Has your continuous improvement kept up with your business? It is a new era for manufacturing, and a new era for continuous improvement (CI) is available too. This eBook gives you ideas for how to update your CI with digital support and new approaches that ensure you build on your CI successes. We interviewed manufacturers,…

- Executive Overview

- New Era in Manufacturing

- The Problem-Solving Story

- Five New-Era CI Needs

- New Era in Manufacturing

- Expected and Engaging

- Distributed and Elevated

- Diverse Yet Harmonized

- Learning-focused and Digital

- Enabling CI Sequels

- Recommendations

- Acknowledgments

- About the Author

Executive Overview

There’s a new Era in Manufacturing; it is time for a new era of continuous improvement (CI). This is a time of digital approaches delivering an array of new capabilities and insights that can move the business beyond unpleasant trade-offs. In this new era, CI gets enterprise-wide standardization and support and keeps the enthusiasm of local teams and employees. It delivers both local breakthroughs and views that support executives in understanding progress and prioritizing resources for the following CI projects in ways that make sense to everyone. Appropriate digitalization enables CI teams to get rapid and reliable access to all the data they need from a wide variety of sources. Beyond that, it supports them in gaining rich insights from the data with far less effort than ever before. Goals and results are translated into a shared, visceral unit of improvement that matters to shop floor operators, supervisors, managers, and executives: time. By feeding shared understanding, this digitally-supported CI will more likely generate enthusiasm and benefits even as the business shifts and changes. The Problem-Solving Story

The Problem-Solving Story

Path to Success

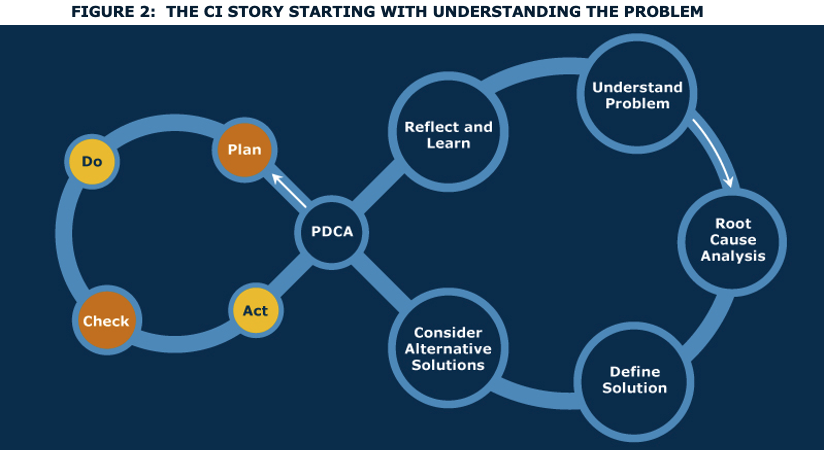

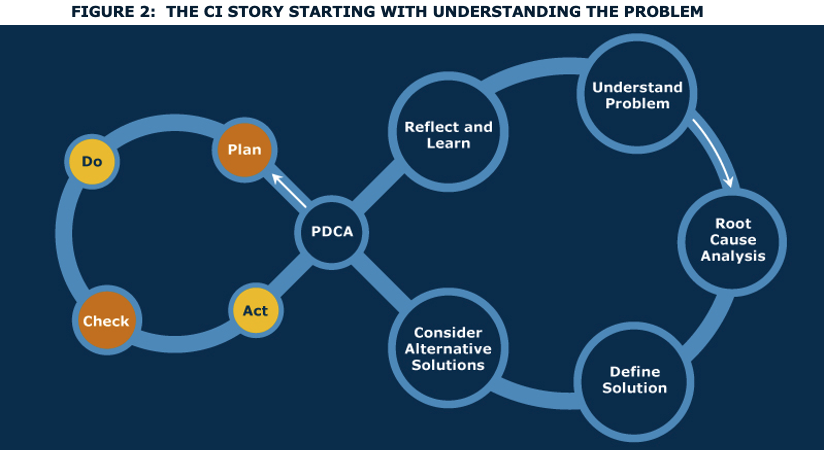

The Toyota Way points to a complete approach to solving problems – or making systemic improvements. The elements are:

- Developing a thorough understanding of the current situation and define the problem

- Complete a thorough root cause analysis

- Thoroughly consider alternative solutions while building consensus

- Plan-Do-Check-Act (PDCA)

- Plan: Develop an action plan

- Do: Implement solutions rapidly

- Check: Verify the result

- Act: Make necessary adjustments to solutions and action plan and determine future steps

- Reflect and learn from the process

Enabling CI Sequels

Enabling CI Sequels

Each step of the CI story can benefit from having digital data available.

- Understanding: The complete set of correct data easily available and analyzed leads to a deeper understanding of the current situation and an accurate definition of the problem.

- RCA: Completing a thorough root cause analysis, such as tree diagramming, is faster and more assured when data is accessible, trusted, and complete.

- Modeling alternative solutions: When all parties trust and can see the data and its provenance, modeling to evaluate alternatives can be a clear and effective way to build consensus.

- Plan-Do-Check-Act (PDCA):

- Plan: Developing and recording the action plan in an IT system enables all to see and contribute equally.

- Do: Implementing solutions can come sooner when generating the plan is faster and the means to monitor progress is in place. The digital system can also help keep everyone in sync with rapid action.

- Check: Evaluating is a data-based exercise, so having a coherent system designed to record progress and unintended consequences in an unbiased and automatic way can contribute to effective and efficient CI.

- Act: Everyone can also participate fully and trust when they can see the basis for making necessary adjustments to solutions and the action plan

- Reflect: A consistent digital system can also facilitate learning from the process. People agree on the data and can use the system to record what they learned and what logic they used to direct future projects.

Switching software architectures, like the current move from web-based enterprise architectures to SaaS, can cause significant cost and disruption. How can companies avoid the increased total cost of ownership and reduced ROI during these transitions? Learn how low-code platforms help eliminate the need to repeat the rip-and-replace cycle as computing paradigms evolve.

Please enjoy the summary* below. For the full research, please visit our sponsor Aras (registration required).

Switching software architectures, like the current move from web-based enterprise architectures to SaaS, can cause significant cost and disruption. How can companies avoid the increased total cost of ownership and reduced ROI during these transitions? Learn how low-code platforms help eliminate the need to repeat the rip-and-replace cycle as computing paradigms evolve.

Please enjoy the summary* below. For the full research, please visit our sponsor Aras (registration required).

Table of Contents

- Continuous IT Architectural Transition

- Impact on Software ROI and TCO

- Impact on People, Process, and Technology

- Changing the Status Quo

- Plan for the Future

- Acknowledgments

Introduction

The Evolution of Software Architectures Impacts ROI Software architectures have changed dramatically over the last several decades as the industry has evolved, innovated, and matured. These technological advances come in “waves” that improve the value of computing by unlocking new capabilities and improving the efficiency of how applications are delivered.

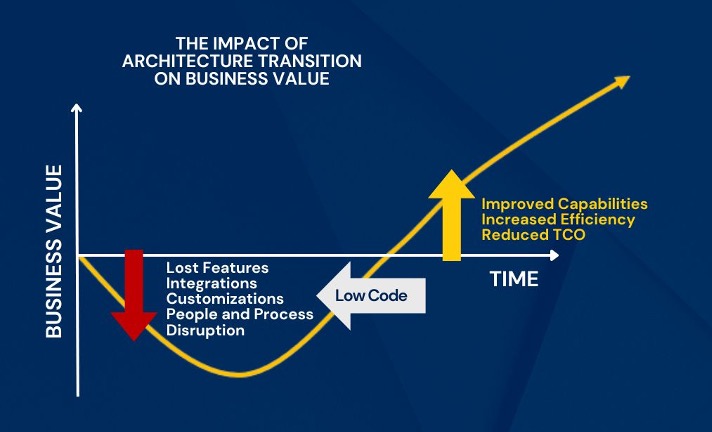

In the long run, new architectures increase the value software provides and drives computing cost down. Greater benefits at lower costs lead to increased software return on investment (ROI). Technology architecture transitions, however, come at a cost. They drive the total cost of ownership (TCO) higher, at least for a while. Although the resulting computing paradigm may be more efficient, migration typically causes significant disruption and decreases the ROI as companies move from existing applications. In the short-term, they must trade off the rich features, extensions, integrations, and customization they’ve developed in their existing software for a more advanced, but less tailored solution.

Optimizing the ROI of Architecture Transition

Today, the cycle is repeating itself. The cloud / SaaS transition is in full swing, reducing barriers to application adoption and supporting digital transformation with better access, agility, granularity, usability, and collaboration. But these benefits are frequently offset by the increased transition cost and functionality tradeoffs. This traditional “rip and replace” approach to software architecture transition is not sustainable.

This eBook shares details on the TCO and ROI impacts of technology waves. It also explains how companies can prepare themselves for continuous evolution at an optimal ROI by using composable, low-code applications to break the expensive rip-and-replace cycle, reduce TCO, and build long-term ROI.

Software architectures have changed dramatically over the last several decades as the industry has evolved, innovated, and matured. These technological advances come in “waves” that improve the value of computing by unlocking new capabilities and improving the efficiency of how applications are delivered.

In the long run, new architectures increase the value software provides and drives computing cost down. Greater benefits at lower costs lead to increased software return on investment (ROI). Technology architecture transitions, however, come at a cost. They drive the total cost of ownership (TCO) higher, at least for a while. Although the resulting computing paradigm may be more efficient, migration typically causes significant disruption and decreases the ROI as companies move from existing applications. In the short-term, they must trade off the rich features, extensions, integrations, and customization they’ve developed in their existing software for a more advanced, but less tailored solution.

Optimizing the ROI of Architecture Transition

Today, the cycle is repeating itself. The cloud / SaaS transition is in full swing, reducing barriers to application adoption and supporting digital transformation with better access, agility, granularity, usability, and collaboration. But these benefits are frequently offset by the increased transition cost and functionality tradeoffs. This traditional “rip and replace” approach to software architecture transition is not sustainable.

This eBook shares details on the TCO and ROI impacts of technology waves. It also explains how companies can prepare themselves for continuous evolution at an optimal ROI by using composable, low-code applications to break the expensive rip-and-replace cycle, reduce TCO, and build long-term ROI.

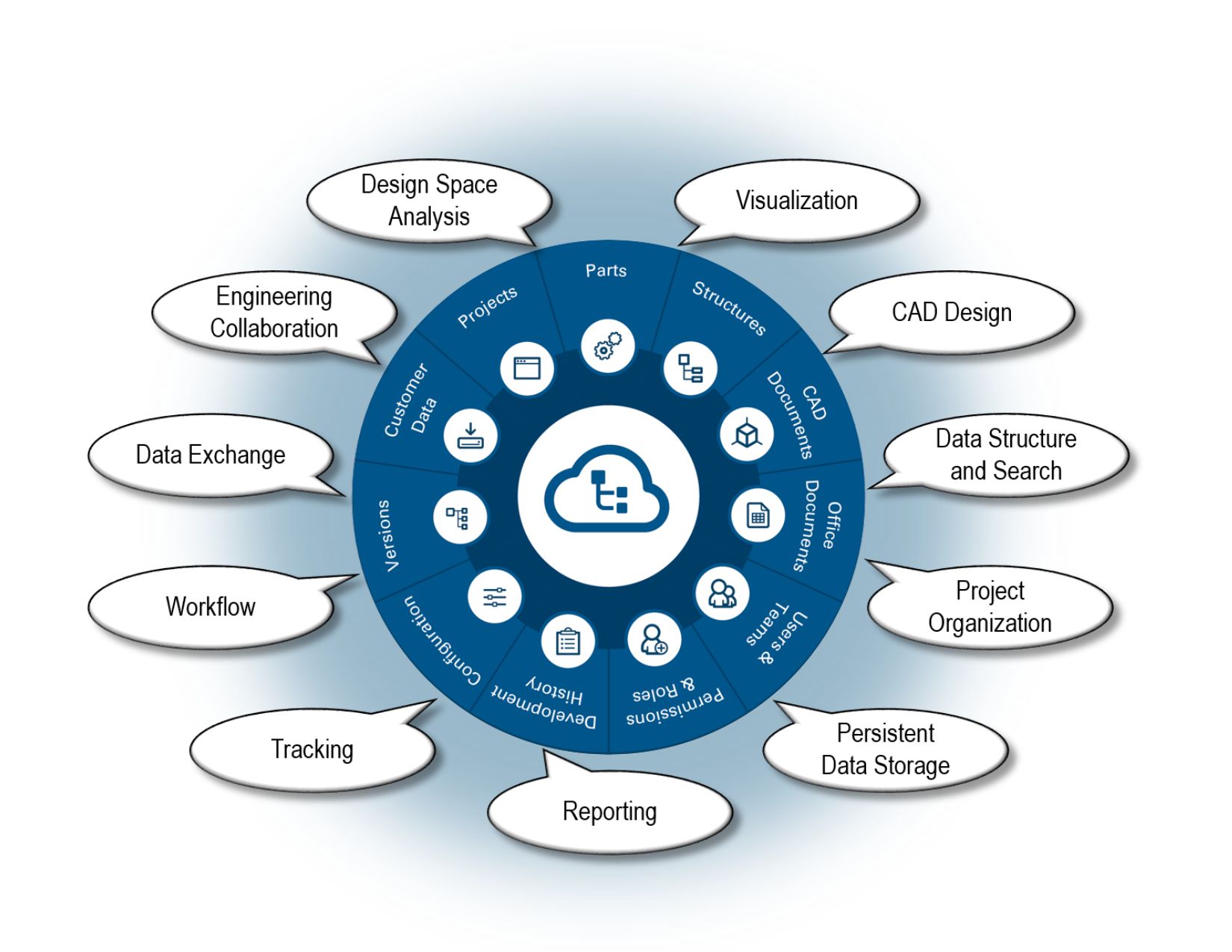

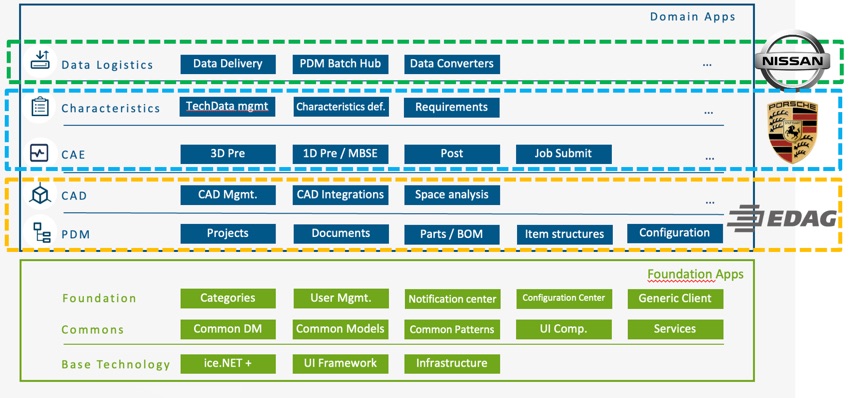

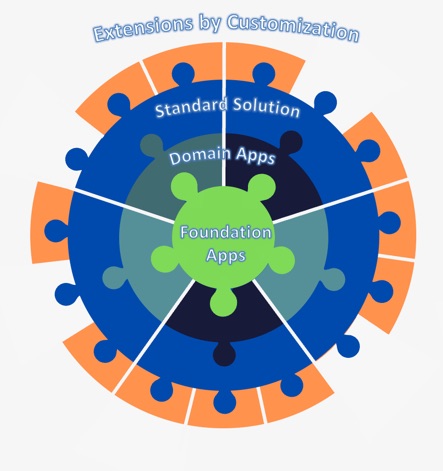

Changing the Status Quo

The Status Quo is High TCO and Reduced ROI Software transition is challenging and expensive, simultaneously impacting people, process, and technology. This leads to companies holding on to systems beyond their useful life and waiting until they are forced to make a change. For example, our research shows that the median time of company’s last primary PLM system upgrade is about 3.3 years ago, and most companies have multiple solutions for legacy reasons.2 These older systems should have been changed, but manufacturers can’t face the disruption and don’t want to suffer the need to rip and replace applications. Technology architecture waves are one of the most common things to force companies to change these systems. Breaking the Rip-and-Replace Cycle Part of the challenge leading to the need to abandon older, comfortable systems is the way most systems are architected. The most common approach creates direct and indirect interdependencies between the software interface, logic, code, data model, and infrastructure. A less common approach, model-based programming, breaks this paradigm by separating business logic and data models from the underlying software architecture that delivers it. Our research shows that a model-based approach, now commonly known as low-code or no-code software, increases companies’ agility and their ability to digitally transform.3 Low-code also allows the software architecture, the service layer, to change underneath while retaining the investment in the application logic and data model. It makes the underlying IT infrastructure, how you operate the software, independent of the solution. This makes applications much easier to upgrade and breaks the need to rip-and-replace solutions to take advantage of a new technical architecture. It offers continuity of functionality, customizations, extensions, integrations, and reporting during upgrades, including architecture transition. There is still work to do to make the transition to a new architecture, but the vast majority of that work is in the inner workings of the system and accomplished by a smaller team within the IT department or the software provider. The rest is insulated from the technical disruption. Reducing the Impact A low-code approach, therefore, allows companies to transition to new architectures and adopt new technologies with far less impact on people, process, and technology. It allows companies to maintain the value of their existing solutions while decreasing cost, risk, and disruption during the transition. This allows companies to more rapidly transition to new architectures with higher ROI and decreased TCO. Beyond the transition, the resulting agility and lack of disruption allows manufacturers to continuously improve to increase the value they receive from software while protecting the investments they’ve already made in people, process, and technology. Plan for the Future

Plan for the Future

Technology Waves are Here to Stay

Technology waves will continue and the value they offer will be compelling. Migrating to these new architectures, however, will reduce the value and increase the cost of applications during the transition. Most companies are facing the Cloud / SaaS transition in some or all of their applications, and arguably facing a simultaneous transition from corporate computing to a more mobile, work from anywhere, multi-device paradigm. Businesses must be strategic about how they make the transition.

Increase ROI and Decrease TCO with Low-Code

Now is the time to break the need to rip-and-replace applications to accommodate the cloud and future architecture transitions. Companies can learn from others who invested in low-code solutions and are able to retain their current investment in applications while migrating the underlying computing architecture. This approach maintains the high level of value companies receive from their solutions without taking a significant step back in capabilities. It also reduces the cost, risk, and disruption of the transition.

Adopting low-code solutions insulates companies from architecture waves and allows them to achieve an optimal application ROI and TCO. Companies transitioning to the cloud should make the change thoughtfully, adopting a system that protects them from the factors that limit benefits and drive high costs. At the same time, they should look for a solution that delivers the functional capabilities they need to optimize their business. Selecting a composable, low-code solution with an application library protects their investment because their existing applications ride on top of the technology waves during future transitions as the app library simultaneously offers new functional capabilities to adopt as valuable.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Aras (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Reducing the Business Impact of Technology Waves

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => technology-waves-ebook

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-29 09:02:29

[post_modified_gmt] => 2024-04-29 13:02:29

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20171

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 20154

[post_author] => 2

[post_date] => 2024-04-24 12:00:55

[post_date_gmt] => 2024-04-24 16:00:55

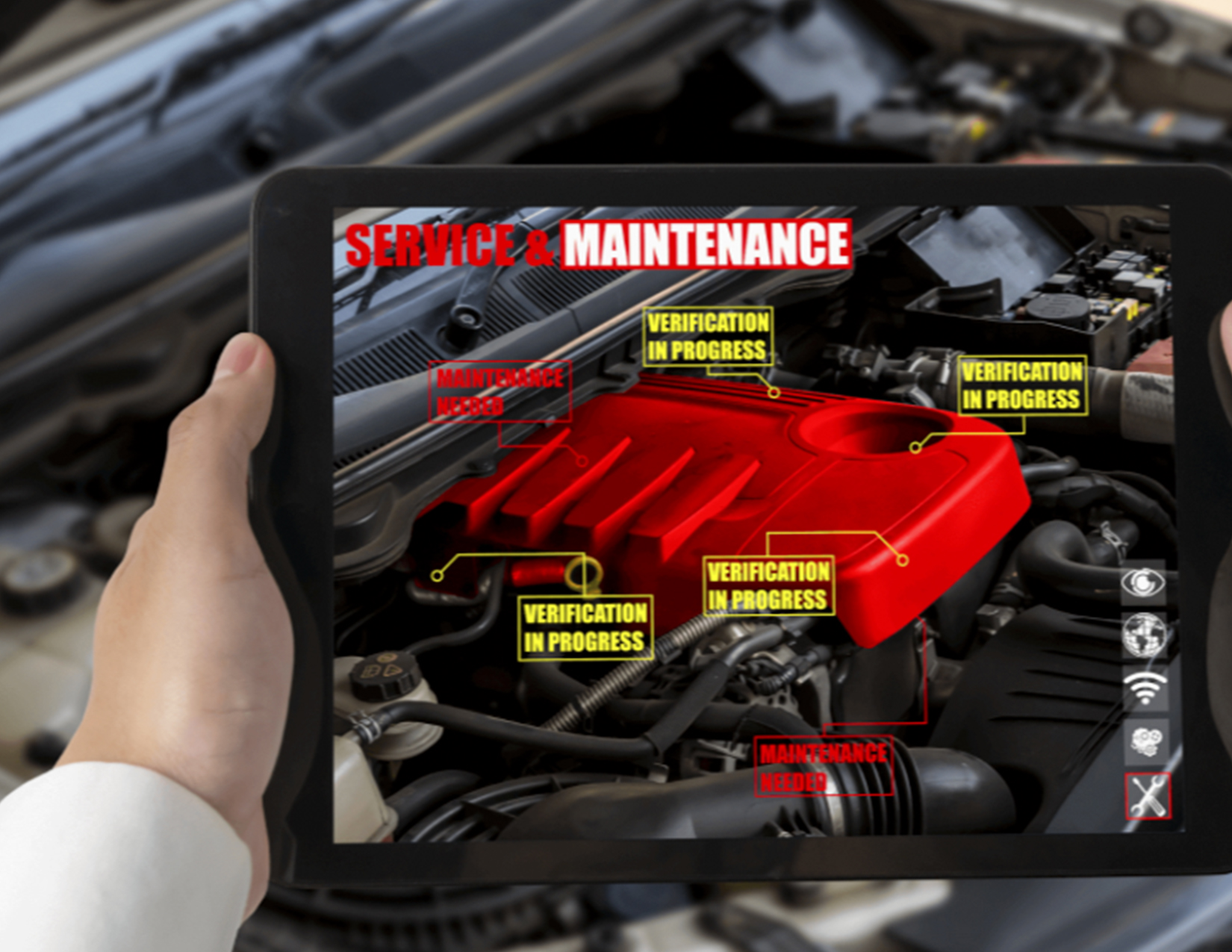

[post_content] => We had a fascinating update briefing with Gridraster COO/Co-founder Dijam Panigrahi, highlighting the growing potential of XR and spatial computing. When we first spoke with them a couple of years ago, we were excited about their platform and what it offers their application provider partners. Namely, Gridraster provides the infrastructure they need to deliver solutions with remote rendering, precise 3D spatial mapping of virtual objects in mixed reality, and other enablers that unlock the power of the metaverse.

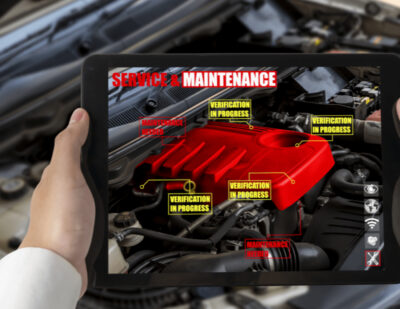

One of the reasons Julie Fraser and I like speaking with Gridraster is that they do quite a bit of work in the aerospace and defense industry. A&D helped pioneer #virtualreality and continues to push the maturity of what mixed reality can do. They have also been leading proponents of digital twins, where Gridraster can provide the granular data underpinning for the industrial metaverse. Of course, it’s hard to discuss XR right now without mentioning Apple. As Dijam told us, “With Apple coming in, the new word is spatial.” The introduction of the Apple Vision Pro created a lot of enthusiasm about the metaverse across industries and should contribute to new use cases and greater adoption.

However, technology is only one part of the equation; gaining real business value is another. Manufacturers are starting to gain more confidence in spatial computing and beginning to achieve real value. Gridraster is working with manufacturers that are applying XR across the product lifecycle, from engineering through support. Some of the critical use cases they’re working with customers and partners on include:

- Improving quality assurance by comparing expected geometry with scanned geometry, whether holographically with headsets or by leveraging other scanners, in near real-time

- Creating high-precision digital twins for existing assets, for example, creating a 3D reconstruction of a physical item without existing 3D designs to support simulation, operations, or training

- Supporting manufacturing by determining the 3D coordinates of a work piece in a robotic work environment to pass along to industrial robots

- Improving maintenance and inspections by scanning with a camera and stitching together multiple scans to create a 3D model to map out an entire interior space without a person physically entering the space

- Supporting maintenance and inspection technicians with active task guidance by overlaying digital instructions over the physical environment

Dijam explained that one of their most compelling capabilities to support these use cases is their ability to capture geometry with millimeter-level accuracy. With this, they can create very precise renderings or compare “as expected” digital models with the scanned truth with high precision and identify discrepancies with very high accuracy.

Our research shows that it may still take some time for XR and the industrial metaverse to become pervasive tools in the manufacturing industries, at least outside of larger companies and industries like automotive and A&D. Still, our discussions with GridRaster Inc. show that the value is available, and we believe the barriers will continue to drop. As devices become more capable, computing power grows, and platforms become more accessible, at least in some part due to the gaming industry, we expect further adoption. Thank you, Dijam Panigrahi to keep us in the “believers” camp for greater adoption – and value – from AI and XR. And thanks to John Sternal for coordinating the discussion.

[post_title] => Gridraster Shows the Art of the Possible in Mixed Reality [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => mixed-reality-gridraster [to_ping] => [pinged] => [post_modified] => 2025-03-07 15:42:23 [post_modified_gmt] => 2025-03-07 20:42:23 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20154 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [3] => WP_Post Object ( [ID] => 20122 [post_author] => 2574 [post_date] => 2024-04-24 10:00:08 [post_date_gmt] => 2024-04-24 14:00:08 [post_content] => Jim Brown and Julie Fraser are enthused after recently catching up with ComplianceQuest’s CSO and VP of Product Marketing, Nikki Willett. Their progress is impressive. At ten years old, ComplianceQuest continues to expand and innovate to realize its vision of software for quality that touches everything. This vision and product suite span engineering and R&D to operations and manufacturing to safety to supply chain to services to customers.

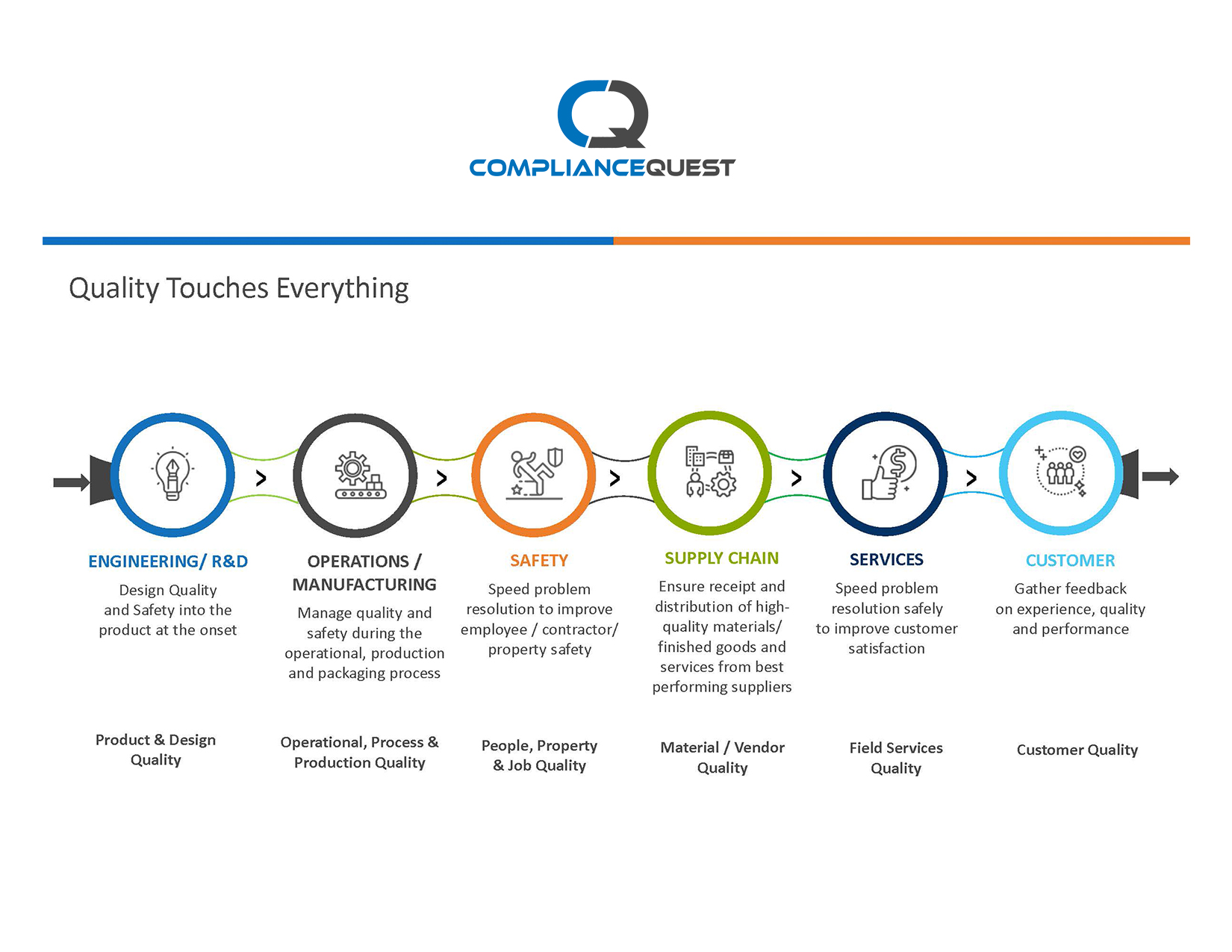

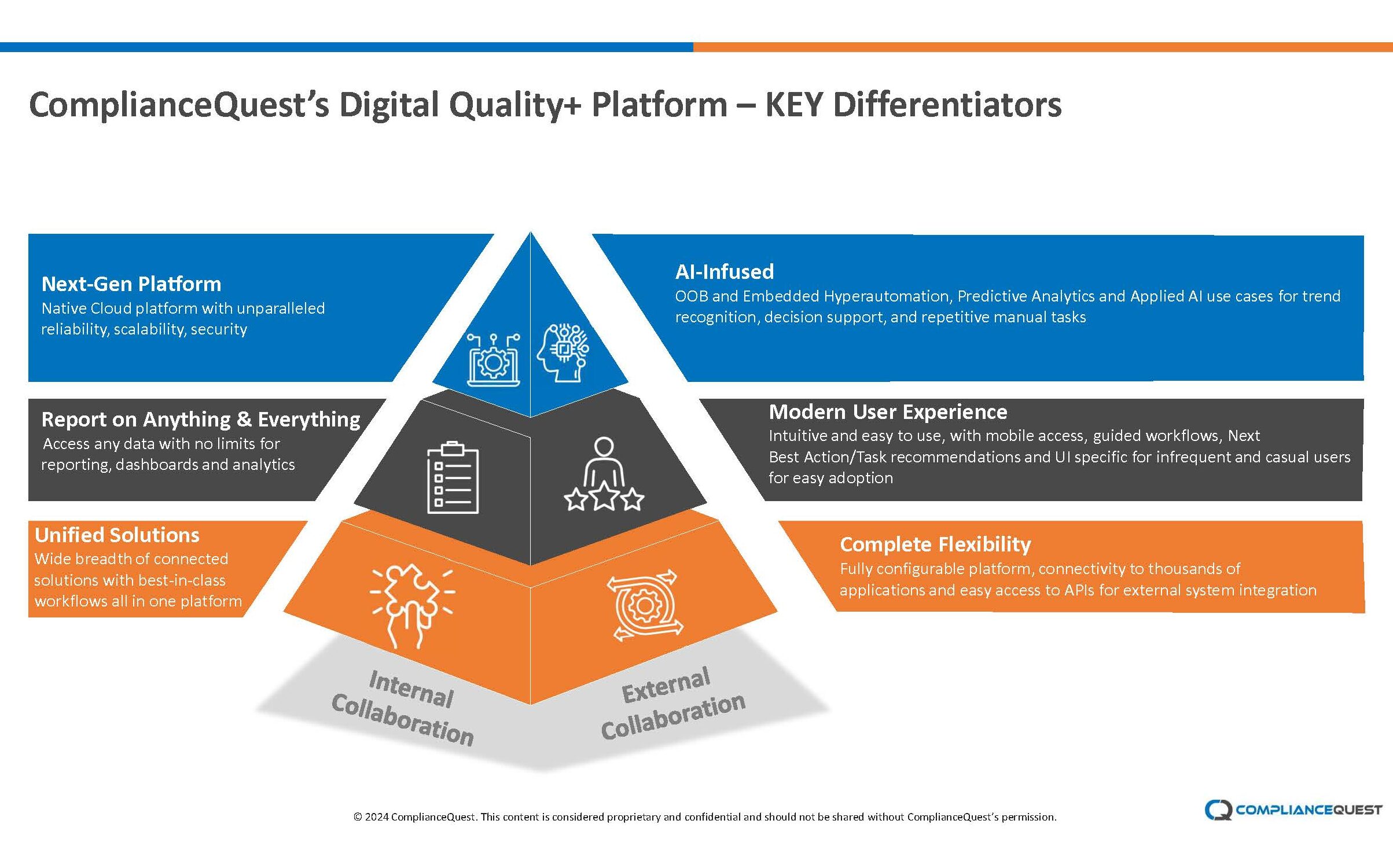

Jim Brown and Julie Fraser are enthused after recently catching up with ComplianceQuest’s CSO and VP of Product Marketing, Nikki Willett. Their progress is impressive. At ten years old, ComplianceQuest continues to expand and innovate to realize its vision of software for quality that touches everything. This vision and product suite span engineering and R&D to operations and manufacturing to safety to supply chain to services to customers.

ComplianceQuest has expanded its product footprint with the ProductQuest (PLM) suite alongside the existing QualityQuest (QMS) and SafetyQuest (EHS) suites. In all, there are 28 products in these three suites. All these applications are integrated on the ComplianceQuest Digital Quality+ platform. If you know the company, you know the software is natively built on the Salesforce Business Cloud platform. ComplianceQuest partners with Salesforce effectively to take advantage of their Force Cloud platform, applications, and ecosystem opportunities.

Last year, new functionality releases included Digital SOPs, CQ.Forms, (both online and offline) PLM, and FMEAs and Control Plans (APQP) for its Design Quality solution, connections from regulations and standards to auditing, an Intake Wizard to quickly guide users to report a nonconformance, a Response Wizard that helps create all the required records needed in an audit finding, Change Control impact assessment, and Supplier Performance rating system. In the AI space, they added CQ.AI agents, enhanced Next Best Actions/tasks (NBA) to drive more than workflow but tasks/steps as well, embedded analytics with AI in non-conformance and complaints so separate reports are no longer necessary, Intelligent Analytics for better current and predictive visibility, and Quality Maturity Index (QMI) to assess quality across the entire organization and by location.

ComplianceQuest targets both Life Sciences and Manufacturing industries. They have also made progress in the government / public sector with a FedRAMP attestation. Their integrator and reseller partner network continues to expand as the company gains customers of all sizes. Sales are also growing in Europe and Asia Pacific English-speaking countries.

ComplianceQuest’s unified solution approach is increasingly attractive as companies seek to improve the success of digital transformation and roll out the same applications across their enterprise. With quality management (QMS), environmental health and safety (EHS), and now quality-focused product lifecycle management (PLM) all on a single platform, ComplianceQuest customers have a strong data flow for the quality digital thread. Those who use the Force.com platform for other purposes can avoid integration headaches even more broadly.

The platform has AI and other decision-making enablers built into it. ComplianceQuest emphasizes the data-driven approach, a break from the document-driven approach of many historical QMS products.

Thank you,Nikki Willett, for taking the time to update us. We look forward to a deeper dive into PLM for product quality and following ComplianceQuest’s continuing growth in the market.

[post_title] => ComplianceQuest Continues to Expand [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => compliancequest-expands [to_ping] => [pinged] => [post_modified] => 2024-04-24 14:08:39 [post_modified_gmt] => 2024-04-24 18:08:39 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20122 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 20111 [post_author] => 2 [post_date] => 2024-04-22 09:00:08 [post_date_gmt] => 2024-04-22 13:00:08 [post_content] => How and why are real estate developers taking a design-build approach to residential real estate development? How does that increase the need for AEC technology to improve communication, validation, and planning?

Please enjoy the summary* below. For the full research, please visit our sponsor Graphisoft (registration required).

How and why are real estate developers taking a design-build approach to residential real estate development? How does that increase the need for AEC technology to improve communication, validation, and planning?

Please enjoy the summary* below. For the full research, please visit our sponsor Graphisoft (registration required).

Table of Contents

- The Design-Build Project Approach

- Construction Delivery Models

- What is Design-Build?

- The Benefits of Using Design-Build

- Challenges and Risks of the DB Model

- The Role of Technology in Enabling Design-Build

- Recommendations and Next Steps

- Acknowledgments

Executive Summary

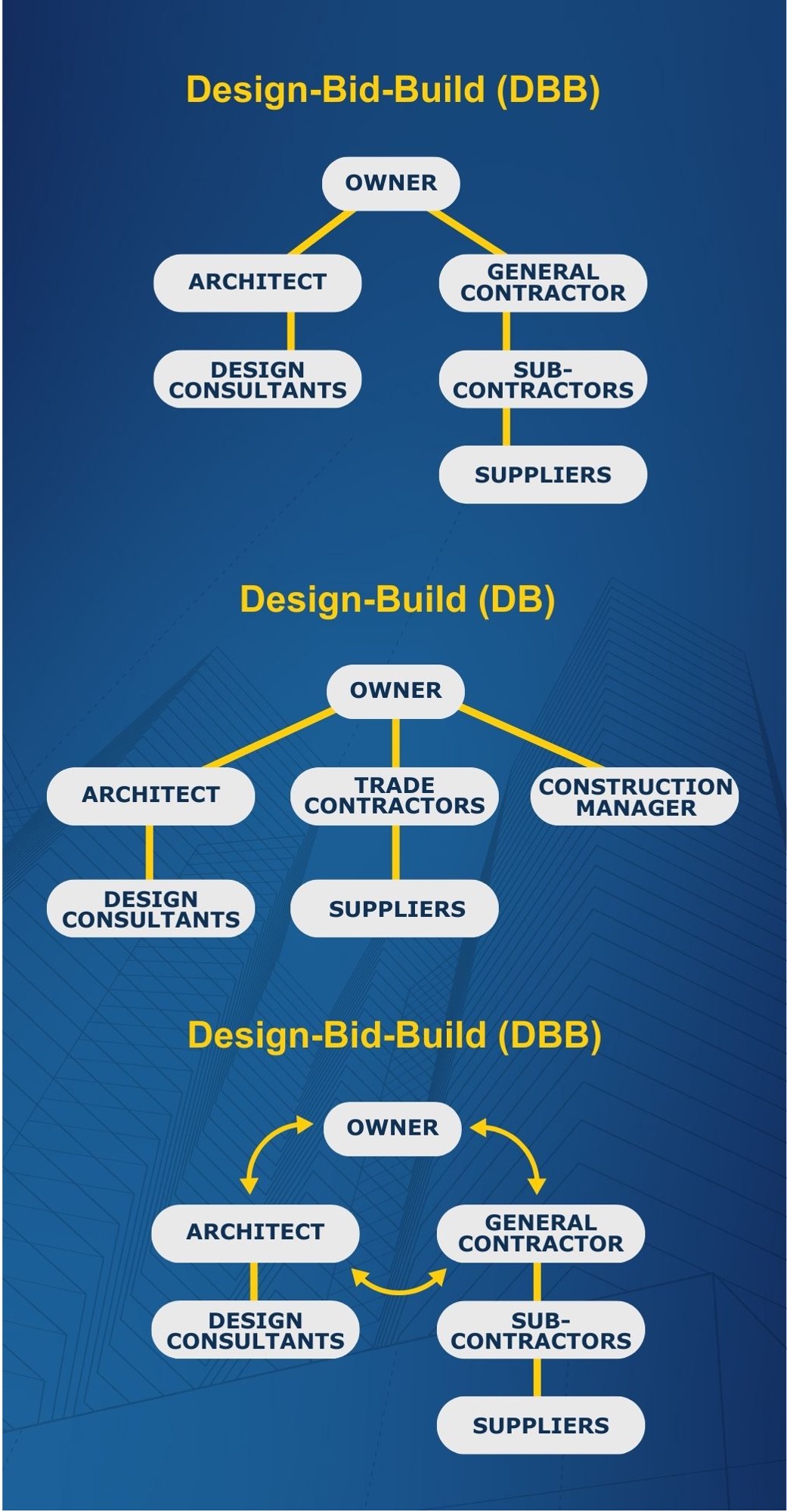

Real estate development is driven by the capitalistic pursuit of opportunity in the face of an imbalance of building supply compared with demand. It is an industry where the final product is most often unique. The business objective of delivering results at the lowest possible cost in light of defined quality objectives and time remains consistent across teams and cultures. Design-build (DB) is a delivery model that has gained significant appeal because of the opportunity to realize savings with the acceptance of slightly more risk but greater transparency with regard to cost. Teamwork and collaboration are at the core of DB, versus the typical disassociated approach of steering design and then seeking fixed-price bids from general contractors. DB inherently incentivizes all parties to identify ways to improve productivity and quality while offering a level of fairness and cost transparency. The cost data understood from prior DB projects contributes to greater awareness heading into new projects. Further, the early involvement of construction trade teams offers architects and designers ongoing feedback as they evolve the design with regard to product and productivity. This environment of collaboration serves to positively impact cost, schedule, and quality; reducing the risk of missing the mark with design and ensuring a tighter trade buy-out process during construction. This eBook takes an in-depth dive into Design-Build in relation to other design and construction delivery frameworks based on discussions with residential real estate development firms who have either adopted this approach or at least experimented with it. It reviews how workflows have evolved in time, the factors that drive a DB approach, and the benefits anticipated. It also highlights the increasing importance of technology adoption for communication across teams, design-build validation, and planning.Construction Delivery Models

Design-Bid-Build Spreads Risk and Supports Specialization

Over the last 100+ years since the Industrial Revolution, the most common approach has been to prepare a collection of design documents and then have builders or general contractors develop pricing to deliver it, often in competitive circumstances.

This evolved beyond the framework initially dominated by the master builder (eventually the architect), who assembled craftspeople at a project location and then developed the design in place with limited pre-planning and almost no estimating and pre-construction pricing. The advent of building services and the pursuit of comfort brought technology advances and the need to preplan in advance of construction. This evolved the question, “How much will this cost?” and Design-Bid-Build (DBB) was born. The increasing complexity of construction assemblies lent itself to alternate forms of bidding and contracting.

Key to this was to establish trade scope packages and then allow the specialized experts to price based on a stipulated sum.

These technological advances led to an increase in specialization that caused design and construction firms to push those out of house due to the nature of boom-bust cycles, and the ebb and flow of work volume. It became undesirable to keep specialized craftspeople on payroll, supervised, mentored, and adequately trained. This led to a mindset of driving risk down the supply chain and lump sum project pricing. Tight stipulated price contracts ensured that owners wouldn’t see any cost escalations unless there were design changes, regardless of the materials and resources needed to deliver the project.

Design-Bid-Build Spreads Risk and Supports Specialization

Over the last 100+ years since the Industrial Revolution, the most common approach has been to prepare a collection of design documents and then have builders or general contractors develop pricing to deliver it, often in competitive circumstances.

This evolved beyond the framework initially dominated by the master builder (eventually the architect), who assembled craftspeople at a project location and then developed the design in place with limited pre-planning and almost no estimating and pre-construction pricing. The advent of building services and the pursuit of comfort brought technology advances and the need to preplan in advance of construction. This evolved the question, “How much will this cost?” and Design-Bid-Build (DBB) was born. The increasing complexity of construction assemblies lent itself to alternate forms of bidding and contracting.

Key to this was to establish trade scope packages and then allow the specialized experts to price based on a stipulated sum.

These technological advances led to an increase in specialization that caused design and construction firms to push those out of house due to the nature of boom-bust cycles, and the ebb and flow of work volume. It became undesirable to keep specialized craftspeople on payroll, supervised, mentored, and adequately trained. This led to a mindset of driving risk down the supply chain and lump sum project pricing. Tight stipulated price contracts ensured that owners wouldn’t see any cost escalations unless there were design changes, regardless of the materials and resources needed to deliver the project.

Recommendations and Next Steps

Design-Build is Driving Change Real estate development projects are high-risk, intense endeavors. Inner-city projects begin with high-value land acquisitions and significant design and municipal fees. Lenders often require 50% pre-sales, and construction financing commitments are generally predicated on building permit releases. Considerable funds are at risk before construction ever sees the light of day. Team focus is first on the entitlement and underwriting process; then, with the re-zoning approvals, the design development begins. As architects and the discipline designers advance towards a development permit and then a building permit the opportunity for trade feedback presents itself regularly. Our research and experience found that design complexity continues to increase, leading to an industry shift to adopt a more integrated and collaborative design approach. Legal frameworks and the fragmented nature of the industry drive a conservative mindset more resistant to change than other industries; however, advances in technology toolsets, the cloud, and software platform approaches are causing practices and approaches to change. These industry catalysts are driving many teams to look to Design-Build to create a more cohesive and cost-effective experience of RE projects, delivering benefits such as schedule compressions, target-value design and delivery, and a fiscal balance reflecting finish quality. Technology Supports DB and Overall Construction Profitability The real wins are reducing cycle times related to project feasibility studies, design development, interfacing with municipal planners, construction cost estimating, third-party quantity surveyors, project managers, general contractors, and trade contractors. It’s about understanding what is permitted to build and creating greater value propositions with project proformas. Authoring tools that facilitate accurate geometry and visualization are critical aids for extended teams to access project data and support them in driving results. The future is about speedier data retrieval and more integrated systems. Access to accurate data will be quick as the design and construction delivery world moves into a 3D paradigm. Data drives the ability to make decisions. The recent advent of deep machine learning models and Artificial Intelligence (AI) also promises significant acceleration in access to data and generative AI will shorten cycle times. However, as much as software may drive the potential for productivity, the banking industry and the municipal bureaucracy structures must also adapt and improve access to and acceptance of data and graphical models. The choke points will soon be with user adoption and training. This cannot be overlooked. We believe design-build will continue to grow in the real estate development market. It creates deeper cohesion amongst project participants. And it hits the bull’s eye for driving cost-efficient projects. Developers that adopt more technology and continue with sound financial and contracting practices appear to be able to better leverage design-build contract arrangement to improve overall cost, speed, and quality. *This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Graphisoft (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => Supporting Design-Build in Real Estate Development [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => design-build [to_ping] => [pinged] => [post_modified] => 2024-04-22 11:06:47 [post_modified_gmt] => 2024-04-22 15:06:47 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20111 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [5] => WP_Post Object ( [ID] => 20128 [post_author] => 2574 [post_date] => 2024-04-19 09:00:06 [post_date_gmt] => 2024-04-19 13:00:06 [post_content] => How does the Digital Manufacturing Journey unfold? What are views of the past, present, and future? Tech-Clarity’s Julie Fraser will be on an industry analysts panel discussing this at the Manufacturing Leadership Council’s Rethink Conference on Marco Island, FL. The conference runs from June 2nd to June 5th and will include a live panel discussion focused on the digital model of manufacturing. Register to hear Julie Fraser and analysts from LNS, ARC, and IDC in person on Tuesday, June 4th at 2:40 PM.

Julie and other panelists have been watching manufacturing IT change over the past 20 or more years. They will bring that experience to discuss current and future steps in the digital manufacturing journey. Digital transformation is inevitable, but how it unfolds is not yet entirely clear. This promises to raise areas of agreement and contention among the never-shy industry analysts.

The Rethink conference is designed for manufacturing and IT leaders and their teams to interact in roundtables and more traditional conference settings. The theme is accelerating digital transformation in manufacturing. Rethink has many networking opportunities as well as an agenda where you’ll hear from leading and award-winning manufacturing peers.

For the full-week agenda, visit the Manufacturing Leadership Council Rethink 2024 homepage.

Thank you, David Brousell of the Manufacturing Leadership Council, for extending the invitation to participate and share our views.

[post_title] => The Digital Manufacturing Journey: Past, Present, and Future

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-manufacturing-journey

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-19 09:38:36

[post_modified_gmt] => 2024-04-19 13:38:36

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20128

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 20062

[post_author] => 2

[post_date] => 2024-03-28 09:00:08

[post_date_gmt] => 2024-03-28 13:00:08

[post_content] => [caption id="attachment_20064" align="aligncenter" width="757"]

How does the Digital Manufacturing Journey unfold? What are views of the past, present, and future? Tech-Clarity’s Julie Fraser will be on an industry analysts panel discussing this at the Manufacturing Leadership Council’s Rethink Conference on Marco Island, FL. The conference runs from June 2nd to June 5th and will include a live panel discussion focused on the digital model of manufacturing. Register to hear Julie Fraser and analysts from LNS, ARC, and IDC in person on Tuesday, June 4th at 2:40 PM.

Julie and other panelists have been watching manufacturing IT change over the past 20 or more years. They will bring that experience to discuss current and future steps in the digital manufacturing journey. Digital transformation is inevitable, but how it unfolds is not yet entirely clear. This promises to raise areas of agreement and contention among the never-shy industry analysts.

The Rethink conference is designed for manufacturing and IT leaders and their teams to interact in roundtables and more traditional conference settings. The theme is accelerating digital transformation in manufacturing. Rethink has many networking opportunities as well as an agenda where you’ll hear from leading and award-winning manufacturing peers.

For the full-week agenda, visit the Manufacturing Leadership Council Rethink 2024 homepage.

Thank you, David Brousell of the Manufacturing Leadership Council, for extending the invitation to participate and share our views.

[post_title] => The Digital Manufacturing Journey: Past, Present, and Future

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-manufacturing-journey

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-19 09:38:36

[post_modified_gmt] => 2024-04-19 13:38:36

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20128

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 20062

[post_author] => 2

[post_date] => 2024-03-28 09:00:08

[post_date_gmt] => 2024-03-28 13:00:08

[post_content] => [caption id="attachment_20064" align="aligncenter" width="757"] Tech-Clarity's Jim Brown at Aras ACE 2024[/caption]

I really enjoyed the Aras ACE 2024 user conference this year. The event gave me the opportunity to hear and learn from Aras leadership, specialists, partners, and users to gain a deeper perspective on the future of Aras. I’ll share my takeaways, but I’ll start with my summary and the advice I give to manufacturers about Aras Innovator. I always tell people that if they’re looking for a PLM system, they should include Aras in their research, not because they are necessarily a better offering but because they are a very different offering. I’ll talk more about that in this post, but I talked about it in my recap of ACE 2023 as the “Aras Difference.” They aren’t the right fit for every organization, but their approach is compelling and high value for the right companies.

Business is Sunny

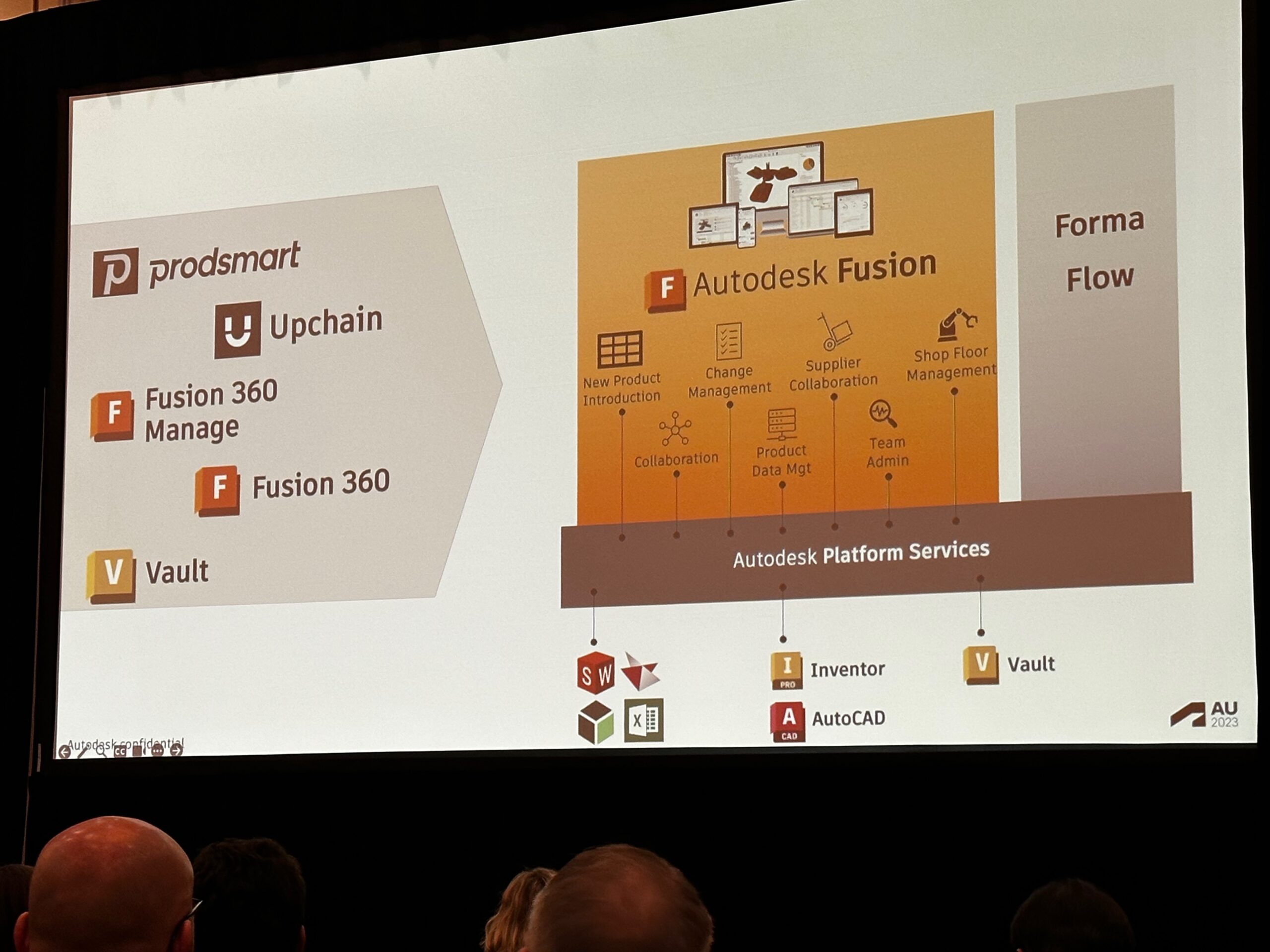

Let’s start with the business. CEO Roque Martin started by sharing some positive growth statistics, specifically a 61% subscriber growth since his arrival in late 2021 and 77% year-over-year growth in SaaS deployments. The SaaS growth is very important as Aras transitions to a cloud business while helping manufacturers modernize their PLM systems.

Business is Cloudy

Forgive the “cloudy” pun but I think it’s important. Most enterprise systems vendors, including PLM, provide some form of cloud offering. What I’ve seen from Aras is more than just a shift in their technology deployment approach. Aras is acting like a cloud business. They’ve adopted a more agile software development cycle and moved to smaller, more frequent releases. They’re thinking more along the lines of web services, delivering more granular, purpose-built APIs to allow Aras Innovator to fit more openly into their customers’ heterogeneous systems ecosystems in the cloud. They’ve reorganized themselves, and their solutions, around a robust DevOps approach for both internal operations and customer deployments. The transition is more than a facade or the ability to run in a cloud environment, it’s a move toward the future way solution providers deliver value.

Crystalizing their Unique Position

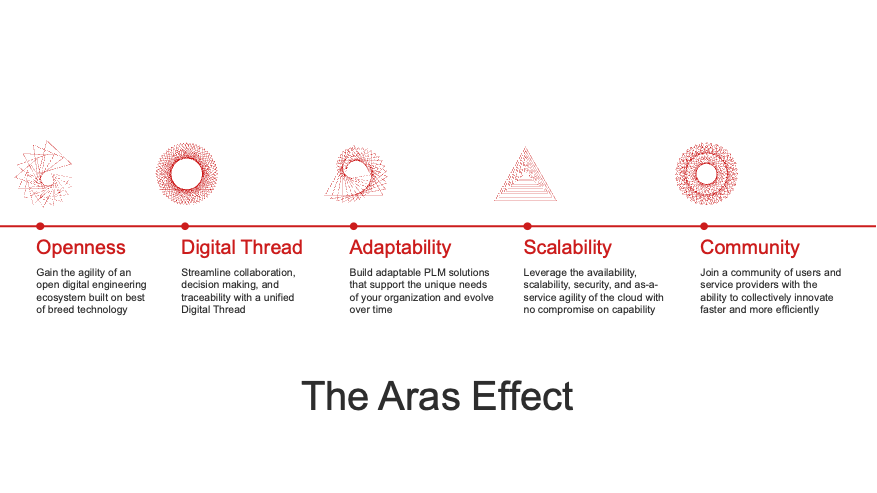

Aras has always been unique. From their “open systems” offering to their low-code architecture, there has always been a pride in being unique. They now have a name and a better definition of what differentiates Aras from other solution providers. It’s “the Aras Effect.” The Aras Effect is the new way they explain their basic principles of openness, support for the digital thread, adaptability, scalability, and community.

[caption id="attachment_20070" align="aligncenter" width="877"]

Tech-Clarity's Jim Brown at Aras ACE 2024[/caption]

I really enjoyed the Aras ACE 2024 user conference this year. The event gave me the opportunity to hear and learn from Aras leadership, specialists, partners, and users to gain a deeper perspective on the future of Aras. I’ll share my takeaways, but I’ll start with my summary and the advice I give to manufacturers about Aras Innovator. I always tell people that if they’re looking for a PLM system, they should include Aras in their research, not because they are necessarily a better offering but because they are a very different offering. I’ll talk more about that in this post, but I talked about it in my recap of ACE 2023 as the “Aras Difference.” They aren’t the right fit for every organization, but their approach is compelling and high value for the right companies.

Business is Sunny

Let’s start with the business. CEO Roque Martin started by sharing some positive growth statistics, specifically a 61% subscriber growth since his arrival in late 2021 and 77% year-over-year growth in SaaS deployments. The SaaS growth is very important as Aras transitions to a cloud business while helping manufacturers modernize their PLM systems.

Business is Cloudy

Forgive the “cloudy” pun but I think it’s important. Most enterprise systems vendors, including PLM, provide some form of cloud offering. What I’ve seen from Aras is more than just a shift in their technology deployment approach. Aras is acting like a cloud business. They’ve adopted a more agile software development cycle and moved to smaller, more frequent releases. They’re thinking more along the lines of web services, delivering more granular, purpose-built APIs to allow Aras Innovator to fit more openly into their customers’ heterogeneous systems ecosystems in the cloud. They’ve reorganized themselves, and their solutions, around a robust DevOps approach for both internal operations and customer deployments. The transition is more than a facade or the ability to run in a cloud environment, it’s a move toward the future way solution providers deliver value.

Crystalizing their Unique Position

Aras has always been unique. From their “open systems” offering to their low-code architecture, there has always been a pride in being unique. They now have a name and a better definition of what differentiates Aras from other solution providers. It’s “the Aras Effect.” The Aras Effect is the new way they explain their basic principles of openness, support for the digital thread, adaptability, scalability, and community.

[caption id="attachment_20070" align="aligncenter" width="877"] The "Aras Effect" as Presented at Aras ACE 2024[/caption]

I’ll touch on each of these based on my experience at ACE. I already mentioned openness due to open, granular interfaces that allow companies to execute and embed Aras capabilities in their cloud ecosystem. Scalability is thanks to the support Microsoft’s Azure cloud computing platform. I’m going to touch on the others directly.

Digital Thread

While I said Aras Innovator may not be the best system, it may be. Their PLM capabilities are extensive. The digital thread is the representation of broad PLM capabilities Aras has built into Aras Innovator to support the product lifecycle. Aras Innovator’s scope starts with requirements and creates traceability throughout the product lifecycle. Although Aras focuses on adaptability, they offer core capabilities as a starting point and announced continued investment in enhancing the standard offering. Aras SVP of Product Management John Sperling announced significant current and planned enhancements to both the low-code capabilities and to functionality. For example, he shared details on important PLM needs like maturing variant management including variant 3D Design with visualization. It’s just one example of Aras continuing to invest in become a more complete digital thread platform.

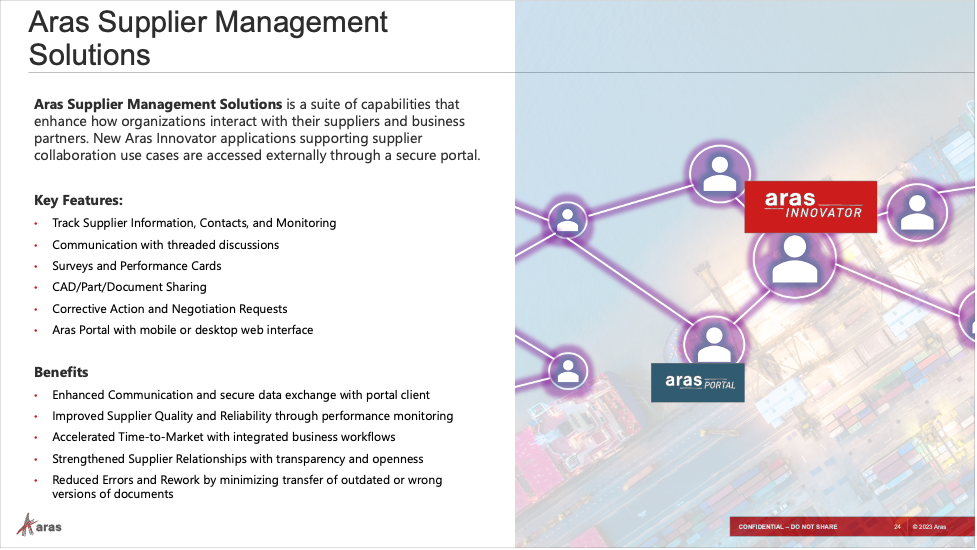

Another significant announcement related to the digital thread was the announcement of a new product to optimize supplier connectivity and collaboration, Supplier Management Solutions and the associated Aras Portal. The new application provides secure, remote access to controlled select digital thread and PLM information through configurable, mobile-optimized web applications. It’s not intended to replace a procurement or logistics system, but it offers direct connectivity in the integrated with data from Aras Innovator. Aras understands that the digital thread doesn’t exist in a single enterprise, but extends out into the value chain.

[caption id="attachment_20071" align="alignnone" width="977"]

The "Aras Effect" as Presented at Aras ACE 2024[/caption]

I’ll touch on each of these based on my experience at ACE. I already mentioned openness due to open, granular interfaces that allow companies to execute and embed Aras capabilities in their cloud ecosystem. Scalability is thanks to the support Microsoft’s Azure cloud computing platform. I’m going to touch on the others directly.

Digital Thread

While I said Aras Innovator may not be the best system, it may be. Their PLM capabilities are extensive. The digital thread is the representation of broad PLM capabilities Aras has built into Aras Innovator to support the product lifecycle. Aras Innovator’s scope starts with requirements and creates traceability throughout the product lifecycle. Although Aras focuses on adaptability, they offer core capabilities as a starting point and announced continued investment in enhancing the standard offering. Aras SVP of Product Management John Sperling announced significant current and planned enhancements to both the low-code capabilities and to functionality. For example, he shared details on important PLM needs like maturing variant management including variant 3D Design with visualization. It’s just one example of Aras continuing to invest in become a more complete digital thread platform.

Another significant announcement related to the digital thread was the announcement of a new product to optimize supplier connectivity and collaboration, Supplier Management Solutions and the associated Aras Portal. The new application provides secure, remote access to controlled select digital thread and PLM information through configurable, mobile-optimized web applications. It’s not intended to replace a procurement or logistics system, but it offers direct connectivity in the integrated with data from Aras Innovator. Aras understands that the digital thread doesn’t exist in a single enterprise, but extends out into the value chain.

[caption id="attachment_20071" align="alignnone" width="977"] Aras Supplier Management Solutions[/caption]

Adaptability

The ability to adapt Aras Innovator to customer needs has long been a key difference between Aras Innovator and the others. Whether it was called a “model-based architecture” as it was when I first started following Aras or more commonly known as “low-code,” the key point is that the operating infrastructure is separated from the data model and the logic. This decoupling allows the solution to change independently from the core underpinnings of the system.

The result is more important than the details, and Aras has leveraged that difference to offer customers more than a “cookie cutter” solution, but instead encourage customization. That’s about as different as you can get from the advice from other vendors. For any given company, “different” might not be better. But what it allows Aras to do is promise customers that they can upgrade their Aras software without disturbing their customizations.

Their low-code-enabled agility also allows them to tackle non-traditional PLM needs like what they’ve done in the process industries, most notably with Red Bull for CPG / batch process and Renesas for semiconductor manufacturing. For these companies that where there are fewer mature PLM offerings, they can modify the solution needs – including the data model – to meet unique industry without creating a dead-end resulting from their customization. It also allows Aras the ability to offer their platform as a service, but I’ll cover that next in community.

Community

Aras also works differently within the software community. That’s true for customers, but also for partners. As I mentioned, Aras offers their platform as a service for other vendors to build solutions based on their core capabilities. Some significant examples include Ansys’s Minerva Simulation Process and Management (SPDM) system and AVEVA’s Asset Lifecycle Management (ALM) offerings that are both built on, “powered by,” the Aras platform. I spoke about those in last year’s coverage as well.

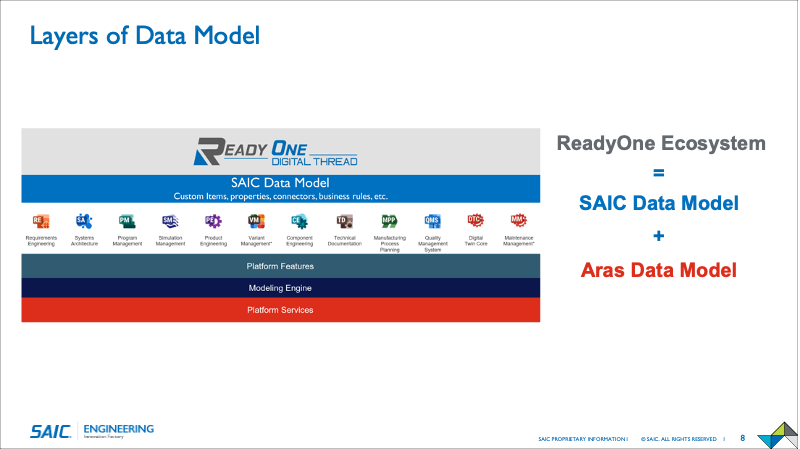

There is a direct relationship between their agility differentiator and their community aspect. The ability for other providers to build on top of Aras is unique. Another new example was uncovered at ACE this year as the result of a partnership with SAIC. I won’t go into detail about the offering, but SAIC announced their ReadyOne offering which is a Digital Engineering solution configured for the specific requirements of the Department of Defense. A quick look at their architecture is very telling, showing Aras platform services, modeling engine, and platform features serving as the underpinning for the SAIC data model and ReadyOne Digital Thread.

[caption id="attachment_20072" align="aligncenter" width="800"]

Aras Supplier Management Solutions[/caption]

Adaptability

The ability to adapt Aras Innovator to customer needs has long been a key difference between Aras Innovator and the others. Whether it was called a “model-based architecture” as it was when I first started following Aras or more commonly known as “low-code,” the key point is that the operating infrastructure is separated from the data model and the logic. This decoupling allows the solution to change independently from the core underpinnings of the system.

The result is more important than the details, and Aras has leveraged that difference to offer customers more than a “cookie cutter” solution, but instead encourage customization. That’s about as different as you can get from the advice from other vendors. For any given company, “different” might not be better. But what it allows Aras to do is promise customers that they can upgrade their Aras software without disturbing their customizations.

Their low-code-enabled agility also allows them to tackle non-traditional PLM needs like what they’ve done in the process industries, most notably with Red Bull for CPG / batch process and Renesas for semiconductor manufacturing. For these companies that where there are fewer mature PLM offerings, they can modify the solution needs – including the data model – to meet unique industry without creating a dead-end resulting from their customization. It also allows Aras the ability to offer their platform as a service, but I’ll cover that next in community.

Community

Aras also works differently within the software community. That’s true for customers, but also for partners. As I mentioned, Aras offers their platform as a service for other vendors to build solutions based on their core capabilities. Some significant examples include Ansys’s Minerva Simulation Process and Management (SPDM) system and AVEVA’s Asset Lifecycle Management (ALM) offerings that are both built on, “powered by,” the Aras platform. I spoke about those in last year’s coverage as well.

There is a direct relationship between their agility differentiator and their community aspect. The ability for other providers to build on top of Aras is unique. Another new example was uncovered at ACE this year as the result of a partnership with SAIC. I won’t go into detail about the offering, but SAIC announced their ReadyOne offering which is a Digital Engineering solution configured for the specific requirements of the Department of Defense. A quick look at their architecture is very telling, showing Aras platform services, modeling engine, and platform features serving as the underpinning for the SAIC data model and ReadyOne Digital Thread.

[caption id="attachment_20072" align="aligncenter" width="800"] SAIC ReadyOne Data Model[/caption]

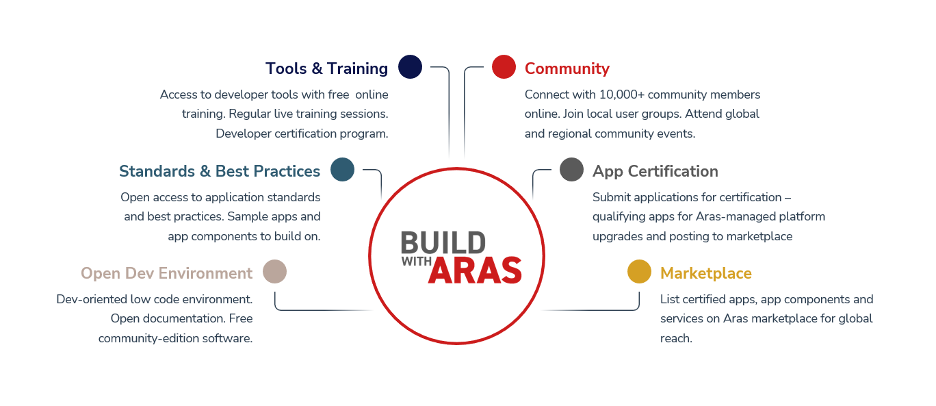

The ability to customize Aras Innovator is now crystalized as the ability to “build with Aras.” The capability not entirely new, but Aras is bringing more to the table including a planned app marketplace. I expect to learn more about that over time.

[caption id="attachment_20078" align="aligncenter" width="936"]

SAIC ReadyOne Data Model[/caption]

The ability to customize Aras Innovator is now crystalized as the ability to “build with Aras.” The capability not entirely new, but Aras is bringing more to the table including a planned app marketplace. I expect to learn more about that over time.

[caption id="attachment_20078" align="aligncenter" width="936"] Build with Aras Program Announced at Aras ACE 2024[/caption]

From a customer community perspective, Aras has always fostered an environment where customers share with each other, even sharing customizations. Another example of doing things differently is Aras in the Round. This final session at ACE opens up the floor to all participants to ask anything as VP Leon Lauritsen tosses foam cubes with microphones to the audience. There were some challenging questions, and Roque Martin and Rob McAveney shared candid answers. It’s a unique experience.

Final Notes

There is always too much to cover at these events. As expected, Aras also discussed their continued investment in AI. In their case, it’s to support Industry 5.0 where systems augment and automate human capabilities. They are bullish on the potential, as Rob McAveney shared in a very interesting panel. As Rob explained, they are “expecting a giant leap forward in how products are designed and manufactured.” They shared some tangible examples, including requirements as a service, syndication of digital twins, and continuous design streams, AI-infused engineering, and an AI-driven chatbox hooked up to Aras Innovator. I expect a lot more from this in the coming months.

Summing Up ACE 2024

Aras is unique and comparing Aras Innovator to other PLM systems is comparing apples to oranges. They offer broad capabilities to support the digital thread, but that’s not the end of the story. Manufacturers looking to implement or upgrade PLM should take a look at Aras, if nothing else to understand the difference the “Aras Effect” delivers.

Thank you to Jason Kasper and Kylie Ochab for organizing my visit and setting up some interesting conversations.

[post_title] => “The Aras Effect” was on Display at Aras ACE 2024

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aras-ace-2024

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-01 10:43:18

[post_modified_gmt] => 2024-04-01 14:43:18

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20062

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 20039

[post_author] => 2

[post_date] => 2024-03-27 10:00:06

[post_date_gmt] => 2024-03-27 14:00:06

[post_content] =>

Build with Aras Program Announced at Aras ACE 2024[/caption]

From a customer community perspective, Aras has always fostered an environment where customers share with each other, even sharing customizations. Another example of doing things differently is Aras in the Round. This final session at ACE opens up the floor to all participants to ask anything as VP Leon Lauritsen tosses foam cubes with microphones to the audience. There were some challenging questions, and Roque Martin and Rob McAveney shared candid answers. It’s a unique experience.

Final Notes

There is always too much to cover at these events. As expected, Aras also discussed their continued investment in AI. In their case, it’s to support Industry 5.0 where systems augment and automate human capabilities. They are bullish on the potential, as Rob McAveney shared in a very interesting panel. As Rob explained, they are “expecting a giant leap forward in how products are designed and manufactured.” They shared some tangible examples, including requirements as a service, syndication of digital twins, and continuous design streams, AI-infused engineering, and an AI-driven chatbox hooked up to Aras Innovator. I expect a lot more from this in the coming months.

Summing Up ACE 2024

Aras is unique and comparing Aras Innovator to other PLM systems is comparing apples to oranges. They offer broad capabilities to support the digital thread, but that’s not the end of the story. Manufacturers looking to implement or upgrade PLM should take a look at Aras, if nothing else to understand the difference the “Aras Effect” delivers.

Thank you to Jason Kasper and Kylie Ochab for organizing my visit and setting up some interesting conversations.

[post_title] => “The Aras Effect” was on Display at Aras ACE 2024

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => aras-ace-2024

[to_ping] =>

[pinged] =>

[post_modified] => 2024-04-01 10:43:18

[post_modified_gmt] => 2024-04-01 14:43:18

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20062

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 20039

[post_author] => 2

[post_date] => 2024-03-27 10:00:06

[post_date_gmt] => 2024-03-27 14:00:06

[post_content] =>  How can manufacturers bring the same digital transformation benefits enjoyed by other operational areas to the lab? How can the lab continuously improve and join the digital transformation? We offer five ways to get started.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes BIOVIA (registration required).

How can manufacturers bring the same digital transformation benefits enjoyed by other operational areas to the lab? How can the lab continuously improve and join the digital transformation? We offer five ways to get started.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes BIOVIA (registration required).

Table of Contents

- The Value of an Integrated Lab Environment

- The Five Dimensions of Lab Integration

- People

- Process

- Software

- Hardware

- Data

- Next Steps

- Acknowledgments

Introduction

Chemical Labs are Overdue for Digital Transformation Chemical labs are critical to every aspect of manufacturing, from R&D through scaleup to operations. While manufacturers have continuously improved product quality and manufacturing productivity through continuous improvement and digital transformation, the lab is often left out of these initiatives. That leaves lab managers with a patchwork of solutions and disjointed processes that burden scientists and technicians with non-value-added work. Poorly integrated lab environments take highly trained lab resources away from innovating and slow down product development, product launch, and product release. It's time to get the most out of the lab through continued digital transformation. We've identified five dimensions to measure and improve lab integration to optimize lab operations and enhance overall business performance. These dimensions include better integration between people, process, and technology in the lab, including integration of systems around a common data model. We'll look at each of the dimensions in detail and discuss how taking a platform approach helps achieve them. The Five Dimensions of Lab Integration

People, Process, and Technology

What does it take to integrate and drive better lab – and business – performance? We've identified five focus areas companies can measure and improve against using a continuous improvement approach. You can look at these "dimensions" across a typical, balanced view of people, process, and technology. This framework provides a proven foundation for developing and introducing more mature operations to drive better outcomes.

Any change effort must start with the people involved. For labs, it's critical to get the most out of highly skilled scientists and technicians. They must be motivated, understand their contribution to the greater cause, and be enabled to collaborate to streamline work, data flows, and innovation. Operator data is also critical to creating a complete digital thread of scientific data.

The Five Dimensions of Lab Integration

People, Process, and Technology

What does it take to integrate and drive better lab – and business – performance? We've identified five focus areas companies can measure and improve against using a continuous improvement approach. You can look at these "dimensions" across a typical, balanced view of people, process, and technology. This framework provides a proven foundation for developing and introducing more mature operations to drive better outcomes.

Any change effort must start with the people involved. For labs, it's critical to get the most out of highly skilled scientists and technicians. They must be motivated, understand their contribution to the greater cause, and be enabled to collaborate to streamline work, data flows, and innovation. Operator data is also critical to creating a complete digital thread of scientific data.

This leads to process. Peoples' activities must be standardized and optimized into efficient workflows and analytical methods that get the most out of people's effort and create well-documented, trusted scientific data. Both physical and virtual processes, such as simulations, must be standardized and streamlined.

Segmenting the Technology Dimension

The third, fourth, and fifth areas relate to technology. Technology is too complex and too important to consider a single dimension. We'll look at how integrating software, hardware, and data significantly improves lab productivity, throughput, and value.

Acknowledging Overlaps

Note that there are clear overlaps between these areas. For example, trusted test results rely on hardware readings but also validated analytical methods executed by people with the right permissions and certifications. Despite these inherent overlaps, we try to discuss each without too much overlap to give them the attention they deserve.

This leads to process. Peoples' activities must be standardized and optimized into efficient workflows and analytical methods that get the most out of people's effort and create well-documented, trusted scientific data. Both physical and virtual processes, such as simulations, must be standardized and streamlined.

Segmenting the Technology Dimension

The third, fourth, and fifth areas relate to technology. Technology is too complex and too important to consider a single dimension. We'll look at how integrating software, hardware, and data significantly improves lab productivity, throughput, and value.

Acknowledging Overlaps

Note that there are clear overlaps between these areas. For example, trusted test results rely on hardware readings but also validated analytical methods executed by people with the right permissions and certifications. Despite these inherent overlaps, we try to discuss each without too much overlap to give them the attention they deserve.

Next Steps

Recognize the Opportunity Today's lab environment is ripe for improvement. Most chemical labs’ productivity hasn’t continuously improved on par with other operations in the manufacturing enterprise. There is still too much inefficiency, inability to find and reuse data, and patchworks of solutions. Lack of integration leads to inefficiency, delays, and a lack of agility in the status quo. It's time to digitally transform and integrate the lab across people, process, and technology using a platform approach to speed up the lab and resulting product development, launch, and release. Get Started Ultimately, companies should integrate from ideation to production in the plant, creating a data continuum or digital thread with effective data governance across the product lifecycle. Most companies should start small. It's essential that they understand their starting point by objectively evaluating their capabilities and identifying what must be improved. But, they shouldn’t expect to change everything at once and they don't have to reinvent the wheel; they can reuse existing methods and processes already developed. Further, they can extend these with simple, out-of-the-box methods. Plan for Success Lab managers have to look at increasing integration across people, process, and technology programmatically with an emphasis on data. It's critical to get management support for their effort and communicate the value in business terms. They must also make sure the lab is involved, sees the advantage for them, and feels empowered to make needed changes. It's important to recognize that this is a journey. Effectively updating people, process, and technology takes time. It's OK to start small but have a plan that leads to fully digital, integrated people, processes, and technology to drive speed and accuracy. But it's time to get started. *This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor Dassault Systèmes BIOVIA (registration required). If you have difficulty obtaining a copy of the report, please contact us. [post_title] => 5 Ways to Digitally Transform the Lab [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => lab-integration [to_ping] => [pinged] => [post_modified] => 2024-03-27 10:50:15 [post_modified_gmt] => 2024-03-27 14:50:15 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20039 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [8] => WP_Post Object ( [ID] => 20027 [post_author] => 2574 [post_date] => 2024-03-26 10:00:09 [post_date_gmt] => 2024-03-26 14:00:09 [post_content] => Can smart manufacturing, connectivity, and IoT reduce the tradeoffs of serving customers well? In this blog post, Julie Fraser explains both the importance of moving to smart manufacturing and how connectivity and IIoT support each other in moving a company forward. No company can afford to stay behind - moving to digital approaches is a foundation for success.

To get manufacturers on the road, this blog starts with unpacking the MESA definition of Smart Manufacturing. Fraser then explains the specific roles that industrial IoT (IIoT) and connectivity play, separately and together.

IIoT is a means to capture new data from equipment and processes. An IIoT platform can also put that data into context with other production data, enriching it to then visualize it and turn it into actionable information. This is a complex set of functions, each of which is crucial - but not easy to set up piecemeal.

Connectivity is what allows that data and information to flow where it’s needed, when it’s needed and to the people who need it to make decisions. What is special about industrial connectivity is that much of the data is not in a traditional database or structured format. Sensor data from IoT devices, time-series data from historians, and more can all be part of the data flows.

These two elements come together to enable smart manufacturing. Some of the benefits include agility, cost savings, efficiency, better customer experience, remote troubleshooting, less downtime, and higher product quality. Manufacturers must improve all of these at once.

Having the data you need, easily available and in context is what IIoT and connectivity together can deliver. Smart manufacturing that leverages IIoT and industrial connectivity is a clear path to the future.

Read the full blog post to understand the impact of smart manufacturing connectivity and IoT. Thank you to PTC for the opportunity to express our views here.

[post_title] => Smart Manufacturing and IoT: How Connectivity and IoT Need Each Other for New Manufacturing Insights

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => smart-manufacturing-connectivity-and-iot

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-26 10:19:28

[post_modified_gmt] => 2024-03-26 14:19:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20027

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 20015

[post_author] => 2572

[post_date] => 2024-03-25 11:45:13

[post_date_gmt] => 2024-03-25 15:45:13

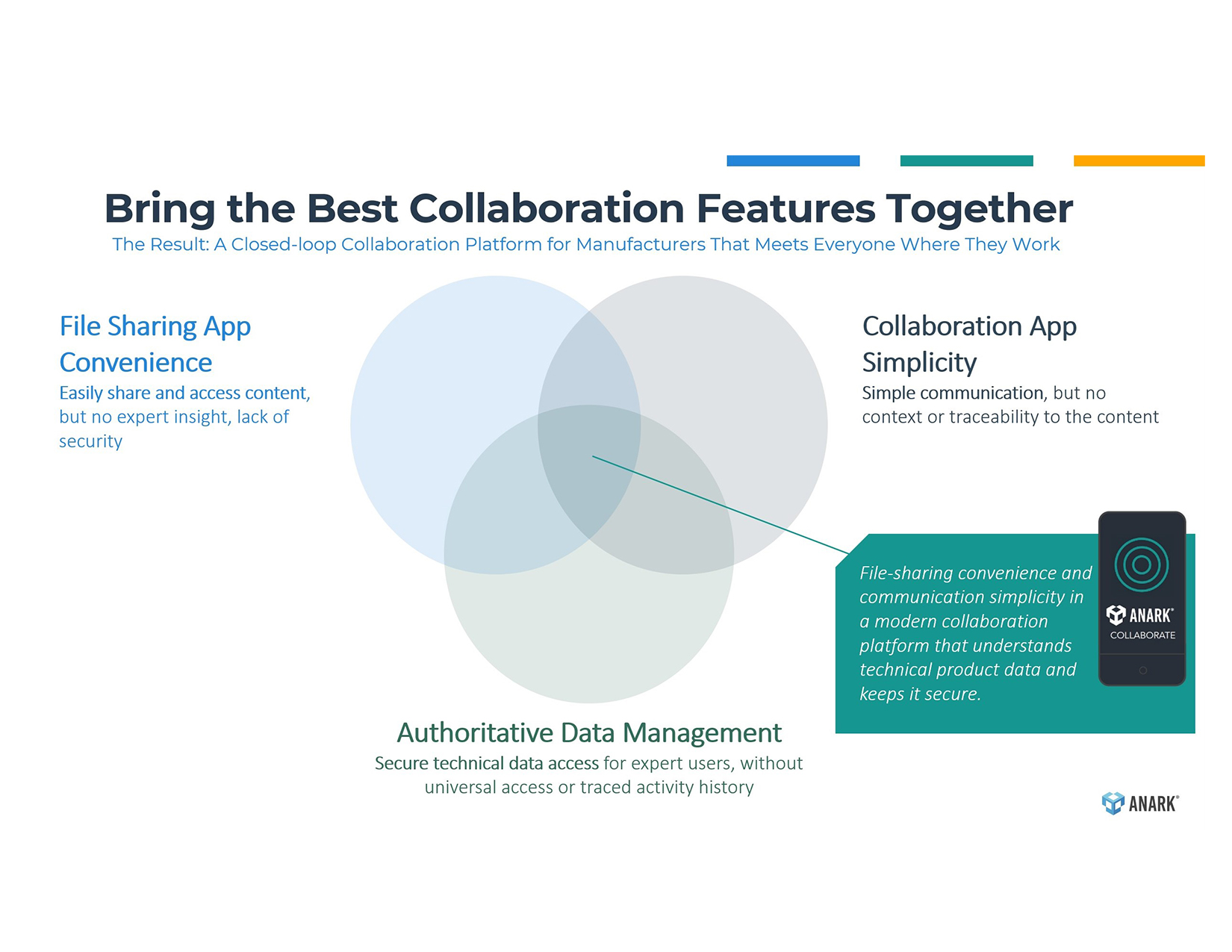

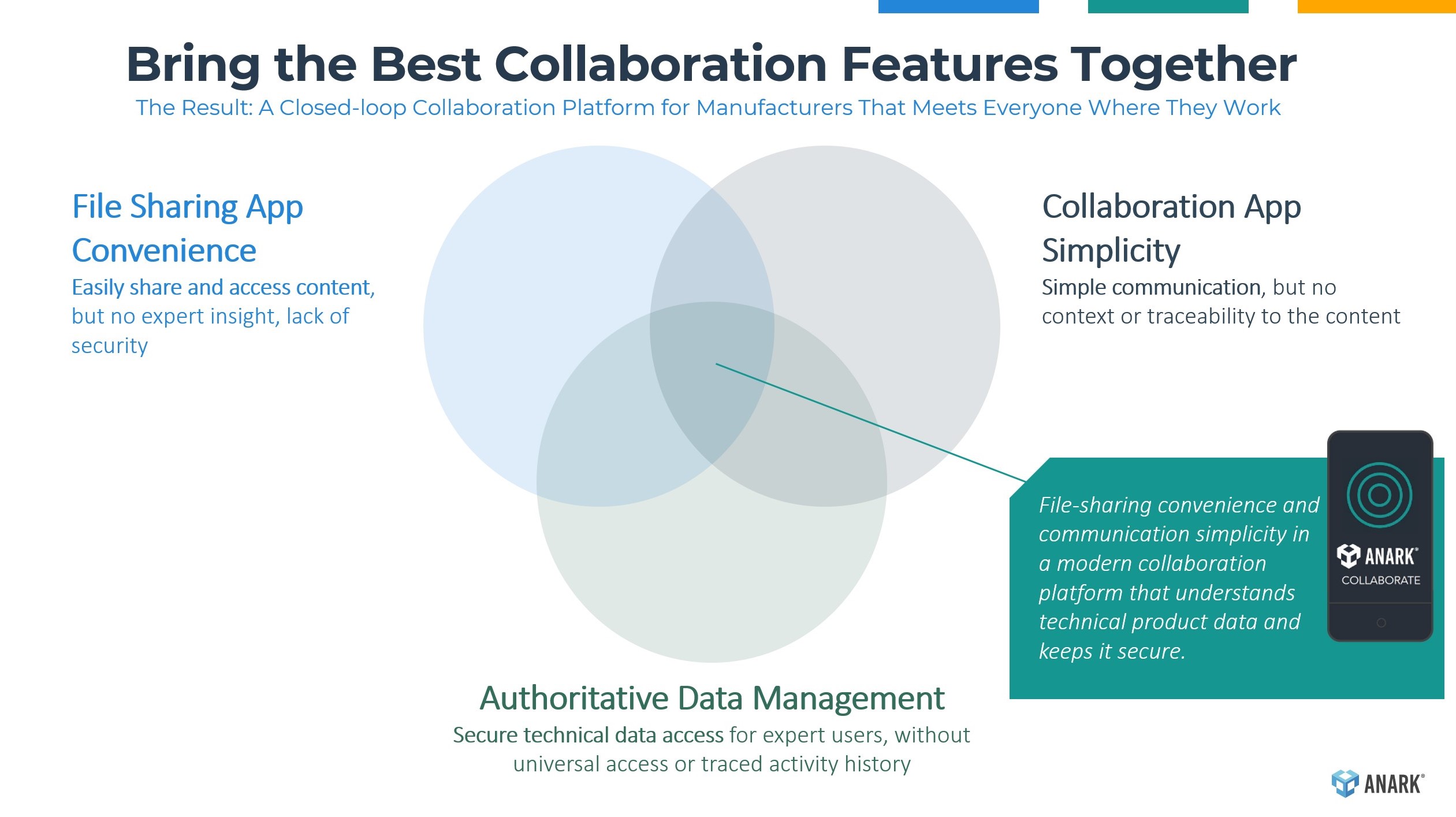

[post_content] => Jim Brown and I had the opportunity to catch up with Anark to get an update. Anark has been serving the engineering and product development community for a long time, starting with their ability to translate and publish 3D visualization data and building that into a collaboration platform for manufacturers, and we wanted to catch up on their progress.

Poor collaboration has been a challenge companies have struggled with for years. In fact, Tech-Clarity's "What's the Cost of Poor Collaboration" finds that an overwhelming 93% of companies need to improve collaboration with different groups. Further, as products become more complex, the need for improved collaboration grows. For example, engineers reported that even for simple products, they collaborate with an average of 21 people and 35 for more complex products. Collaborators include other engineers, manufacturing, suppliers, customers, product managers, and more.

A digital thread can offer significant value by connecting different systems, but it doesn't capture the many communications that happen during product development. Product data is still often siloed in proprietary formats in CAD, PLM, ERP, and other systems, making it difficult to share. Consequently, engineers often share data via email just because it is easier. However, once data is shared via email, the digital thread is broken, and there is no control or visibility if that email is forwarded to anyone else. Not to mention, those communications are lost in email and need references to keep it in context with the product data.

These collaboration issues are particularly challenging when working with third parties. Our research, "How to Reduce Non-Value-Added Work in Engineering," finds that data becomes outdated 29% of the time when working with third parties, resulting in rework, delayed time to market, and excess cost.

Anark is leveraging its history and experience with CAD and PLM integrations to address the collaboration problem. They’ve expanded beyond their early publication approach to help manufacturers, particularly those in discrete manufacturing industries like aerospace, defense, automotive, industrial equipment, and medical device, improve product development. Their goal is to offer an all-in-one collaboration solution for manufacturers that provides the ease of use of a general-purpose collaboration tool, with the security to protect IP, and the ability to put the data in context.

Their integrations and adapters bring together:

Can smart manufacturing, connectivity, and IoT reduce the tradeoffs of serving customers well? In this blog post, Julie Fraser explains both the importance of moving to smart manufacturing and how connectivity and IIoT support each other in moving a company forward. No company can afford to stay behind - moving to digital approaches is a foundation for success.

To get manufacturers on the road, this blog starts with unpacking the MESA definition of Smart Manufacturing. Fraser then explains the specific roles that industrial IoT (IIoT) and connectivity play, separately and together.

IIoT is a means to capture new data from equipment and processes. An IIoT platform can also put that data into context with other production data, enriching it to then visualize it and turn it into actionable information. This is a complex set of functions, each of which is crucial - but not easy to set up piecemeal.

Connectivity is what allows that data and information to flow where it’s needed, when it’s needed and to the people who need it to make decisions. What is special about industrial connectivity is that much of the data is not in a traditional database or structured format. Sensor data from IoT devices, time-series data from historians, and more can all be part of the data flows.

These two elements come together to enable smart manufacturing. Some of the benefits include agility, cost savings, efficiency, better customer experience, remote troubleshooting, less downtime, and higher product quality. Manufacturers must improve all of these at once.

Having the data you need, easily available and in context is what IIoT and connectivity together can deliver. Smart manufacturing that leverages IIoT and industrial connectivity is a clear path to the future.

Read the full blog post to understand the impact of smart manufacturing connectivity and IoT. Thank you to PTC for the opportunity to express our views here.

[post_title] => Smart Manufacturing and IoT: How Connectivity and IoT Need Each Other for New Manufacturing Insights

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => smart-manufacturing-connectivity-and-iot

[to_ping] =>

[pinged] =>

[post_modified] => 2024-03-26 10:19:28

[post_modified_gmt] => 2024-03-26 14:19:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20027

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 20015

[post_author] => 2572

[post_date] => 2024-03-25 11:45:13

[post_date_gmt] => 2024-03-25 15:45:13

[post_content] => Jim Brown and I had the opportunity to catch up with Anark to get an update. Anark has been serving the engineering and product development community for a long time, starting with their ability to translate and publish 3D visualization data and building that into a collaboration platform for manufacturers, and we wanted to catch up on their progress.

Poor collaboration has been a challenge companies have struggled with for years. In fact, Tech-Clarity's "What's the Cost of Poor Collaboration" finds that an overwhelming 93% of companies need to improve collaboration with different groups. Further, as products become more complex, the need for improved collaboration grows. For example, engineers reported that even for simple products, they collaborate with an average of 21 people and 35 for more complex products. Collaborators include other engineers, manufacturing, suppliers, customers, product managers, and more.

A digital thread can offer significant value by connecting different systems, but it doesn't capture the many communications that happen during product development. Product data is still often siloed in proprietary formats in CAD, PLM, ERP, and other systems, making it difficult to share. Consequently, engineers often share data via email just because it is easier. However, once data is shared via email, the digital thread is broken, and there is no control or visibility if that email is forwarded to anyone else. Not to mention, those communications are lost in email and need references to keep it in context with the product data.

These collaboration issues are particularly challenging when working with third parties. Our research, "How to Reduce Non-Value-Added Work in Engineering," finds that data becomes outdated 29% of the time when working with third parties, resulting in rework, delayed time to market, and excess cost.

Anark is leveraging its history and experience with CAD and PLM integrations to address the collaboration problem. They’ve expanded beyond their early publication approach to help manufacturers, particularly those in discrete manufacturing industries like aerospace, defense, automotive, industrial equipment, and medical device, improve product development. Their goal is to offer an all-in-one collaboration solution for manufacturers that provides the ease of use of a general-purpose collaboration tool, with the security to protect IP, and the ability to put the data in context.

Their integrations and adapters bring together:

- Design data 2D & 3D CAD, including advanced MBD support

- PLM, PDM, and other data sources

- Other standard / neutral file formats like STEP, DXF, QIF, XML, and more

- Documents and other non-technical file types

The Anark Product Suite leverages this data foundation with three offerings:

The Anark Product Suite leverages this data foundation with three offerings:

- Anark Collaborate: A mobile-first hosted platform (on-prem or SaaS) that offers collaboration in context, with real-time chat, markup capabilities, and traceability. Team members can share, access, and discuss technical data with markups, notes, pictures, videos and chat.

- Anark Workstation: A desktop solution for engineers and other authors to create recipe-driven technical data packages.