We recently had the opportunity to reconnect with aPriori Technologies, a company we’ve known for years. It has been exciting to watch their solution evolve from a product cost management tool into a comprehensive digital manufacturing intelligence platform. Today, their platform enables improved decision-making across sales, design engineering, sourcing, sustainability, and manufacturing. Who They Are…

- Manufacturing simulation: By modeling real-world processes (machining, molding, casting, additive manufacturing, assembly, etc.), it provides design for manufacturability (DFM) feedback, cycle time estimates, and associated costs and carbon footprint. Detailed cost breakdowns include labor, machine, tooling, and material.

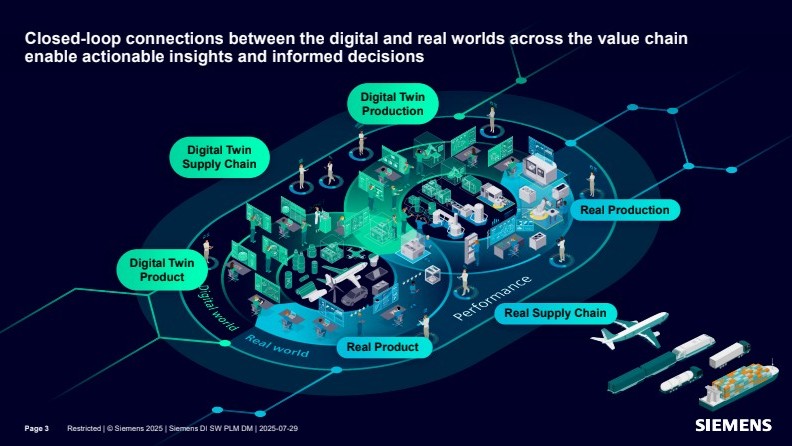

- Integration and enterprise support: It connects with PLM, CAD, and sourcing systems to leverage existing data and automate analysis across parts, assemblies, and entire BOMs.

- Sustainability alongside cost optimization: Users can evaluate carbon footprint and energy consumption in parallel with cost.

- Usability: The platform features a drag-and-drop model import tool, guided process selection, and scenario comparisons, making it convenient for design engineers, cost analysts, and sourcing teams.

What Makes Them Different

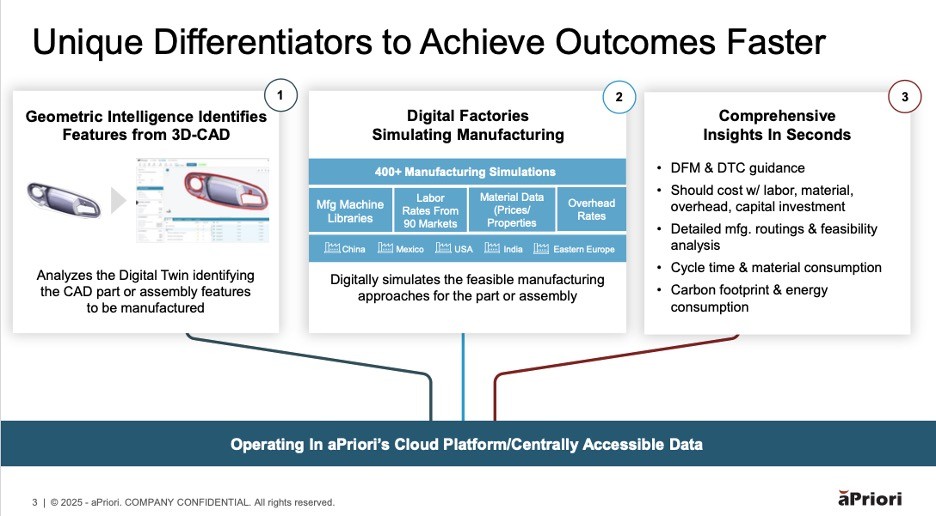

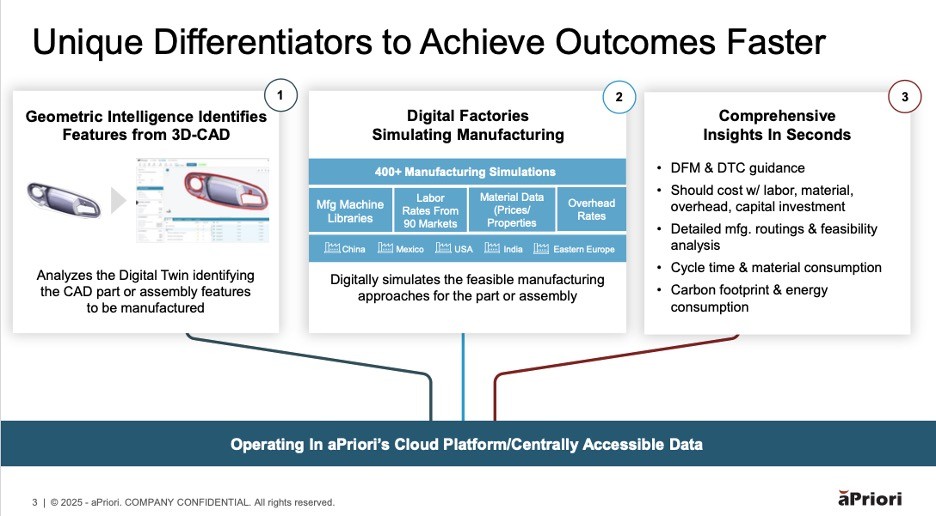

According to aPriori, several factors differentiate their solution:

- Automated insights: Continuous cost, carbon, and DFM governance is available through PLM-triggered analyses and automated alerts for cost or manufacturability exceptions.

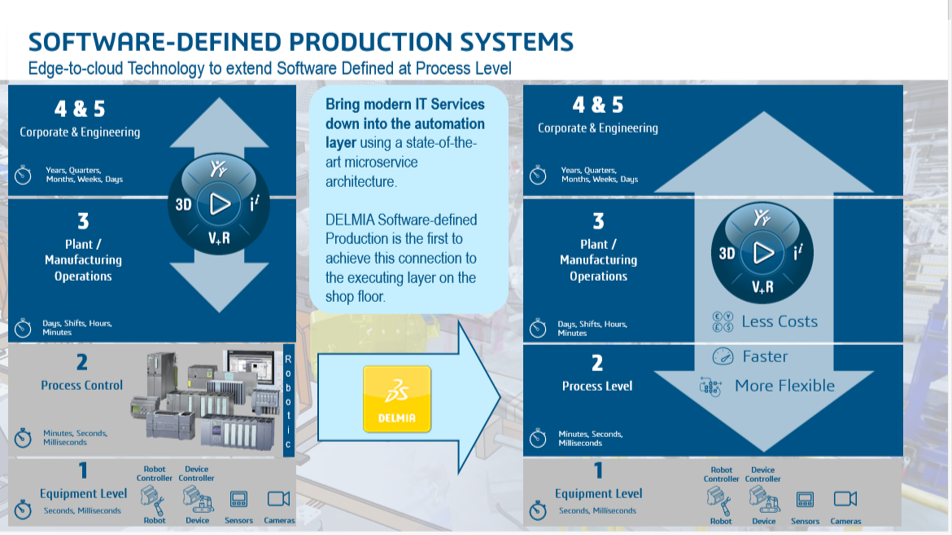

- 3D CAD intelligence interprets geometry to assess manufacturability, cost, and sustainability implications. Design engineers can leverage this intelligence inside CAD.

- Extensive digital factory models offer more than 400 manufacturing simulations, providing insights into potential production approaches.

- Comprehensive feedback encompasses cost, manufacturability, and sustainability, delivering actionable insights, which they say takes only seconds.

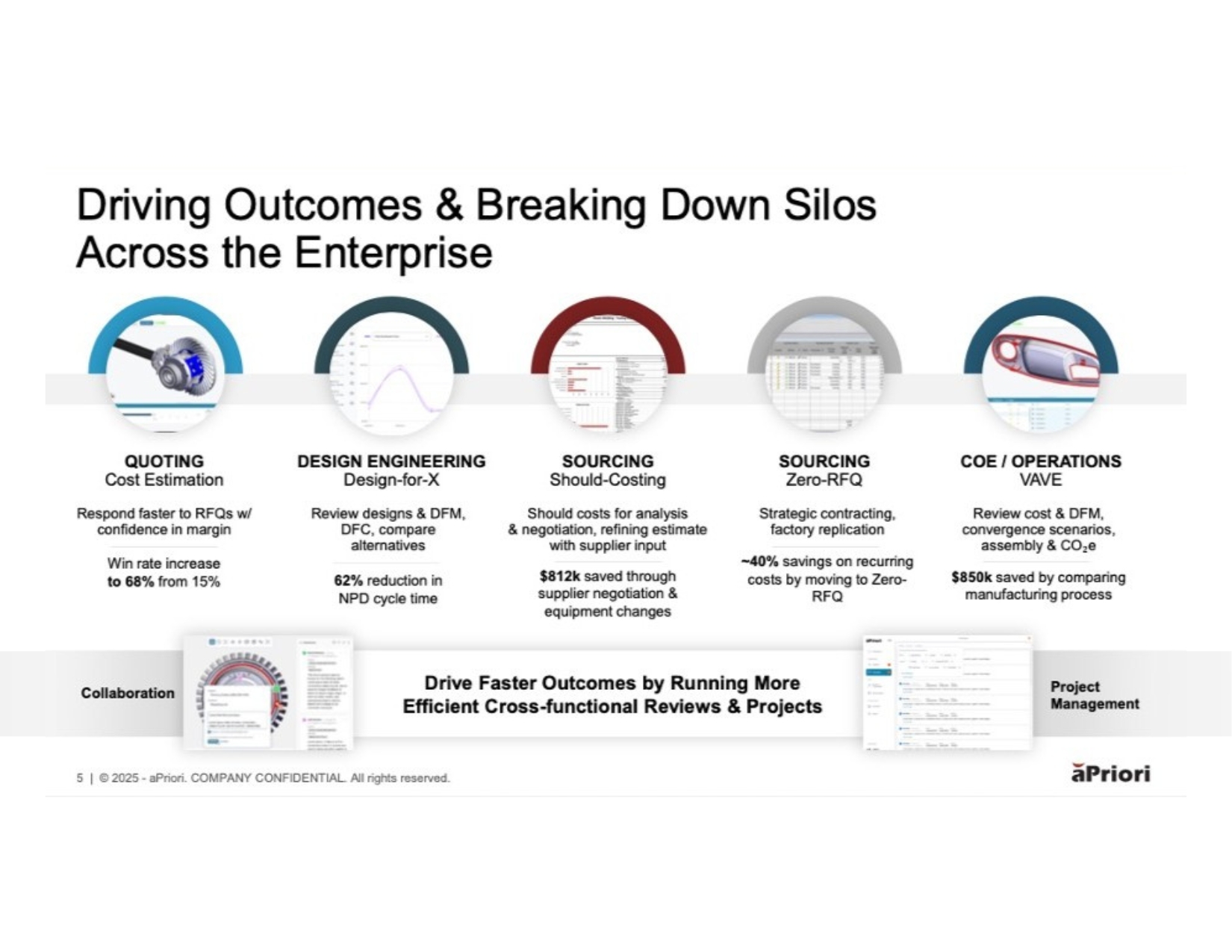

How They Help

aPriori says its customers use the platform to solve three primary challenges:

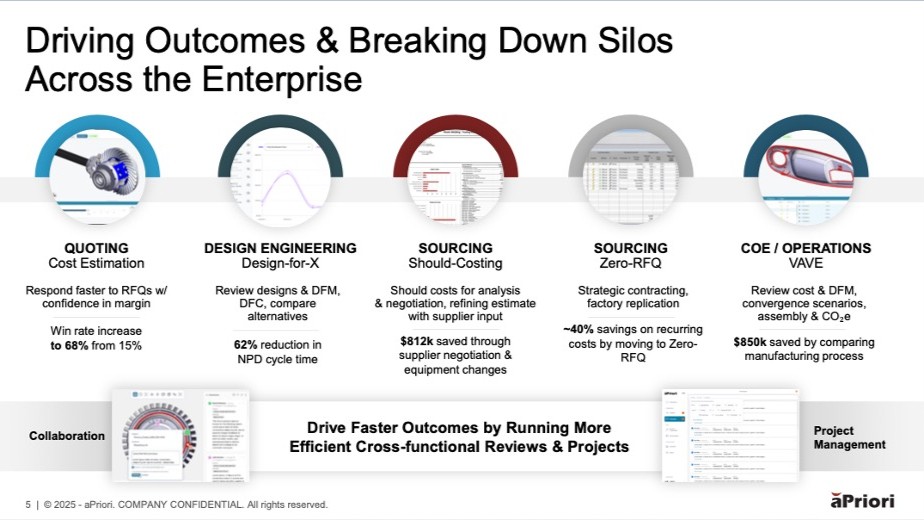

- Improve product margins: Many companies lack the time or resources to analyze cost. With aPriori, they can quickly identify cost drivers. For example, Rivian reduced its BOM cost for the R1 model by 20–25% using aPriori.

- Reduce NPI delays: The late discovery of DFM issues often results in engineering change orders (ECOs), delays, and increased costs. aPriori flags issues like thin walls or improper tolerances early, before tooling or sourcing decisions are made. Dana, a large automotive supplier, achieved 8% cost savings, half of that in the first year, largely through fewer late-stage ECOs.

- Win new business: Accurate cost estimates take time, especially if there isn’t past work to reference; however, the competitive advantage often goes to the supplier who responds first. aPriori can quickly produce accurate quote estimates, accelerating the time to produce a bid. Flex improved its win rate from 15% to 68% by using aPriori to accelerate quoting while protecting margins.

Our Take

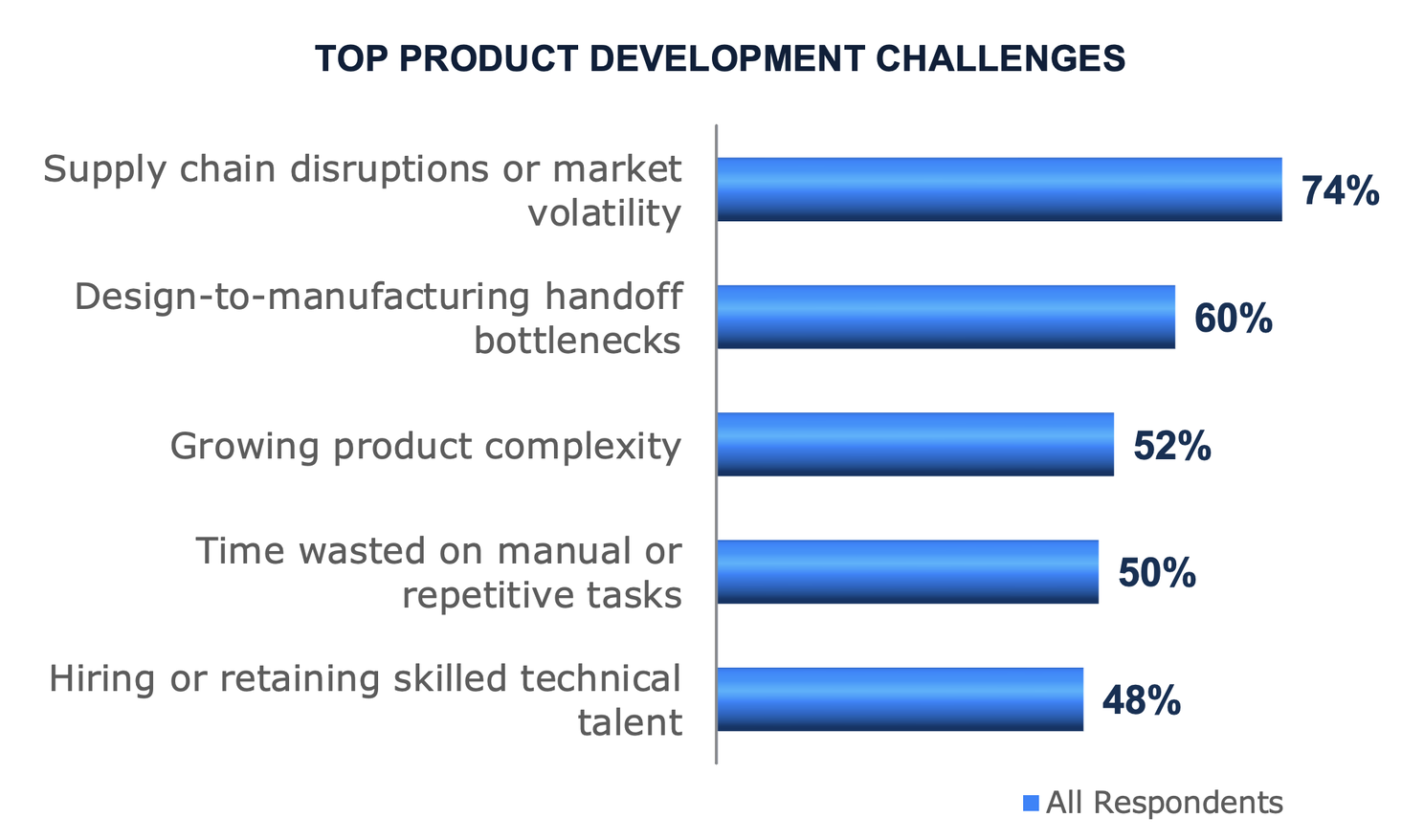

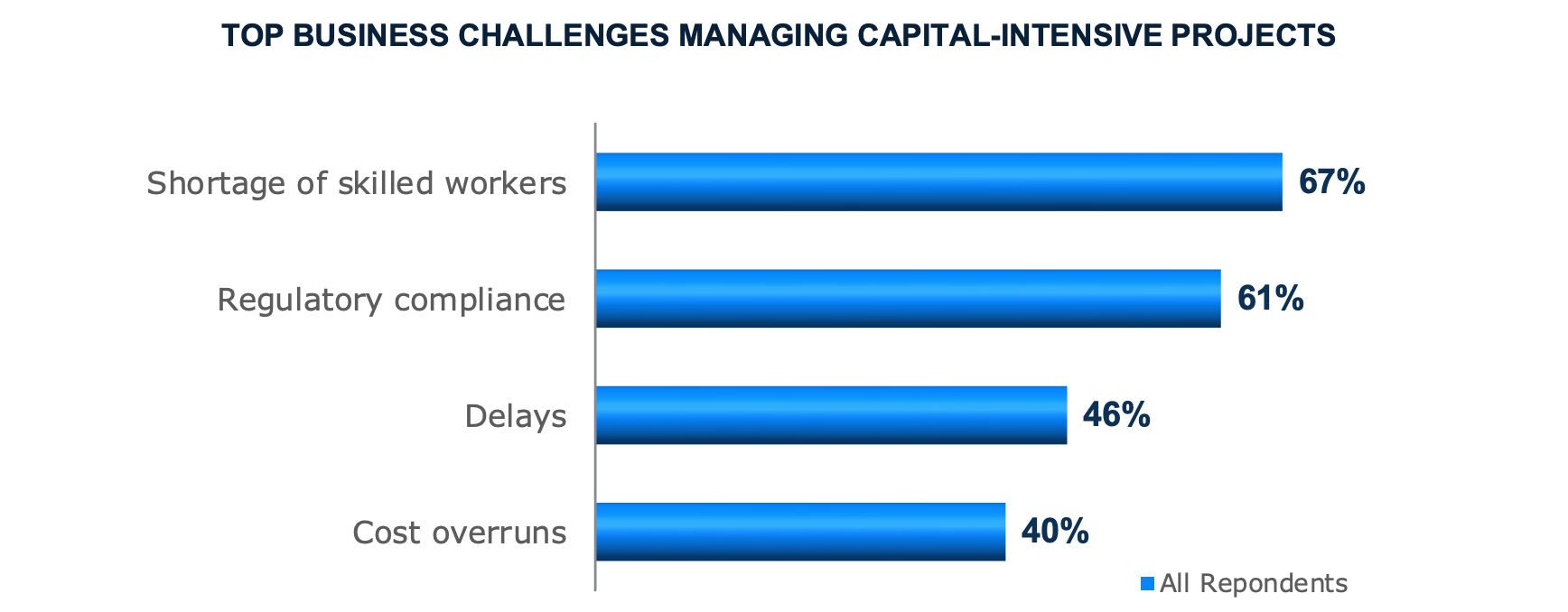

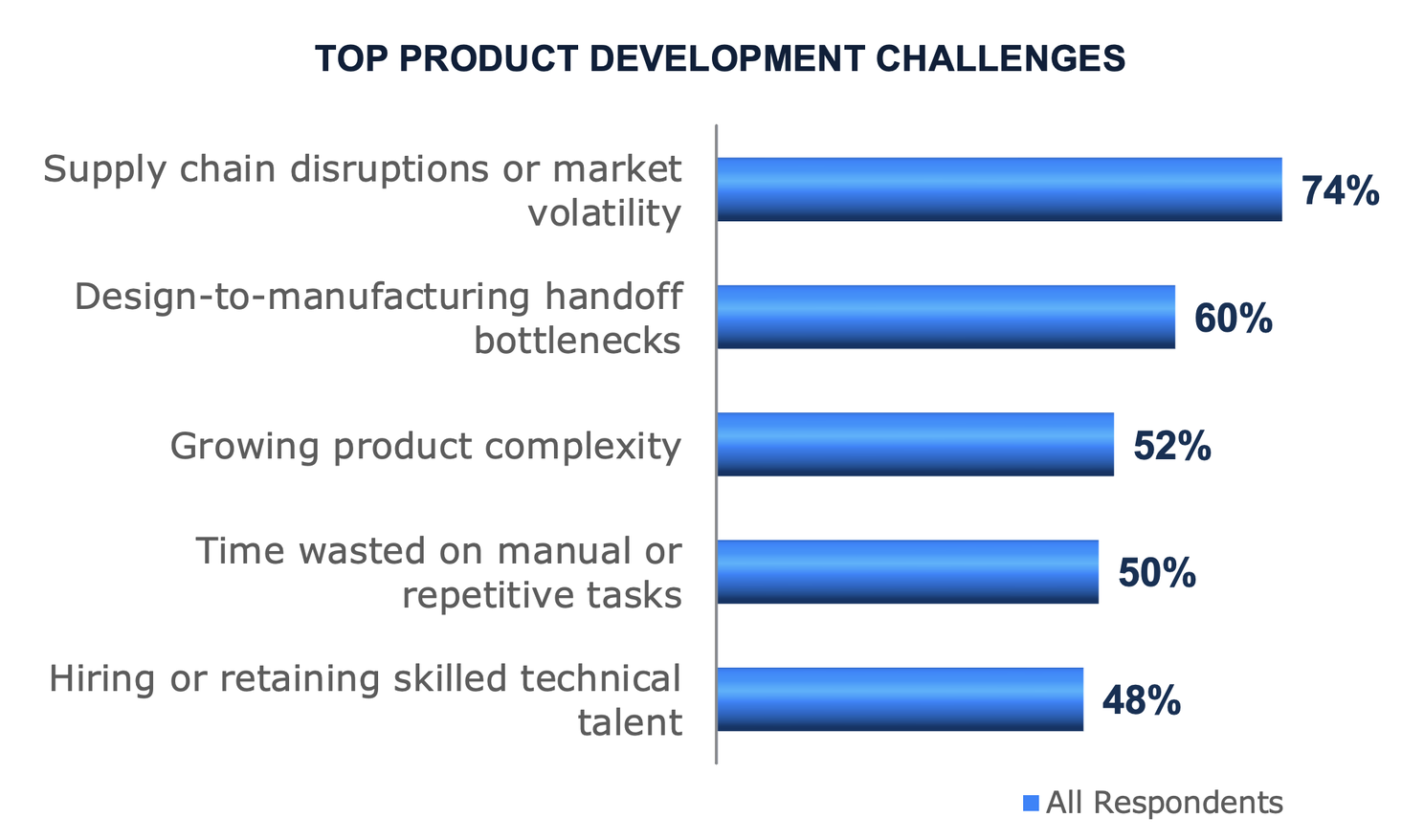

Tech-Clarity’s State of Product Development: 7 Trends Shaping Product Innovation research highlights top challenges facing product development:

- Supply chain disruptions / market volatility

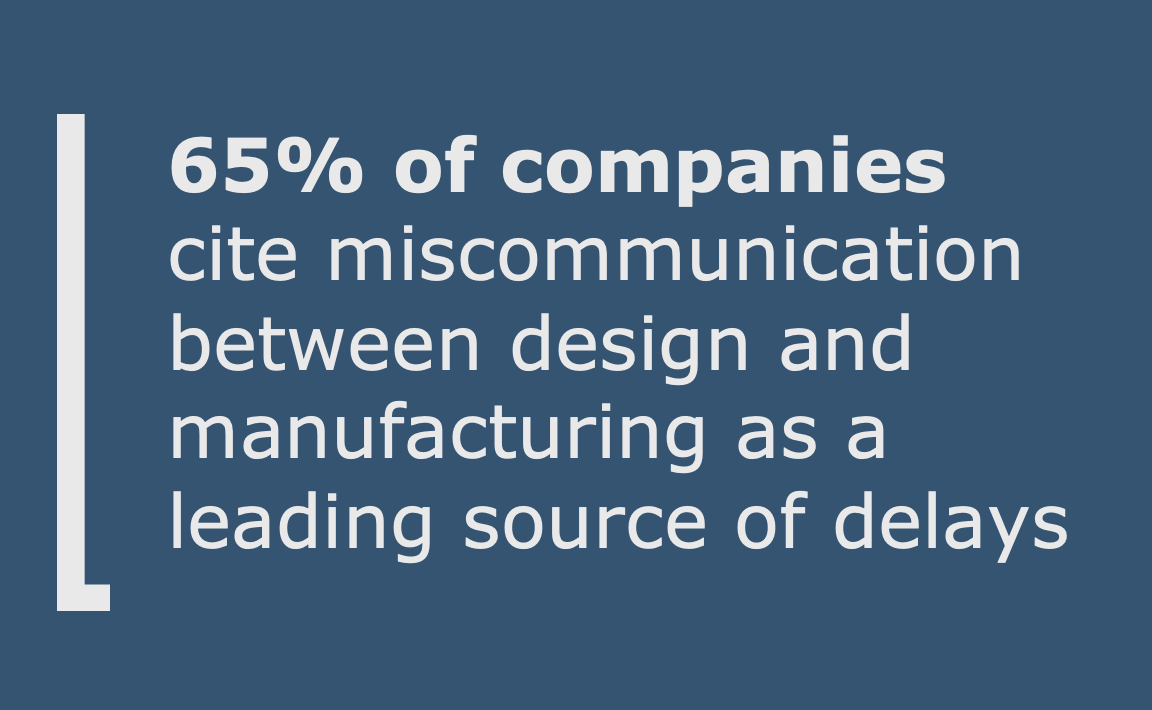

- Design-to-manufacturing handoff bottlenecks

- Growing product complexity

- Time wasted on manual or repetitive tasks

- Difficulty hiring and retaining skilled technical talent

aPriori seems well-positioned to help manufacturers address all of these challenges.

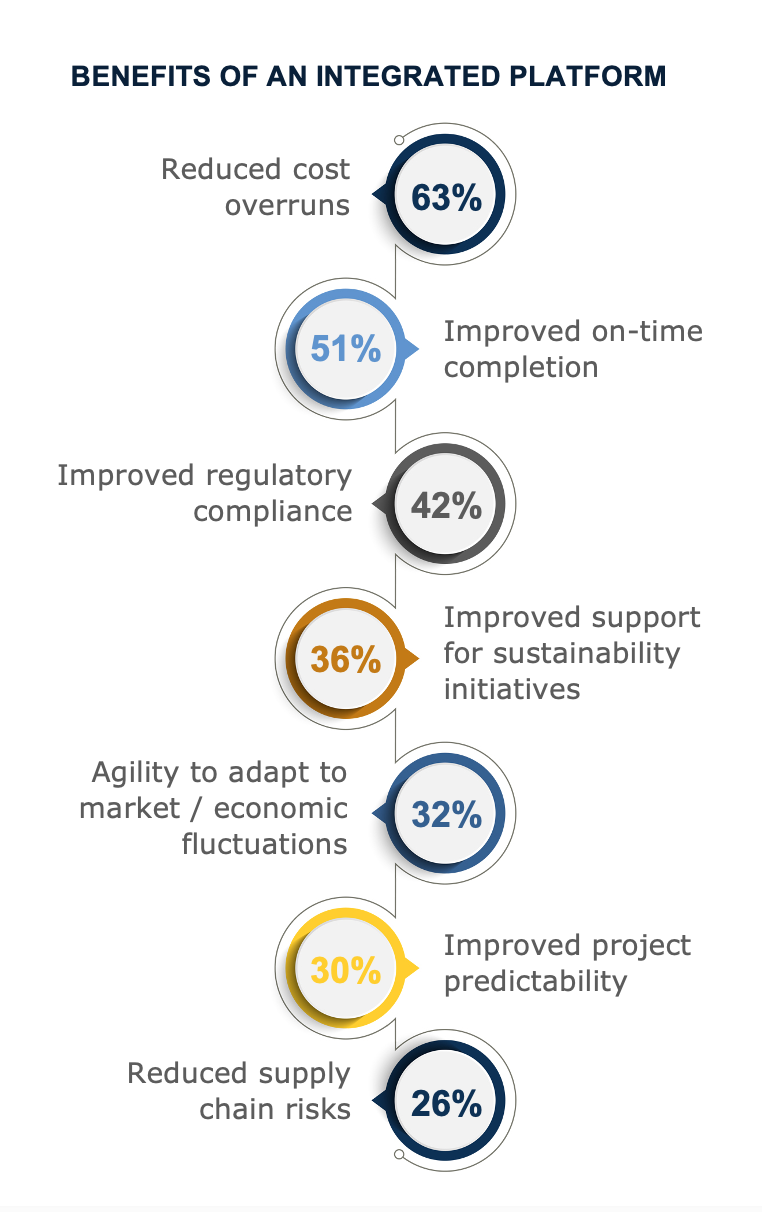

In an era of volatile supply chains and unpredictable costs, predictability in cost and sourcing can be a competitive advantage. aPriori’s ability to model what-if manufacturing scenarios across regions could help. For example, comparing production in China, Vietnam, Germany, Brazil, Mexico, or the US extends its value beyond cost optimization to supply chain resilience and agility. The solution could help hedge against volatility and enable companies to plan and pivot with greater confidence.

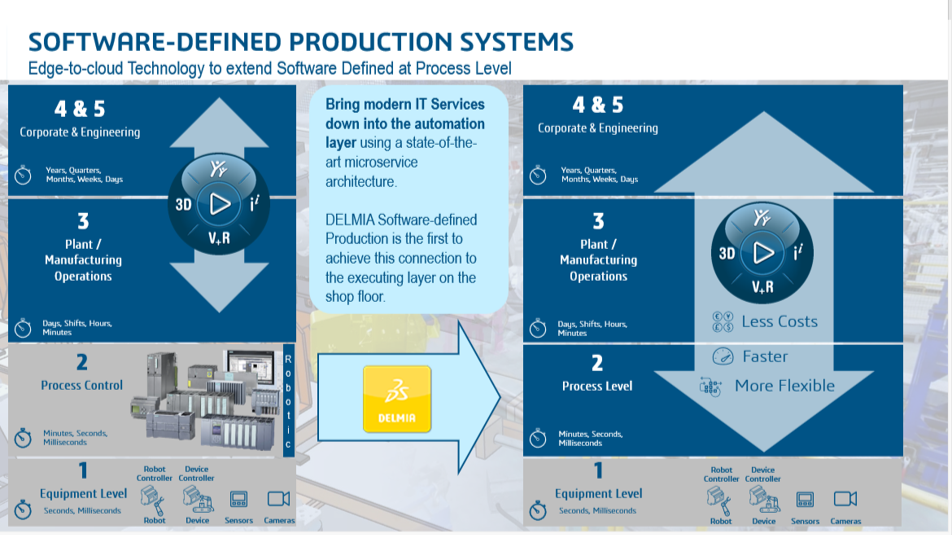

aPriori describes their solution as having a “manufacturing engineer in your pocket,” with its ability to embed process expertise into the product development lifecycle. Not only can this help address bottlenecks in handoffs to manufacturing, but it can also help overcome knowledge loss due to the retirement of experienced engineers. Retirements are eroding decades of tacit knowledge, while many younger engineers have limited shop-floor experience. It can help identify manufacturability issues earlier, despite growing complexity, and automate many manual tasks required to support decision-making on cost, manufacturability, and sustainability.

As younger employees join the workforce, a cultural shift is taking shape. As digital natives, they are adept at using technology for decision-making, rather than relying on years of accumulated experience and rules of thumb. As product complexity increases, decisions will become increasingly difficult, so this new generation will likely accelerate the adoption of intelligent solutions like aPriori to support better-informed decisions.

Given current market trends, aPriori appears well-placed to support manufacturers amid economic change and workforce evolution. The company’s next wave of innovation will center on AI-driven guidance, from sourcing coaches to intelligent DFM assistants, which should build upon their existing capabilities. The appointment of a new CTO with deep AI expertise demonstrates a commitment to this strategy.

We look forward to seeing how these developments further expand aPriori’s role in shaping the future of embedding manufacturing intelligence into the product lifecycle.

Thank You

Thanks to Rick Burke, Chris Jeznach, and Mark Rushton for briefing us.

[post_title] => aPriori Evolves from Product Cost Management to Manufacturing Intelligence Platform [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => apriori [to_ping] => [pinged] => [post_modified] => 2026-02-25 13:47:55 [post_modified_gmt] => 2026-02-25 18:47:55 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23198 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [1] => WP_Post Object ( [ID] => 23169 [post_author] => 2581 [post_date] => 2025-11-19 10:49:52 [post_date_gmt] => 2025-11-19 15:49:52 [post_content] => Is your manufacturing organization ready for AI? In this conversation David J. Jacq, CEO of Mapex, and Rick Franzosa, VP of Research for Manufacturing at Tech-Clarity, Inc., will bring their deep expertise in digital transformation, operations, and advanced manufacturing to explore the challenges and opportunities in smart manufacturing in the age of AI.

Listen as David asks Rick about what companies should prioritize in this fast-changing world. Rick shares his view of top challenges and the evolving perceptions of MES, including when it became more strategic. They also explore MES implementation wisdom, including common mistakes and what companies need to do before an implementation. Even implementation failures come into the session.

They wrap up with a discussion of how AI has changed the role of MES – shallow or deep? Is AI a differentiating factor for MES already? How to avoid false starts when adding AI to MES. And a look ahead at what industrial companies should be doing now to prepare their operations for unknown future realities. Watch the full video podcast here.

[post_title] => Inaugural Mapex International Smart Industry Podcast on Digital Manufacturing and AI

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => smart-industry-podcast-on-digital-manufacturing-and-ai

[to_ping] =>

[pinged] =>

[post_modified] => 2025-11-19 10:52:06

[post_modified_gmt] => 2025-11-19 15:52:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=23169

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 23181

[post_author] => 2574

[post_date] => 2025-11-18 10:42:49

[post_date_gmt] => 2025-11-18 15:42:49

[post_content] =>

Is your manufacturing organization ready for AI? In this conversation David J. Jacq, CEO of Mapex, and Rick Franzosa, VP of Research for Manufacturing at Tech-Clarity, Inc., will bring their deep expertise in digital transformation, operations, and advanced manufacturing to explore the challenges and opportunities in smart manufacturing in the age of AI.

Listen as David asks Rick about what companies should prioritize in this fast-changing world. Rick shares his view of top challenges and the evolving perceptions of MES, including when it became more strategic. They also explore MES implementation wisdom, including common mistakes and what companies need to do before an implementation. Even implementation failures come into the session.

They wrap up with a discussion of how AI has changed the role of MES – shallow or deep? Is AI a differentiating factor for MES already? How to avoid false starts when adding AI to MES. And a look ahead at what industrial companies should be doing now to prepare their operations for unknown future realities. Watch the full video podcast here.

[post_title] => Inaugural Mapex International Smart Industry Podcast on Digital Manufacturing and AI

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => smart-industry-podcast-on-digital-manufacturing-and-ai

[to_ping] =>

[pinged] =>

[post_modified] => 2025-11-19 10:52:06

[post_modified_gmt] => 2025-11-19 15:52:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=23169

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[2] => WP_Post Object

(

[ID] => 23181

[post_author] => 2574

[post_date] => 2025-11-18 10:42:49

[post_date_gmt] => 2025-11-18 15:42:49

[post_content] =>

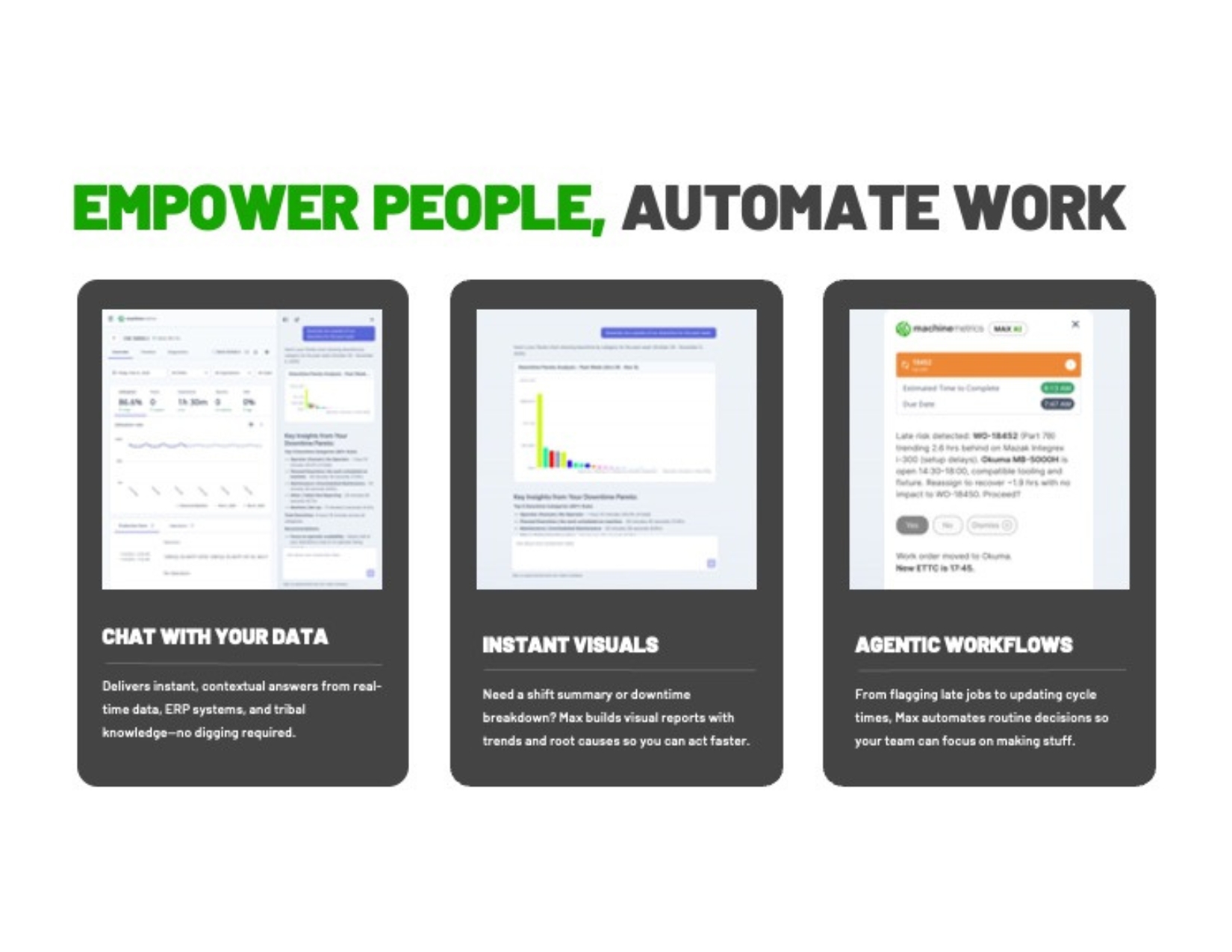

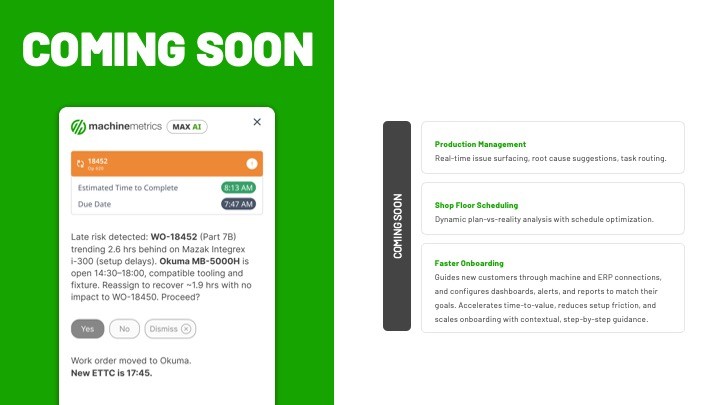

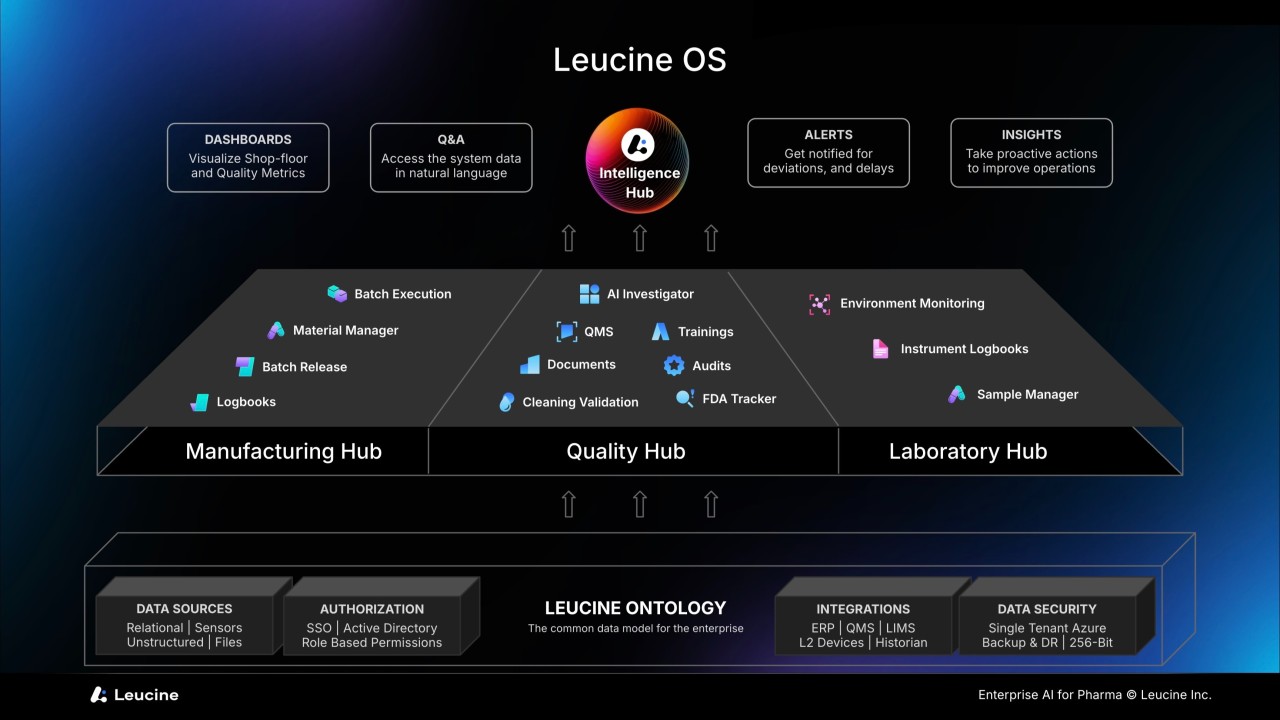

Once you have machine monitoring, MES, and scheduling on a common plant data model, how can you improve the ability to automate and execute the work? MachineMetrics is doing that by adding Max AI. While the company started in machine performance monitoring, this year it has expanded to focus on plant performance and frontline worker performance (See previous insight). This comprehensive plant data set, which can also encompass multiple plants, serves as the foundation for Max AI.

Agentic Execution

Can you un-tribalize knowledge? This is how MachineMetrics aims to tackle the frontline skills shortage challenge. They are creating a fleet of agentic digital coworkers as part of the Max AI addition. These agents have full access to the unified data model, so they know what’s happening and when, as well as who needs what data at any given moment.

Like a good expert coworker, the human workers can engage with these digital coworkers using natural language prompts. The system can find data, provide quick responses to questions, adjust and direct, or even automate core production tasks. It can also create a software widget for ongoing use for issues that arise on a regular basis.

One example of a specific agent is for shift note handoffs. The agent can automate the basics, since it has access to the full record for that shift, and operators can augment that with their own annotations. Another is for Continuous Improvement (CI), and the analysis capabilities of Max AI can help everyone be involved. The CI agent can greatly speed up data analysis and understanding, allowing people to focus their efforts where they will make the most impact on performance.

Configure the UX

Digital coworkers are great, and people also need all elements of their experience with MES to be intuitive and match their expectations and specific job needs. MachineMetrics claims all screens are now configurable. A widget framework for building the UI enables drag-and-drop and adjustable customization to tailor screens so they truly support users. With the LLM-based capabilities of Max AI, customers can add a summary to a dashboard.

They claim some of this can replace Power BI and other data analysis and visualization tools for customers. A significant upgrade in functional scope this year has enabled MachineMetrics to be a more comprehensive single platform for the frontline than it was before. MES, scheduling, analytics, and data from connected machines and other software feeds any needed data through this single interface.

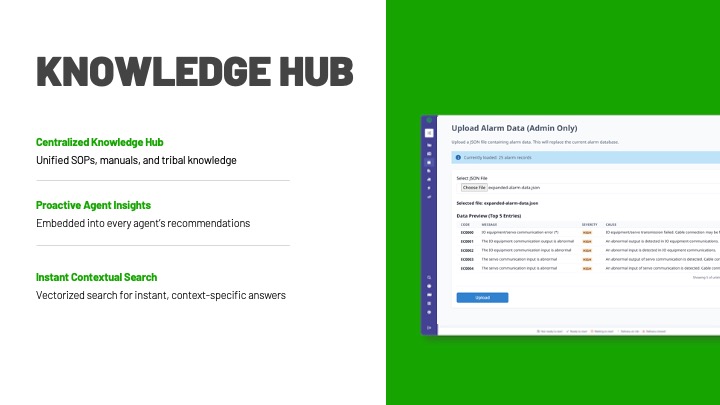

Beyond the unified data model, the software now also features a Knowledge Hub, where manufacturers can upload and centralize any knowledge they need. MachineMetrics has already uploaded thousands of machine manuals. Customers can provide work instructions and SOPs, safety and hazardous materials information, and generate documents based on experienced and skilled workers’ knowledge on any topic.

Even snippets from these experts can contribute to success if they leave or retire. For example, each machine may have a different impact when it’s down. The experts know whether a 10-minute downtime is important to address or not; when a particular vibrational pattern is likely to lead to a downtime event, and more.

All of this expert knowledge in a central location can be beneficial, as anyone who searches for the data they need to act knows. The Knowledge Hub is also part of what agents use to make recommendations.

The Knowledge Hub augments the rich set of data models, time-series data stores, vector and graph databases, and APIs. All of this builds on the original connectivity through APIs that got MachineMetrics its start.

What’s Next

MachineMetrics plans to release new agents soon. The shift handoff agent is scheduled to launch in 2025. After that, in early 2026, an agent to automate scheduling is due. The goal is to change behavior for operators and other manufacturing and production support staff.

The team believes that frontline workers require an easy, intuitive user experience, with access to the real-time data they need. This encompasses not just the task at hand, but also improving it and solving problems.

An onboarding agent aims to improve the implementation and rollout of this young MES. The company has already structured itself for long-term customer relationships in a land-and-expand manner. They have three main teams: Commercial, Product, and Technical Solutions that provide implementation.

Our Take

MachineMetrics is rapidly making the transition from its machine monitoring roots to MES and an industrial data management system. While some of the core MES functionality is just coming online, the data structures and AI approach seem solid. These, along with the existing customer relationships, will form the foundation for continued growth and delivering value to customers.

Discrete manufacturers seeking a rapid approach to get up and running, both to keep equipment humming and empower operators, may find MachineMetrics worth exploring. Current customers are the focus, and they have reason to celebrate the rapid expansion of functionality and AI capabilities.

Thank you, Graham Immerman and Rutherford Wilson, for updating Rick Franzosa and Julie Fraser on Max AI and MachineMetrics’ progress in the market.

[post_title] => MachineMetrics Launches Max AI to Augment its MES [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => adding-ai-to-mes [to_ping] => [pinged] => [post_modified] => 2025-11-21 10:42:59 [post_modified_gmt] => 2025-11-21 15:42:59 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23181 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [3] => WP_Post Object ( [ID] => 23150 [post_author] => 2581 [post_date] => 2025-11-10 21:17:11 [post_date_gmt] => 2025-11-11 02:17:11 [post_content] => The market for MES in mid-sized manufacturers has traditionally been underserved. Major MES vendors find it unsuitable, as it conflicts with their direct sales model and complex product offerings. However, mid-sized manufacturers have the same MES needs as larger companies but lack the IT resources necessary to implement and support these systems.

The market for MES in mid-sized manufacturers has traditionally been underserved. Major MES vendors find it unsuitable, as it conflicts with their direct sales model and complex product offerings. However, mid-sized manufacturers have the same MES needs as larger companies but lack the IT resources necessary to implement and support these systems.

Decades of Service to Discrete Manufacturers

ISE has provided MES and paperless shop floor solutions for forty years through its MV2 MES solution. It has been proven to excel at understanding and addressing the needs of mid-market discrete manufacturers. The combination of customer satisfaction, recommendations, and ISE’s longevity suggests it’s delivering to customer needs. Topping the list of differentiators is ease of use, which was evident in its demonstration.

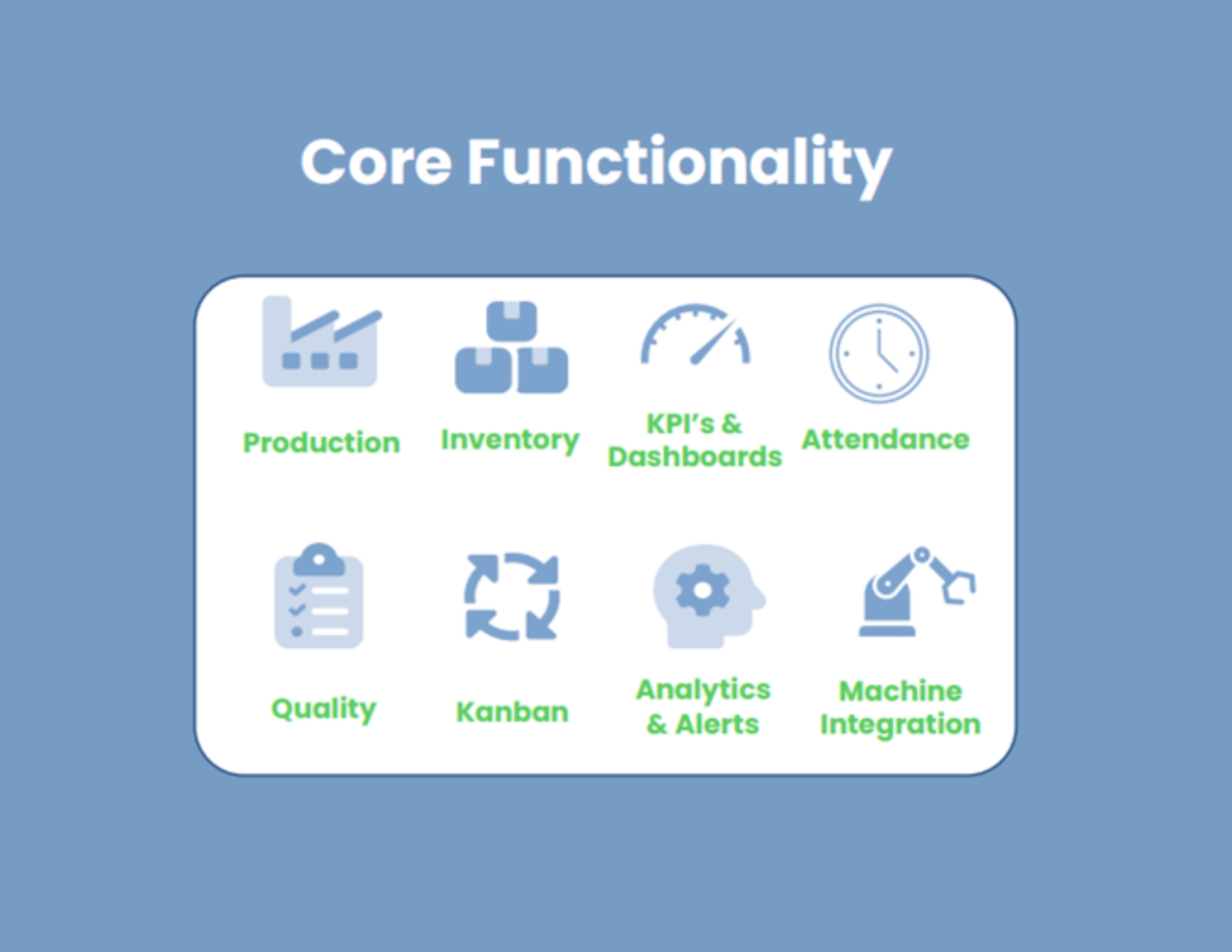

Broad-based Standard Functionality

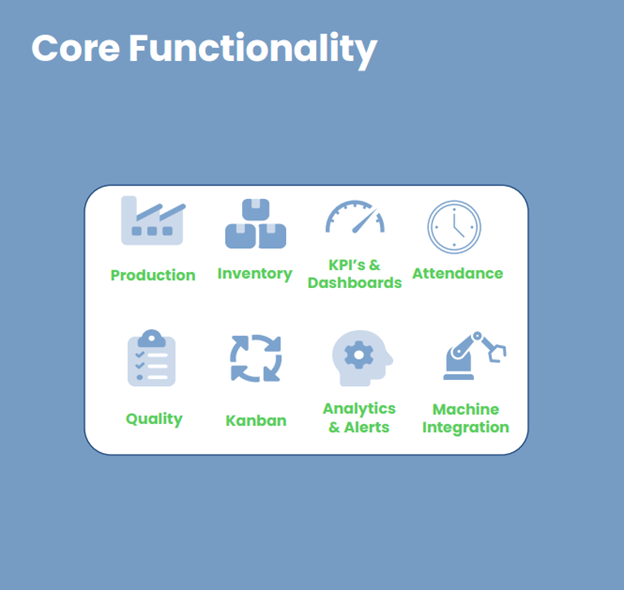

The MV2 product's broad-based standard functionality encompasses essential MES features, including production scheduling and execution, quality management, inventory control, time and attendance, Kanban, machine integration, and real-time analytics. These tools are specifically designed to meet the needs of mid-sized discrete manufacturers, ensuring cost-effective implementation and operational efficiency. Its MV2 platform is positioned as a flexible and scalable solution for a diverse range of discrete manufacturing environments, with a breadth of functionality that matches and, in some cases, exceeds that of enterprise-scale MES solutions.

Expanded ERP Support

ISE has been providing solutions to discrete manufacturing industries, with a focus on the unique challenges faced by mid-sized manufacturers in this market. The company was established to complement and integrate with what is now the Infor XA ERP system. More recently, ISE added standard ERP integration to Microsoft Dynamics 365 Business Central. Through its open architecture and API integration toolkit, MV2 has been integrated with other ERP systems such as SAP and Epicor Kinetic.

Focused on Results

I had the pleasure of attending ISE’s Manufacturing Optimization Forum event on September 25, 2025. The event included a panel session featuring four customers who shared their experiences and the benefits they realized from MV2. Some highlights I heard include:

- Simplicity & User Adoption: Customers highlighted how MV2’s straightforward interface allows users to quickly learn the solution and adopt it in their production facilities. They also reported that it is easily tailored to fit business needs without requiring someone with strong IT skills.

- Cultural transformation: Customers said that MV2 is fostering a mindset of continuous improvement and empowering their shop floor teams to drive change.

- Efficiency gains: There were reports of a significant reduction in manual data entry with MV2, helping to enable proactive management. One customer reportedly eliminated 20 hours a week spent manually keying in data.

- Inventory Accuracy: One customer went from 70% data accuracy to averaging 90% accuracy over the past two years. Another touted the elimination of their annual physical inventory by achieving 95% daily accuracy on their cycle counts with MV2.

- Data-driven decisions: Customers reported increased accuracy in quoting, pricing, and labor cost analysis due to accurate production data in MV2.

Looking Forward

The evolution of MV2 is centered around three main pillars: scalability, interoperability, and user-centric design. Scalability ensures the MV2 product can grow alongside its customers' operations, accommodating increasing complexity without compromising performance. Interoperability focuses on seamless integration with other enterprise software systems, ensuring adaptability to different technological ecosystems. Ultimately, the user-centric approach prioritizes intuitive interfaces and streamlined processes, enabling manufacturers to optimize efficiency with minimal training and support requirements. Together, these pillars form the foundation for ISE's vision of delivering its comprehensive MV2 MES solution tailored to the distinct needs of smaller manufacturers.

Thanks to Jay Gentle, Erin Bonde, Chris McLean, Dan Van Kempen, Jim Rozewicz, and Rick Reith at ISE for catching us up on the latest news.

[post_title] => ISE MV2 Provides MES Functionality for an Underserved Market [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => ise-mv2 [to_ping] => [pinged] => [post_modified] => 2025-11-11 21:17:26 [post_modified_gmt] => 2025-11-12 02:17:26 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23150 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 23136 [post_author] => 2582 [post_date] => 2025-11-07 12:00:27 [post_date_gmt] => 2025-11-07 17:00:27 [post_content] =>Software Components and AI

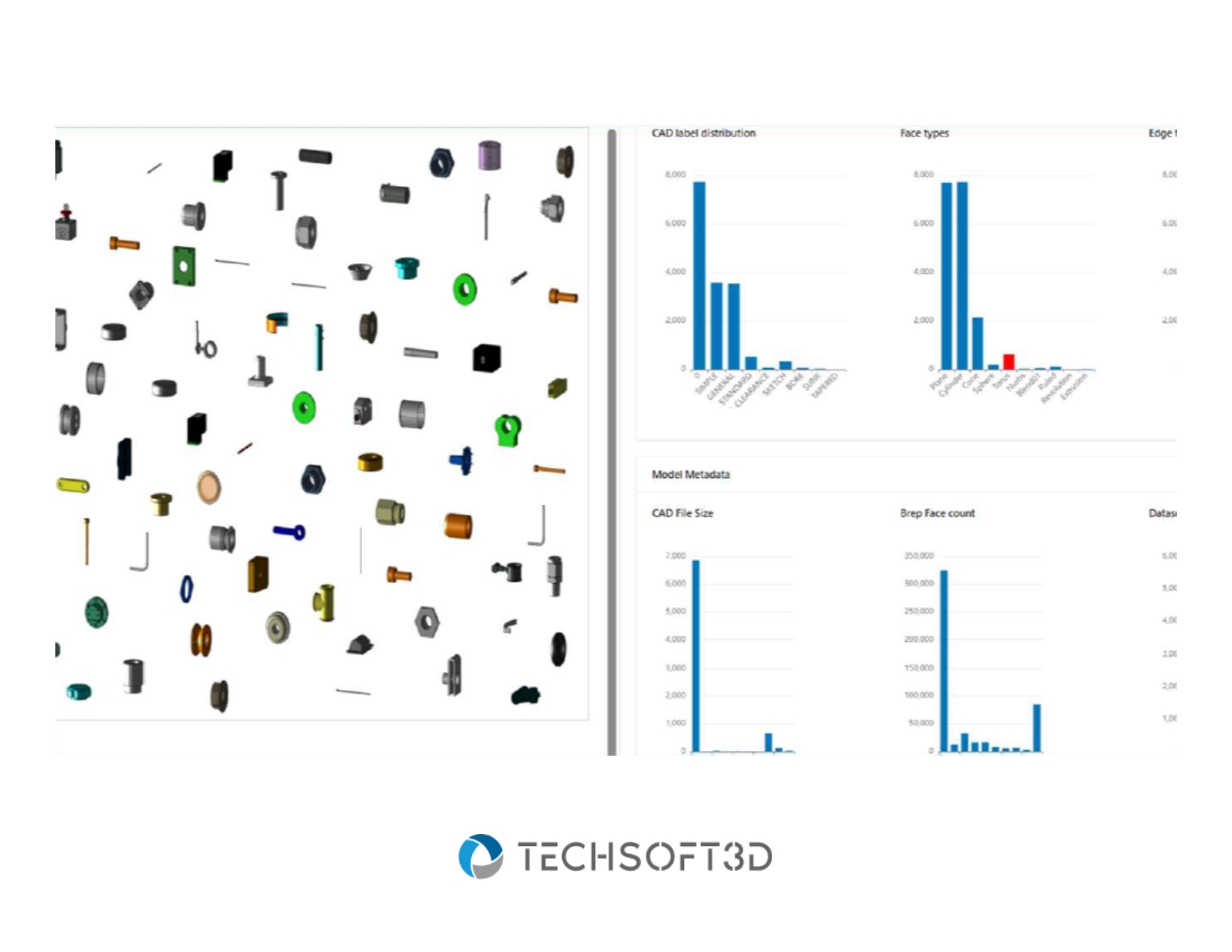

Developing 3D engineering applications is seldom fast or easy. One way to ease development is to use commercially available software components. Software components are developer toolkits that provide standard application capabilities such as modeling, visualization, and data exchange. By using components, development resources can focus on the secret sauce that makes their application more valuable, different, or better at solving end-user challenges.

Today, it seems every application must include AI. Not only does AI enable unique, modern, and highly useful capabilities for companies doing internal software development, but it has also become table stakes for new applications entering the market. AI-enabled functionality will differ across applications. However, software components could provide some fundamental frameworks for AI development. Enter HOOPS AI.

Preview of HOOPS AI

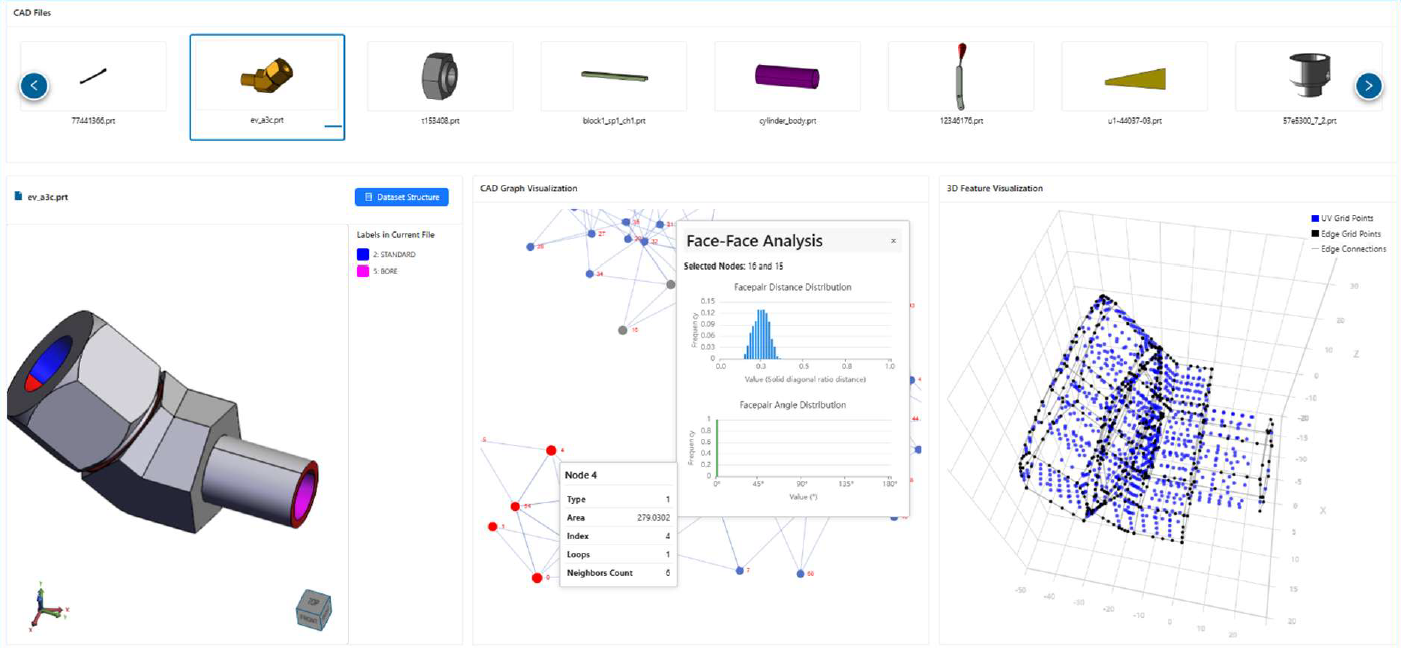

Recently, Jonathan Girroir from Tech Soft 3D gave us a preview of HOOPS AI, a framework to help developers jumpstart their AI development. HOOPS AI is a set of tools built on top of HOOPS Exchange that support machine learning and AI research and development. Rich data sources are at the heart of machine learning. As a long-term provider of data interoperability tools, Tech Soft 3D toolkits process a robust set of translators that can provide rich engineering data to feed machine learning models. HOOPS AI can be used to clean, segment, and organize CAD data. This framework has the potential to quickly allow developers to build their own unique ML workflows.

Unlike typical text-based datasets for LLMs, HOOPS AI works with 3D engineering data such as surface geometry (B-rep), topology, metadata, and assembly relationships. HOOPS AI converts this data into machine-learning formats and connects to popular ML libraries. The machine learning framework includes additional tools for recording, storing, and optimizing workflows.

It should be noted that users of HOOPS AI will need to have their own training data. Tech Soft 3D provides an application development framework for connecting this data to ML algorithms. Tech Soft 3D does not have direct access to this data.

While the toolkit applies across a wide variety of applications and industries, Tech Soft 3D is currently focusing on early adopters in manufacturing, including internal development teams and commercial software vendors.

Our Take

Large independent software vendors likely have the data and resources to accomplish what Tech Soft 3D provides on their own; however, small to medium-sized companies with limited resources and data may find HOOPS AI to be a way to jumpstart their AI-enabled application development. Of course, it takes time for applications to leverage new toolkits and incorporate software components into their offerings. It will be fascinating to see the AI-enabled applications and corresponding capabilities that emerge leveraging HOOPS AI.

Thank you, Charrise Dalton, Fiona Minchella, and Jonathan for the briefing on HOOPS AI!

[post_title] => Tech Soft 3D Introduces HOOPS AI for Accelerated AI Adoption [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => hoops-ai-for-accelerated-ai-adoption [to_ping] => [pinged] => [post_modified] => 2025-11-11 21:19:26 [post_modified_gmt] => 2025-11-12 02:19:26 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23136 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [5] => WP_Post Object ( [ID] => 23126 [post_author] => 2574 [post_date] => 2025-11-06 21:00:51 [post_date_gmt] => 2025-11-07 02:00:51 [post_content] => Once you have a digital twin of a plant that includes predictive and prescriptive AI capabilities, how could you improve it? TwinThread is doing that by adding genAI and agentic AI in Advisor to help accelerate model interpretation, as well as a new solution aptly named Perfect Centerline to help manage and stabilize the process effectively. These can both improve time-to-value for customers.

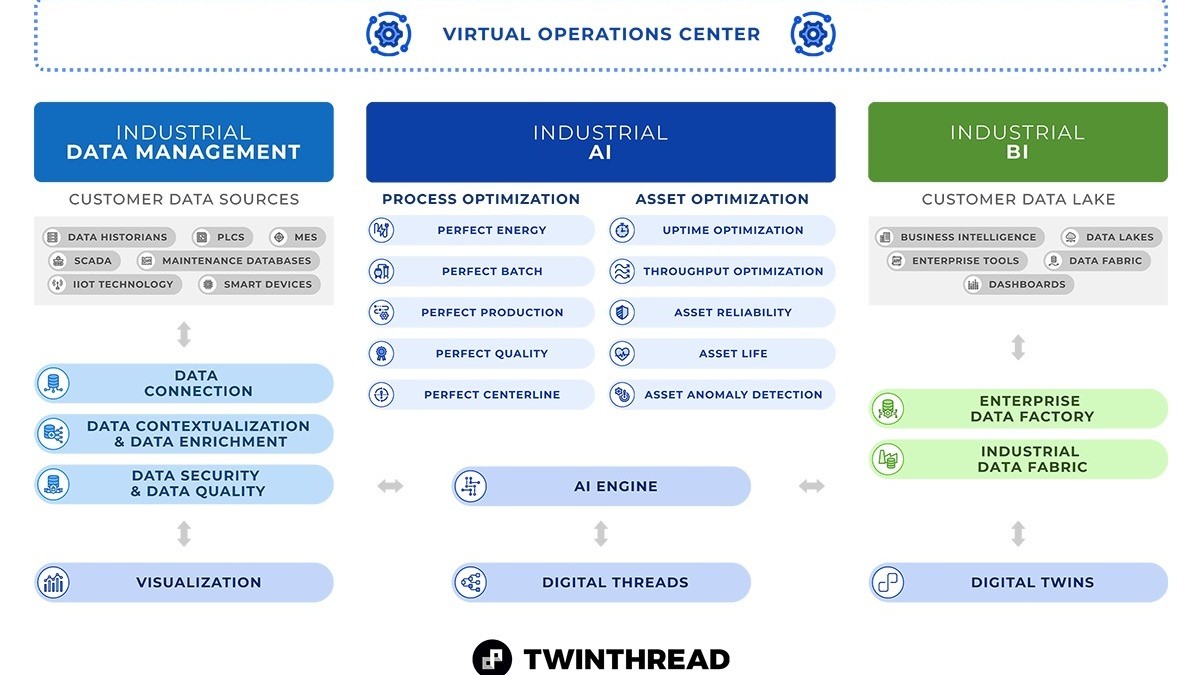

Once you have a digital twin of a plant that includes predictive and prescriptive AI capabilities, how could you improve it? TwinThread is doing that by adding genAI and agentic AI in Advisor to help accelerate model interpretation, as well as a new solution aptly named Perfect Centerline to help manage and stabilize the process effectively. These can both improve time-to-value for customers.

Additional AI: Advisor

The TwinThread Industrial AI platform is founded on pulling in operational data to build a comprehensive digital twin. To optimize performance, this PaaS includes predictive AI (as machine learning), and to take it a step further and close the loop, it also includes prescriptive AI. In addition to the core platform, TwinThread offers

- a virtual operations center enabling a manufacturing engineer anywhere to support the operation

- pre-built solutions for an even faster start.

You can find the basics about TwinThread and its offerings in our Insight posted in May 2025.

What’s new in this release is TwinThread Advisor, which includes both GenAI and Agentic AI capability. These language-based AI capabilities are context-aware, helping people interact with and interpret the results from the numbers-based predictive and prescriptive models in the core platform. This, in turn, can accelerate time to value, as anyone who has used AI to leverage a vast pile of information has experienced.

Incorporating the Advisor on top of TwinThread’s rich data set in a complete digital twin live model of a production site offers many potential benefits. Supporting understanding is a foundation. Process engineers, operators, and digital teams, as well as data scientists, can all benefit. It enables Q&A in their native language, performs global search, and builds analytical content. The agents in Advisor can integrate with various systems, and each has a specific persona that works in conjunction with other agents in a context-aware manner.

Advisor can use the TwinThread knowledge base of that customer’s operation, plus, if desired, the Internet. The customer has complete control of where the system pulls data. Using the corporation’s own data only is an option that can actually reduce spending on the cloud hosting service. It has complete security, is designed for privacy, and does not entail the sharing of one customer’s data with others. Advisor is currently available as a preview, an optional capability.

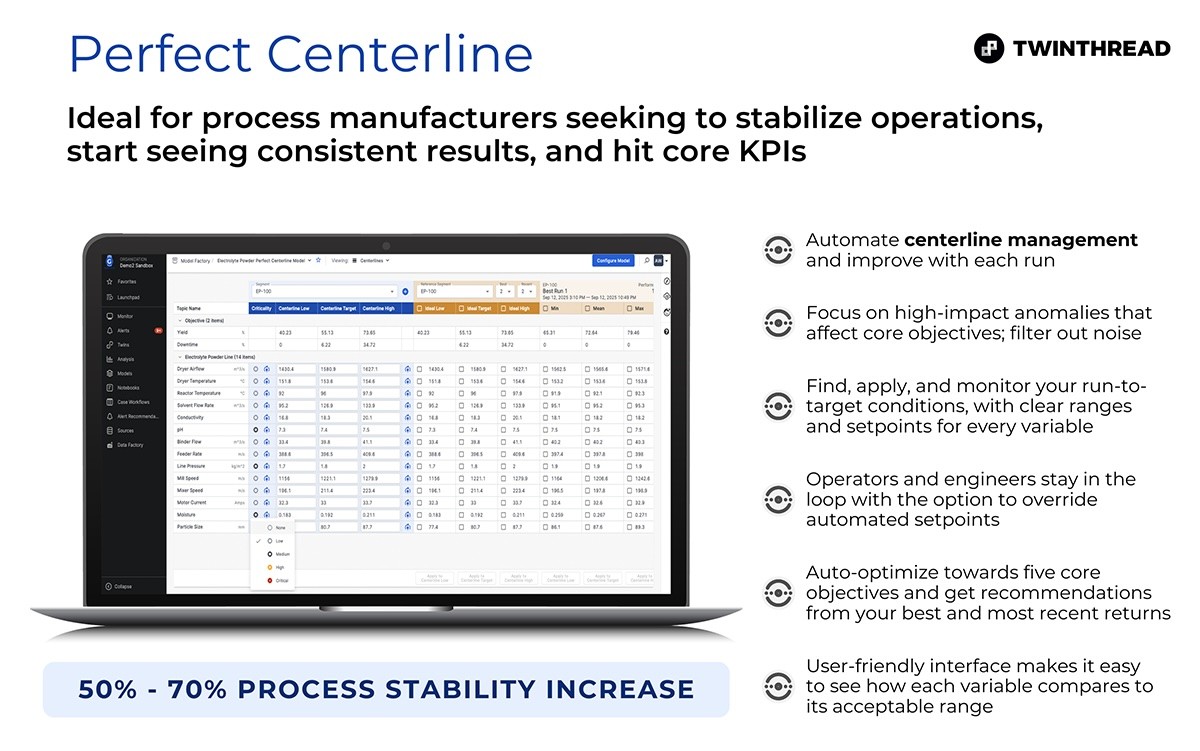

Perfect Centerline

Engineers in process industries are almost certainly familiar with centerlining to minimize variability from run to run. Most companies do it, but this new pre-built TwinThread Perfect Centerline solution automates managing the centerlining process and improves it with each run. These advanced capabilities are now fully launched to make it simpler to derive and manage centerlines with confidence.

The customer can set up to five target KPIs. The system will then monitor and automatically optimize to those objectives. The system enables overriding automated setpoints and displays the centerline, current readings, and statistics about the run in real-time. To avoid users being overwhelmed, the system can also simply display centerline deviations. TwinThread projects a 50-75% increase in process stability, which can yield significant benefits.

TwinThread expects this to be a point of entry for most customers, as a baseline. The process model first derives a centerline, which process engineers can modify, if desired. Once the data is all connected in the platform, centerline analysis can be performed in minutes, indicating how much the process might improve. If the financial impact per percentage of each objective KPI is established upfront, the system can deliver a value-based view of optimizing to the centerline. TwinThread states that if the company has a historian, this transition from legacy to advanced approach may even occur within a week.

Deeper Insights for Value

Once implemented, TwinThread’s proven predictive and prescriptive industrial AI and digital twin platform has a comprehensive and up-to-date data set. This is a rich starting point for genAI and agentic AI to deliver value. It is also a perfect home for advanced centerlining capabilities.

Thank you, Elise Loffredo, Jason Dietrich, and Andrew Waycott, for briefing Rick Franzosa and Julie Fraser.

on these new capabilities. We are excited to see both the added AI and the streamlined centerlining. We look forward to learning what you add next.

[post_title] => TwinThread Adds Advisor, Centerline Solution [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => perfect-centerline [to_ping] => [pinged] => [post_modified] => 2025-11-11 21:09:59 [post_modified_gmt] => 2025-11-12 02:09:59 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23126 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [6] => WP_Post Object ( [ID] => 23071 [post_author] => 2 [post_date] => 2025-11-05 10:06:12 [post_date_gmt] => 2025-11-05 15:06:12 [post_content] => Product innovation today is driven by an orchestration of mechanical, electrical, and software components working together as a system. So why hasn’t ECAD data management gotten the attention compared to MCAD data management with PDM? ECAD designs have gone uncontrolled in most engineering organizations for too long. It’s time for manufacturers to modernize how they manage EDA designs. This eBook shares five key ways that companies can bring ECAD into the product digital thread.

Please enjoy the summary* below. For the full research, please visit our sponsor, Accelerated Designs (registration required).

Product innovation today is driven by an orchestration of mechanical, electrical, and software components working together as a system. So why hasn’t ECAD data management gotten the attention compared to MCAD data management with PDM? ECAD designs have gone uncontrolled in most engineering organizations for too long. It’s time for manufacturers to modernize how they manage EDA designs. This eBook shares five key ways that companies can bring ECAD into the product digital thread.

Please enjoy the summary* below. For the full research, please visit our sponsor, Accelerated Designs (registration required).

Table of Contents

- The Business Imperative to Improve Electronic Design

- The Role of ECAD and PLM in the Digital Thread

- 1) Enable Efficient Engineering

- 2) Enable Better Design Decisions

- 3) Manage the ECAD Digital Thread

- 4) Collaborate on the Full Product Design

- 5) Connect the Holistic Digital Thread

- Conclusion / Call to Action

- About the Author

The Business Imperative to Improve Electronic Design

Today’s Processes are too Slow and Disconnected Today’s products are more hardware and software-driven across almost every industry. This raises the bar on efficient, effective electronic design to rapidly bring quality, innovative products to market. ECAD (electronic computer-aided design) solutions have enabled great strides for individual engineers, but there is still too much inefficiency and non-value-added work in electronic design, slowing design cycles. Beyond inefficiency impacting individual engineers, current processes and tools typically lead to disconnected design efforts across teams and disciplines. Combined, these inefficiencies further slow design times and time to market, resulting in reduced market share and profit margins. Improving Time to Market How can manufacturers improve their electronic design processes to bring products to market faster and drive profitable revenue? We identified five keys to help.The Role of ECAD and PLM in the Digital Thread

The Status Quo

Why are design cycles slow? Today’s status quo is disconnected processes and disconnected systems. Engineers too frequently make decisions without accurate, timely information. Further, lack of integrated design processes, ECAD systems, and electronic design data leads to suboptimal decisions that require costly and time-consuming rework. Finally, lack of ECAD interoperability limits design reuse and hampers sharing and collaboration across design teams and the supply chain.

It’s Time to Change

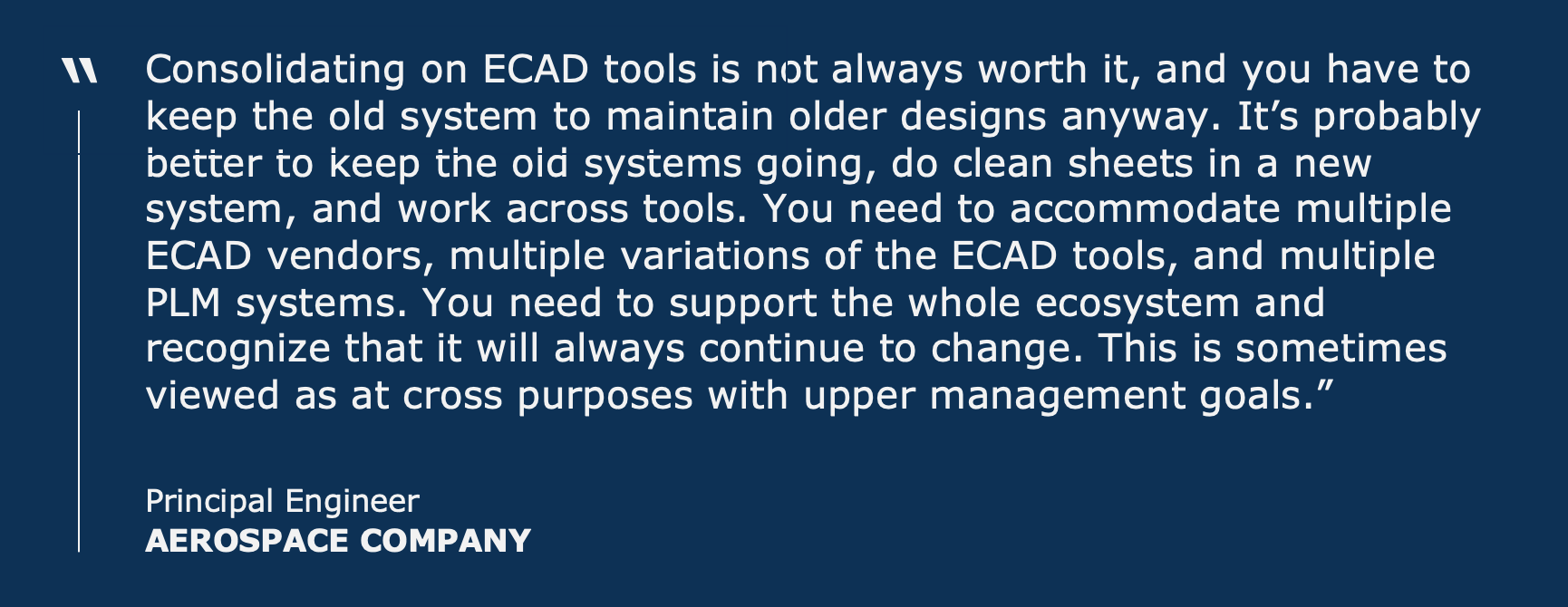

Companies must increase the efficiency of their engineers and engineering teams. They can’t do it without integrating electronic design data into the full product digital thread. First, engineers must have data readily available to make design decisions to get products right the first time. They should have accurate, up-to-date information in a common environment and centralized ECAD data management across teams, locations, and systems to enable collaboration and reuse. As a principal engineer for an aerospace company explains, “Ideally, I want one master system that talks to all ECAD systems, manages the whole ecosystem, and talks to multiple toolsets and PLMs.”

Electronic designs should be centrally managed across ECAD solutions. Then, the design data should be made available in a broader product context to facilitate collaboration across design disciplines and enable other applications, including AI. Unfortunately, there are no ECAD and PLM solutions available as part of a single platform. The best path to include ECAD in the digital thread in the foreseeable future is to consolidate ECAD design data, manage data from different design disciplines separately, and then create a holistic view at the product level in PLM.

Improving the Status Quo

So how can companies get the most out of ECAD and PLM investments to drive time to market? We propose five ways companies can improve processes and we’ll review each of these in detail:

The Status Quo

Why are design cycles slow? Today’s status quo is disconnected processes and disconnected systems. Engineers too frequently make decisions without accurate, timely information. Further, lack of integrated design processes, ECAD systems, and electronic design data leads to suboptimal decisions that require costly and time-consuming rework. Finally, lack of ECAD interoperability limits design reuse and hampers sharing and collaboration across design teams and the supply chain.

It’s Time to Change

Companies must increase the efficiency of their engineers and engineering teams. They can’t do it without integrating electronic design data into the full product digital thread. First, engineers must have data readily available to make design decisions to get products right the first time. They should have accurate, up-to-date information in a common environment and centralized ECAD data management across teams, locations, and systems to enable collaboration and reuse. As a principal engineer for an aerospace company explains, “Ideally, I want one master system that talks to all ECAD systems, manages the whole ecosystem, and talks to multiple toolsets and PLMs.”

Electronic designs should be centrally managed across ECAD solutions. Then, the design data should be made available in a broader product context to facilitate collaboration across design disciplines and enable other applications, including AI. Unfortunately, there are no ECAD and PLM solutions available as part of a single platform. The best path to include ECAD in the digital thread in the foreseeable future is to consolidate ECAD design data, manage data from different design disciplines separately, and then create a holistic view at the product level in PLM.

Improving the Status Quo

So how can companies get the most out of ECAD and PLM investments to drive time to market? We propose five ways companies can improve processes and we’ll review each of these in detail:

- Enable efficient engineering

- Enable better design decisions

- Manage the ECAD digital thread

- Collaborate in full product design context

- Connect the holistic digital thread

Conclusion / Call to Action

Status Quo It’s time to get beyond today’s status quo of disconnected systems for electronic design. Instead, companies should adopt centralized ECAD data management and leverage PLM to orchestrate the full design process without owning the electronic design process or managing detailed ECAD data. We identified five ways to improve over the status quo that can help create an integrated digital thread, reduce errors, corrective actions, and rework to get products to market faster. At the same time, these approaches improve designs by optimizing design decisions early to design in greater supply chain resilience, better compliance, lower cost, and lower risk. Enable the Change These changes must be supported by the right combination of technology, including ECAD data management to manage multi-CAD electronic data, a consolidated component library to improve design decision-making, and integration with PLM to create a holistic product digital thread. Ideally, this would all be on a single platform from a single vendor, but that’s not the reality today. Today, the better way to operate is to:- Put the right data directly into the ECAD environment, regardless of the ECAD tool, to create a central source of truth for electronic design data

- Provide component library data inside the ECAD environment to provide data ranging from technical specifications to business and supply chain data

- Manage the ECAD digital thread across ECAD tools to improve collaboration, efficiency, and reuse

- Collaborate in the full product design context

- Connect the holistic digital thread in PLM

*This summary is an abbreviated version of the ebook and does not contain the full content. For the full report, please visit our sponsor Accelerated Designs.

If you have difficulty obtaining a copy of the research, please contact us.

[post_title] => Five Keys to Bring ECAD into the Digital Thread

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ecad-into-the-product-digital-thread

[to_ping] =>

[pinged] =>

[post_modified] => 2025-11-05 10:56:21

[post_modified_gmt] => 2025-11-05 15:56:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=23071

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 23039

[post_author] => 2

[post_date] => 2025-10-15 09:27:25

[post_date_gmt] => 2025-10-15 13:27:25

[post_content] =>

*This summary is an abbreviated version of the ebook and does not contain the full content. For the full report, please visit our sponsor Accelerated Designs.

If you have difficulty obtaining a copy of the research, please contact us.

[post_title] => Five Keys to Bring ECAD into the Digital Thread

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => ecad-into-the-product-digital-thread

[to_ping] =>

[pinged] =>

[post_modified] => 2025-11-05 10:56:21

[post_modified_gmt] => 2025-11-05 15:56:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=23071

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[7] => WP_Post Object

(

[ID] => 23039

[post_author] => 2

[post_date] => 2025-10-15 09:27:25

[post_date_gmt] => 2025-10-15 13:27:25

[post_content] =>  How can manufacturers manage their complex design data, including both MCAD and ECAD files, to streamline design, eliminate wasted time looking for design data, and improve collaboration? Jim Brown will moderate a webinar, From Chaos to Collaboration: Solving the Design Data Dilemma, to hear from Propel and their partners on how they can seamlessly manage CAD data of different formats.

Learn from:

How can manufacturers manage their complex design data, including both MCAD and ECAD files, to streamline design, eliminate wasted time looking for design data, and improve collaboration? Jim Brown will moderate a webinar, From Chaos to Collaboration: Solving the Design Data Dilemma, to hear from Propel and their partners on how they can seamlessly manage CAD data of different formats.

Learn from:

- CEO of Propel, Ross Meyercord

- CPO of Propel, Eric Schrader

- President & Founder of Tech-Clarity, Jim Brown

- Head, Value Engineering & Services for Accelerated Designs, Sanjay Keswani

- CEO of Bild, Pradyut Paul

- VP of Product, Razorleaf, Tim Noce

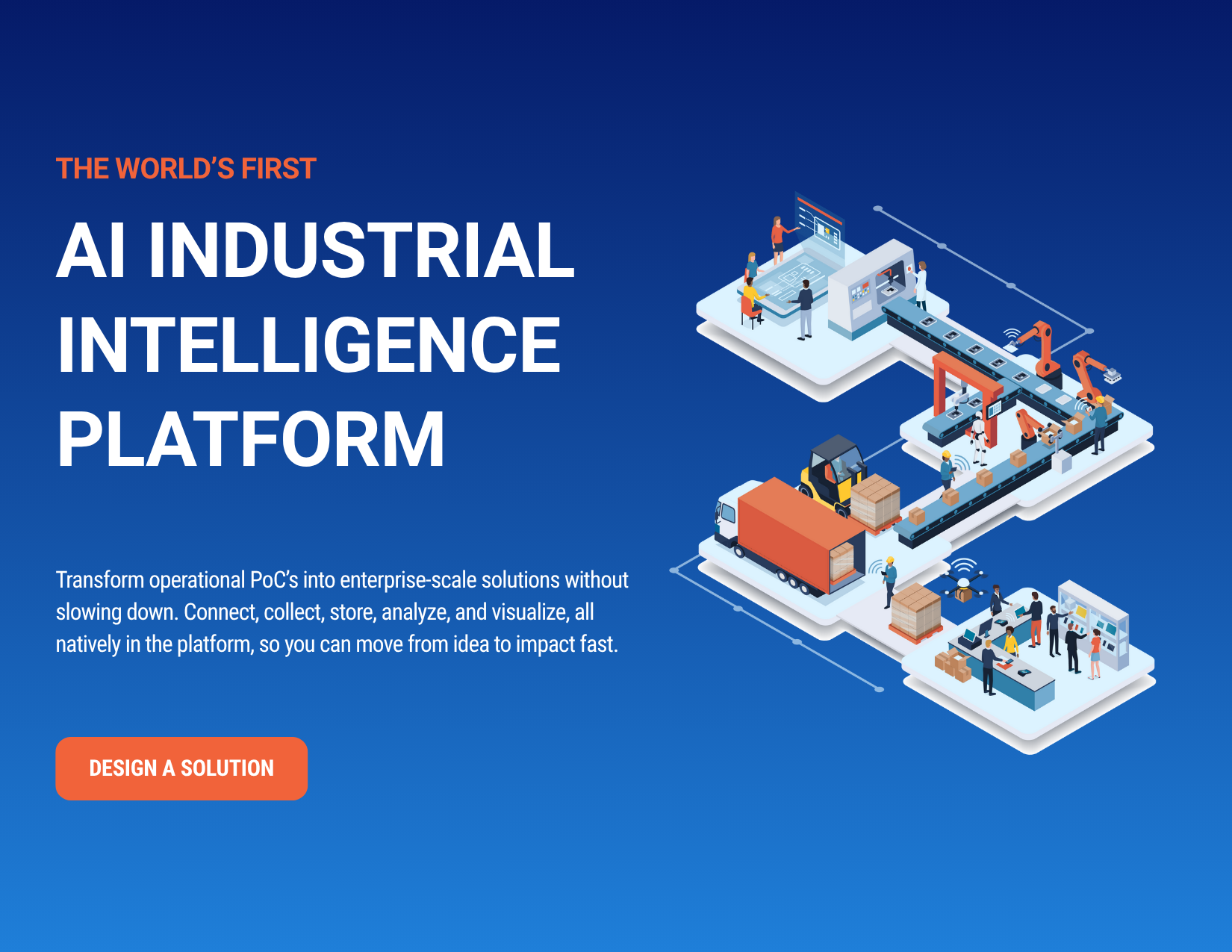

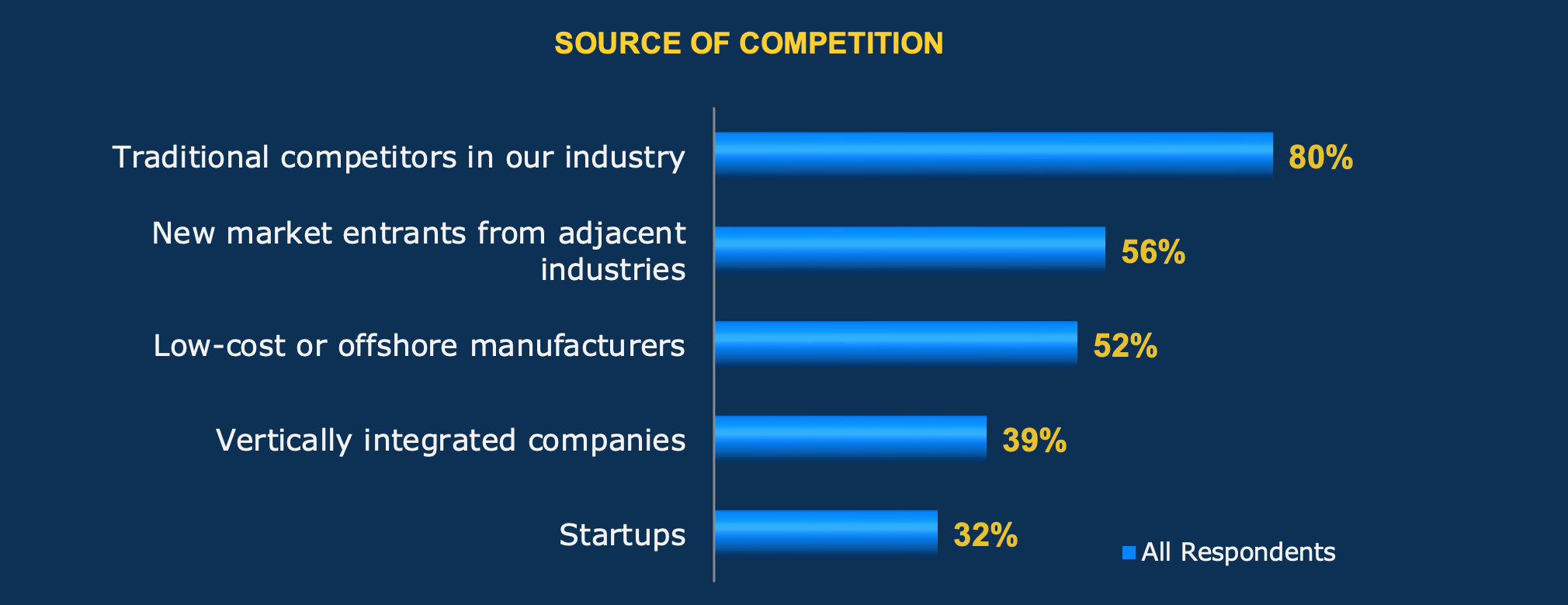

How far can large enterprises go in consolidating their software stack from IIoT and data foundations to apps? Could a startup EV OEM run its business on just two pieces of software? Fuuz, by MFGx, aims to answer that second question with a yes, using just Fuuz and Oracle NetSuite. We recently had an update briefing with Fuuz, and their focus has changed since our last conversation. They don’t fit neatly into a category and are calling what they do an industrial intelligence platform. Fuuz includes IIoT, a comprehensive data stack, no-code/low-code rapid application development tools, and MES, WMS, APS, Quality, CMMS, as well as Production and Process Monitoring solutions.

Fuuz initially aimed its platform and applications offering at small and medium businesses (SMBs) who wanted to extend their ERP to the shop floor. It still serves many SMBs with greenfield operations; however, they discovered that manufacturers with over $300 million in revenue are more mature. Their experience typically means they have a deeper understanding of why the combination of IIoT, a modern full-stack data management platform, and Purdue Model or ISA95 Level 3 applications can deliver immediate and lasting benefits.

The Fuuz platform is within multi-tenant SaaS, where each customer has their own segmented resources and database. This delivers cloud benefits while also accommodating highly regulated industries. Its Gateway enables edge connection for devices such as industrial controls, printers, scales, and CMMs, as well as edge computing. The Fuuz team claims to be winning against OT software players, IT data platform players, and manufacturing IT application powerhouses.

IT Consolidation with Intelligence

Many larger companies have been attempting to build out their architecture for years. One Fuuz customer is planning to replace 12 different software products with one. Some of the recent customer announcements include large and startup companies in pet food (planning to replace eight applications), EVs, auto parts, aviation, and life sciences.

Fuuz offers consolidation at many levels.

- Industrial device and IIoT connection and data structuring

- Unified name space (UNS) where OT systems data all feed into a single, structured data model

- Manufacturing IT data ontology, management, and governance, where IT and OT data come together in a comprehensive, managed way for clean data with clear provenance and lineage

- Manufacturing applications, including MES, WMS, APS, Quality, CMMS, Production and Process Monitoring

- Supply chain partner visibility – this is a new area that an automnning to replace 12 different software products with one. Some of the recent customer announcements include large and startup companies in pet food (planning to replace eight applications), EVs, auto parts, aviation, and life sciences.

Customers Choose

Tailor UIs, Workflows, and Apps – The Fuuz Platform offers tools, including a responsive UI builder, a workflow builder, and its own apps, as well as low-code app-building capabilities. A key differentiator is that they built these tools to address the scaling challenges of low-code/no-code solutions, implementing them as an SI before shifting entirely to a software company.

Unified Data Ontology – Each customer can select whether to use ISA95 or another structure for their enterprise data. The ontology is based on a no-code MongoDB and can span the entire enterprise.

AI Tools – The Fuuz team has decided not to build AI into the system. Customers can use its GraphQL APIs, data flows, and native MCP cloud or edge capabilities to integrate with any LLMs or AI tools they choose.

High-Value Starting Points – Since the platform encompasses everything an app needs, companies can start with their high-priority applications and obtain the entire infrastructure required for them to function. This is in stark contrast to many enterprise infrastructure approaches, which can require years before the high-value applications work well.

Continued Growth

Fuuz’s strategy to sell and implement through partners remains strong. The ecosystem is growing, and partners have substantial control over the IP they put out on the Fuuz marketplace.

Partners have traditionally included ERP companies and their service partners. These include NetSuite, PwC, CohnReznick, Strategic Information Group, Western Computer, and Guidepath Consulting. Other partners are from IIoT, OT, or PLM backgrounds, such as Razorleaf Corporation, Castor Engineering, and newly-launched Abelara. Some have used the Fuuz platform to build their own MES, WMS, and EDI applications. Recently, Fanuc Robotics America Inc has started building Fuuz into its products to enable remote monitoring and predictive maintenance.

Fuuz’s partners often have deep and lasting relationships with customers. The partner vetting process is rigorous, ensuring that partner solution architects can help companies envision their future digital support. The goal is to grow with customers through these strong partner relationships.

Looking to the Future

Fuuz built to a vision a decade ago that few others had. At the core of the platform are flexible, modern, scalable technologies. They continue to improve, but are not flitting from one new technology trend to the next. They are building out from the original vision in a versionless approach, where upgrades never entail downtime, and customer implementations continue to support evolution.

Thank you, Craig Scott, Brad Hafer, and Steve Modrall, for briefing us on the state of the Fuuz and where Fuuz is igniting value.

[post_title] => Fuuz Doubles Down on Enterprise for Industrial DataOps and Level 3 Apps [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => industrial-intelligence-platform [to_ping] => [pinged] => [post_modified] => 2025-11-03 20:34:30 [post_modified_gmt] => 2025-11-04 01:34:30 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23104 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [9] => WP_Post Object ( [ID] => 23025 [post_author] => 2574 [post_date] => 2025-10-14 08:26:03 [post_date_gmt] => 2025-10-14 12:26:03 [post_content] => How mature is your digital approach to manufacturing operations? What are the next steps you need to take on your journey to improve digital support for the plant floor and support teams? Take our Manufacturing Operations Digital Maturity Assessment to find out.

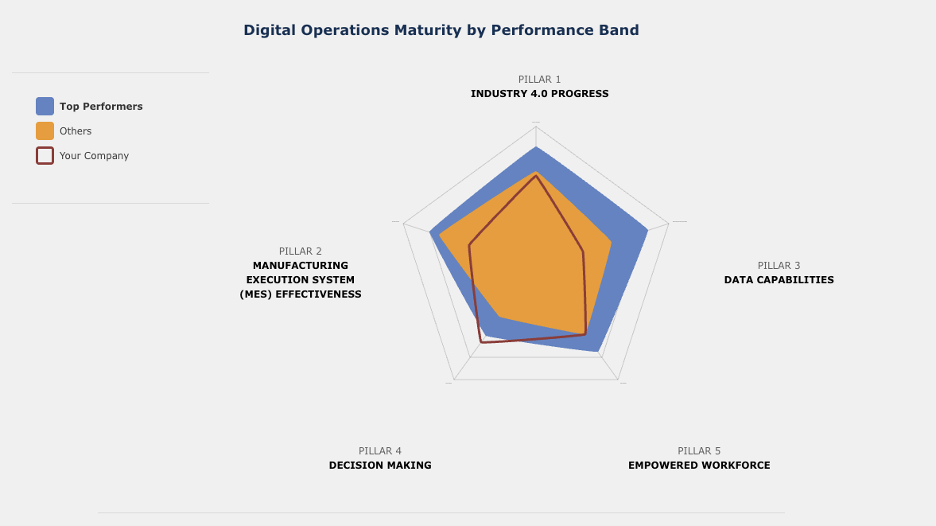

The assessment leverages our research to assess your company’s digitalization progress in manufacturing operations. What could you do to build out from where you have already invested and succeeded? How are Top Performers doing things differently?

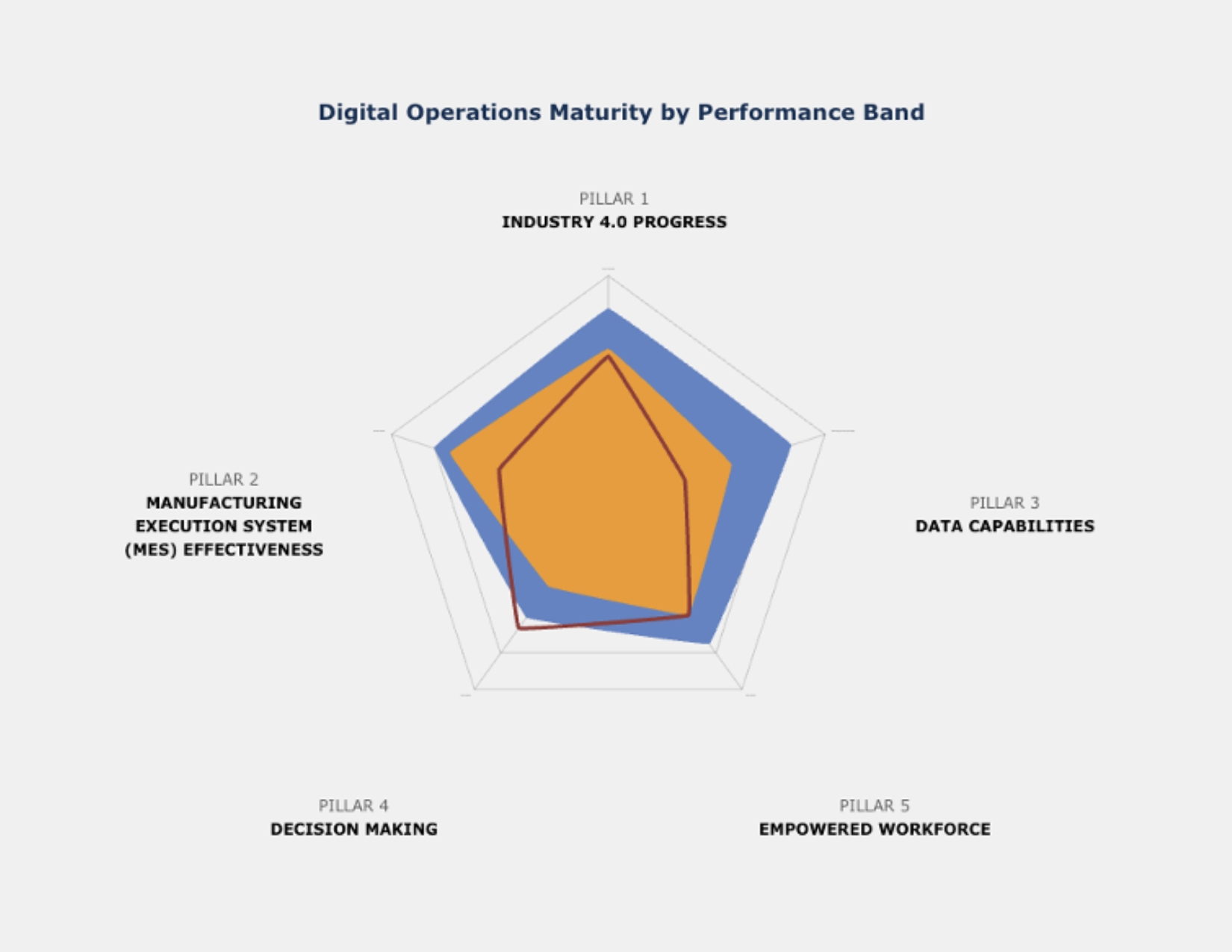

The assessment asks about your top objectives and challenges. It also considers five pillars of manufacturing operations digital maturity.

How mature is your digital approach to manufacturing operations? What are the next steps you need to take on your journey to improve digital support for the plant floor and support teams? Take our Manufacturing Operations Digital Maturity Assessment to find out.

The assessment leverages our research to assess your company’s digitalization progress in manufacturing operations. What could you do to build out from where you have already invested and succeeded? How are Top Performers doing things differently?

The assessment asks about your top objectives and challenges. It also considers five pillars of manufacturing operations digital maturity.

- Industry 4.0 Progress

- MES Effectiveness

- Data Capabilities

- Decision Making

- Empowered Workforce

[post_title] => Manufacturing Operations Digital Assessment

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-operations-digital-maturity

[to_ping] =>

[pinged] =>

[post_modified] => 2025-10-14 08:26:03

[post_modified_gmt] => 2025-10-14 12:26:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=23025

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 23257

[post_author] => 2574

[post_date] => 2025-10-09 10:21:46

[post_date_gmt] => 2025-10-09 14:21:46

[post_content] =>

[post_title] => Manufacturing Operations Digital Assessment

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => manufacturing-operations-digital-maturity

[to_ping] =>

[pinged] =>

[post_modified] => 2025-10-14 08:26:03

[post_modified_gmt] => 2025-10-14 12:26:03

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=23025

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[10] => WP_Post Object

(

[ID] => 23257

[post_author] => 2574

[post_date] => 2025-10-09 10:21:46

[post_date_gmt] => 2025-10-09 14:21:46

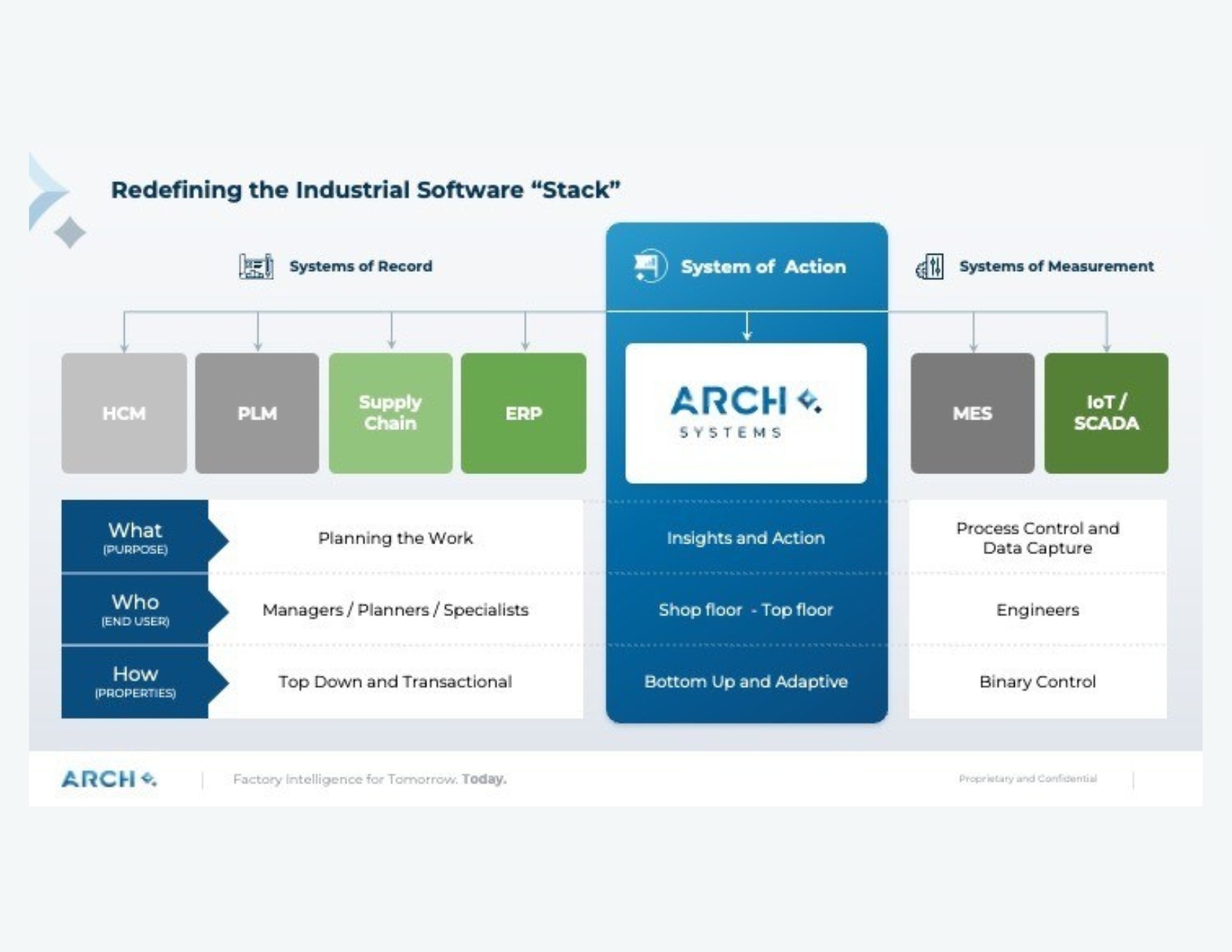

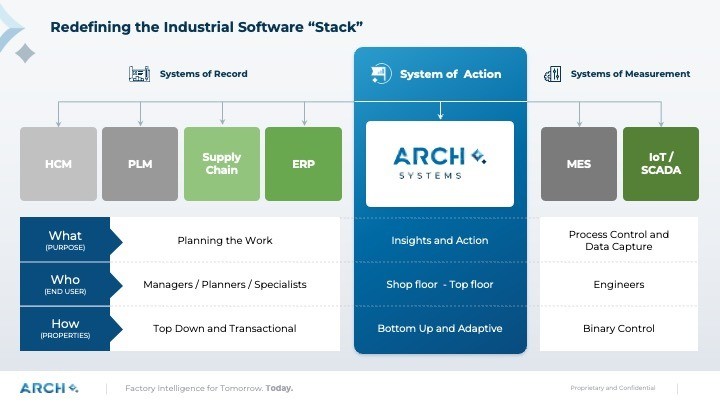

[post_content] =>  How can manufacturers gain the data connectivity, analytics, and AI capabilities necessary to make informed decisions with confidence? Arch Systems was founded to provide that, and it continues to accelerate customer success via, in their words, “Intelligent Actions for Manufacturing”. Arch customers are finding that building their own AI infrastructure does not make sense when they can purchase this pre-built architecture, which includes connectors, dashboarding, a knowledge graph for context, analytics, and AI capabilities. We are excited about the progress they have made since our first briefing in the summer of 2024.

How can manufacturers gain the data connectivity, analytics, and AI capabilities necessary to make informed decisions with confidence? Arch Systems was founded to provide that, and it continues to accelerate customer success via, in their words, “Intelligent Actions for Manufacturing”. Arch customers are finding that building their own AI infrastructure does not make sense when they can purchase this pre-built architecture, which includes connectors, dashboarding, a knowledge graph for context, analytics, and AI capabilities. We are excited about the progress they have made since our first briefing in the summer of 2024.

Envision Unlimited 30-Year Experts

For many plants, the limiting factor in achieving excellent results is not a lack of data – in fact, most are overwhelmed with data – but a lack of experienced personnel. The Arch Systems vision goes beyond decision-making support into ensuring intelligent action in production. As you might expect, this takes the form of agentic AI-based factory experts. As both manufacturing and AI experts, the Arch Systems core team recognized early on that they needed to provide not just alerts, but also concrete details, including recommended actions. Specific agents know various processes extremely well and will identify the root cause of a problem and identify a particular sequence of steps to perform to correct or preveniot problems. Traceable steps lead to measurable improvements in each agent’s focus area. Arch Systems agents work with nearly any form of plant IT or OT data through API. Even for data without an API, Arch can interpret information on dashboards using a capability called Dashboard Vision. Remember that Arch Systems offers the entire stack, from data ingestion to a common knowledge graph, for any data the factory may need to take action.Common Use Case Benefits

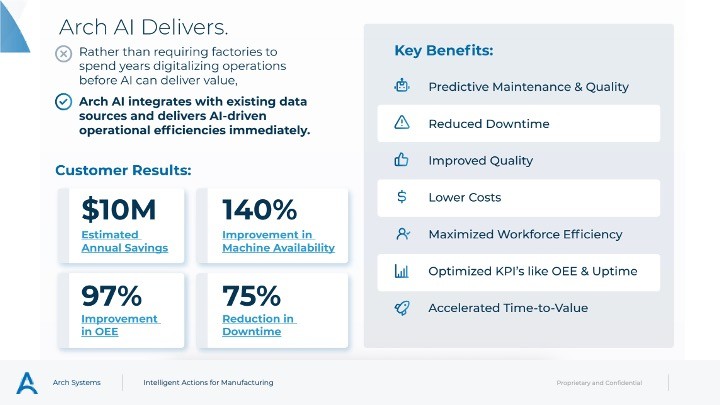

Arch claims some compelling customer value examples across a wide range of KPIs. Downtime – One plant with an Arch site license focused on downtime and reported gaining $2.8M in a single year, an enormous ROI. Another reports $3.7M in hard savings over two years with no disruption to operations during deployment. Machine Utilization – One CM was performing a full line freeze for every changeover, as requested by a customer. Conducting quality checks with AI in real-time resulted in a 97% increase in OEE. CapEx Avoidance – With less downtime, higher quality, and improved yield, companies can defer or avoid adding equipment for increased throughput demands. One company reported $7M CapEx avoidance and ROI in less than three months as a result of visibility from Arch. Quality – Like downtime, Arch focuses on tackling the investigation process. One customer reduced SMT line attrition by 12% in the first week of use, resulting in over $5,000 in monthly savings per line. Getting to root causes is valuable. For yield, Arch offers a “machine of blame” agent that can identify which machine is likely causing anomalies, automate root cause analysis, and provide recommendations on corrective action.

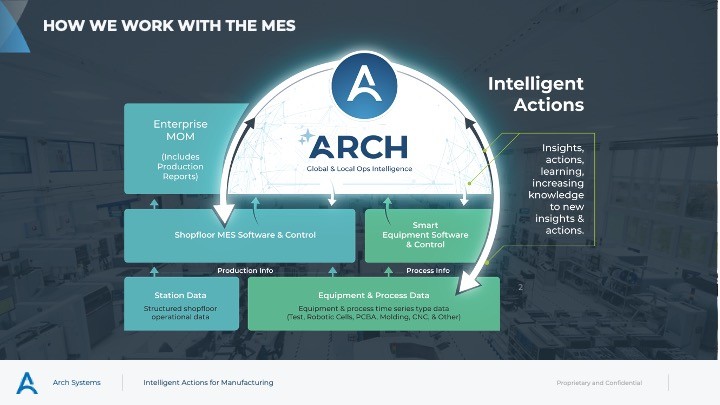

Powerful Partnering

Arch Systems not only partners with customers, but with a wide array of other software providers. Their technology integrates seamlessly with major cloud platforms and leading manufacturing systems, delivering unified insights and AI-driven intelligence. Strategic collaborations include Fuji, Aegis, NMTronics, and Dassault Systèmes, which extend capabilities and help customers accelerate digital transformation and operational excellence. With MES partners, Arch’s intelligence can come through the MES UI or their own. Some MES providers offer robust dashboards, analytics, and data structures that are analytics-friendly, while others do not. So, the approach varies. What is essential in a tight integration is the Arch IIoT Event data layer and ontological model to link all aspects of the factory. Note that several of Arch Systems’ largest customers have a homegrown MES where Arch integrates and provides a superior user experience.

Customer Expansion

Arch Systems has achieved significant success in discrete manufacturing, including electronics, automotive, aerospace, defense, and medical technology. Because the expert data model or knowledge graph at the core of the software is based on modeling steps or batches, the company does not plan to serve continuous process industries. In May, Flex issued a joint press release with Arch regarding their global expansion of an already strong relationship. In June, at the Manufacturing Leadership Council Rethink conference, Arch Systems’ joint customer announcement was with another enormous contract manufacturer, Jabil. Both companies’ COOs sit on the Arch Systems board of directors. Contract manufacturers (CMs) are among the most accomplished manufacturers, not only in electronics but also in other types of manufacturing. As the manufacturing arm for other companies, they are expected to perform well across all production KPIs. Cost, quality, and speed are not tradeoffs, but all are expected to be excellent. Six of the 10 largest CMs are currently Arch Systems customers.Bridges of Trust

Its research shows that the Arch AI Dashboard vision, paired with expert-guided reasoning models, can match or surpass human expert performance in root cause analysis and corrective action recommendations. It can do so much faster and less expensively. Arch Systems appears to be living up to its name – the powerful and trustworthy bridge to support data in the factory crossing into the realm of intelligent action. Thank you, Andrew Scheuermann and Laura Horvath, for keeping us updated. We intend to continue following your progress in the market. [post_title] => Arch Systems Accelerates AI for Large Manufacturers [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => accelerate-ai [to_ping] => [pinged] => [post_modified] => 2025-12-30 10:22:15 [post_modified_gmt] => 2025-12-30 15:22:15 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=23257 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [11] => WP_Post Object ( [ID] => 22999 [post_author] => 2580 [post_date] => 2025-10-09 08:38:24 [post_date_gmt] => 2025-10-09 12:38:24 [post_content] => Why is managing CAD/CAM important to job shops? How does poor manufacturing data management negatively impact job shop performance and profits? More importantly, what lessons learned can they from managing product data to add control without burdening already busy resources?

Read the full report here, or download the full PDF, courtesy of Siemens.

You can also learn more from Siemens Digital Industries Software here. Thank you Siemens for supporting our work and helping us educate manufacturers on the value of improving CAD/CAM data management.

Why is managing CAD/CAM important to job shops? How does poor manufacturing data management negatively impact job shop performance and profits? More importantly, what lessons learned can they from managing product data to add control without burdening already busy resources?

Read the full report here, or download the full PDF, courtesy of Siemens.

You can also learn more from Siemens Digital Industries Software here. Thank you Siemens for supporting our work and helping us educate manufacturers on the value of improving CAD/CAM data management.

Table of Contents

- CAD/CAM Data Management is often Underappreciated

- Manufacturing is Data Intensive

- Unmanaged CAD/CAM Data Hurts Performance

- How to Improve Data Management

- 1 — Stop Wasting Time

- 2 — Eliminate Mistakes

- 3 — Estimate with Confidence

- 4 — Create a Compelling Customer Experience

- Prepare for the Future

- Control, Access, and Share with PDM

- Manage CAD/CAM Data without the Big Investment

- Acknowledgments

CAD/CAM Data Management is often Underappreciated

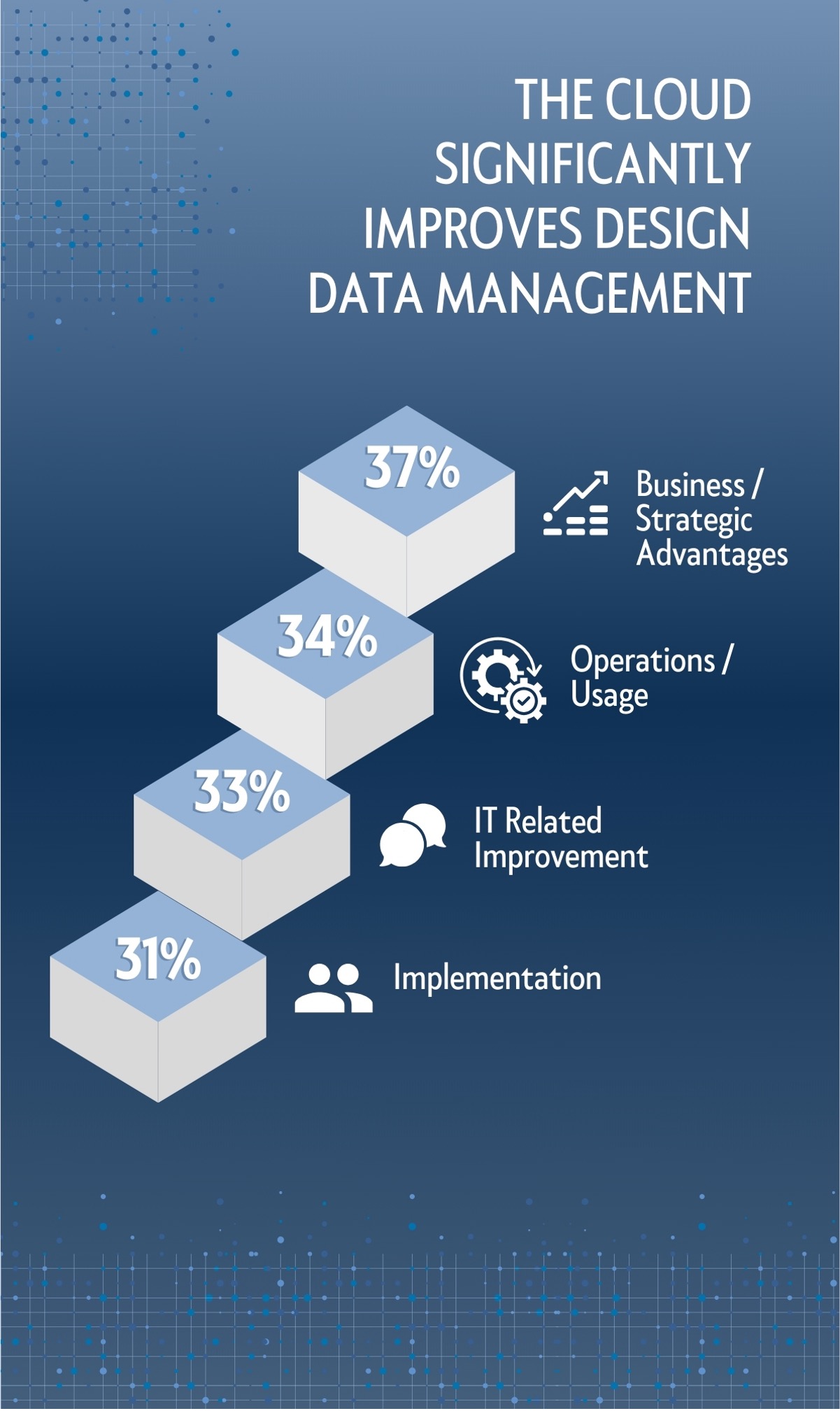

Agility is Crucial for Job Shops Job shops play a critical role in the manufacturing supply chain by producing low-volume, high-variety, or custom parts. These shops need to be fast, responsive, and efficient. Agility is essential whether the shop is prototyping or delivering production runs. However, speed can't come at the expense of the quality, cost, and customer relationships that drive profitability and repeat business. Job shops, whether internal departments or independent businesses, need to strive for operational excellence in all ways to be trusted partners. CAD/CAM Data Management is Essential Accessible, trusted data is a proven contributor to operational excellence, and job shops create a significant amount of manufacturing data to produce their customers' designs. Keeping this data in sync is critical, but job shop leaders typically don't want to slow down or add overhead to implement enablers like formal design and manufacturing data management. Our data, though, indicates that inadequate data management wastes time and impacts results. How can job shops adopt the basic data management capabilities they need to avoid the downfalls of unmanaged CAD and related manufacturing data? We explore four ways job shops can leverage the cloud to gain control and protect their customers' IP without adding counterproductive cost and overhead.Manufacturing is Data Intensive

Customer Design Data Needs Control Job shops receive a lot of engineering and PMI data from their customers. Customers typically send, at a minimum, the design intent for their orders. They may send this in a formal manufacturing package or more informal methods like compressed files, shared drives, and emails. This information, which may include job specs, quality standards, 3D CAD models, drawings, GD&T, and material specifications, must be securely stored and controlled so the right people can access it. Further, the shop has to manage design changes to ensure that they produce to the right final specs. Manufacturing Runs on Data Beyond design data received from customers, job shops create an even greater amount of data to order materials, create tooling, produce the items, and inspect them for quality. This data may include NC code, STL files, shop drawings, tool paths, cut sheets, fixture designs, inspection plans, and additional information needed to produce parts right the first time. This information is typically more varied and larger than the customer's original data. This is in addition to downstream production data that may be managed in systems like ERP, MES, or QMS if they are in place.Unmanaged CAD/CAM Data Hurts Performance

Linking Design and Manufacturing Data Design and production data are intrinsically related, and the data created by the shop should be managed in the context of the customer's CAD design. Unfortunately, job shops don't always manage this data and data relationships well because they don't want to be slowed down by cumbersome enterprise data management solutions. Some may not even have IT departments or the resources to implement formal data management solutions like PDM or PLM. This leads to disconnected data that is difficult to find and nearly impossible to manage as changes are received.

Unmanaged CAD/CAM Costs the Shop

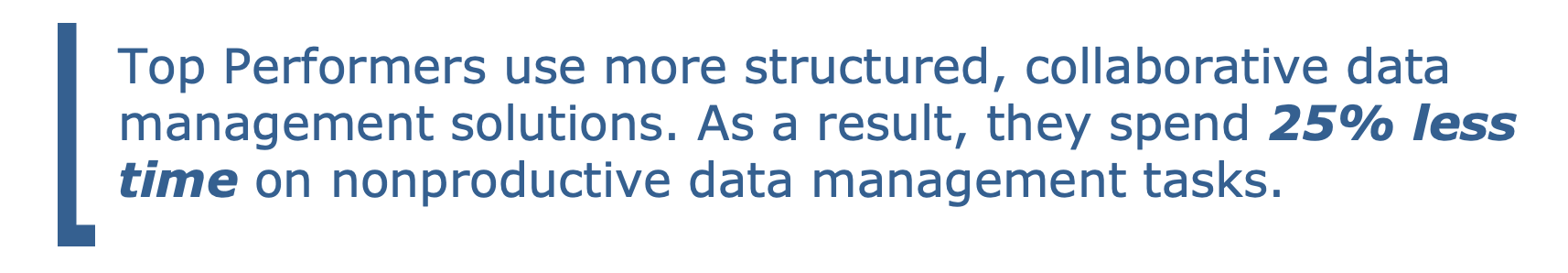

Despite the challenges adopting data management, unmanaged CAD/CAM data causes frustration and reduces productivity. Our research on non-value-added time shares that technical resources only spend about one-half of their time on technical work on a typical project. They spend 19% of their time, about one day a week, on non-value-added (NVA) data management tasks such as finding information, working with the wrong data, recreating data, translating formats, and other common time wasters.1

Unmanaged CAD/CAM hurts a job shop's performance and profitability in four ways:

Design and production data are intrinsically related, and the data created by the shop should be managed in the context of the customer's CAD design. Unfortunately, job shops don't always manage this data and data relationships well because they don't want to be slowed down by cumbersome enterprise data management solutions. Some may not even have IT departments or the resources to implement formal data management solutions like PDM or PLM. This leads to disconnected data that is difficult to find and nearly impossible to manage as changes are received.

Unmanaged CAD/CAM Costs the Shop

Despite the challenges adopting data management, unmanaged CAD/CAM data causes frustration and reduces productivity. Our research on non-value-added time shares that technical resources only spend about one-half of their time on technical work on a typical project. They spend 19% of their time, about one day a week, on non-value-added (NVA) data management tasks such as finding information, working with the wrong data, recreating data, translating formats, and other common time wasters.1

Unmanaged CAD/CAM hurts a job shop's performance and profitability in four ways:

- Wasting time

- Causing mistakes

- Creating estimating / quoting challenges

- Delivering a poor customer experience

How to Improve Data Management

Four Ways to Improve

Now that we've discussed how poor data management negatively impacts job shops let's talk about how to fix it. Few job shop leaders would disagree that they should have effective control over their data, be able to reuse existing work, and capture learnings to continuously improve and avoid repeating mistakes. These factors are important to running an efficient, profitable shop. However, they can't always achieve the control they need over their CAD/CAM data because of the potential overhead of data management solutions.

In this eBook, we'll discuss four ways to increase profitability, performance, and customer satisfaction with minimal disruption and investment by taking a lightweight data management approach that manages CAD and related data like NC programs and CAM project files so they can:

Four Ways to Improve

Now that we've discussed how poor data management negatively impacts job shops let's talk about how to fix it. Few job shop leaders would disagree that they should have effective control over their data, be able to reuse existing work, and capture learnings to continuously improve and avoid repeating mistakes. These factors are important to running an efficient, profitable shop. However, they can't always achieve the control they need over their CAD/CAM data because of the potential overhead of data management solutions.

In this eBook, we'll discuss four ways to increase profitability, performance, and customer satisfaction with minimal disruption and investment by taking a lightweight data management approach that manages CAD and related data like NC programs and CAM project files so they can:

- Stop wasting time by effectively managing CAD/CAM and related manufacturing data

- Eliminate mistakes by improving collaboration and control

- Estimate accurately by using facts from prior projects

- Enrich customer experiences by building trust and confidence

1 – Stop Wasting Time

Unmanaged Data Wastes Time Let's step back to understand the problem. We've already shared that technical resources waste significant time due to unmanaged data. There are a number of ways this occurs. One of the most common is time lost searching for the appropriate data in different folders, on different computers, or on shared drives. Another significant inefficiency is taking the time to ask others for data or responding to data requests from others. Further, even if an engineer, CNC programmer, or operator finds what they are looking for, they are unsure if the data is correct or the latest revision. They still need to ask others for confirmation. Even worse is when CAD or manufacturing data gets lost, and people must recreate it from scratch or go back to the customer for it. All of these non-value-added activities waste precious time and resources. Control, Access, and Share Data

Tech-Clarity's research shows that engineering and manufacturing teams must put three key capabilities in place to reduce wasted, non-value-added work. These basic capabilities include effectively controlling, accessing, and sharing information (see details on page "Control, Access, and Share with PDM").

PDM is a critical enabler to centralize and manage CAD/CAM and other related manufacturing data. It's proven to enable job shops to control, access, and share information effectively. PDM centralizes data to limit the time wasted on non-value-added tasks. It ensures that data stays current and updated, so there is no need to question or recreate work. It also allows other technical resources to have easier access to needed CAD/CAM or other data in a self-service model so they don't have to interrupt others who have their own jobs to do. Lastly, without PDM, CAM and other manufacturing data are not managed, and it is likely recreated every time a job comes in, instead of reusing NC data when the CAD is the same revision or using the manufacturing as a starting point if only minor details have changed.

Control, Access, and Share Data

Tech-Clarity's research shows that engineering and manufacturing teams must put three key capabilities in place to reduce wasted, non-value-added work. These basic capabilities include effectively controlling, accessing, and sharing information (see details on page "Control, Access, and Share with PDM").

PDM is a critical enabler to centralize and manage CAD/CAM and other related manufacturing data. It's proven to enable job shops to control, access, and share information effectively. PDM centralizes data to limit the time wasted on non-value-added tasks. It ensures that data stays current and updated, so there is no need to question or recreate work. It also allows other technical resources to have easier access to needed CAD/CAM or other data in a self-service model so they don't have to interrupt others who have their own jobs to do. Lastly, without PDM, CAM and other manufacturing data are not managed, and it is likely recreated every time a job comes in, instead of reusing NC data when the CAD is the same revision or using the manufacturing as a starting point if only minor details have changed.

2 — Eliminate Mistakes

Mistakes Cost Time and Money Inefficiency is not the only way that job shops suffer from ineffective data management. Operational excellence relies on a trusted digital thread of data, starting with the customer's CAD designs and continuing through inspection. Poor CAD/CAM data and poor collaboration around it can lead to costly mistakes. For example, if the shop starts manufacturing planning using the wrong CAD revision to develop CAM toolpaths or uses the wrong CAM data to manufacture, they must rework and/or deal with scrap. At a minimum, they have to rework manufacturing plans. But they can miss first-time quality goals if it's not caught before manufacturing. Of course, the worst scenario is when quality issues due to incorrect CAD/CAM data lead to part quality problems that leave the shop and get rejected by the customer. This situation compromises the job shop's reputation and hurts customer relationships. Improve Collaboration For effective collaboration within a shop and between a job shop and their customers, it must be easy for everyone involved to collaborate easily and effectively. All related data should be available and easily accessible in one place, not lost in emails or in unmanaged shared folders. Everybody should be able to securely access what they need, securely, in a format they can understand and use for their work. People should only see what they need based on security and release status, and changes must be tracked to make it easy to see the latest information. Effectively collaborating on a single source of information also improves reviews and DfM (design for manufacturability) processes so the shop can proactively identify and report potential issues to provide early feedback regarding manufacturability and cost. Improved 3D collaboration with customers' engineering teams sets the conditions for companies to "shift left" to improve the value of the shop to the customer.3 — Estimate with Confidence

Poor Information Leads to Poor Estimates Poor data management issues are not limited to the shop, they can also impact the front office. For example, effective estimates and quotes, whether for internal or external purposes, have enormous consequences. First, it's important to develop quotes quickly. Slow quote response time can result in lost business opportunities. But speed alone is not sufficient. Inaccurate or low-confidence estimates hurt the business in other ways. Either the quote is too low and the shop loses money, or the shop inflates quotes to compensate for low confidence in the estimates and the shop misses business opportunities. Guide Quotes with Facts Quick access to past projects with all the associated data can help job shops quote accurately and maintain margins without reinventing the wheel each time a quote is needed. If data management extends beyond technical data, estimators can leverage past quotes and actual outcomes to see the results of similar jobs. In addition, shops can access related manufacturing data in context with the 3D CAD model and associated manufacturing data. If the shop can easily retrieve data such as the equipment/machines used, quality defects, actual cost of production, tooling cost, and manufacturing time, they can develop quotes with confidence. Connecting CAD/CAM data with manufacturing information allows estimators to guide estimates and quotes with facts to rapidly develop accurate quotes that lead to more business, create higher customer confidence, and protect budgets or margins.4 – Create a Compelling Customer Experience

Lack of Control Reflects Poorly on the Job Shop As we've discussed, poor CAD/CAM data management can lead to internal problems, including outdated revisions and miscommunication that result in costly rework, quality leaks, and production delays. It may also prevent them from meaningfully participating in continuous improvement exercises with customers. These issues indirectly impact the job shop's customers, whether they are part of the same company or independent entities. Beyond that, poor CAD/CAM data management practices put customers' engineering data at risk of being accidentally shared. Inefficient CAD/CAM data management does more than just waste resources. It also signals a lack of discipline and organizational excellence to customers that can potentially jeopardize future business opportunities. These issues can tarnish the shop's reputation, erode customer trust, and raise doubts about the firm's competence. Build Customer Trust and Confidence The ability for a job shop to manage CAD, CAM, and other manufacturing data, along with industrial-grade data security, proves it can comply with the requirements that its customers expect. Effective data management makes it easy for the shop to feel they have a reliable partner and are confident their IP is safe. It can also help them demonstrate compliance with industry standards to improve their marketability and qualify for more projects. Finally, improving customer experience by increasing data management maturity leads to more repeat business and new customers through referrals.Prepare for the Future

Don’t Get Left Behind We discussed four ways that managing CAD/CAM data helps the business, and we'll add a fifth about how it creates a foundation for even greater benefits. For example, everyone is talking about how AI has the potential to change work as we know it. As a progressive job shop, you may already be using AI to analyze complex manufacturing data to optimize machining parameters, tool paths, and cutting conditions in CAM software. Effective CAD/CAM data management sets the stage for AI to leverage that data in novel ways. For example, AI could help job shops quickly and accurately estimate and generate quotes based on prior project data. Beyond internal value, customers may be more inclined to work with tech-savvy partners who can deliver more data and data-driven insights. Customers may value this information to train their own AI or improve their design process. On the other hand, job shops that are not leveraging AI have the potential to be perceived as outdated or less capable. Beyond AI, better managing CAD/CAM data sets the foundation for broader PLM capabilities. Our data shows that PDM / PLM improves operational control leading to reduced cost and higher profitability. However, the most important step is to get started by controlling, accessing, and sharing CAD/CAM data with PDM.

Build a Foundation for Future Value

Effective CAD/CAM data management is a core capability that drives agility and operational excellence internally. It also sets the stage for higher value and positive customer perception. One thing is sure, if AI does become a necessity, companies will want to have their CAD and manufacturing data in order so that AI can learn from it and leverage it. And if customers begin demanding PDM or PLM capabilities, you will have the foundation in place to support them. Mature CAD/CAM data management prepares the shop to answer questions about what they're doing about AI and PLM – internally and externally.

Beyond internal value, customers may be more inclined to work with tech-savvy partners who can deliver more data and data-driven insights. Customers may value this information to train their own AI or improve their design process. On the other hand, job shops that are not leveraging AI have the potential to be perceived as outdated or less capable. Beyond AI, better managing CAD/CAM data sets the foundation for broader PLM capabilities. Our data shows that PDM / PLM improves operational control leading to reduced cost and higher profitability. However, the most important step is to get started by controlling, accessing, and sharing CAD/CAM data with PDM.

Build a Foundation for Future Value