Customer expectations for rapid, complete shipments are rising constantly. How can a business set supply chain strategy to meet current and future needs? Listen to this webcast from July 19, 2022 where Julie Fraser explores this with Kenny William of Parts Town and Victoria Brown of Körber Supply Chain. Both have deep experience in…

- how to manage uncertainty

- examples of how to stay agile

- WMS software flexibility and ability to support constant change

- keeping up with process improvements

- accelerating movement through the warehouse

Beyond implementing lab technologies, what can laboratories do to leverage them effectively? We surveyed 222 people working in corporate labs to find out.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systemès BIOVIA (registration required).

Beyond implementing lab technologies, what can laboratories do to leverage them effectively? We surveyed 222 people working in corporate labs to find out.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systemès BIOVIA (registration required).

Table of Contents

- Current Situation

- Challenges

- Technology - The Solution?

- Additional Needs

- Recommendations

- About the Research

- Acknowledgements

Introduction

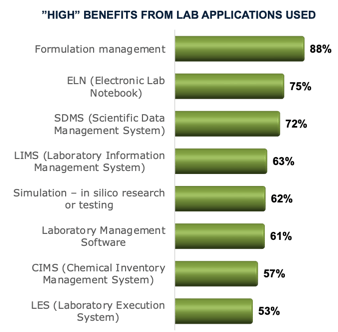

Technology Pays Off, but Maximum Performance Requires More Can new technology in the laboratory help make companies more successful? Apparently. Almost universally, those who use them report they deliver significant business benefits. Yet constant changes, including changes in processes, materials, and technology, create challenges. To minimize inefficiency, most labs have worked toward good processes and practices. All of that is still not delivering total potential value.

This research of 222 respondents from labs worldwide indicates that new technologies and processes are insufficient. Very few respondents report good – let alone excellent – performance on throughput, cycle time, documentation for compliance, or analyzing data and making sound decisions. It appears that greater integration and data standardization, a data-centric mindset, and process shift are also required.

Can new technology in the laboratory help make companies more successful? Apparently. Almost universally, those who use them report they deliver significant business benefits. Yet constant changes, including changes in processes, materials, and technology, create challenges. To minimize inefficiency, most labs have worked toward good processes and practices. All of that is still not delivering total potential value.

This research of 222 respondents from labs worldwide indicates that new technologies and processes are insufficient. Very few respondents report good – let alone excellent – performance on throughput, cycle time, documentation for compliance, or analyzing data and making sound decisions. It appears that greater integration and data standardization, a data-centric mindset, and process shift are also required.

Recommendations

Recommendations and Next Steps- Don’t rest on current processes and practices' successes; leverage new technology. You can expect excellent benefits.

- Choose technologies that will deliver the performance improvements your business most needs from the lab.

- Recognize that new technology may cause challenges for the lab. Prepare both education on the goals and training on the changes needed for each role to leverage it fully.

- Be sure you gain significant benefits from each new technology you deploy; measure and quantify gains.

- Beyond investing in new technology, be prepared to standardize and integrate it, possibly with a single platform.

- Learn about industry standards such as Allotrope and consider whether they might support and guide your efforts in making laboratory data broadly usable.

- Focus on not just having data but making it accessible and ready to aggregate, correlate, and use in new ways, such as advanced analytics.

- Ensure that data scientists and lab domain experts work together closely to generate actionable insights that deliver business value from the data.

- Realize that the data-centric mindset and approach are likely to be missing or immature, so get a top management sponsor who can support a culture shift and appropriate resources.

What does MES need for manufacturing IT agility and to stay current in our uncertain world? It’s more than fit and functionality: a modern IT architecture. We talked to leading high-tech manufacturers to understand their vision for this.

Please enjoy the summary below. For the full paper, please visit our sponsor Critical Manufacturing (registration required).

For related research, please watch the MES Architecture for More Resilient, Responsive, and Agile Manufacturing webcast.

What does MES need for manufacturing IT agility and to stay current in our uncertain world? It’s more than fit and functionality: a modern IT architecture. We talked to leading high-tech manufacturers to understand their vision for this.

Please enjoy the summary below. For the full paper, please visit our sponsor Critical Manufacturing (registration required).

For related research, please watch the MES Architecture for More Resilient, Responsive, and Agile Manufacturing webcast.

Table of Contents

- Executive Summary

- Nothing is Stable

- Production Process Impact

- The Challenge of Enterprise MES

- Modern MES Capabilities

- Containerization for Deployment Choice

- Container Orchestration to Optimize IT Performance

- DevOps Environment for Progress

- Extending DevOps for Ecosystem Access

- Deployment Coordination

- Conclusion

- References

- About the Author

Executive Summary

Digital transformation aims to enhance agility. It must encompass every aspect of a business, including information technology (IT), business teams, and production operations, including the operations technology (OT) teams. Manufacturing execution systems (MES) and related plant floor software have been challenging to implement, maintain, and upgrade. However, manufacturers operating in uncertain times need better agility to succeed with continuous improvement and operational excellence. The ability to change quickly has become more complex. Today, it involves greater collaboration. Investment in new digital technologies, operating systems, and software applications has become a top strategic priority. This shift is now driving a digital transformation across manufacturing IT systems. Upgrading to a modern Manufacturing IT system unlocks exponential performance improvement by improving responsiveness. Manufacturers can leverage containerization strategies and DevOps environments by investing in new IT solutions with an advanced technology architecture to improve efficiency, customer satisfaction, and profit margins.FIGURE 6: OPENING DEVOPS FOR ECOSYSTEM ACCESS BEYOND THE SOFTWARE PROVIDER TO SERVICES PARTNERS AND MANUFACTURING IT TEAMS ENABLES ALL PARTIES TO KEEP THE SOFTWARE CURRENT AND OPTIMIZED

Conclusion

Conclusion

Today’s relentless pace and scope of change have forever altered how manufacturers operate. This requires companies to change the evaluation and selection process for purchasing software and systems. Companies can no longer risk staying with legacy IT systems or MES software applications in a world of extreme change and uncertainty. Even many current MES products cannot keep up.

Innovation in the software industry has yielded an array of new architectures, deployment methodologies, and hosting options. They are finally arriving on the factory floor. These advanced technologies can overcome the challenges associated with uncertainty by streamlining the configuration, standardization, and update processes related to application management. Orchestrated containerization and new DevOps platforms improve collaboration and facilitate enterprise MES deployment. This agility in architecture and tooling is fundamental to overcoming extreme uncertainty.

Manufacturers can implement a modern MES to unlock these benefits – provided it is built on a fully up-to-date architecture. With this foundation, is it possible to:

- Establish a perfect fit in every site and line, even with special one-off needs

- Manage, customize, and update applications consistently from a Center of Excellence (CoE)

- Boost performance and progress from a digital transformation strategy by using a single enterprise manufacturing software suite that is agile, responsive, and fully supports both line of business and IT needs.

Tech-Clarity Celebrates 20 Years of Making the Value of Technology Clear

A message from Jim Brown, President of Tech-Clarity...

A message from Jim Brown, President of Tech-Clarity...

Why Tech-Clarity?

Seeing how software technology can help improve business performance in manufacturing is a fascinating thing. I had the chance to experience it from a variety of angles – in manufacturing, as a management consultant, and as a product manager and marketing leader in the software industry. Everywhere I went, I saw a consistent need. Tech people didn’t understand business people, and business people didn’t understand tech people. Somebody needed to bridge the gap in understanding between software and the business value it drives. That’s why Tech-Clarity was created with the mission to make the business value of technology clear.Time has Passed, Surely People “Get it” Now?

So much has changed over the last 20 years. Technology has evolved at a blistering pace. Business has transitioned from business process re-engineering, to lean, to digital transformation. The way people educate themselves about software has also changed, from attending conferences and reading paper reports to consuming eBooks, videos, infographics, interactive benchmarking tools, animations, and more. The web and the rise of social media put extensive information at everyone’s fingertips. Yet, even as younger, more tech-savvy generations have entered the workforce, the need – and our mission – has not changed. In fact, we believe it’s more important today than ever because business people are a more significant part of the process.What Now? Thanking Everyone (and sorry for inevitably missing some)

After 20, what I feel most is grateful. I have so much to be thankful for and so many people to thank. First, I want to thank Michelle Boucher for being the “A-Team” and helping us continuously improve. You have been the stable presence in “Team Tech-Clarity.” Thanks to Julie Fraser, who expanded our coverage as product innovation and engineering converged with manufacturing operations, and for all of the wisdom you provide. And thank you to Mandy Jiang for helping our research reach and inspire so many people. I also want to thank James White and Jeff Hojlo for the roles they played on our analyst team. I also want to express my gratitude to my team at Aberdeen Group. I learned a lot from them as Tech-Clarity was acquired to create the Product Innovation and Engineering practice. I also learned from the manufacturing team when they joined us before I left to resume the Tech-Clarity mission independently. I was fortunate to work with some talented and amazing people, many of whom have gone on to bigger and better things. Thank you to Chad Jackson for helping create and lead the practice, and to a team that always made things work, including Michelle Boucher, Risa Barnett, Dave Houlihan, Maura Buxton, Marjorie Westerman, Dave Mesgar, Adam Hollander, Scott Mitchem, Ric Stanley, and Dave Ableman. A special thanks also to Matt Littlefield, Mehul Shah, and Cindy Jutras, who put up with me as we merged our teams – we were ahead of the times! Thanks to my friends at COFES, including Brad Holtz and Joel Orr, for trusting me as a part of the team. Thanks also to Pete Wells, Lynne Allen, and Jim Doxey for teaming up on the Board of Directors to keep the spirit alive. May it rise again in some form. Thanks to our partners along the way. Thanks to my clients. There are too many of you to name, but please know how much I appreciate your support over the years. I am deeply touched and appreciative for your trust and willingness to support our mission. Thank you to the multitude of manufacturers that I’ve surveyed, interviewed, and worked with for keeping me grounded in the reality of what it takes to design and produce products amidst increasing complexity. Thanks to my family and especially my wife Cori Brown for their support and understanding of why what we do at Tech-Clarity means so much to me.Time to Get Started on the Next 20 Years

In addition to feeling grateful, I feel energized. I am excited about how digital transformation is fundamentally changing the manufacturing industry in profound ways. There are so many cool things happening in manufacturing itself and the engineering, manufacturing, and enterprise software that supports it. With the technological evolution and advances and the lines blurring between business and technology, we still need education on how tech drives better business results. The Tech-Clarity team and I are looking forward to the next 20 years!Be a Part of It

I invite you to be a part of it. Click the follow button on the Tech-Clarity, Inc. LinkedIn page. Visit our website to sign up for our newsletter and surveys. And most of all, keep us up to date on all of the cool, innovative things you’re seeing and doing. Let’s keep moving forward. There is still a lot of business value to be uncovered and realized. Thanks again for the opportunity to be a part of it.Our History in Visuals (Just for Fun)

[post_title] => Tech-Clarity Celebrates 20 Years

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 20-years-anniversary-tech-clarity

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:57

[post_modified_gmt] => 2022-11-15 03:25:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11514

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 11456

[post_author] => 2

[post_date] => 2022-06-17 09:30:32

[post_date_gmt] => 2022-06-17 13:30:32

[post_content] =>

[post_title] => Tech-Clarity Celebrates 20 Years

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => 20-years-anniversary-tech-clarity

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:25:57

[post_modified_gmt] => 2022-11-15 03:25:57

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11514

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 11456

[post_author] => 2

[post_date] => 2022-06-17 09:30:32

[post_date_gmt] => 2022-06-17 13:30:32

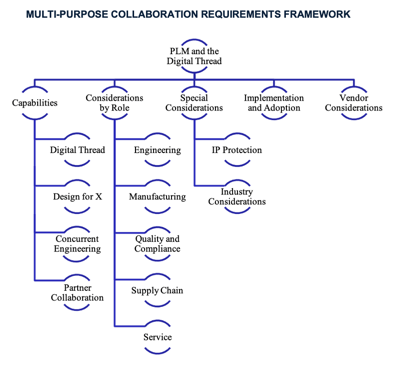

[post_content] =>  How does the right PLM help improve product development collaboration to create agility, speed, and quality in product innovation? What collaborative capabilities should companies look for when they select a PLM platform?

Products and product development have become increasingly challenging as manufacturers push the boundaries of product innovation and product development velocity. Manufacturers have to be increasingly agile to react to changing customer needs and market opportunities in the global economy. To support this, today’s product innovation process requires contributions from many roles across the enterprise and the supply chain. Efficient and effective design collaboration across departments, customers, the supply chain, and regulators is more critical than ever.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

For related research, please read some of our previous buyer's guides, 'How to' Choose the Right PDM System, Engineering Buyer's Guide for Multi-Discipline Systems, or PLM for the Medical Device Digital Thread.

How does the right PLM help improve product development collaboration to create agility, speed, and quality in product innovation? What collaborative capabilities should companies look for when they select a PLM platform?

Products and product development have become increasingly challenging as manufacturers push the boundaries of product innovation and product development velocity. Manufacturers have to be increasingly agile to react to changing customer needs and market opportunities in the global economy. To support this, today’s product innovation process requires contributions from many roles across the enterprise and the supply chain. Efficient and effective design collaboration across departments, customers, the supply chain, and regulators is more critical than ever.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

For related research, please read some of our previous buyer's guides, 'How to' Choose the Right PDM System, Engineering Buyer's Guide for Multi-Discipline Systems, or PLM for the Medical Device Digital Thread.

Table of Contents

- Introducing the Buyer's Guide

- The Collaboration Imperative

- What to Look for: Digital Thread

- What to Look for: Design for X

- What to Look for: Concurrent Engineering

- What to Look for: Partner Collaboration

- Considerations by Role

- Special Considerations

- Implementation and Adoption

- Vendor Considerations

- Conclusions and Next Steps

- Acknowledgments

Introducing the Buyer’s Guide

Structure of the Guide This buyer’s guide analyzes the strategic necessity of effective multi-enterprise collaboration and shares the criteria companies should consider when choosing a supporting PLM solution. The guide begins with functional requirements needed to streamline collaboration and create digital continuity across the product lifecycle. The guide looks at collaboration capabilities along four critical categories:- Supporting the digital thread

- Allowing “design for x”

- Enabling concurrent engineering

- Ensuring secure partner collaboration

Conclusions and Next Steps

Effective Multi-Enterprise Collaboration is Mandatory Better multi-enterprise collaboration streamlines and improves product innovation processes to get the right products to market, the right way, at the right time. It helps companies get products to market faster and avoid costly, time-consuming errors. Beyond that, collaboration allows manufacturers to embrace product and product development complexity to push the boundaries of product innovation, product development speed, and agility. To operate effectively in this complex environment, manufacturers must collaborate effectively across departments, customers, the supply chain, and regulators. PLM Serves as the Backbone for Multi-Enterprise Collaboration PLM is the backbone for multi-enterprise collaboration. Companies must choose a PLM platform that can serve as the foundation to improve product development collaboration to create agility, speed, and quality in product innovation. To do this, they must select a PLM system that allows them to:- Support the digital thread

- Allow “design for x”

- Enable concurrent engineering

- Ensure secure partner collaboration

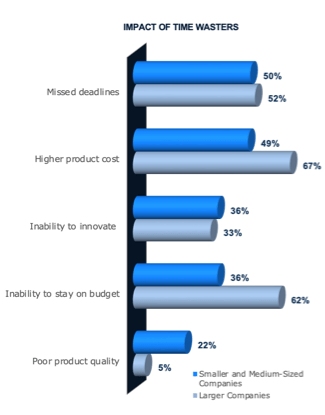

How much better would your machine designs be if engineers wasted less time on non-value-added work?

Unfortunately, machine designs have grown so complex that engineers waste significant time on non-value-added work. Consequently, they often lack the bandwidth to meet all of these expectations. An overwhelming, 98% of machine designers report that their challenges negatively impact the business. Consequently, it can be hard to identify conflicts and find the time to fully evaluate essential engineering decisions affecting quality and cost. As a result, many struggle to avoid cost overruns and risks to delivery dates.

This research identifies six strategies machine designers can implement to reduce non-value-added work.

Please enjoy the summary below.* For the full report, please visit our sponsor Dassault Systèmes SolidWorks (registration required).

For related research, you may be interested in our other eBooks How to Reduce Non-Value-Added Work in Engineering and Industrial Design: 7 Ways to Reduce Non-Value-Added Work which provide additional insights on reducing wasted engineering effort.

How much better would your machine designs be if engineers wasted less time on non-value-added work?

Unfortunately, machine designs have grown so complex that engineers waste significant time on non-value-added work. Consequently, they often lack the bandwidth to meet all of these expectations. An overwhelming, 98% of machine designers report that their challenges negatively impact the business. Consequently, it can be hard to identify conflicts and find the time to fully evaluate essential engineering decisions affecting quality and cost. As a result, many struggle to avoid cost overruns and risks to delivery dates.

This research identifies six strategies machine designers can implement to reduce non-value-added work.

Please enjoy the summary below.* For the full report, please visit our sponsor Dassault Systèmes SolidWorks (registration required).

For related research, you may be interested in our other eBooks How to Reduce Non-Value-Added Work in Engineering and Industrial Design: 7 Ways to Reduce Non-Value-Added Work which provide additional insights on reducing wasted engineering effort.

Table of Contents

- Executive Summary

- Importance of Machine Design

- Identifying Machine Design Top Performers

- Strategies to Reduce Non-Value-Added Work

- 1. Access Product Data from Anywhere

- 2. Maximize Reuse

- 3. Improve Collaboration

- 4. Automate Machine Design Tasks

- 5. Streamline Mechanism Design Tasks

- 6. Solicit More Feedback

- Conclusion

- Recommendations

- About the Research

- Acknowledgments

The Value of Increasing Engineering Bandwidth

Imagine the Impact of Reducing Non-Value-Added Engineering Work in Machine Design How much better would your machine designs be if engineers wasted less time on non-value-added work? Engineering work is critical to competitive machine designs. However, as designs become more complex, engineering decisions become more challenging. Unfortunately, engineers waste so much time on non-value-added work, it impacts their bandwidth. Consequently, it can be hard to identify conflicts and find the time to fully evaluate essential engineering decisions affecting quality and cost. As a result, many struggle to avoid cost overruns and risks to delivery dates. About the Research Based on a survey of 228 manufacturers, this research study examines machine design practices, where engineers waste time, and best practices to avoid non-value-added work. These best practices will improve your ability to produce higher quality machines in less time, while improving your ability to meet your customers' expectations.Importance of Machine Design

Engineers Need Empowerment

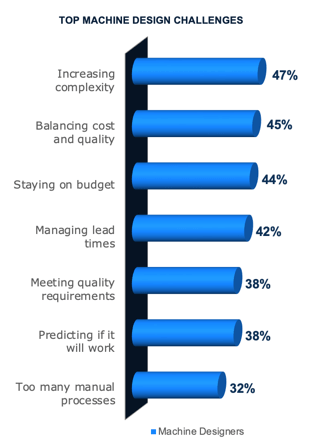

For companies that develop machines, especially industrial equipment manufacturers, engineering is critical to success. Global competition is so steep that much of what makes a machine stand out is the engineering behind it. However, many challenges hold engineers back (see graph).

Increasing Complexity

As machines become more innovative, they also get more complex. More components, smarter products, numerous configurations, mechanism calculations, and more drive product complexity. In turn, the more complex machines become, the more complicated engineering decisions get, making it difficult to balance cost and quality. These factors make predictability difficult. Plus, minor errors easily contribute to cost overruns and delays. Changes also require agility to quickly pivot and adapt without compromising lead times.

Business Impacts

Engineers Need Empowerment

For companies that develop machines, especially industrial equipment manufacturers, engineering is critical to success. Global competition is so steep that much of what makes a machine stand out is the engineering behind it. However, many challenges hold engineers back (see graph).

Increasing Complexity

As machines become more innovative, they also get more complex. More components, smarter products, numerous configurations, mechanism calculations, and more drive product complexity. In turn, the more complex machines become, the more complicated engineering decisions get, making it difficult to balance cost and quality. These factors make predictability difficult. Plus, minor errors easily contribute to cost overruns and delays. Changes also require agility to quickly pivot and adapt without compromising lead times.

Business Impacts

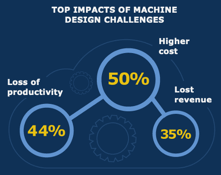

An overwhelming 98% of machine designers report that these challenges impact the business,

hurting profitability (see graph). If engineers are not more empowered, products will cost more. Meanwhile, quality issues can lead to missed delivery dates, market delays, or fewer key features, making you less competitive. Consequently, customers may go elsewhere, leading to revenue losses. At the same time, dealing with increasing complexity or addressing problems related to errors, manufacturability issues, and other difficulties hurt productivity.

Increase Engineering Bandwidth

Engineers need to be empowered to be as productive as possible to have the capacity to deal with the top machine design challenges. Unfortunately, previous Tech-Clarity research has found that engineers waste 33% of their time on non-value-added work.1 By reducing some of that time, engineers will have more bandwidth to address the top challenges of machine design.

An overwhelming 98% of machine designers report that these challenges impact the business,

hurting profitability (see graph). If engineers are not more empowered, products will cost more. Meanwhile, quality issues can lead to missed delivery dates, market delays, or fewer key features, making you less competitive. Consequently, customers may go elsewhere, leading to revenue losses. At the same time, dealing with increasing complexity or addressing problems related to errors, manufacturability issues, and other difficulties hurt productivity.

Increase Engineering Bandwidth

Engineers need to be empowered to be as productive as possible to have the capacity to deal with the top machine design challenges. Unfortunately, previous Tech-Clarity research has found that engineers waste 33% of their time on non-value-added work.1 By reducing some of that time, engineers will have more bandwidth to address the top challenges of machine design.

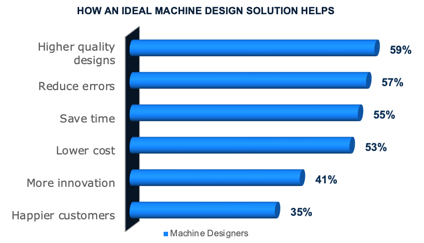

Conclusion

Ideal Machine Design Solution Regardless of their performance, machine designers indicate numerous business advantages to using an ideal machine design solution (see graph). While products will still get out even without an ideal solution, engineers waste so much time on non-value-added work, companies miss out on opportunities that would give them a competitive advantage. An ideal solution that supports easy access to product data from anywhere, maximizes reuse, improves collaboration, enables design automation, including mechanisms, and facilitates more opportunities for feedback will reduce this non-value-added work and free up engineering bandwidth. As a result, engineers will have more time to improve design quality, lower costs, and innovate. There will be less risk for errors, which will save time. The result will be happier customers, helping you win customer loyalty and capture market share.Recommendations

Recommendations and Next Steps By limiting the time machine designers waste on non-value-added work, you can increase engineering bandwidth, empowering them to produce higher quality designs, in less time, at a lower cost. Based on industry experience and research for this report, Tech-Clarity offers the following recommendations: Ensure machine designers can easily access product data in real-time from anywhere. This will limit their time searching for data, recreating work

because they couldn't find the data, or reworking designs due to outdated information.

Ensure machine designers can easily access product data in real-time from anywhere. This will limit their time searching for data, recreating work

because they couldn't find the data, or reworking designs due to outdated information.- Maximize reuse by making data easier to find and with a reuse library. This will save engineering time by using previously proven work, reducing the risk of introducing new errors.

- Improve collaboration by making it easier for stakeholders, especially analysts, to access design data in real-time.

- Automate machine design tasks to limit the amount of time engineers waste on tedious tasks.

- Streamline mechanism design tasks with specialized applications tailored for mechanism design that enable engineers to design mechanisms in the context of the entire assembly.

- Solicit more feedback by improving the efficiency of design reviews by extending access to all stakeholders, including customers. A cloud platform allows the flexibility to extend access to third parties and then turn it off so that you never lose control of your intellectual property.

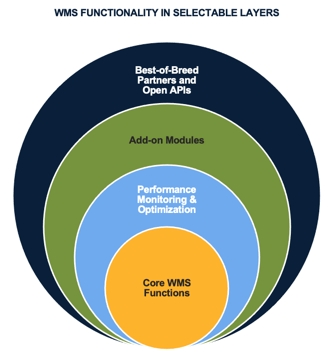

What are the key factors to consider when selecting warehouse management software (WMS)? As fast as supply chains are changing, how can you be ready for the future? Our new WMS Buyer’s Guide has the answers, informed by interviews with companies who have found WMS that keeps up with their business.

Please enjoy the summary below.* For the full report, please visit our sponsor Körber Supply Chain (registration required).

For related research, stay tuned for the upcoming webcast with Julie Fraser of Tech-Clarity, Kenny Williams of Parts Town, and Victoria Brown of Körber Supply Chain.

What are the key factors to consider when selecting warehouse management software (WMS)? As fast as supply chains are changing, how can you be ready for the future? Our new WMS Buyer’s Guide has the answers, informed by interviews with companies who have found WMS that keeps up with their business.

Please enjoy the summary below.* For the full report, please visit our sponsor Körber Supply Chain (registration required).

For related research, stay tuned for the upcoming webcast with Julie Fraser of Tech-Clarity, Kenny Williams of Parts Town, and Victoria Brown of Körber Supply Chain.

Table of Contents

- Introducing the Buyer’s Guide

- Flexible Flows to Meet Enterprise Needs

- Enterprise-Capable

- Enterprise IT-Capable

- Functionality

- Visibility and Optimization

- Software Technology

- Vendor Requirements

- Implementation and Service Criteria

- Optimize and Reoptimize

- Acknowledgments

- Selecting the Right WMS

Optimizing Warehouse Operations into the Unforeseeable Future

Today, many enterprises are finding their business transformation path. Companies must change, whether it's changing up suppliers or customers, moving into new product lines, regions, or markets, offering new services, or adjusting to unpredictable demand and supply situations. Competitive advantage and strategy are no longer fixed. As a result, companies need to select warehouse management systems (WMS) carefully. What are the primary considerations, and how can choosing the right WMS impact a company’s ability to succeed in their business and digital transformations today and into the future?Introducing the Buyer’s Guide

Perfect Orders in a Changing World Every industry has been suffering from disruptions and radical changes in supply, demand, and business realities. As a result, supply chain responsiveness for perfect orders is often top of mind, and enterprise warehouse management systems (WMS) are foundational to achieving that. Warehouse performance is crucial, not only for wholesale and distribution enterprises but also for retailers, e-tailers, producers, and manufacturers. Structure of the Guide This buyer’s guide describes the needs of larger enterprises to transform and continue to improve their business. It then lays out a set of critical considerations for selecting a WMS that will support the strategy now and into the future. Functionality is just the beginning of the considerations. Technology is also crucial and needs to be future-ready as the digital transformation continues. Even if the software is good, the solution provider partner or vendor plays many vital roles. To gain business value with an excellent total cost of ownership, implementation, and the ongoing relationship matter also.Optimize and Reoptimize

Get WMS that will Fit In today’s challenging supply chain environment, every company needs all of the advantages they can get. Enterprises compete on best practices they have discovered: choose a WMS designed to mold to those, and keep up as you learn, grow, and change.

Optimize the Operation

Today’s enterprise needs more from WMS than just executing the same flows repeatedly. The goal is to improve what you are doing, even as things change. The opportunity to optimize flows with simulation for the warehouse is enormous. Predictive analytics are not just a shiny buzzword but are available today in some WMS.

Future-ready

Looking ahead is the core to choosing the right WMS. Companies must prepare for what's next, whether it’s automating more, hiring new people, serving new markets, or just knowing something unforeseen will happen. Ensure your WMS is ready.

Total Cost of Ownership

Look for WMS with a good fit, self-configuration, robust integration, optimization, and a reliable software partner. All of the above adds up to a lower total cost of ownership (TCO) for an enterprise. It also points to the potential for better performance for the warehouse, the enterprise, and the entire supply chain.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Körber Supply Chain (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Warehouse Management Systems (WMS) (buyer's guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => warehouse-management-systems-buyers-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:03

[post_modified_gmt] => 2022-11-15 03:28:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11471

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 11447

[post_author] => 2

[post_date] => 2022-06-13 09:00:12

[post_date_gmt] => 2022-06-13 13:00:12

[post_content] =>

In today’s challenging supply chain environment, every company needs all of the advantages they can get. Enterprises compete on best practices they have discovered: choose a WMS designed to mold to those, and keep up as you learn, grow, and change.

Optimize the Operation

Today’s enterprise needs more from WMS than just executing the same flows repeatedly. The goal is to improve what you are doing, even as things change. The opportunity to optimize flows with simulation for the warehouse is enormous. Predictive analytics are not just a shiny buzzword but are available today in some WMS.

Future-ready

Looking ahead is the core to choosing the right WMS. Companies must prepare for what's next, whether it’s automating more, hiring new people, serving new markets, or just knowing something unforeseen will happen. Ensure your WMS is ready.

Total Cost of Ownership

Look for WMS with a good fit, self-configuration, robust integration, optimization, and a reliable software partner. All of the above adds up to a lower total cost of ownership (TCO) for an enterprise. It also points to the potential for better performance for the warehouse, the enterprise, and the entire supply chain.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Körber Supply Chain (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Warehouse Management Systems (WMS) (buyer's guide)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => warehouse-management-systems-buyers-guide

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:28:03

[post_modified_gmt] => 2022-11-15 03:28:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11471

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 11447

[post_author] => 2

[post_date] => 2022-06-13 09:00:12

[post_date_gmt] => 2022-06-13 13:00:12

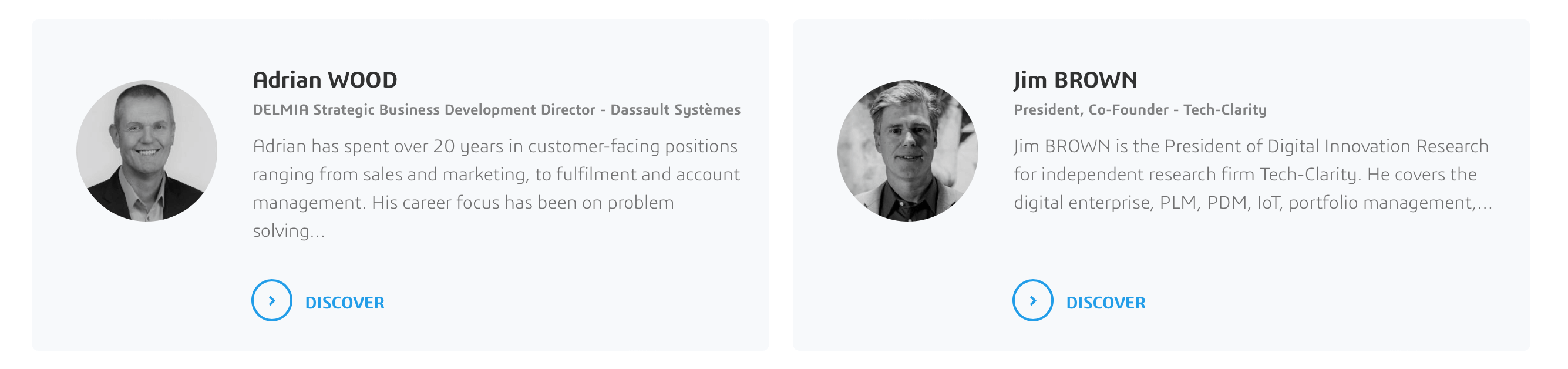

[post_content] =>  How are manufacturers improving manufacturing engineering performance with better practices and technology? Join this webcast as Jim Brown previews survey results from our 3D and Virtual Simulation in Manufacturing Engineering study.

Companies are under increasing pressure to deliver more complex and personalized products to market faster to meet consumer demands. As the pace of design, engineering and manufacturing climbs, so does the challenge of maintaining high levels of quality without incurring additional cost and delays.

The virtual build process focuses on technology and process that can bridge the gap that exists between engineering and manufacturing and enable companies to achieve their goals of satisfying customer demand and capturing market share without sacrificing profit or quality.

Join Tech-Clarity’s Jim Brown and Dassault Systemes Delmia’s Strategic Business Development Director Adrian Wood in a discussion about how manufacturing engineering is evolving.

How are manufacturers improving manufacturing engineering performance with better practices and technology? Join this webcast as Jim Brown previews survey results from our 3D and Virtual Simulation in Manufacturing Engineering study.

Companies are under increasing pressure to deliver more complex and personalized products to market faster to meet consumer demands. As the pace of design, engineering and manufacturing climbs, so does the challenge of maintaining high levels of quality without incurring additional cost and delays.

The virtual build process focuses on technology and process that can bridge the gap that exists between engineering and manufacturing and enable companies to achieve their goals of satisfying customer demand and capturing market share without sacrificing profit or quality.

Join Tech-Clarity’s Jim Brown and Dassault Systemes Delmia’s Strategic Business Development Director Adrian Wood in a discussion about how manufacturing engineering is evolving.

Register now for the final webcast of this three part series hosted by Dassault Systemes Delmia.

Click here to watch the first webcast in this series, also featuring Jim Brown and Adrian Wood.

[post_title] => The Future of Manufacturing Engineering

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-engineering-webcast-2

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 17:25:07

[post_modified_gmt] => 2023-12-15 22:25:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11447

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 11439

[post_author] => 2

[post_date] => 2022-06-09 09:00:07

[post_date_gmt] => 2022-06-09 13:00:07

[post_content] =>

Register now for the final webcast of this three part series hosted by Dassault Systemes Delmia.

Click here to watch the first webcast in this series, also featuring Jim Brown and Adrian Wood.

[post_title] => The Future of Manufacturing Engineering

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-engineering-webcast-2

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 17:25:07

[post_modified_gmt] => 2023-12-15 22:25:07

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11447

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 11439

[post_author] => 2

[post_date] => 2022-06-09 09:00:07

[post_date_gmt] => 2022-06-09 13:00:07

[post_content] =>  There is a clear, industry-wide transition of software solutions to the cloud, but not all solutions are moving at the same pace. Cloud PLM adoption has accelerated, but how quickly are companies transitioning? And how can they make sure that they continue to drive business value from PLM while enjoying the benefits of cloud computing?

Register for this webcast on Thursday, June 30th at 11am ET to hear Tech-Clarity’s Jim Brown share previews from his recent survey on the State of Cloud PLM 2022 and Aras’ Bruce Bookbinder as he offers insights from his conversations with customers. Join us for this interactive discussion.

[post_title] => How Fast is PLM Moving to the Cloud?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-plm-webcast-2

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 17:20:23

[post_modified_gmt] => 2023-12-15 22:20:23

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11439

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 10502

[post_author] => 2574

[post_date] => 2022-06-08 09:00:30

[post_date_gmt] => 2022-06-08 13:00:30

[post_content] => Are your manufacturing workers safe? Many companies don’t know. Yet, the risk of not knowing is high.

The global COVID-19 pandemic has brought a new focus to the health and safety of onsite frontline employees. Those workers are in high demand, and part of knowing who is at risk comes down to their training, certifications, and qualifications. Another part is analyzing the types of issues that commonly arise in each work area and having preventive measures in place.

A modern and proactive enterprise approach to health and safety software and processes is essential. For many companies, it’s quite different from the piecemeal and reactive processes currently in place.

Join this webinar on June 17th at 12PM EST with Tech-Clarity’s Julie Fraser and ComplianceQuest’s Michael Bower to learn more. Be a part of this important discussion about the rightful place of health and safety in your company’s strategy. Hear about ways to lower workplace health and safety risks.

There is a clear, industry-wide transition of software solutions to the cloud, but not all solutions are moving at the same pace. Cloud PLM adoption has accelerated, but how quickly are companies transitioning? And how can they make sure that they continue to drive business value from PLM while enjoying the benefits of cloud computing?

Register for this webcast on Thursday, June 30th at 11am ET to hear Tech-Clarity’s Jim Brown share previews from his recent survey on the State of Cloud PLM 2022 and Aras’ Bruce Bookbinder as he offers insights from his conversations with customers. Join us for this interactive discussion.

[post_title] => How Fast is PLM Moving to the Cloud?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => cloud-plm-webcast-2

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 17:20:23

[post_modified_gmt] => 2023-12-15 22:20:23

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11439

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 10502

[post_author] => 2574

[post_date] => 2022-06-08 09:00:30

[post_date_gmt] => 2022-06-08 13:00:30

[post_content] => Are your manufacturing workers safe? Many companies don’t know. Yet, the risk of not knowing is high.

The global COVID-19 pandemic has brought a new focus to the health and safety of onsite frontline employees. Those workers are in high demand, and part of knowing who is at risk comes down to their training, certifications, and qualifications. Another part is analyzing the types of issues that commonly arise in each work area and having preventive measures in place.

A modern and proactive enterprise approach to health and safety software and processes is essential. For many companies, it’s quite different from the piecemeal and reactive processes currently in place.

Join this webinar on June 17th at 12PM EST with Tech-Clarity’s Julie Fraser and ComplianceQuest’s Michael Bower to learn more. Be a part of this important discussion about the rightful place of health and safety in your company’s strategy. Hear about ways to lower workplace health and safety risks.

[post_title] => Could you do more to Reduce your Manufacturing Workplace Safety Risks?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => workplace-safety-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2025-05-28 16:10:41

[post_modified_gmt] => 2025-05-28 20:10:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10502

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 11430

[post_author] => 2

[post_date] => 2022-06-07 09:30:03

[post_date_gmt] => 2022-06-07 13:30:03

[post_content] =>

[post_title] => Could you do more to Reduce your Manufacturing Workplace Safety Risks?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => workplace-safety-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2025-05-28 16:10:41

[post_modified_gmt] => 2025-05-28 20:10:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=10502

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 11430

[post_author] => 2

[post_date] => 2022-06-07 09:30:03

[post_date_gmt] => 2022-06-07 13:30:03

[post_content] =>  How can manufacturers improve product development performance and more consistently hit their product development targets? We surveyed over 200 companies to find out.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

How can manufacturers improve product development performance and more consistently hit their product development targets? We surveyed over 200 companies to find out.

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

Table of Contents

- Collaborative Systems are Key to Successful NPD

- Missing Product Development Targets is the Norm

- Collaboration Basics are Challenging

- Collaboration Challenges Impact the Business

- Collaborating Across Boundaries is Hard

- Collaborating Out of the Office is Difficult

- Why do Some Companies Better Meet NPD Targets?

- Top Performers have a Collaboration Advantage

- Top Performers Use More Cloud File Sharing

- Cloud File Sharing is Attractive for Collaboration

- The Ease of Cloud with Engineering Context

- Conclusion and Next Steps

- About the Research

- Acknowledgments

Improving Product Development Performance

Leveraging CAD and Product Development Collaboration to Hit Product Development Targets Rapid new product development (NPD) is critical for success in the manufacturing industries, but 85% of manufacturers routinely miss their project due dates. Our survey results show that Top Performers, those that more frequently hit their product development targets, have better collaboration capabilities and are more likely to use the cloud for both CAD and project collaboration. It finds, however, that these Top Performers are not necessarily just using general cloud file sharing solutions like Dropbox, Drive, or OneDrive. The leaders’ cloud solutions include more design and engineering-specific collaboration capabilities.Collaborative Systems are Key to Successful NPD

Collaboration is Mandatory, but Challenging Collaboration is crucial to efficient and effective new product development. Today’s products are complex and typically require input from multiple design and engineering disciplines. Beyond technical product design, developing a profitable commercial offering demands input from a variety of other departments and the supply chain. But our research1 shows that about 40% of companies say collaborating with other departments and 3rd parties on NPD is a challenge. Leverage Structured Solutions Product Lifecycle Management (PLM) and Product Data Management (PDM) are proven to help drive better NPD collaboration and performance. Our surveys2 show that Top Performers are more likely to use data management tools to collaborate – both externally and internally. This study confirms that, showing that Top Performers are more likely to use PLM. But we also recognize that although many smaller companies see the value of PDM / PLM, they feel it’s out of reach. Turn to the Cloud The cloud can help make structured, collaborative solutions more attainable. The cloud has clear collaboration benefits, and a recent study3 shows that companies using the cloud for product development are more likely to report that collaboration is “very easy.” That same study shows that Top Performers are 21% more likely to use cloud systems to support product development. But, not all of the solutions that companies use are structured, formal PDM or PLM. Data from that study also shows that 62% of Top Performers (and 60% of companies overall) use cloud file sharing solutions for product development, although those tools are not necessarily the only solution they use. This study further investigates how leading companies leverage the cloud for better CAD and product development collaboration.

Conclusions and Next Steps

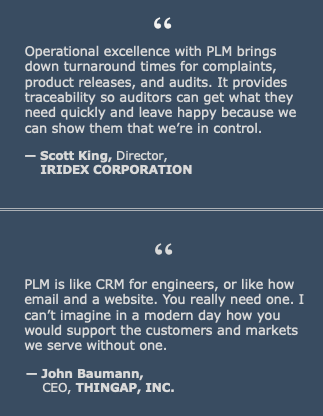

Better Collaboration Leads to Better Product Development Performance Top Performing manufacturers, those that better hit their product development targets, have better collaboration capabilities than the poorer-performing Others. These companies, particularly larger ones, are more likely to use formal systems like PDM and PLM. But they are also more likely to use cloud SaaS file sharing tools. Cloud File Sharing has a Place in CAD and PD Collaboration Despite the shortcomings for engineering data, cloud / SaaS file sharing solutions can provide significant value in CAD and product development collaboration. Cloud file sharing can help improve product development collaboration, leading to the ability to better meet product development targets. To be most effective, however, the solution must address the challenges of CAD and Product development collaboration – primarily sharing CAD with non-engineers and multi-CAD. Engineering-enabled cloud file sharing solutions have the potential to improve performance by complementing formal, proven PLM or PDM systems. For smaller companies, who may find cloud file sharing more accessible than formal solutions, these solutions have the potential to add value to NPD performance even as standalone solutions. We believe that cloud file sharing solutions are worth investigating and may be able to play an important role in CAD and product development collaboration. *This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Siemens (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Leveraging the Cloud for CAD and Product Development Collaboration (eBook) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => product-development-collaboration-ebook [to_ping] => [pinged] => [post_modified] => 2023-12-15 17:21:33 [post_modified_gmt] => 2023-12-15 22:21:33 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=11430 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [11] => WP_Post Object ( [ID] => 11396 [post_author] => 2 [post_date] => 2022-06-02 09:00:30 [post_date_gmt] => 2022-06-02 13:00:30 [post_content] => How can PLM, traditionally an engineering-centric solution, drive innovation, agility, and operational excellence? Manufacturers need to create agility in their business and processes so they can respond to increasing business risk and bounce forward better than ever. To do this, Engineering and product development have to fundamentally change. They have to focus on the big picture, not just engineering, to develop profitable products. PLM’s role needs to expand to support them.

Read our eBook to understand how to choose the right PLM to support operational excellence.

Please enjoy the summary* below. For the full research, please visit our sponsor QuadRite (registration required).

How can PLM, traditionally an engineering-centric solution, drive innovation, agility, and operational excellence? Manufacturers need to create agility in their business and processes so they can respond to increasing business risk and bounce forward better than ever. To do this, Engineering and product development have to fundamentally change. They have to focus on the big picture, not just engineering, to develop profitable products. PLM’s role needs to expand to support them.

Read our eBook to understand how to choose the right PLM to support operational excellence.

Please enjoy the summary* below. For the full research, please visit our sponsor QuadRite (registration required).

Table of Contents

- Risk and Disruption Demand Change

- The Evolution of Engineering

- Choosing PLM

- The Basics

- Expanding PLM for Operational Excellence

- Expanding PLM - Process

- Expanding PLM - People

- Expanding PLM - Lifecycle

- Expanding PLM - Product

- Conclusions and Next Steps

- Acknowledgments

Expanding PLM for Operational Excellence

The Four Dimensions of PLM Expansion PLM implementations must go beyond the basics to support operational excellence. We’ll discuss four important ways that PLM has expanded in order to support operational excellence:

PLM implementations must go beyond the basics to support operational excellence. We’ll discuss four important ways that PLM has expanded in order to support operational excellence:

- Process: Improving processes beyond basic revision control and release to manufacturing

- People: Including more people and departments beyond Engineering, including partners, the supply chain, and customers

- Lifecycle: Supporting upstream and downstream capabilities beyond design

- Product: Expanding beyond product design to a full product definition

- Inbound: Enabling engineers to better use information coming out of other business areas such as Procurement, Quality, Manufacturing, and others to design for operational excellence

- Outbound: Making better use of information coming out of Engineering in other areas of business such as Marketing, Sales, Service, and more to support broader product innovation, development, manufacturing, and support process to drive operational efficiency

"To start, PLM supports document management, design control, and training. That sets the foundation for product development process compliance. Then, you can build on that to support operational needs like NCMR, suppliers, CAPA, change control, and complaint handling as you go to the commercial phase." - Scott King, Director, IRIDEX CORPORATION

"We started with ECOs, took some small bites, then expanded it more broadly by implementing it with supply chain, customers, drawings, orders, contract tracking, and source tracking. They lend themselves perfectly to PLM." - John Baumann, CEO, THINGAP, INC.

Conclusions and Next Steps

Moving Toward Operational Excellence Manufacturers have to recognize the need for innovation, agility, and operational improvement. Business risk and disruption are threatening profitability and survival for many businesses. Products and markets have changed, demanding more. Recognize the New Role of the Engineer To support more supply-chain centric, operationally-focused product development processes the role of engineers has changed. They must be able to access a wider array of information in order to make broader product-related decisions. This, in turn, changes the requirements for the PLM systems that support them. Choose the Right PLM Solution to Drive Operational Excellence The four dimensions of PLM expansion provide a framework to understand what’s needed to drive operational excellence. Traditional, Engineering-centric PLM systems are not sufficient for fast-moving industries like high-tech and medical devices. Companies in these industries need a PLM solution built for the enterprise and the supply chain.

Lastly, manufacturers must get a solution that delivers on the promise of PLM. Systems selections and implementations should be driven by cross-functional teams that represent all aspects that impact product profitability. Selection requirements should span the enterprise and focus on how the system supports the new role of engineers and product developers. This is the way that companies can ensure that they select the right PLM systems to drive operational excellence.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor QuadRite (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => PLM for Operational Excellence

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-operational-excellence-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 17:23:14

[post_modified_gmt] => 2023-12-15 22:23:14

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11396

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 11416

[post_author] => 2574

[post_date] => 2022-05-13 09:36:21

[post_date_gmt] => 2022-05-13 13:36:21

[post_content] =>

The four dimensions of PLM expansion provide a framework to understand what’s needed to drive operational excellence. Traditional, Engineering-centric PLM systems are not sufficient for fast-moving industries like high-tech and medical devices. Companies in these industries need a PLM solution built for the enterprise and the supply chain.

Lastly, manufacturers must get a solution that delivers on the promise of PLM. Systems selections and implementations should be driven by cross-functional teams that represent all aspects that impact product profitability. Selection requirements should span the enterprise and focus on how the system supports the new role of engineers and product developers. This is the way that companies can ensure that they select the right PLM systems to drive operational excellence.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor QuadRite (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => PLM for Operational Excellence

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => plm-operational-excellence-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 17:23:14

[post_modified_gmt] => 2023-12-15 22:23:14

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11396

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 11416

[post_author] => 2574

[post_date] => 2022-05-13 09:36:21

[post_date_gmt] => 2022-05-13 13:36:21

[post_content] =>  What does future-proof manufacturing plant floor software look like? Is it possible to have all the flexibility and choices each site needs and still adhere to enterprise standards? Yes; find out what modern MES architecture can promise for this uncertain era.

Listen to the recording of this fireside chat to find out:

What does future-proof manufacturing plant floor software look like? Is it possible to have all the flexibility and choices each site needs and still adhere to enterprise standards? Yes; find out what modern MES architecture can promise for this uncertain era.

Listen to the recording of this fireside chat to find out:

- Why plant floor software must reach beyond functional fit into MES architecture

- How to be ready for anything: M&A, new plants, new regulations, moving products between plants

- The benefits of easily moving software to public or private cloud, on-prem, or hybrid

- Why containerization, orchestration, DevOps, and one-click deployment from a central CoE can avoid the MES trap of fit that fades over the years

Tech transfer is critical to competitiveness in the life sciences industry. Yet most companies still rely on document-based, manual, people-dependent processes to transfer analytical and manufacturing methods. How can life sciences companies digitally transform tech transfer to improve efficiency and success?

Join this webcast to hear the benefits of:

Tech transfer is critical to competitiveness in the life sciences industry. Yet most companies still rely on document-based, manual, people-dependent processes to transfer analytical and manufacturing methods. How can life sciences companies digitally transform tech transfer to improve efficiency and success?

Join this webcast to hear the benefits of:

- Transitioning to a data-driven process

- Digitalizing tech transfer data and processes

- Taking a holistic approach to product data modeling

Jim Brown

President

Digital Innovation Research

Tech-Clarity

Jim Brown

President

Digital Innovation Research

Tech-Clarity

Dr. Daniela Jansen

Director of Product Marketing at

Dassault Systèmes BIOVIA

[post_title] => Improve Tech Transfer with Digital Transformation (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tech-transfer-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:11

[post_modified_gmt] => 2022-11-15 03:27:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11373

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 11259

[post_author] => 2

[post_date] => 2022-05-03 08:00:10

[post_date_gmt] => 2022-05-03 12:00:10

[post_content] =>

Dr. Daniela Jansen

Director of Product Marketing at

Dassault Systèmes BIOVIA

[post_title] => Improve Tech Transfer with Digital Transformation (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => tech-transfer-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:11

[post_modified_gmt] => 2022-11-15 03:27:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11373

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[14] => WP_Post Object

(

[ID] => 11259

[post_author] => 2

[post_date] => 2022-05-03 08:00:10

[post_date_gmt] => 2022-05-03 12:00:10

[post_content] =>  Can improving design data management practices improve innovation and product development performance? We surveyed 131 companies to understand how they manage CAD files, bills of material, and other product-related information to find out.

Please enjoy the summary below.* For the full report, please visit our sponsor Siemens (registration required).

For related research, please see two of our prior surveys on design data management best practices to see what’s changed: Design Data Management Maturity Improves Profitability, Analyzing Best Practices for Managing Designs from 2017 and Best Practices for Managing Design Data from 2012.

Can improving design data management practices improve innovation and product development performance? We surveyed 131 companies to understand how they manage CAD files, bills of material, and other product-related information to find out.

Please enjoy the summary below.* For the full report, please visit our sponsor Siemens (registration required).

For related research, please see two of our prior surveys on design data management best practices to see what’s changed: Design Data Management Maturity Improves Profitability, Analyzing Best Practices for Managing Designs from 2017 and Best Practices for Managing Design Data from 2012.

Table of Contents

- Executive Overview

- The Importance of Effective Data Management

- Data Management Must Address Today's Challenges

- Data Management Challenges Reduce Productivity

- Evaluating the Practices of the Top Performers

- Data Management Practices of the Top Performers

- Enabling Top Performing Product Development

- Top Performers are More Likely to Embrace the Cloud

- Conclusions and Recommendations

- About the Research

- Acknowledgments

Leveraging Data Management to Enable Product Development

Analyzing Data Management Practices for Successful Product Development How do design data management practices impact product development performance? We surveyed 131 companies that design, engineer, and/or manufacture products to understand how they manage design data like CAD files, bills of material, and other product-related information to find out. We conducted this study as a follow-up to our previous studies to understand what has changed over time.Executive Overview

Survey Approach Tech-Clarity research shows that effective data management helps companies design innovative, high-quality products quickly and efficiently. This report shows how data management best practices relate to business performance based on 131 responses to a web-based data management survey.

Researchers benchmarked participating companies on their performance related to quality, innovation, product development speed, and efficiency. Survey analysis compared companies with the highest performance in these important product development metrics with their data management approaches.

Top Performers Have More Effective Data Management

The data shows that Top Performing product developers are more likely to have very effective data management capabilities. Top Performers are more likely to be able to:

Tech-Clarity research shows that effective data management helps companies design innovative, high-quality products quickly and efficiently. This report shows how data management best practices relate to business performance based on 131 responses to a web-based data management survey.

Researchers benchmarked participating companies on their performance related to quality, innovation, product development speed, and efficiency. Survey analysis compared companies with the highest performance in these important product development metrics with their data management approaches.

Top Performers Have More Effective Data Management

The data shows that Top Performing product developers are more likely to have very effective data management capabilities. Top Performers are more likely to be able to:

- Find the data they need

- Share it with others

- Manage their design projects

- Provide the correct data to manufacturing

- Are more likely to use advanced features of their data management systems beyond simply storing and controlling CAD files

- Are 70% more likely to share data using the cloud for design and/or engineering

- Have 3 times as many people using their PLM system*

- Are 4.3 times as likely to have third parties such as customers and suppliers use their PLM systems *

Conclusions and Recommendations

Conclusions Effective design data management fundamentals enable better product development performance. The data shows, however, that companies face significant challenges in managing their critical design data due to product complexity. These challenges can lead to quality problems and inefficiency, and prevent companies from taking advantage of strategic opportunities such as design reuse. Addressing these challenges with effective design data management practices and technology leads to significant business advantages, including improved efficiency, quality, and time to market. Top Performers are more effective at data management and take a more collaborative approach to managing designs. To enable this, Top Performers leverage more mature use of their design data management systems. The fundamentals of design data management, supported by an effective data management solution, provide significant business value and provide a foundation that can be expanded on for future benefits. But to differentiate today, companies must go beyond controlling and accessing data. Recommendations Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Ensure that your business has the basic fundamentals of data management in place, but expand the maturity of data management usage to drive higher value

- Improve design data management effectiveness to improve business performance in product design and development

- Explore the use of cloud collaboration to improve data management and product development performance

Is it time to change the way manufacturing processes are developed? Products have dramatically increased in complexity and time-to-market expectations continue to shrink. Is a virtual, 3D based manufacturing engineering transformation the way for manufacturing engineers to ramp up products quicky without compromising quality?

Join Tech-Clarity’s Jim Brown and Dassault Systèmes Delmia’s Strategic Business Development Director Adrian Wood in a panel discussion investigating the need and potential to evolve the way manufacturing processes are developed.

Register now for the first of a three-part webinar series.

Is it time to change the way manufacturing processes are developed? Products have dramatically increased in complexity and time-to-market expectations continue to shrink. Is a virtual, 3D based manufacturing engineering transformation the way for manufacturing engineers to ramp up products quicky without compromising quality?

Join Tech-Clarity’s Jim Brown and Dassault Systèmes Delmia’s Strategic Business Development Director Adrian Wood in a panel discussion investigating the need and potential to evolve the way manufacturing processes are developed.

Register now for the first of a three-part webinar series.

[post_title] => Is it Time to Transform Manufacturing Engineering? (webcast) [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => manufacturing-engineering-webcast [to_ping] => [pinged] => [post_modified] => 2022-11-14 22:27:10 [post_modified_gmt] => 2022-11-15 03:27:10 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=11354 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [16] => WP_Post Object ( [ID] => 11306 [post_author] => 2 [post_date] => 2022-04-20 09:15:40 [post_date_gmt] => 2022-04-20 13:15:40 [post_content] => Is PLM ready to support the future of the digital consumer packaged goods industry? Join an interactive panel discussion featuring:

- PepsiCo Senior Director of Global R&D Susan Hamel

- Kalypso Consumer Goods Global Director Colin Speakman

- Tech-Clarity President Jim Brown

You can also download the related research from that page, or learn more about the State of PLM in CPG 2022 research on our site.

[post_title] => The Future of PLM in CPG (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => future-of-plm-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:08

[post_modified_gmt] => 2022-11-15 03:27:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11306

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 11326

[post_author] => 2

[post_date] => 2022-04-19 17:56:42

[post_date_gmt] => 2022-04-19 21:56:42

[post_content] =>

You can also download the related research from that page, or learn more about the State of PLM in CPG 2022 research on our site.

[post_title] => The Future of PLM in CPG (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => future-of-plm-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:08

[post_modified_gmt] => 2022-11-15 03:27:08

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11306

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 11326

[post_author] => 2

[post_date] => 2022-04-19 17:56:42

[post_date_gmt] => 2022-04-19 21:56:42

[post_content] =>  Jim Brown is hosting a panel of experts to discuss the challenges, benefits, and approaches for deploying simulation technology as a part of a digital twin initiative. Join the fourth interactive discussion in the AMC Bridge Executive Series on Tuesday, April 26, 2022, at 12:30 p.m. EST.

Speakers:

Jim Brown is hosting a panel of experts to discuss the challenges, benefits, and approaches for deploying simulation technology as a part of a digital twin initiative. Join the fourth interactive discussion in the AMC Bridge Executive Series on Tuesday, April 26, 2022, at 12:30 p.m. EST.

Speakers:

- David Heiny, Co-Founder and CEO of SimScale

- David Weir-McCall, Industry Marketing Manager Architecture – Epic Games

- Eveart Foster, Director Technology Adoption of BuiltWorlds

- Igal Kaptsan, General Manager Software of GE Additive

- Igor Tsinman, Co-Founder and President of AMC Bridge

- Yuan Qinghui, Director Modeling and Data Science of Donaldson

To view past webcasts, please visit:

https://tech-clarity.com/aec-digital-twin-webcast/10947

https://tech-clarity.com/cloud-engineering-software-webcast/10541

https://tech-clarity.com/industrial-additive-webcast/10420

[post_title] => The Role of Simulation Technology in Digital Twins (webcast)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => simulation-technology-in-digital-twins-webcast

[to_ping] =>

[pinged] =>

[post_modified] => 2022-11-14 22:27:09

[post_modified_gmt] => 2022-11-15 03:27:09

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11326

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw