01 13:28:52

[post_modified_gmt] => 2024-05-01 17:28:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18440

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 18421

[post_author] => 2574

[post_date] => 2023-07-11 10:00:11

[post_date_gmt] => 2023-07-11 14:00:11

[post_content] =>

This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor PTC (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Confidently Prioritize Manufacturing Improvement Opportunities

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => prioritize-manufacturing-improvement

[to_ping] =>

[pinged] =>

[post_modified] => 2024-05-01 13:28:52

[post_modified_gmt] => 2024-05-01 17:28:52

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18440

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[1] => WP_Post Object

(

[ID] => 18421

[post_author] => 2574

[post_date] => 2023-07-11 10:00:11

[post_date_gmt] => 2023-07-11 14:00:11

[post_content] =>  What most contributes to a supply chain having a positive impact on the business? Which disciplines and data sets make the most difference in supply chain resilience? Learn what Top Performers have to say about these that’s different. Julie Fraser, Tech-Clarity’s VP of Research for Operations and Manufacturing, will discuss initial findings of a soon-to-be released survey of 229 industry professionals. We will discuss supply chain findings including:

What most contributes to a supply chain having a positive impact on the business? Which disciplines and data sets make the most difference in supply chain resilience? Learn what Top Performers have to say about these that’s different. Julie Fraser, Tech-Clarity’s VP of Research for Operations and Manufacturing, will discuss initial findings of a soon-to-be released survey of 229 industry professionals. We will discuss supply chain findings including:

- Top supply chain challenges

- What Top Performers see as the top factor enabling their supply chain to have a positive impact on the business

- Where Top Performers have visibility others may not have consistently

- Which data and disciplines Top Performers are more likely to have than Others

- Which types of Digital Twins should be part of an ideal planning solution

How can companies leverage the digital thread to grow their top line and market share through better customer experiences? Our new eBook teaches companies how to adapt people, processes, and technology to improve revenue and customer experiences by connecting the product digital thread from design through product commercialization.

Please enjoy the summary* below. For the full research, please visit our sponsor Propel (registration required).

To learn how extending the digital thread into the customer experience can help, please read our earlier eBook: Extending Digital Threads to the Customer Experience.

How can companies leverage the digital thread to grow their top line and market share through better customer experiences? Our new eBook teaches companies how to adapt people, processes, and technology to improve revenue and customer experiences by connecting the product digital thread from design through product commercialization.

Please enjoy the summary* below. For the full research, please visit our sponsor Propel (registration required).

To learn how extending the digital thread into the customer experience can help, please read our earlier eBook: Extending Digital Threads to the Customer Experience.

Table of Contents

- Recognize the Downside of Disconnects

- Connect the Product Digital Thread through Commercialization

- The Two Primary Values of the Digital Thread

- Extend the Digital Thread through Commercialization

- Connect People

- Connect Processes

- Connect Technology

- Recommendations and Next Steps

- Acknowledgments

Grow Revenue with Better Customer Experience

Provide Consistent, Compelling Product Experience

One way to improve customer experiences, and business performance, is by feeding compelling, accurate, and consistent product experiences across channels to entice customers and influence their buying decisions. It’s important to recognize, however, that the job doesn’t end there. Experiences can’t be static. They have to evolve as products, messaging, customer needs, channels, and markets change and expand.

Digitally Transform the Product Experience Pipeline

Conveying consistent product experiences relies on speed and accuracy. Today’s processes, however, are typically manual, slow, disconnected, and error-prone. To drive growth, companies need reliable, trusted information as soon as it is available. It’s time to digitally transform the product information pipeline. Without this, companies can’t be fast and accurate enough to create compelling customer experiences that drive growth across channels and the product lifecycle.

Provide Consistent, Compelling Product Experience

One way to improve customer experiences, and business performance, is by feeding compelling, accurate, and consistent product experiences across channels to entice customers and influence their buying decisions. It’s important to recognize, however, that the job doesn’t end there. Experiences can’t be static. They have to evolve as products, messaging, customer needs, channels, and markets change and expand.

Digitally Transform the Product Experience Pipeline

Conveying consistent product experiences relies on speed and accuracy. Today’s processes, however, are typically manual, slow, disconnected, and error-prone. To drive growth, companies need reliable, trusted information as soon as it is available. It’s time to digitally transform the product information pipeline. Without this, companies can’t be fast and accurate enough to create compelling customer experiences that drive growth across channels and the product lifecycle.

Extend the Digital Thread through Commercialization

Understand the Need / Priority

Most people recognize that designing a great product is only half of the job. They have to effectively bring them to market. Beyond the initial introduction, they also need to support channel growth. Ember Technologies, Inc. is a global company whose mission is to harness the power of temperature control to transform how the world eats, drinks and lives. “Ember started out strictly eCommerce, then added Amazon, before growing into a large retail business,” says Ember’s Siobhan Hunter. Rapid growth adds effort and complexity because companies with a trajectory like Ember must continue to provide consistent product experiences even as they expand to broader channels.

Recognize Broad Applicability

Consumer goods companies like Ember are more likely to have cross-departmental processes defined to link product design with commercialization. But even these companies typically have room for improvement. The evolution of the digital thread, however, applies to virtually every industry and channel. For example:

Understand the Need / Priority

Most people recognize that designing a great product is only half of the job. They have to effectively bring them to market. Beyond the initial introduction, they also need to support channel growth. Ember Technologies, Inc. is a global company whose mission is to harness the power of temperature control to transform how the world eats, drinks and lives. “Ember started out strictly eCommerce, then added Amazon, before growing into a large retail business,” says Ember’s Siobhan Hunter. Rapid growth adds effort and complexity because companies with a trajectory like Ember must continue to provide consistent product experiences even as they expand to broader channels.

Recognize Broad Applicability

Consumer goods companies like Ember are more likely to have cross-departmental processes defined to link product design with commercialization. But even these companies typically have room for improvement. The evolution of the digital thread, however, applies to virtually every industry and channel. For example:

- Business to Consumer (B2C) companies can quickly get consistent, accurate, and compelling information into their channels

- Business to Business (B2B) companies can get the right specifications and information for their datasheets, spec sheets, website, distributors, catalogs, portals, and customers

- Regulated industries can ensure information is accurate and auditable in a trusted source for improved control and traceability

Recommendations and Next Steps

Recognize the Urgency It’s time to recognize the value and the need to change how product experiences and product information flows through the organization. Companies that want to outpace the market, grow faster, drive revenue, reach customers sooner, and create better experiences should extend their digital thread from design through commercialization. Companies that adopt this approach will be able to:- Improve time to market

- Bring continuity, timeliness, and quality to product data

- Build customer loyalty and brand trust

- Give marketing and commercialization teams the information they need, when they need it, in a way they trust

- Allow marketers to enrich, structure, and organize product data for the buyer

- Allow them to put forward a consistent, compelling product experience to customers, regardless of the channel or platform they interact with it

- Connect people across the product digital thread

- Develop cross-departmental processes from design through commercialization

- Integrate technology, or find a solution that prioritizes integration in the places that add the most value to your business

- SaaS Strategy

- Support for Software/Smart Products

- Extending Field Service Capabilities

- Design for Sustainability

1. SaaS Strategy

Most significant was PTC's strengthened SaaS strategy with the acquisitions of cloud-native Onshape and Arena for product design (CAD and CAE/Simulation), product data management (PDM), and product lifecycle management (PLM). These products make up its Velocity Group. PTC then created its Altas SaaS platform based on Onshape technology. This platform was used to create SaaS offerings for its existing products. They designate their SaaS offerings as "+," meaning the current offering, "plus more," with added cloud capabilities. These capabilities include real-time collaboration, faster deployment, reduced hardware costs, and easier methods for the broader enterprise to access product information. PTC previously launched Windchill+, Kepware +, and Vfuria+. The newest addition, Creo+, was announced at LiveWorx 2023. Brian Thompson explained that Creo+ offers all the capabilities of Creo 10 (also announced at LiveWorx 2023), but with new cloud-based tools. Creo+ enables real-time collaboration so internal and external team members can simultaneously work on the same design. While an exciting development, does PTC need two cloud-based solutions with Onshape/Arena and Creo+ / Windchill+? How should customers determine which is best for them? I liked how Jim Heppleman positioned this during a Q&A session. He explained that customers can decide between two product development priorities, and select the solution that best matches their needs. The priorities are: Agile Product Development: This approach applies the Agile methodologies that have been successful in software development to the entire product. Agile focuses on customer needs and providing value quickly. Work is completed in short intervals, or sprints, typically two weeks long, and validated along the way. The goal is to have a workable, high-quality product in less time. In contrast, the traditional Waterfall method waits until development work is complete before testing. Typically, teams then spend months fixing problems. An Agile approach could be particularly valuable for companies looking for high growth. For these customers, PTC suggests Onshape and Arena and David Katzman explained how these solutions support an Agile methodology.

Agile Product Development: This approach applies the Agile methodologies that have been successful in software development to the entire product. Agile focuses on customer needs and providing value quickly. Work is completed in short intervals, or sprints, typically two weeks long, and validated along the way. The goal is to have a workable, high-quality product in less time. In contrast, the traditional Waterfall method waits until development work is complete before testing. Typically, teams then spend months fixing problems. An Agile approach could be particularly valuable for companies looking for high growth. For these customers, PTC suggests Onshape and Arena and David Katzman explained how these solutions support an Agile methodology. Model-Based Digital Thread: With this approach, companies need the digital thread across the lifecycle. This supports traceability, reuse, efficiency, and a more disciplined approach. For companies that value this and profitability over growth, PTC recommends Creo and Windchill. PTC also reassures customers that all Creo data is upward compatible with Creo+.

Model-Based Digital Thread: With this approach, companies need the digital thread across the lifecycle. This supports traceability, reuse, efficiency, and a more disciplined approach. For companies that value this and profitability over growth, PTC recommends Creo and Windchill. PTC also reassures customers that all Creo data is upward compatible with Creo+.

2. Support for Software/Smart Products

Smart products have become increasingly critical to product success. In fact, Tech-Clarity's Profiting from Smart Products found that 86% of survey respondents indicated that smart products are important for their company's long-term success and profitability. PTC already supports this with PTC Integrity for Application Lifecycle Management (ALM), including Model-Based Systems Engineering (MBSE). However, with the acquisition of Codebeamer, PTC expands their solution to support software development for manufactured products with a cloud-ready solution. With software continuing to be a major innovation driver for today's modern products, this remains an important area for a complete product development solution.

Smart products have become increasingly critical to product success. In fact, Tech-Clarity's Profiting from Smart Products found that 86% of survey respondents indicated that smart products are important for their company's long-term success and profitability. PTC already supports this with PTC Integrity for Application Lifecycle Management (ALM), including Model-Based Systems Engineering (MBSE). However, with the acquisition of Codebeamer, PTC expands their solution to support software development for manufactured products with a cloud-ready solution. With software continuing to be a major innovation driver for today's modern products, this remains an important area for a complete product development solution.

3. Extending Field Service Capabilities

PTC has several offerings to support product service, including PTC Arbortext for technical publications and service manuals, Servigistics for optimized spare parts management, and Vuforia. for 3D work instructions and augmented reality. PTC significantly expanded this portfolio by acquiring ServiceMax, the largest acquisition in its history. Neil Barua explained that ServiceMax supports field service operations. It keeps a record of prior issues, previous maintenance, and part replacements. The offering is further strengthened with ThingWorx to monitor the product fleet for more predictive and preventative maintenance.

PTC has several offerings to support product service, including PTC Arbortext for technical publications and service manuals, Servigistics for optimized spare parts management, and Vuforia. for 3D work instructions and augmented reality. PTC significantly expanded this portfolio by acquiring ServiceMax, the largest acquisition in its history. Neil Barua explained that ServiceMax supports field service operations. It keeps a record of prior issues, previous maintenance, and part replacements. The offering is further strengthened with ThingWorx to monitor the product fleet for more predictive and preventative maintenance.

4. Design for Sustainability

Finally, EVP Chief Strategy & Sustainability Officer, Catherine Kniker (CK) stressed the importance of sustainability considerations during design, emphasizing that design decisions determine 80% of a product's environmental footprint. Engineers can improve sustainability by evaluating materials, energy efficiency, and waste reduction. PTC plans to support some of these decisions through expanded partnerships with Ansys and aPriori Technologies. Integrated workflows with Ansys Granta, a Materials Information Management solution (Ansys Materials), Creo, and Windchill, will allow engineers to assess the impact of different materials on performance, recyclability, and carbon footprint. Ansys CEO Ajei Gopal also joined Jim Hepplemann on stage to discuss the strength of their partnership in other ways to support for digital transformation and simulation-driven design with continued and tighter integrations across products lines including Windchill and Ansys Minerva.

PTC and aPriori are also planning for greater interoperability between aPriori, Creo, and Windchill so that engineers can leverage aPriori to assess cost, manufacturability, and sustainability. Engineers will be able to understand their impact on the manufacturing footprint and cost as the design evolves. aPriori's software will also make improvement recommendations.

Beyond these expanded partnerships, PTC signed the Science Based Targets initiative (SBTi) commitment letter, pledging to reduce near-term emissions reductions and meet long-term net-zero targets.

We look forward to hearing how these investments offer PTC customers even more value. Thanks to Coray Thibaut de Maisieres, and Ernestine Tiongson for hosting us at PTC LiveWorx 2023.

[post_title] => PTC LiveWorx 2023

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ptc-liveworx-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 12:53:21

[post_modified_gmt] => 2023-12-15 17:53:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18366

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 18334

[post_author] => 2

[post_date] => 2023-06-13 09:00:09

[post_date_gmt] => 2023-06-13 13:00:09

[post_content] =>

Integrated workflows with Ansys Granta, a Materials Information Management solution (Ansys Materials), Creo, and Windchill, will allow engineers to assess the impact of different materials on performance, recyclability, and carbon footprint. Ansys CEO Ajei Gopal also joined Jim Hepplemann on stage to discuss the strength of their partnership in other ways to support for digital transformation and simulation-driven design with continued and tighter integrations across products lines including Windchill and Ansys Minerva.

PTC and aPriori are also planning for greater interoperability between aPriori, Creo, and Windchill so that engineers can leverage aPriori to assess cost, manufacturability, and sustainability. Engineers will be able to understand their impact on the manufacturing footprint and cost as the design evolves. aPriori's software will also make improvement recommendations.

Beyond these expanded partnerships, PTC signed the Science Based Targets initiative (SBTi) commitment letter, pledging to reduce near-term emissions reductions and meet long-term net-zero targets.

We look forward to hearing how these investments offer PTC customers even more value. Thanks to Coray Thibaut de Maisieres, and Ernestine Tiongson for hosting us at PTC LiveWorx 2023.

[post_title] => PTC LiveWorx 2023

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ptc-liveworx-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 12:53:21

[post_modified_gmt] => 2023-12-15 17:53:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18366

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 18334

[post_author] => 2

[post_date] => 2023-06-13 09:00:09

[post_date_gmt] => 2023-06-13 13:00:09

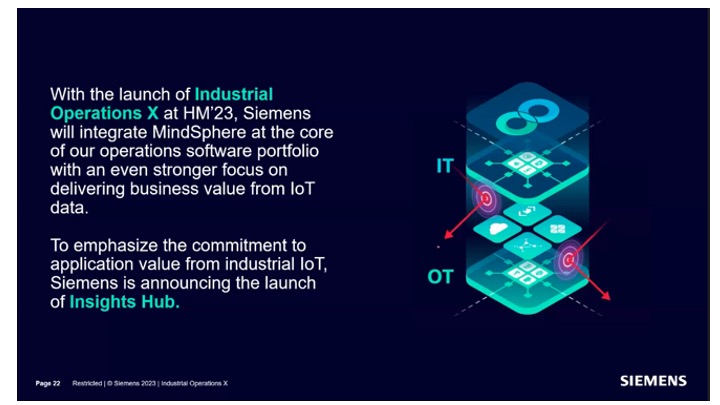

[post_content] =>  Machine builders must continuously raise the bar to compete in today's dynamic, global markets. How are they leveraging digital twins to improve how they quote, design, produce, install, and commission more complex, smart, connected, flexible, and tailored equipment than ever? Further, how can they extend their digital twins to improve installation, commissioning, and service?

Please enjoy the summary below and visit our sponsor Siemens to learn more about machine builder digital twins and other solutions for machine builders. You can also download the full eBook to learn more.

For related research, please read Increasing Equipment Design Velocity and Increasing Performance Engineering Performance.

Machine builders must continuously raise the bar to compete in today's dynamic, global markets. How are they leveraging digital twins to improve how they quote, design, produce, install, and commission more complex, smart, connected, flexible, and tailored equipment than ever? Further, how can they extend their digital twins to improve installation, commissioning, and service?

Please enjoy the summary below and visit our sponsor Siemens to learn more about machine builder digital twins and other solutions for machine builders. You can also download the full eBook to learn more.

For related research, please read Increasing Equipment Design Velocity and Increasing Performance Engineering Performance.

Table of Contents

- Recognize the Potential of the Digital Twin

- Making Progress Toward Your Digital Twin

- 1) Design in Full Product Context

- 2) Embrace BOMs / Configurations / Variability

- 3) Simulate / Optimize / Virtually Validate Equipment

- 4) Expand Further Down the Lifecycle

- Get Started

- Acknowledgments

Improving Engineering, and more, with the Digital Twin

Digital Twin Potential

Machine builders must continuously raise the bar to compete in today's dynamic, global markets. How are they leveraging digital twins to improve how they quote, design, produce, install, and commission more complex, smart, connected, flexible, and tailored equipment than ever? Further, how can they extend their digital twins to improve installation, commissioning, and service

Increase Digital Twin Maturity to Drive Value

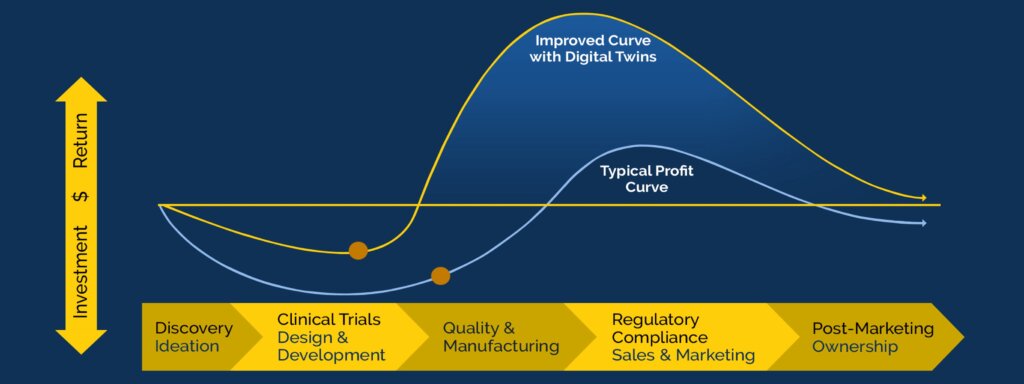

Digital twin improvement opportunities span the product lifecycle and offer significant new business value from bids through service. Our research shows that top-performing manufacturers use more advanced, mature digital twin capabilities.1 But few machine builders have tapped the full potential.

Continuous improvement through a comprehensive digital twin spanning the lifecycle is valuable, but it is a journey. There is plenty of room for most manufacturers to improve and drive increased profitability, but they can't do it all at once. Instead, they can implement the basics and find ways to expand the value through higher maturity at each step. This eBook introduces four areas where machine builders can improve their digital twins, sharing a combination of first steps and more advanced actions to drive business value and increase profitability.

Digital Twin Potential

Machine builders must continuously raise the bar to compete in today's dynamic, global markets. How are they leveraging digital twins to improve how they quote, design, produce, install, and commission more complex, smart, connected, flexible, and tailored equipment than ever? Further, how can they extend their digital twins to improve installation, commissioning, and service

Increase Digital Twin Maturity to Drive Value

Digital twin improvement opportunities span the product lifecycle and offer significant new business value from bids through service. Our research shows that top-performing manufacturers use more advanced, mature digital twin capabilities.1 But few machine builders have tapped the full potential.

Continuous improvement through a comprehensive digital twin spanning the lifecycle is valuable, but it is a journey. There is plenty of room for most manufacturers to improve and drive increased profitability, but they can't do it all at once. Instead, they can implement the basics and find ways to expand the value through higher maturity at each step. This eBook introduces four areas where machine builders can improve their digital twins, sharing a combination of first steps and more advanced actions to drive business value and increase profitability.

Recognize the Potential of the Machine Builder Digital Twin

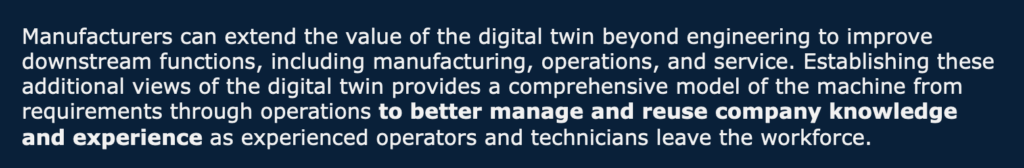

The Growing Need for Machine Digital Twins Machine builders face increased challenges, including increased equipment complexity, greater market complexity, and new demands for sustainability. These issues impact their operations and their operators, driving additional engineering requirements such as increased machine automation, monitoring, and the need for remote service. Extend Machine Builder Digital Twin Value over the Product Lifecycle Comprehensive digital twins allow equipment manufacturers to innovate and experiment in the virtual world to get unique machines right the first time. Virtual design helps them improve machine design cycles, quality, performance, configurability, and sustainability by allowing all disciplines to collaborate starting as early as equipment requirements on a holistic, contextualized product model. Lastly, running digital twin simulations enable them to optimize designs virtually before building them. But the value doesn't end in Engineering. Machine digital twins incorporating manufacturing operations and quality data allow them to produce equipment faster and more efficiently with higher first-time quality. Machine digital twins extended to the operating environment can speed up commissioning, ensure equipment runs the first time, improve performance for machine operators, and enhance operator training. Twins can also enhance service through service transformation, including machine monitoring and analytics. Finally, they can help in product retirement by enabling circular thinking where equipment can be brought back, refurbished, or harvested for valuable components.Making Progress Toward Your Digital Twin

Choosing a Starting Point For many companies, the improvements described on the previous page sound like rocket science. In fact, it is. Industries like aerospace have proven the value, and the potential is nearly limitless. But adoption can be intimidating, especially for manufacturers that haven't fully achieved the value a holistic digital twin can offer to Engineering. What should machine builders do now? Each manufacturer needs to define what the digital twin means to their business, assess their current capabilities and then make tangible, incremental steps to improve their maturity and associated business value. Digital twin initiatives should have rapid ROIs, providing value right away and making progress toward a fully mature future state. The value will be different for each company, but we've identified a number of improvements for companies to use as a starting point based on their goals and maturity. Create a Value-Driven Strategy It's essential to develop a practical plan based on what would be the most valuable to the company. Find practical problems and use the digital twin to address them. The challenges may relate to quality, speed to market, or supporting additional configurability without compromising quality. Or, they may be supplier collaboration challenges. For some, they could be sales enablers to let potential customers experience how configured equipment will behave in their environment using high-fidelity simulations. We recognize that each company is different in their starting point, what will drive the most value, and the practical sequence in which they can implement changes. It's time to identify ways to get started, create a customized plan with first steps to drive business success, extend the value, and expand on the competitive advantages achieved. Let's look at some opportunities. Start Small, then Expand The opportunities are expansive and potentially overwhelming. Remember that every company is different in where they start and what will drive the most value. Don't try to do too much at once or skip maturity steps. Focus on the tangible steps that add value to your business. But, keep the big picture in mind to ensure that early successes can be built on to reach a higher vision. Focus on People and Process

The end goal is a better way of doing business, an integrated design and development process supported by the machine digital twin. To achieve this vision, make sure to get key people and departments aligned with the vision and the transformation. Help them understand the big picture, the steps to achieve it, and how it will help them in addition to helping the company.

Enable the Transition

New ways of working require the right tools. It's essential to evaluate your current software solution portfolio to ensure they are sufficient for the job. An effective machine digital twin requires support from a variety of engineering solutions, including CAD, multiphysics CAE, software design, and PLM. It also requires industrial and factory automation solutions, including CAM, MES, HMI, SCADA, virtual commissioning, and the IIoT. Depending on maturity, it may also require asset lifecycle and service management solutions (ALM and SLM).

Think Holistically

It's important to consider more than individual tools. Evaluating how solutions work together to support the digital thread across the lifecycle is crucial. The machine digital twin is best served by a platform of solutions that work together. The platform should provide a central data model, the digital twin backbone, kept in configured context. It should be able to be acted on from different angles so everyone can contribute and get what they need in a secure, collaborative environment. Together, these product innovation platform capabilities support the machine digital twin.

It's essential to acknowledge, though, that no single platform will support every need. It's critical that the platform is open to allow integration and offers the capability to develop new applications that pull information together for specific purposes, ideally in a no-code or low-code environment.

Let’s Get Started

There are many options and a lot to do, but the value should come fast and be extended over time. Let's get started.

[post_title] => The Machine Builder Digital Twin

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => machine-builder-digital-twin

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 15:01:36

[post_modified_gmt] => 2023-12-15 20:01:36

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18334

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 18325

[post_author] => 2

[post_date] => 2023-06-08 10:00:57

[post_date_gmt] => 2023-06-08 14:00:57

[post_content] =>

Focus on People and Process

The end goal is a better way of doing business, an integrated design and development process supported by the machine digital twin. To achieve this vision, make sure to get key people and departments aligned with the vision and the transformation. Help them understand the big picture, the steps to achieve it, and how it will help them in addition to helping the company.

Enable the Transition

New ways of working require the right tools. It's essential to evaluate your current software solution portfolio to ensure they are sufficient for the job. An effective machine digital twin requires support from a variety of engineering solutions, including CAD, multiphysics CAE, software design, and PLM. It also requires industrial and factory automation solutions, including CAM, MES, HMI, SCADA, virtual commissioning, and the IIoT. Depending on maturity, it may also require asset lifecycle and service management solutions (ALM and SLM).

Think Holistically

It's important to consider more than individual tools. Evaluating how solutions work together to support the digital thread across the lifecycle is crucial. The machine digital twin is best served by a platform of solutions that work together. The platform should provide a central data model, the digital twin backbone, kept in configured context. It should be able to be acted on from different angles so everyone can contribute and get what they need in a secure, collaborative environment. Together, these product innovation platform capabilities support the machine digital twin.

It's essential to acknowledge, though, that no single platform will support every need. It's critical that the platform is open to allow integration and offers the capability to develop new applications that pull information together for specific purposes, ideally in a no-code or low-code environment.

Let’s Get Started

There are many options and a lot to do, but the value should come fast and be extended over time. Let's get started.

[post_title] => The Machine Builder Digital Twin

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => machine-builder-digital-twin

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 15:01:36

[post_modified_gmt] => 2023-12-15 20:01:36

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18334

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 18325

[post_author] => 2

[post_date] => 2023-06-08 10:00:57

[post_date_gmt] => 2023-06-08 14:00:57

[post_content] => ACE is Back!

PLM conferences are back, and it seems there’s a conference a week right now! The first one I attended this Spring was Aras’ ACE conference. This

was a special one for me because it was my first time attending in person. I was planning to attend in 2020 but it was canceled due to the pandemic, and this event marked the first in-person ACE since 2019. You could feel, and hear, the energy and excitement customers and Aras employees shared about being back in person as you walked the halls and the exhibit floor. It was a large and excited crowd of customers and partners eager to share information and experience with each other and learn from Aras.

Other than the excitement of the event and the enthusiastic customer support, there are several main things I took away from the conference:

PLM conferences are back, and it seems there’s a conference a week right now! The first one I attended this Spring was Aras’ ACE conference. This

was a special one for me because it was my first time attending in person. I was planning to attend in 2020 but it was canceled due to the pandemic, and this event marked the first in-person ACE since 2019. You could feel, and hear, the energy and excitement customers and Aras employees shared about being back in person as you walked the halls and the exhibit floor. It was a large and excited crowd of customers and partners eager to share information and experience with each other and learn from Aras.

Other than the excitement of the event and the enthusiastic customer support, there are several main things I took away from the conference:

- First, a confirmation about how different the Aras Innovator offering is

- Second, how that impacts the way Aras partners with others

- Third, that Aras Innovator can compete on the strengths of their solution capabilities even without the “Aras difference”

- Aras and Microsoft announced that Aras Enterprise SaaS is now available in the Azure Marketplace, allowing Azure customers to use their Microsoft Azure contract (MAC) credits gain to access Aras’ cloud-based PLM

- CTO Rob McAveney shared that Aras is not resting on their current platform advantage, but working on “next-gen low-code” that they will deliver over the coming years

- Aras’ Alan Mendel highlighted their efforts to help manufacturers achieve sustainability needs by leveraging a variety of Aras Innovator capabilities, this appears to be an important initiative for Aras

[post_title] => Aras Showcases Differentiation and Strengths at ACE 2023 (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aras-insight-ace-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-14 14:23:26

[post_modified_gmt] => 2023-12-14 19:23:26

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18325

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 18300

[post_author] => 2574

[post_date] => 2023-06-06 09:30:22

[post_date_gmt] => 2023-06-06 13:30:22

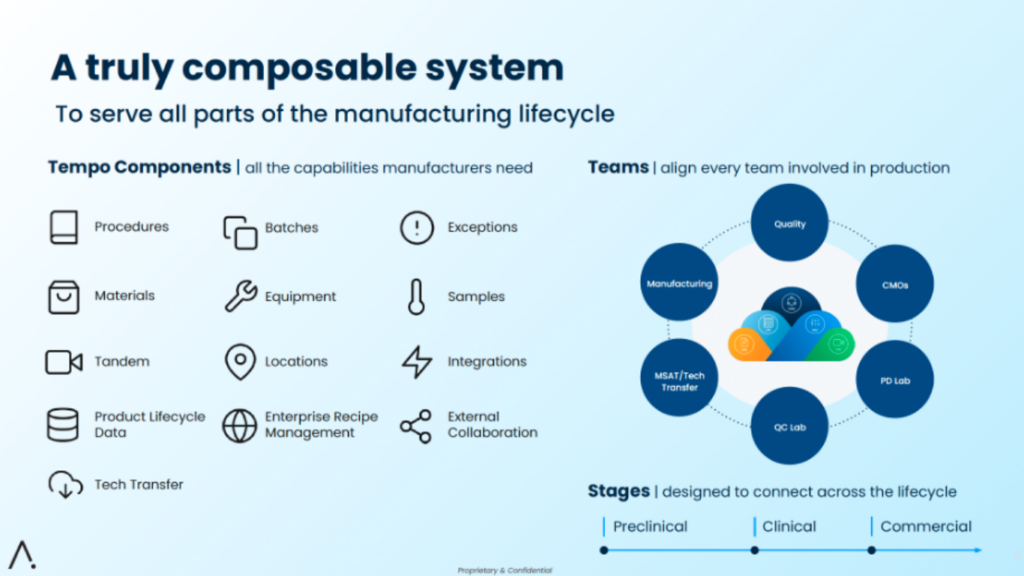

[post_content] => I feel rejuvenated after a briefing with Apprentice. Their Tempo suite is a fresh approach that marries the latest enterprise mobile and SaaS technologies with composable applications for pressing industry issues. Yes, there’s a SaaS MES – but there is more for the plant, quality lab, enterprise, and manufacturing network. It serves the product lifecycle, starting with preclinical and clinical.

The company came into being in 2014. The founders saw the industry move toward large molecule and personalized products, and they predicted the resulting radical changes in the structure of the industry. They believed older software could not support production needs such as faster changes, higher mix, continuous processes, demanding processes to grow and culture biologics, and tight collaboration with contract manufacturers. So they leveraged the most modern B2B SaaS technologies to develop the GMP-compliant Tempo Manufacturing Cloud.

The latest addition to the Tempo suite is Connected Manufacturing Network, to connect internal and external sites and teams. Capabilities include product lifecycle, enterprise recipe management, external manufacturing collaboration, and streamlined tech transfer. This real-time data-sharing capability could revolutionize how biopharma companies manage global and CMO operations.

The Tempo product line started with Tandem Virtual Collaboration, a connected worker platform with headset. Augmented Work Instructions for EBR, Procedures management, line clearance, training, and an electronic logbook came from that foundation. MES includes built-in quality, no-code procedure and recipe authoring, and enforcement. LES for the quality lab leverages some of the strengths of the MES but tailored for scientific testing and managing samples, materials, and equipment.

Apprentice.io has been growing rapidly for the past five years and has just raised another VC round to keep that momentum going. Like the company itself, their team of VCs includes both traditional high tech and life-science-focused investment companies.

I now understand how a company less than a decade old got on the Gartner Magic Quadrant for the second year in a row and moved into the visionary quadrant. The time appears to be right to infuse the most modern B2B software capabilities into the biopharma production process.

Thank you, Kristen Kucks and Marie Forshaw, for taking the time to get me up to speed!

[post_title] => Aras Showcases Differentiation and Strengths at ACE 2023 (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aras-insight-ace-2023

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-14 14:23:26

[post_modified_gmt] => 2023-12-14 19:23:26

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18325

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 18300

[post_author] => 2574

[post_date] => 2023-06-06 09:30:22

[post_date_gmt] => 2023-06-06 13:30:22

[post_content] => I feel rejuvenated after a briefing with Apprentice. Their Tempo suite is a fresh approach that marries the latest enterprise mobile and SaaS technologies with composable applications for pressing industry issues. Yes, there’s a SaaS MES – but there is more for the plant, quality lab, enterprise, and manufacturing network. It serves the product lifecycle, starting with preclinical and clinical.

The company came into being in 2014. The founders saw the industry move toward large molecule and personalized products, and they predicted the resulting radical changes in the structure of the industry. They believed older software could not support production needs such as faster changes, higher mix, continuous processes, demanding processes to grow and culture biologics, and tight collaboration with contract manufacturers. So they leveraged the most modern B2B SaaS technologies to develop the GMP-compliant Tempo Manufacturing Cloud.

The latest addition to the Tempo suite is Connected Manufacturing Network, to connect internal and external sites and teams. Capabilities include product lifecycle, enterprise recipe management, external manufacturing collaboration, and streamlined tech transfer. This real-time data-sharing capability could revolutionize how biopharma companies manage global and CMO operations.

The Tempo product line started with Tandem Virtual Collaboration, a connected worker platform with headset. Augmented Work Instructions for EBR, Procedures management, line clearance, training, and an electronic logbook came from that foundation. MES includes built-in quality, no-code procedure and recipe authoring, and enforcement. LES for the quality lab leverages some of the strengths of the MES but tailored for scientific testing and managing samples, materials, and equipment.

Apprentice.io has been growing rapidly for the past five years and has just raised another VC round to keep that momentum going. Like the company itself, their team of VCs includes both traditional high tech and life-science-focused investment companies.

I now understand how a company less than a decade old got on the Gartner Magic Quadrant for the second year in a row and moved into the visionary quadrant. The time appears to be right to infuse the most modern B2B software capabilities into the biopharma production process.

Thank you, Kristen Kucks and Marie Forshaw, for taking the time to get me up to speed!

[post_title] => Apprentice.io Grows with Biopharma 4.0 SaaS Software (Insight) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => biopharma-saas-software-insight [to_ping] => [pinged] => [post_modified] => 2023-08-31 17:01:09 [post_modified_gmt] => 2023-08-31 21:01:09 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18300 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [7] => WP_Post Object ( [ID] => 18306 [post_author] => 2574 [post_date] => 2023-06-05 23:07:10 [post_date_gmt] => 2023-06-06 03:07:10 [post_content] =>

What most contributes to supply chain resiliency? What are the challenges and impacts of doing it well? Can better collaboration, cadence, or technology improve manufacturers' capability to respond to disruptions? What does it take to recover with operational continuity and minimal negative impact? What is the role of departments beyond Supply Chain?

Tech-Clarity is conducting research on these topics right now. Julie Fraser, Tech-Clarity’s VP of Research for Operations and Manufacturing, will discuss what questions are included and why. We will explore these topics:

What most contributes to supply chain resiliency? What are the challenges and impacts of doing it well? Can better collaboration, cadence, or technology improve manufacturers' capability to respond to disruptions? What does it take to recover with operational continuity and minimal negative impact? What is the role of departments beyond Supply Chain?

Tech-Clarity is conducting research on these topics right now. Julie Fraser, Tech-Clarity’s VP of Research for Operations and Manufacturing, will discuss what questions are included and why. We will explore these topics:

- Supply chain challenges and impacts in these disrupted times

- Drivers, benefits, and goals for investing in resilience

- The impact of having established and effective planning at various cadences

- The role of visibility to production capabilities and product changes in resilience

- Integration of varied disciplines and technologies to support resilience

[post_title] => Supply Chain Resiliency: Taking the Road Less Traveled

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => supply-chain-resiliency-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-27 14:51:03

[post_modified_gmt] => 2023-12-27 19:51:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18306

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 18276

[post_author] => 2

[post_date] => 2023-05-31 09:00:30

[post_date_gmt] => 2023-05-31 13:00:30

[post_content] =>

[post_title] => Supply Chain Resiliency: Taking the Road Less Traveled

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => supply-chain-resiliency-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-27 14:51:03

[post_modified_gmt] => 2023-12-27 19:51:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18306

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 18276

[post_author] => 2

[post_date] => 2023-05-31 09:00:30

[post_date_gmt] => 2023-05-31 13:00:30

[post_content] =>  How can manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability in the industrial equipment industry as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity.

Survey results show that Top Performers waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. They accomplish this through best practices, including more advanced collaboration and communication methods and increased use of 3D and simulation, to plan and validate manufacturing operations with digital twins.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

This eBook shares additional data analysis and insights for the industrial equipment industry from our Transforming Manufacturing Engineering with Virtual Build research. Watch this three-part on-demand webinar series with Jim Brown to learn how manufacturers can improve manufacturing engineering and technology.

How can manufacturers improve manufacturing engineering? We surveyed 177 people directly involved with manufacturing engineering and found that modernizing processes and technology drives higher manufacturing engineering productivity and performance. These improvements are crucial to profitability in the industrial equipment industry as customers demand high quality, more personalized products at increasingly faster time to market; all despite rising product and manufacturing complexity.

Survey results show that Top Performers waste less time on non-value-added activities, find issues sooner, and spend less on physical prototypes. They accomplish this through best practices, including more advanced collaboration and communication methods and increased use of 3D and simulation, to plan and validate manufacturing operations with digital twins.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required).

This eBook shares additional data analysis and insights for the industrial equipment industry from our Transforming Manufacturing Engineering with Virtual Build research. Watch this three-part on-demand webinar series with Jim Brown to learn how manufacturers can improve manufacturing engineering and technology.

Address Process Designer Challenges

Manufacturing Engineers Face Increased Complexity and Change Manufacturing is more complex than ever. Complexity has increased in three areas; products, manufacturing processes, and markets. Today’s products are offered with increasing numbers of variants and configuration options and require a combination of mechanical, electrical, and software components. Today’s production may include industrial additive manufacturing capabilities, and involves increased automation. In addition, increasing demand for automation and new power sources including electric, hydrogen, and solar are accelerating the rate of change in the industrial equipment industry. Finally, manufacturers are shifting production and reshoring as the industry is trying to cope with supply chain issues. Despite these, manufacturing engineers need to decrease cycle times and improve quality.

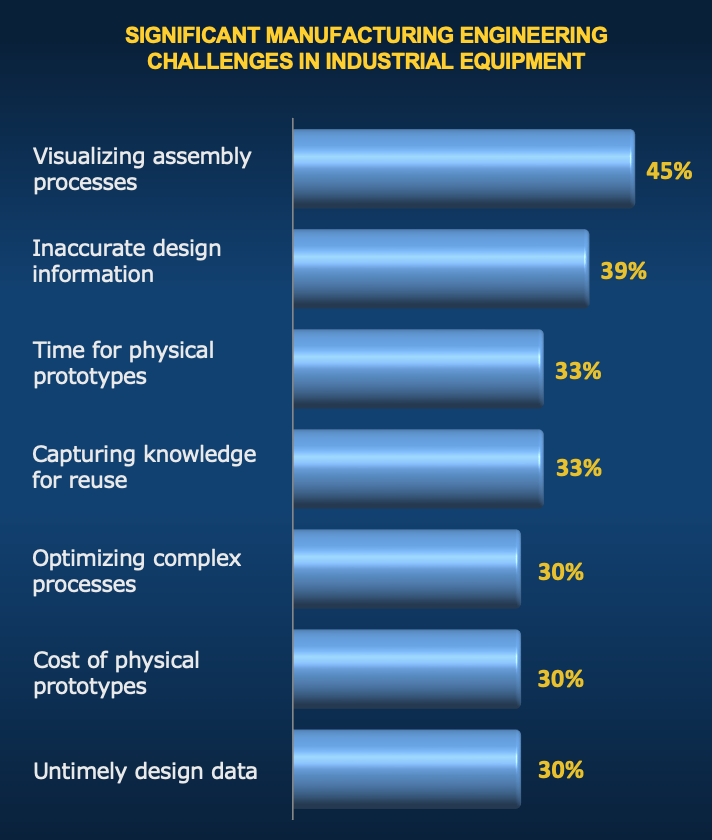

Challenges Reflect Lack of Ability to Visualize, Data Challenges

Manufacturing engineers must overcome significant challenges to design and validate production processes. The most commonly reported challenge is the inability to visualize assembly processes. This makes it challenging for planners to optimize process plans and provide feedback on manufacturability. The inability to experience production virtually leads to the need for time-consuming, costly physical mockups.

They also report challenges with obtaining accurate, timely product design data which limits the ability for manufacturing engineers to work in parallel to shorten time to market. Finally, respondents report challenges with the time required to build prototypes, their ability to capture knowledge for reuse, and optimizing complex processes.

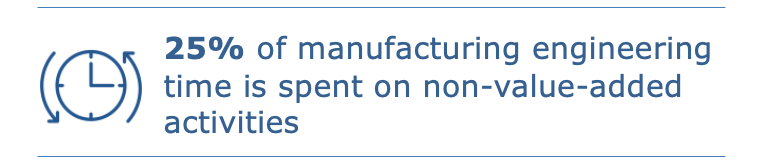

Too Much Wasted Time

Survey respondents identified manufacturing engineering inefficiency as both a challenge and profitability requirement. Researchers further inquired about the amount of manufacturing engineering time that participants estimate their companies spend on non-value-added activities, including:

Manufacturing is more complex than ever. Complexity has increased in three areas; products, manufacturing processes, and markets. Today’s products are offered with increasing numbers of variants and configuration options and require a combination of mechanical, electrical, and software components. Today’s production may include industrial additive manufacturing capabilities, and involves increased automation. In addition, increasing demand for automation and new power sources including electric, hydrogen, and solar are accelerating the rate of change in the industrial equipment industry. Finally, manufacturers are shifting production and reshoring as the industry is trying to cope with supply chain issues. Despite these, manufacturing engineers need to decrease cycle times and improve quality.

Challenges Reflect Lack of Ability to Visualize, Data Challenges

Manufacturing engineers must overcome significant challenges to design and validate production processes. The most commonly reported challenge is the inability to visualize assembly processes. This makes it challenging for planners to optimize process plans and provide feedback on manufacturability. The inability to experience production virtually leads to the need for time-consuming, costly physical mockups.

They also report challenges with obtaining accurate, timely product design data which limits the ability for manufacturing engineers to work in parallel to shorten time to market. Finally, respondents report challenges with the time required to build prototypes, their ability to capture knowledge for reuse, and optimizing complex processes.

Too Much Wasted Time

Survey respondents identified manufacturing engineering inefficiency as both a challenge and profitability requirement. Researchers further inquired about the amount of manufacturing engineering time that participants estimate their companies spend on non-value-added activities, including:

- Searching for data

- Rekeying information

- Recreating data

- Documenting feedback for others

- Modeling common assets

- Other activities that don’t involve engineering innovation and decision making

Recommendations and Next Steps

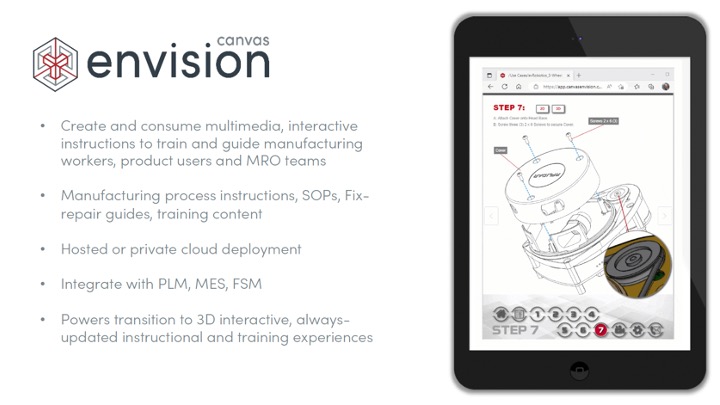

Make a Strategic Improvement Today’s product, manufacturing process, and market complexity demand new ways of working. The Top Performers are transforming manufacturing engineering through digitalization, better collaboration, 3D, and simulation allowing them to overcome efficiency, quality, and cost challenges. Using virtual, digital twins offers manufacturing engineers in the industrial equipment industry both the ability to improve their own performance and a strategic opportunity to increase overall product development profitability. These leaders spend 17% less time on non-value-added activities in manufacturing engineering, directly reducing development cycle times. Increase Quality Respondents indicate that they can reduce ECOs by over one-third. They do this by improving manufacturing process design using virtual technologies. Top Performers are more likely to find physical manufacturing issues in a virtual model than Others who are more likely to discover them in physical prototypes and actual production. Reduce Cost Survey respondents share that they can eliminate 37% of their prototypes by increasing manufacturing engineering maturity, leading to significant cost savings per product. They do this by shifting validation and issue identification sooner in the product development process so they need fewer physical prototypes. Improve Time to Market Survey respondents report that they can reduce time to market by 35% by using 3D and simulation to plan and validate manufacturing operations. This is done, in part, by increasing efficiency, reducing time-consuming physical prototyping, and lowering rework by finding issues sooner in product development. Get Started It’s time to improve manufacturing engineering productivity and performance. Industrial equipment companies can follow the lead of the Top Performers to increase maturity in how they plan, validate, and communicate manufacturing plans. To increase maturity, manufacturers should adopt the best practices of the Top Performers, including using integrated solutions such as 3D and simulation for manufacturing engineering. *This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes DELMIA (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Transforming Manufacturing Engineering in Industrial Equipment [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => manufacturing-engineering-in-industrial-equipment [to_ping] => [pinged] => [post_modified] => 2024-01-30 13:56:35 [post_modified_gmt] => 2024-01-30 18:56:35 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=18276 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [9] => WP_Post Object ( [ID] => 18248 [post_author] => 2574 [post_date] => 2023-05-11 10:00:09 [post_date_gmt] => 2023-05-11 14:00:09 [post_content] => Jim Brown, Michelle Boucher, and I got an introduction to Canvas GFX and its Envision product for interactive work instructions in a recent briefing. The question I, as the manufacturing analyst had, was: Can a system for model-based interactive work instructions really be easy enough for non-engineering users to embrace? Canvas GFX says yes, and continues to enhance and expand its Canvas Envision product. Now, beyond a wide array of 2D and 3D CAD formats, it is ready to integrate with major PLM platforms such as Aras, Propel, and Siemens Teamcenter. This company has 30 years of history, starting in the 1980s as a Mac-based 2D illustration program. Since the mid-1990s, large aerospace, defense, and industrial equipment organizations adopted Canvas as a solution for technical illustrations. This foundation brings strength in 2D CAD, including some older and less-common formats. Canvas Envision came out in 2021, after new investors and executives joined. Canvas Envision is intended as a SaaS platform for all phases of work instruction: creation, customization, and consumption. However, some of its major customers have pushed it into on-prem and private cloud offerings. Canvas’ vision for Envision extends through the product lifecycle:- Manufacturing process instructions

- SOPs

- Technical documentation or manuals

- employee training

- MRO or field service repair guides

[post_title] => Canvas Envision Takes Work Instructions to New Levels of Ease (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => work-instructions-canvas-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-05-13 14:17:32

[post_modified_gmt] => 2023-05-13 18:17:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18248

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 18236

[post_author] => 2

[post_date] => 2023-05-10 13:42:30

[post_date_gmt] => 2023-05-10 17:42:30

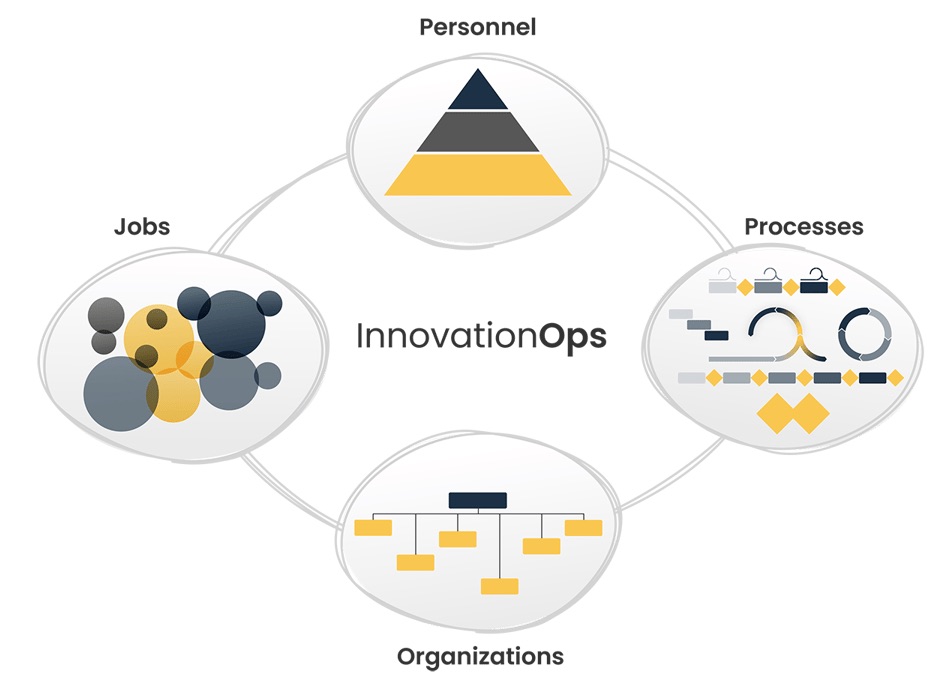

[post_content] => We’ve been talking about operationalizing innovation for some time. It’s a crucial need because, as our research shows, innovation for products and services is among the top factors driving long-term business success. It can’t be left to organic inspiration or luck. It must be targeted and driven to provide a repeatable, scalable market advantage that drives profitable growth.

But what does it take to operationalize innovation? After a recent call with Sopheon, I’m happy to see there is effort being put into this question. Sopheon is supporting an initiative to define and support “InnovationOps” to serve the same role as DevOps, SecurityOps, or other approaches to take innovation to the next level. Unlike most software companies, they aren’t taking a “not invented here” approach. Instead, they are pulling together leaders in innovation practice and theory to help further the concept.

I suspect they will use what they learn to help drive their product strategy, which as I’ve written previously, has been extended to cover a broader set of processes than their traditional portfolio management solution alone. It’s a win-win, and an exciting idea that should provide a strong framework for companies to improve innovation value, speed, and efficiency.

Thank you Greg Coticchia, Mike Bauer, and Paul Heller for sharing the concept with me and inviting me to participate in the roundtables.

[post_title] => Canvas Envision Takes Work Instructions to New Levels of Ease (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => work-instructions-canvas-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-05-13 14:17:32

[post_modified_gmt] => 2023-05-13 18:17:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18248

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 18236

[post_author] => 2

[post_date] => 2023-05-10 13:42:30

[post_date_gmt] => 2023-05-10 17:42:30

[post_content] => We’ve been talking about operationalizing innovation for some time. It’s a crucial need because, as our research shows, innovation for products and services is among the top factors driving long-term business success. It can’t be left to organic inspiration or luck. It must be targeted and driven to provide a repeatable, scalable market advantage that drives profitable growth.

But what does it take to operationalize innovation? After a recent call with Sopheon, I’m happy to see there is effort being put into this question. Sopheon is supporting an initiative to define and support “InnovationOps” to serve the same role as DevOps, SecurityOps, or other approaches to take innovation to the next level. Unlike most software companies, they aren’t taking a “not invented here” approach. Instead, they are pulling together leaders in innovation practice and theory to help further the concept.

I suspect they will use what they learn to help drive their product strategy, which as I’ve written previously, has been extended to cover a broader set of processes than their traditional portfolio management solution alone. It’s a win-win, and an exciting idea that should provide a strong framework for companies to improve innovation value, speed, and efficiency.

Thank you Greg Coticchia, Mike Bauer, and Paul Heller for sharing the concept with me and inviting me to participate in the roundtables.

[post_title] => Sopheon Champions new InnovationOps Movement

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => innovationops-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-10-24 10:38:29

[post_modified_gmt] => 2023-10-24 14:38:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18236

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 18227

[post_author] => 2574

[post_date] => 2023-05-02 09:53:38

[post_date_gmt] => 2023-05-02 13:53:38

[post_content] => Jim Brown and I are jazzed up after learning about how Elisa IndustrIQ is combining the data management and analytics of the parent telco to strengthen already successful manufacturing applications. This combination of data structures, analytics algorithms for AI and ML, and applications that serve specific industries’ needs can deliver very high value. Elisa IndustrIQ is making its modular solution available in a way that also leverages data from outside the suite to make it even more valuable and broadly applicable.

A true digital transformation changes or extends the business model, and Finnish telco Elisa has done just that. It recognized that its analytics and automation to run the telco could apply to optimizing manufacturing. They also realized that embedding this into applications that solve real business issues would boost the customer’s value. So, for the past few years, it has been building and acquiring manufacturing applications to address manufacturing challenges, including production speed, connected supply chain, skilled workforce, climate change, and cybersecurity.

Their research showed that increased agility in production would be paramount to manufacturers’ success. Acquisitions have fueled the depth of the company’s applications and geographic spread of manufacturing-savvy people and customers:

[post_title] => Sopheon Champions new InnovationOps Movement

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => innovationops-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-10-24 10:38:29

[post_modified_gmt] => 2023-10-24 14:38:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18236

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[11] => WP_Post Object

(

[ID] => 18227

[post_author] => 2574

[post_date] => 2023-05-02 09:53:38

[post_date_gmt] => 2023-05-02 13:53:38

[post_content] => Jim Brown and I are jazzed up after learning about how Elisa IndustrIQ is combining the data management and analytics of the parent telco to strengthen already successful manufacturing applications. This combination of data structures, analytics algorithms for AI and ML, and applications that serve specific industries’ needs can deliver very high value. Elisa IndustrIQ is making its modular solution available in a way that also leverages data from outside the suite to make it even more valuable and broadly applicable.

A true digital transformation changes or extends the business model, and Finnish telco Elisa has done just that. It recognized that its analytics and automation to run the telco could apply to optimizing manufacturing. They also realized that embedding this into applications that solve real business issues would boost the customer’s value. So, for the past few years, it has been building and acquiring manufacturing applications to address manufacturing challenges, including production speed, connected supply chain, skilled workforce, climate change, and cybersecurity.

Their research showed that increased agility in production would be paramount to manufacturers’ success. Acquisitions have fueled the depth of the company’s applications and geographic spread of manufacturing-savvy people and customers:

- CalcuQuote: Purchasing automation software for electronics manufacturing service companies or contract manufacturers based in Dallas, TX, USA

- camLine: MES and advanced SPC-based quality for semiconductor and high tech industries that originated in Germany

- TenForce: Environmental health and safety (EH&S) software company out of Belgium that is strong in chemicals

- sedApta: Supply chain planning, execution, and intelligence solutions with strength in food and beverage and customers in process, batch, and discrete industries out of Italy has Elisa as a minority owner

[post_title] => Elisa IndustrIQ Combines Advanced Analytics into Established Applications (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => elisa-industriq-ai-modular-applications

[to_ping] =>

[pinged] =>

[post_modified] => 2023-05-06 09:55:01

[post_modified_gmt] => 2023-05-06 13:55:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18227

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 18218

[post_author] => 2

[post_date] => 2023-04-28 09:00:07

[post_date_gmt] => 2023-04-28 13:00:07

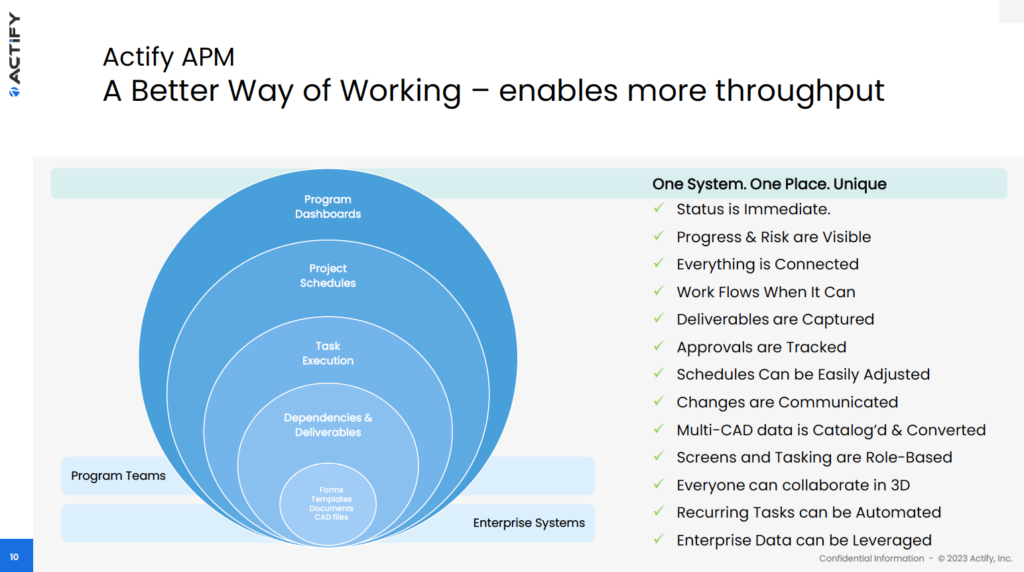

[post_content] => It’s exciting when you see a company reinvent themselves to take on an important, unsolved problem in the industry. That’s exactly what Actify has done. We’ve been following them from the time of their early, very successful CAD viewer product line SpinFire through their new evolution to create a holistic solution for automotive project management. What they’ve done opens up a new era of solutions for program managers working for automotive suppliers, and likely for other industries to follow.

I can hear people saying “there are already lots of project management tools on the market.” True. There are also lots of PLM solutions to manage data, cloud storage solutions to manage files, and collaboration solutions to manage…well…collaboration. But automotive program management needs all of those things, and all but the biggest companies have trouble implementing and integrating all of those capabilities. What Actify has done is build a solution that is tailor-made for program managers. It not only manages documents and collaboration - it manages these in the context of an automotive program. During the demonstration, we noted how the tasks maintain the context of the program, for example a DFMEA, so managing the schedule and the work to be done are joined in one place to avoid the need for program managers to manually connect status, schedules, and work objects.

Top tier automotive suppliers live and die by their OEM relationships and the profitability of their programs. To support this, program management has evolved as a unique and critical discipline. Actify has even coined a new phrase, “Make to Program,” that reflects the unique manufacturing style and processes they support in the automotive supply chain. It’s nice to see someone developing tools that are built to work specifically for them. Especially at a time with so many new programs and the dramatic change as the automotive industry electrifies.

Thank you Peter West, Bob Anson, and Charisse Dalton for spending time and sharing the progress toward your vision with me, Julie, and Michelle.

[post_title] => Elisa IndustrIQ Combines Advanced Analytics into Established Applications (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => elisa-industriq-ai-modular-applications

[to_ping] =>

[pinged] =>

[post_modified] => 2023-05-06 09:55:01

[post_modified_gmt] => 2023-05-06 13:55:01

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=18227

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 18218

[post_author] => 2

[post_date] => 2023-04-28 09:00:07

[post_date_gmt] => 2023-04-28 13:00:07

[post_content] => It’s exciting when you see a company reinvent themselves to take on an important, unsolved problem in the industry. That’s exactly what Actify has done. We’ve been following them from the time of their early, very successful CAD viewer product line SpinFire through their new evolution to create a holistic solution for automotive project management. What they’ve done opens up a new era of solutions for program managers working for automotive suppliers, and likely for other industries to follow.

I can hear people saying “there are already lots of project management tools on the market.” True. There are also lots of PLM solutions to manage data, cloud storage solutions to manage files, and collaboration solutions to manage…well…collaboration. But automotive program management needs all of those things, and all but the biggest companies have trouble implementing and integrating all of those capabilities. What Actify has done is build a solution that is tailor-made for program managers. It not only manages documents and collaboration - it manages these in the context of an automotive program. During the demonstration, we noted how the tasks maintain the context of the program, for example a DFMEA, so managing the schedule and the work to be done are joined in one place to avoid the need for program managers to manually connect status, schedules, and work objects.

Top tier automotive suppliers live and die by their OEM relationships and the profitability of their programs. To support this, program management has evolved as a unique and critical discipline. Actify has even coined a new phrase, “Make to Program,” that reflects the unique manufacturing style and processes they support in the automotive supply chain. It’s nice to see someone developing tools that are built to work specifically for them. Especially at a time with so many new programs and the dramatic change as the automotive industry electrifies.