I caught up with a really interesting software company that I’ve been following named Soley. I shared a bit about them after our first discussion last year and I was impressed with their unique solution. At that time, I saw how they used cloud, analytics, and collaborative decision-making to understand the impact products have on…

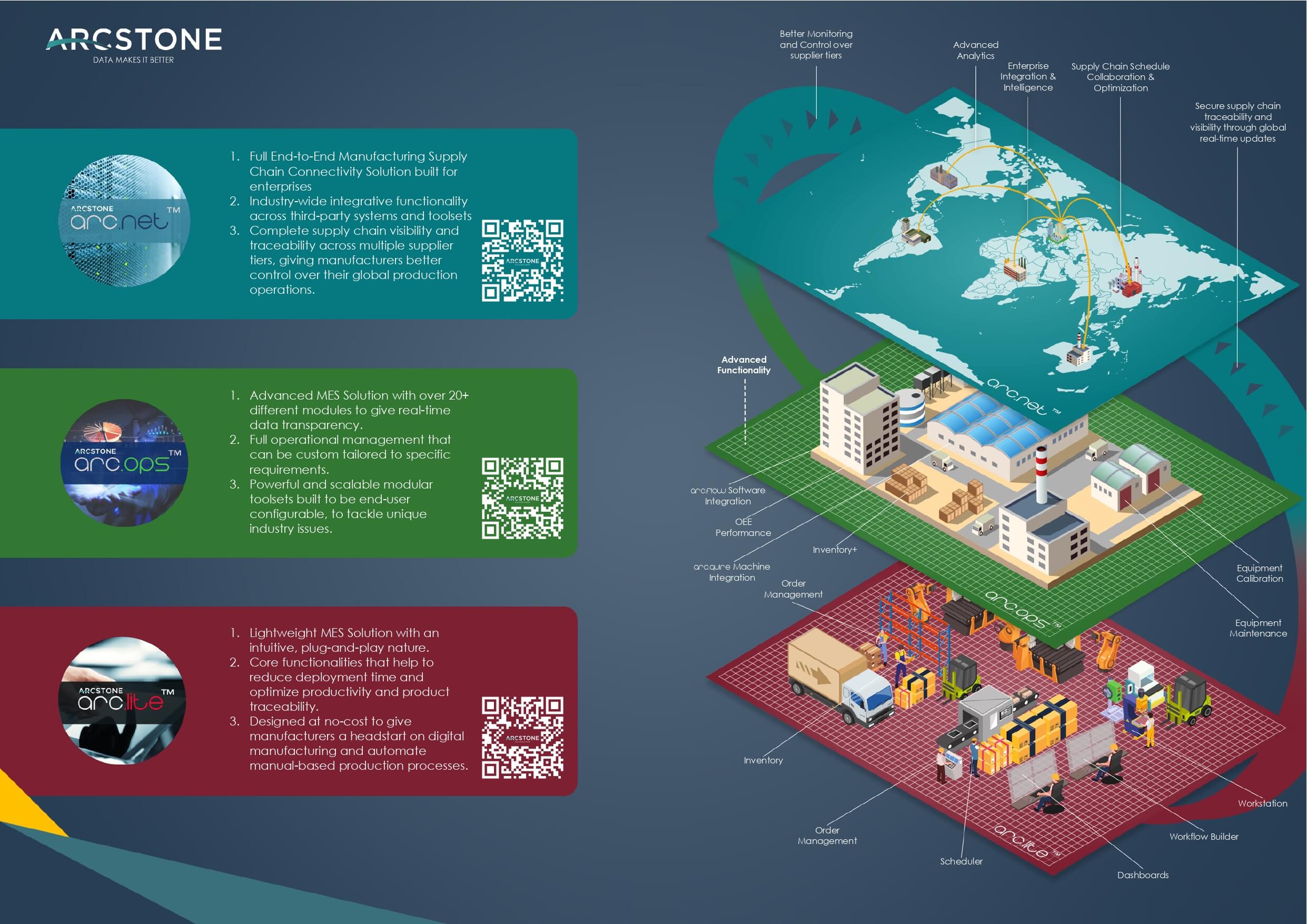

- arc.lite is a free MES for companies that might not otherwise have an IT system for production that digitizes paper-based operations.

- arc.ops is a low-code modular MES with 20 modules and powerful integration capabilities.

- arc.net is a multi-tier supply chain partner collaboration and real-time visibility tool that can deliver secure traceability through blockchain. T

- arc.green leverages all of that supply chain-wide data to create a carbon footprint rating.

[post_title] => Arcstone: MES to Feed Supply Chain Compliance and Sustainability

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => mes-for-supply-chain-visibility

[to_ping] =>

[pinged] =>

[post_modified] => 2022-12-02 14:58:06

[post_modified_gmt] => 2022-12-02 19:58:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17591

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 17575

[post_author] => 2

[post_date] => 2022-11-21 08:30:54

[post_date_gmt] => 2022-11-21 13:30:54

[post_content] =>

[post_title] => Arcstone: MES to Feed Supply Chain Compliance and Sustainability

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => mes-for-supply-chain-visibility

[to_ping] =>

[pinged] =>

[post_modified] => 2022-12-02 14:58:06

[post_modified_gmt] => 2022-12-02 19:58:06

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17591

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[4] => WP_Post Object

(

[ID] => 17575

[post_author] => 2

[post_date] => 2022-11-21 08:30:54

[post_date_gmt] => 2022-11-21 13:30:54

[post_content] =>  Business risk continues to grow and disrupt businesses, markets, and supply chains. Companies struggle to just bounce back from each disruption. But how can they do more, using digital transformation and analytics to bounce forward to take advantage of the opportunities that disruption presents?

In this webinar, Jim Brown will share how companies have accelerated new technology adoption and increased corporate agility, helping them better face the never-ending list of disruptions that now includes energy shortages and inflation in addition to unpredictable supply chains and workforce shortages.

We will also hear from our sponsor, Dassault Systemes Netvibes about how successful companies gain the full benefits of digital twins by combining the science-based representation of products, factories, and companies through modeling and simulation with the intelligence brought by data science.

Register for the live webinar to learn more on December 13 at 11:00 AM EST.

[post_title] => Bouncing Forward with Digital Transformation and Analytics

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-transformation-analytics-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 15:38:33

[post_modified_gmt] => 2023-12-15 20:38:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17575

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 12007

[post_author] => 2

[post_date] => 2022-11-16 09:30:10

[post_date_gmt] => 2022-11-16 14:30:10

[post_content] =>

Business risk continues to grow and disrupt businesses, markets, and supply chains. Companies struggle to just bounce back from each disruption. But how can they do more, using digital transformation and analytics to bounce forward to take advantage of the opportunities that disruption presents?

In this webinar, Jim Brown will share how companies have accelerated new technology adoption and increased corporate agility, helping them better face the never-ending list of disruptions that now includes energy shortages and inflation in addition to unpredictable supply chains and workforce shortages.

We will also hear from our sponsor, Dassault Systemes Netvibes about how successful companies gain the full benefits of digital twins by combining the science-based representation of products, factories, and companies through modeling and simulation with the intelligence brought by data science.

Register for the live webinar to learn more on December 13 at 11:00 AM EST.

[post_title] => Bouncing Forward with Digital Transformation and Analytics

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => digital-transformation-analytics-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 15:38:33

[post_modified_gmt] => 2023-12-15 20:38:33

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17575

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[5] => WP_Post Object

(

[ID] => 12007

[post_author] => 2

[post_date] => 2022-11-16 09:30:10

[post_date_gmt] => 2022-11-16 14:30:10

[post_content] =>  Jim Brown will host a panel discussion focusing on what it takes to deliver on the promise of the digital twin. The webinar will focus on what’s currently achievable and what results companies can reasonably expect from today’s commercially available solutions. We’ll compare the pros and cons of buying, building, and assembling digital twins and explore how far a company can go with a platform versus a “best-of-breed” approach.

Hear from a fantastic panel of experts:

Jim Brown will host a panel discussion focusing on what it takes to deliver on the promise of the digital twin. The webinar will focus on what’s currently achievable and what results companies can reasonably expect from today’s commercially available solutions. We’ll compare the pros and cons of buying, building, and assembling digital twins and explore how far a company can go with a platform versus a “best-of-breed” approach.

Hear from a fantastic panel of experts:

- Sameer Kher, Senior Director, R&D - Digital Twins, Ansys

- Robert Bray, VP & General Manager, Autodesk Tandem, Autodesk, Inc.

- Neil Garnett, Ericsson Service Transformation, Ericsson

- Jonathan Girroir, Director of Marketing, Tech Soft 3D

- Igor Tsinman, Co-Founder and President, AMC Bridge

- Game Engines and Digital Twins - Let's Play

- The Role of Simulation Technology in Digital Twins

- Digital Twin - Bridging the Gap Between Vision and Reality

To keep pace with your competition, is it time to upgrade your CAD tool?

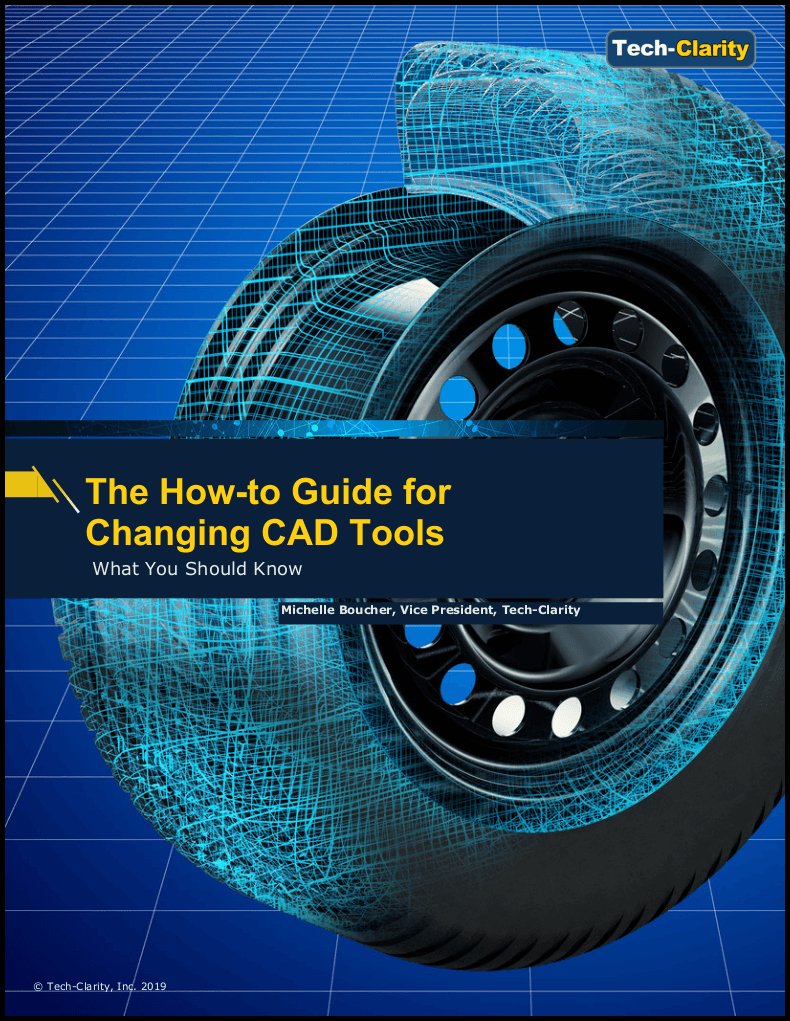

Tech-Clarity’s How-to Guide for Changing CAD Tools takes a look at this question and investigates what’s involved. Standing out in today’s global economy is not an easy task, so there is the constant quest for innovation. To innovate, many companies are turning to new technologies like 3D printing, new materials, smarter products, and digitalization. Tech-Clarity’s research How to Futureproof Your Product Design finds that 83% of Top Performing companies rate new technology as very important to their innovation goals. At the same time, new technologies can mean new approaches to design. Is your current CAD solution up to the challenge of new design approaches? If not, your CAD tool may be holding you back from bringing higher-performing, higher-quality, and more innovative products to market, making the struggle to keep up with the competition even harder.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systemes - SOLIDWORKS.

To keep pace with your competition, is it time to upgrade your CAD tool?

Tech-Clarity’s How-to Guide for Changing CAD Tools takes a look at this question and investigates what’s involved. Standing out in today’s global economy is not an easy task, so there is the constant quest for innovation. To innovate, many companies are turning to new technologies like 3D printing, new materials, smarter products, and digitalization. Tech-Clarity’s research How to Futureproof Your Product Design finds that 83% of Top Performing companies rate new technology as very important to their innovation goals. At the same time, new technologies can mean new approaches to design. Is your current CAD solution up to the challenge of new design approaches? If not, your CAD tool may be holding you back from bringing higher-performing, higher-quality, and more innovative products to market, making the struggle to keep up with the competition even harder.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systemes - SOLIDWORKS.

Table of Contents

- Table of Contents

- Executive Overview

- Understand Business Needs for Design

- What Drives a Change in CAD?

- Set Expectations for the Change

- Identifying Top Performers

- Identify the Right CAD Solution

- Extend CAD

- Conclusion

- Recommendations

- About the Author

- About the Research

- Acknowledgments

Executive Overview

Do you need to upgrade your design capabilities to keep up with competitors? Competing in today’s global economy is not easy. With significant global competition plus pressure from new entrants and innovative startups, it is tough to stand out. Many companies are turning to new technologies such as 3D printing, new materials, smarter products, digitalization, and more to innovate. Tech-Clarity’s research, How to Futureproof Your Product Design, finds that 83% of Top Performing companies rate new technology as very or extremely important to their innovation goals. However, many of these technologies require new approaches to design. Will your CAD tool support these new approaches? With the right design tools, companies are better positioned to quickly bring high-performing, high-quality, innovative products to market. If you are struggling to keep up with competitors, your CAD tool may be holding you back. So what should you do if you find your CAD tool is holding you back? Should you consider a change? If so, what should you expect? Is it worth the time to convert archived data into a new format? Most importantly, do the benefits outweigh potential risks? Tech-Clarity surveyed 192 companies to answer these questions. While there are many interesting findings, the most striking is that over time, business reasons rather than problems with CAD tools have become more influential when choosing a new CAD tool. Growing influencers include supply chains, the vendor’s vision for design, and the CAD vendors’ full breadth of offerings. This indicates CAD is now viewed as a strategic piece of a larger product development solution.

The biggest challenges of switching CAD tools are overcoming the learning curve and reusing legacy data. However, you do not need to convert all legacy data. In fact, on average, companies only convert about half of it, 52%. Despite the efforts involved, companies who have made a CAD change tend to be very happy. Eighty-three percent (83%) of respondents rate their satisfaction a four or five on a scale of one to five.

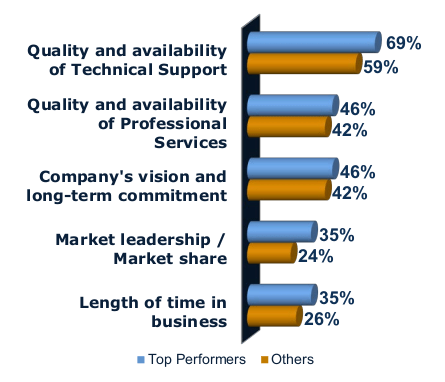

The study also identified what successful companies look for in a new CAD tool. Top Performers are more likely to consider ease of use, Technical Support, software quality, and market share, which includes the size of the user community. Since implementing their current CAD tools, Top Performers have reduced development time by 19%, development costs by15%, and the time to implement ECOs (engineering change orders) by 16%. They have also been able to increase the number of design iterations by 17%, helping them achieve greater levels of innovation.

So what should you do if you find your CAD tool is holding you back? Should you consider a change? If so, what should you expect? Is it worth the time to convert archived data into a new format? Most importantly, do the benefits outweigh potential risks? Tech-Clarity surveyed 192 companies to answer these questions. While there are many interesting findings, the most striking is that over time, business reasons rather than problems with CAD tools have become more influential when choosing a new CAD tool. Growing influencers include supply chains, the vendor’s vision for design, and the CAD vendors’ full breadth of offerings. This indicates CAD is now viewed as a strategic piece of a larger product development solution.

The biggest challenges of switching CAD tools are overcoming the learning curve and reusing legacy data. However, you do not need to convert all legacy data. In fact, on average, companies only convert about half of it, 52%. Despite the efforts involved, companies who have made a CAD change tend to be very happy. Eighty-three percent (83%) of respondents rate their satisfaction a four or five on a scale of one to five.

The study also identified what successful companies look for in a new CAD tool. Top Performers are more likely to consider ease of use, Technical Support, software quality, and market share, which includes the size of the user community. Since implementing their current CAD tools, Top Performers have reduced development time by 19%, development costs by15%, and the time to implement ECOs (engineering change orders) by 16%. They have also been able to increase the number of design iterations by 17%, helping them achieve greater levels of innovation.

Conclusion

Empowering engineers can help companies as they struggle to compete in today’s global economy. Quickly developing high-quality, innovative products, more economically helps companies differentiate and stand out from competitors. CAD tools, in particular, can have a significant impact on a company’s ability to achieve this. CAD has evolved significantly, and those who find their existing tool no longer meets their needs or will not support plans for growth may want to consider switching CAD tools. In many cases, companies have found it has had a very positive impact on their business. Top Performing companies are more likely to consider ease of use and support resources when selecting a CAD tool. This contributes to their ability to realize even more value, in less time.Recommendations

Based on industry experience and research for this report, Tech-Clarity offers the following recommendations:- Understand the business goals of your design process and ensure your CAD tool will support them. If not, consider a change.

- Consider other factors beyond the features and functions of the CAD tool, but also the ability to collaborate with your supply chain, market share including available community, the vendor’s vision, the relationship with the vendor, and the needs for other supporting design tools.

- Consider extended applications as part of the CAD solution, such as embedded simulation, PDM, technical communications, and support for electrical components.

- Avoid overestimating requirements for training and loss of productivity by considering ease of use as well as available resources such as Technical Support, market share, and potential hiring pools.

- Convert only the legacy data you need. It’s likely, you will only need half of it.

How can PLM, traditionally an engineering-centric solution, drive innovation, agility, and operational excellence throughout the entire product lifecycle? Attend this webinar to learn how the right PLM can help manufacturers focus on the big picture, not just engineering, to develop profitable products. Hear from:

How can PLM, traditionally an engineering-centric solution, drive innovation, agility, and operational excellence throughout the entire product lifecycle? Attend this webinar to learn how the right PLM can help manufacturers focus on the big picture, not just engineering, to develop profitable products. Hear from:

- Jim Brown, President of Tech-Clarity, reviewing findings from his recent research and leading the panel discussion.

- John Baumann, CEO of ThinGap, providing his experience in expanding the role of PLM for manufacturing of sophisticated and precise electric motors

- Deb Mishra, CEO of QuadRite, sharing his experience applying technology to drive operational excellence

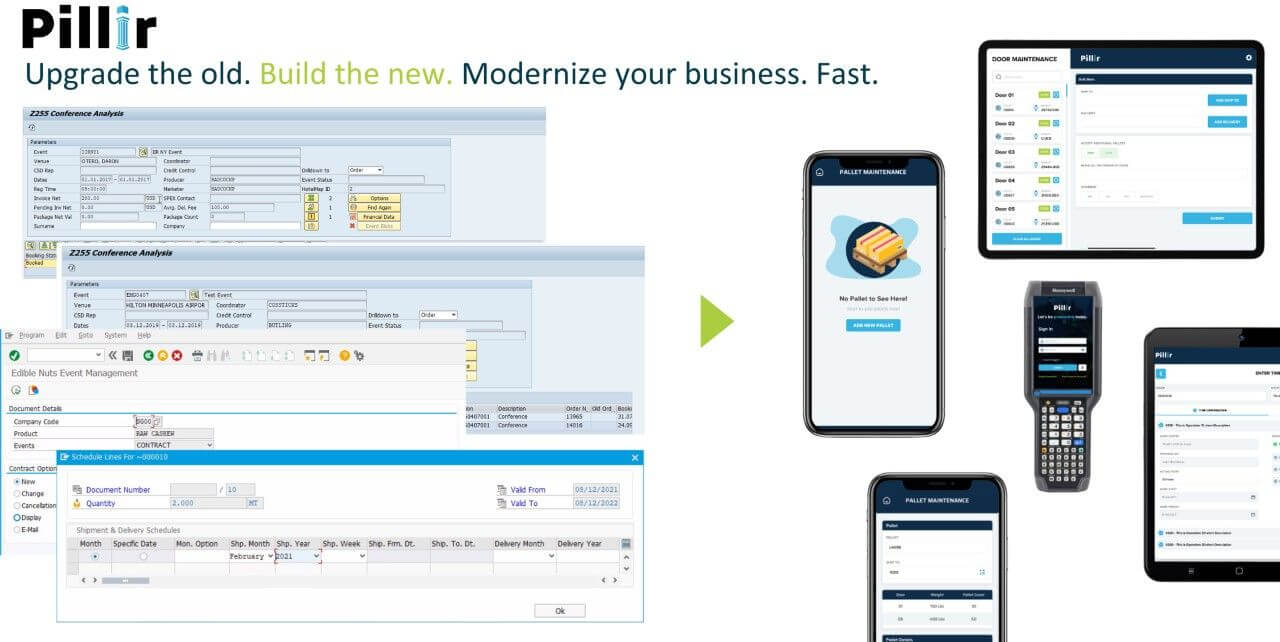

It’s really exciting to see low code / no code solutions hitting their stride. We’ve been following the approach for a long time and we’re seeing it take shape in some really interesting ways. Julie Fraser and I spoke with Pillir to understand how they’re applying low-code to improve manufacturing and supply chain in the SAP ecosystem. They’ve developed a cloud-based platform aimed at helping companies automate manual gaps with low-code, extending SAP, and modernizing legacy applications.

Companies are facing significant disruption and desperately need ways to increase agility and get more value from existing systems, what our research calls filling digital transformation gaps. Pillir helps by providing pre-built applications built on their platform and allowing customers to use them as is, modify them, or build their own applications tapping into underlying systems. One of the really interesting aspects of their approach is their focus on scanners and other rugged devices, in addition to supporting mobile, online, and offline use cases that are common in manufacturing plants and distribution facilities.

Thanks for sharing what you do, Vaidya Aiyer and Irit Gillath, we’re looking forward to learning more. And thank you for setting up the discussion Suzanne Mattaboni.

It’s really exciting to see low code / no code solutions hitting their stride. We’ve been following the approach for a long time and we’re seeing it take shape in some really interesting ways. Julie Fraser and I spoke with Pillir to understand how they’re applying low-code to improve manufacturing and supply chain in the SAP ecosystem. They’ve developed a cloud-based platform aimed at helping companies automate manual gaps with low-code, extending SAP, and modernizing legacy applications.

Companies are facing significant disruption and desperately need ways to increase agility and get more value from existing systems, what our research calls filling digital transformation gaps. Pillir helps by providing pre-built applications built on their platform and allowing customers to use them as is, modify them, or build their own applications tapping into underlying systems. One of the really interesting aspects of their approach is their focus on scanners and other rugged devices, in addition to supporting mobile, online, and offline use cases that are common in manufacturing plants and distribution facilities.

Thanks for sharing what you do, Vaidya Aiyer and Irit Gillath, we’re looking forward to learning more. And thank you for setting up the discussion Suzanne Mattaboni.

[post_title] => Pillir Lowcode Solutions are Improving the SAP Ecosystem (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => pillir-low-code-solutions-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-01-30 11:53:51

[post_modified_gmt] => 2023-01-30 16:53:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17762

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 11959

[post_author] => 2574

[post_date] => 2022-10-24 15:15:10

[post_date_gmt] => 2022-10-24 19:15:10

[post_content] =>

[post_title] => Pillir Lowcode Solutions are Improving the SAP Ecosystem (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => pillir-low-code-solutions-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2023-01-30 11:53:51

[post_modified_gmt] => 2023-01-30 16:53:51

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17762

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[9] => WP_Post Object

(

[ID] => 11959

[post_author] => 2574

[post_date] => 2022-10-24 15:15:10

[post_date_gmt] => 2022-10-24 19:15:10

[post_content] =>  How can you supercharge continuous improvement (CI) to keep up with accelerating demands and stiff competition? As a manufacturer, this is a key question. Tech-Clarity research has some pointers to the answer, and FactoryEye’s got examples too. Join this webinar discussion Nov 16, 2022 at 2pm Eastern time to learn:

How can you supercharge continuous improvement (CI) to keep up with accelerating demands and stiff competition? As a manufacturer, this is a key question. Tech-Clarity research has some pointers to the answer, and FactoryEye’s got examples too. Join this webinar discussion Nov 16, 2022 at 2pm Eastern time to learn:

- A new set of expectations for today’s CI program

- Why you must go beyond PDCA for more powerful CI results

- What data management capabilities deliver superior results

- What aspects of plant data top performers have mastered that others have not

- Elements of a new style of software designed to supercharge CI

This Tech-Clarity TV episode explains how manufacturers can get started with Product Lifecycle Management to improve engineering, innovation, and product development performance by helping them manage product-related data, processes, and projects.

Thank you Siemens for sponsoring this educational video. Watch this episode about getting started with PLM and more educational videos on the Tech-Clarity YouTube channel.

[embed]https://youtu.be/RazUg-fQM-k[/embed]

For related animations, please watch our previous episodes: Choosing your Path to PLM and The Payback of PLM.

-----------------

This Tech-Clarity TV episode explains how manufacturers can get started with Product Lifecycle Management to improve engineering, innovation, and product development performance by helping them manage product-related data, processes, and projects.

Thank you Siemens for sponsoring this educational video. Watch this episode about getting started with PLM and more educational videos on the Tech-Clarity YouTube channel.

[embed]https://youtu.be/RazUg-fQM-k[/embed]

For related animations, please watch our previous episodes: Choosing your Path to PLM and The Payback of PLM.

-----------------

Transcript

Product lifecycle management, PLM, improves engineering, innovation, and product development performance by helping manufacturers manage product-related data, processes, and projects. But how can you get started with limited resources? Let’s get some clarity. Barriers to PLM are dropping. The cloud offers faster implementations with lower risk and resources. This makes it easier for even small manufacturers and startups to get started with PLM. In fact, leading companies are now more likely to use the cloud for both CAD and product development collaboration. But not all PLM options are the same. Some PLM solutions can be intimidating. You can configure them to be exactly what you want, but it can take a lot of time, effort, and expertise. That might be attractive to some, but many companies can't afford to configure a solution to their exact needs. They just want to hit the easy button and have PLM start managing engineering data and processes - right out of the box. But a cookie-cutter approach with no flexibility may not meet your needs and won’t provide the flexibility you need to adapt over time. Simple solutions won't let you scale or add new capabilities, creating a dead end with nowhere to grow. You need the right foundation with standard processes and configurations - to let you start fast. But you need the flexibility to configure the solution to your needs, so you can compete and differentiate. You need room to grow as your needs change, so you can get even more value over time, leveraging your easy start as a foundation for growth. Tech Clarity's research shows that cloud PLM for product design data management helps manufacturers:- Get started quickly

- Reduce implementation barriers

- And Improve collaboration

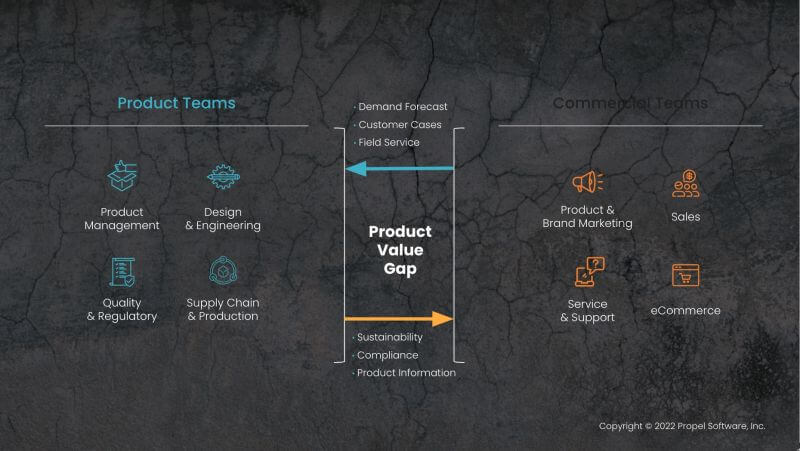

I had the chance to check in with Propel to get an update on their Product Value Management (PVM) strategy. I’m usually not a big fan of new acronyms, but they really are talking about something more than the current state of PLM. When I started researching PLM (two decades ago, yikes), I developed a comprehensive framework for what the solution could and should be. At the time, it was influenced quite a bit by consumer-oriented new product development (NPD) processes, where NPD needed to expand to NPDI (adding introduction). Few, if any, PLM vendors had that vision, and I would propose that none fully delivered on the promise. Propel is now realizing that vision. The key difference is filling what they call the “product value gap” between product and commercial teams. Propel’s strategy goes beyond what I envisioned, though, focusing on a comprehensive customer experience that spans products and product experiences. It includes three pillars: Defining the product, product operations, and market engagement. It fits the times and how consumers want to engage with products and companies. Propel is led by strategic, visionary thinkers, including Ray Hein, and has the strong support of Salesforce. Keep your eyes on them. If anyone can shake up the industry and move it beyond PLM to PVM it’s probably them. Thanks Tom Shoemaker for sharing the vision with me.

I had the chance to check in with Propel to get an update on their Product Value Management (PVM) strategy. I’m usually not a big fan of new acronyms, but they really are talking about something more than the current state of PLM. When I started researching PLM (two decades ago, yikes), I developed a comprehensive framework for what the solution could and should be. At the time, it was influenced quite a bit by consumer-oriented new product development (NPD) processes, where NPD needed to expand to NPDI (adding introduction). Few, if any, PLM vendors had that vision, and I would propose that none fully delivered on the promise. Propel is now realizing that vision. The key difference is filling what they call the “product value gap” between product and commercial teams. Propel’s strategy goes beyond what I envisioned, though, focusing on a comprehensive customer experience that spans products and product experiences. It includes three pillars: Defining the product, product operations, and market engagement. It fits the times and how consumers want to engage with products and companies. Propel is led by strategic, visionary thinkers, including Ray Hein, and has the strong support of Salesforce. Keep your eyes on them. If anyone can shake up the industry and move it beyond PLM to PVM it’s probably them. Thanks Tom Shoemaker for sharing the vision with me.

[post_title] => Propel's Product Value Management (PVM) Strategy (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => product-value-management-insight-propel

[to_ping] =>

[pinged] =>

[post_modified] => 2023-01-30 12:07:24

[post_modified_gmt] => 2023-01-30 17:07:24

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17772

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 11909

[post_author] => 2

[post_date] => 2022-10-11 12:15:46

[post_date_gmt] => 2022-10-11 16:15:46

[post_content] =>

[post_title] => Propel's Product Value Management (PVM) Strategy (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => product-value-management-insight-propel

[to_ping] =>

[pinged] =>

[post_modified] => 2023-01-30 12:07:24

[post_modified_gmt] => 2023-01-30 17:07:24

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17772

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[12] => WP_Post Object

(

[ID] => 11909

[post_author] => 2

[post_date] => 2022-10-11 12:15:46

[post_date_gmt] => 2022-10-11 16:15:46

[post_content] =>  How can remote equipment monitoring improve service performance and profitability? Our buyer's guide shares tangible, practical steps companies can take to improve service through IoT remote equipment monitoring, how IoT platforms help deliver value, and how they can increase benefits with increased maturity.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

How can remote equipment monitoring improve service performance and profitability? Our buyer's guide shares tangible, practical steps companies can take to improve service through IoT remote equipment monitoring, how IoT platforms help deliver value, and how they can increase benefits with increased maturity.

Please enjoy the summary* below. For the full research, please visit our sponsor PTC (registration required).

Table of Contents

- Improving Service Profitability with Remote Monitoring

- Begin the Remote Monitoring Journey to Service Performance

- Set Your Business Targets

- Access Equipment and Equipment Data

- Communicate with Equipment

- Transform Data to Increase Value

- Analyze Data to Create Service Intelligence

- Share Actionable Service Information

- Implementation and Adoption

- Selecting a Strategic Partner

- Next Steps

- Buyer's Guide Checklist

- Acknowledgments

Remote Machine Monitoring Drives Operational Improvements

IoT Machine Monitoring Opportunities Monitoring machines using the IoT offers significant business value including increased quality, manufacturing throughput, and service performance. Of these opportunities, transforming service has become a proven way to improve equipment performance and profitability in the field and in the factory. Service transformation is a good target because service organizations have increased their maturity in the last decade and are now more sophisticated and data-driven. In addition, IoT platforms are now available to ensure companies get beyond a “proof of concept” to improve performance and profitability at scale. And as Dr. Yuri Hovanski, Associate Professor of Mechanical Engineering at Brigham Young University (BYU), explains, “Companies have been using predictive maintenance for decades. It’s not new, but the cost to deploy it 20 years ago was phenomenally expensive.” The Time for Service Transformation is Now The leaders now have the opportunity to expand on early efforts, apply lessons learned from initial projects, and drive repeatable value that they can grow over time. Those that have not started, on the other hand, likely face competitive threats from more mature organizations.Improving Service Profitability with Remote Monitoring

Service is a Proven Value Driver The most common way that companies gain tangible performance gains from IoT is through improved service. The IoT lets companies transform service to generate more – and more profitable – service revenue. They do this by moving from reactive to proactive to predictive service. Service is an excellent opportunity to leverage advanced technologies like AI, machine learning, and big data analytics. The most common first step is reducing the cost of service through remote monitoring and is within reach for most companies. In addition, companies can improve performance through new service delivery processes like remote service. Use this Guide to Achieve Results This guide shares the tangible, practical steps companies can take to improve service through IoT remote equipment monitoring, how IoT platforms help deliver value, and how they can increase benefits with increased maturity. Then, the buyer’s guide focuses on the essential needs companies must consider to ensure a successful initiative. The requirements are intended to help companies frame their search process and efficiently find the right solution. The checklists go beyond software functionality to cover factors important to implementation, adoption, partner choice, and more. These are the factors that drive long-term business success from an IoT initiative.Manufacturers can see double-digit increases in throughput from predictive maintenance Dr. Yuri Hovanski, Associate Professor, BYU

A machine failed in 2020 that cost $450k in downtime and repair to get it back up and running. We implemented a monitoring solution and got an alert allowing us to take the machine down in planned downtime and repair it for $20k to $30k. Todd Earis, EATON

Next Steps

Recognize the Potential

Leveraging the IoT can help companies improve service for themselves and their customers by reducing cost and transitioning to proactive and predictive service. Remote monitoring allows companies to identify and resolve issues remotely, providing faster service and increased uptime for the customer while reducing the cost of truck rolls and putting service technicians on site. It can go beyond cost savings to create a new source of revenue from paid upgrades or remotely enhancing equipment capabilities or permissions by “unlocking” enhanced capabilities via a subscription.

Get Started

Now, more than ever, it’s critical to get started. Service transformation has gone beyond the early adopters and is now becoming necessary to compete. Companies have to avoid “paralysis through analysis” and make tangible progress. As Danny Jackson of Autoliv advises, “Done is better than perfect, start doing some things. We lost some time trying to do it perfectly, then made more progress by doing things and learning from them.”

Adopt a Pragmatic Approach

Companies have to get started, but they shouldn’t try to accomplish everything at once. Instead, it’s essential to adopt an incremental approach. Companies can organize their service and machine monitoring efforts in small, manageable, incremental “sprints” that will result in broader, transformational value. Each effort should build on the prior one. Companies should create a framework as they solve the first problem, focusing on operationalizing their capabilities and building repeatable solutions.

Extend the Value

As companies become more experienced and data-centric, they can increase the maturity of their service applications and analytics. They can apply results in their own facilities to improve how they service smart products at customer locations. They can extend to other use cases such as customer self-service, remote maintenance, predicting yield, optimizing manufacturing processes, predicting scrap/rework, or reducing process variability. There is a lot of value available across the enterprise and the value chain in addition to improving service.

Recognize the Potential

Leveraging the IoT can help companies improve service for themselves and their customers by reducing cost and transitioning to proactive and predictive service. Remote monitoring allows companies to identify and resolve issues remotely, providing faster service and increased uptime for the customer while reducing the cost of truck rolls and putting service technicians on site. It can go beyond cost savings to create a new source of revenue from paid upgrades or remotely enhancing equipment capabilities or permissions by “unlocking” enhanced capabilities via a subscription.

Get Started

Now, more than ever, it’s critical to get started. Service transformation has gone beyond the early adopters and is now becoming necessary to compete. Companies have to avoid “paralysis through analysis” and make tangible progress. As Danny Jackson of Autoliv advises, “Done is better than perfect, start doing some things. We lost some time trying to do it perfectly, then made more progress by doing things and learning from them.”

Adopt a Pragmatic Approach

Companies have to get started, but they shouldn’t try to accomplish everything at once. Instead, it’s essential to adopt an incremental approach. Companies can organize their service and machine monitoring efforts in small, manageable, incremental “sprints” that will result in broader, transformational value. Each effort should build on the prior one. Companies should create a framework as they solve the first problem, focusing on operationalizing their capabilities and building repeatable solutions.

Extend the Value

As companies become more experienced and data-centric, they can increase the maturity of their service applications and analytics. They can apply results in their own facilities to improve how they service smart products at customer locations. They can extend to other use cases such as customer self-service, remote maintenance, predicting yield, optimizing manufacturing processes, predicting scrap/rework, or reducing process variability. There is a lot of value available across the enterprise and the value chain in addition to improving service.

Buyer’s Guide Checklist

Set Your Criteria and Get Started Remote equipment monitoring is a proven way to improve service. It’s also a valuable first step in the IoT journey and digital transformation. Companies embarking on a remote monitoring initiative to improve service should look for the capabilities outlined in this guide to help ensure they get the value they seek. In addition, they can use the following checklist as high-level criteria to compare offerings. Machine Monitoring Solution Checklist:- Develop a strategy to improve service performance

- Start small and expand value quickly

- Identify a problem that would be valuable to solve and will make a meaningful business impact

- Get the right capabilities to monitor equipment, analyze data, put data in context, and create actionable service intelligence

- Look for predefined connectivity, dashboards, analysis, and applications and don’t start from scratch

- Avoid the cost, repeatability, integration, and scalability pitfalls of “do it yourself” initiatives

- Adopt a platform approach to remote equipment monitoring

- Get the right business and technical help to drive successful adoption

- Create a foundation for future growth

- Look for a partner with IoT and business expertise and a comprehensive ecosystem

- Get started with remote monitoring to reduce service cost, grow service revenue, and develop stronger customer relationships

- Expand to other use cases to drive additional value

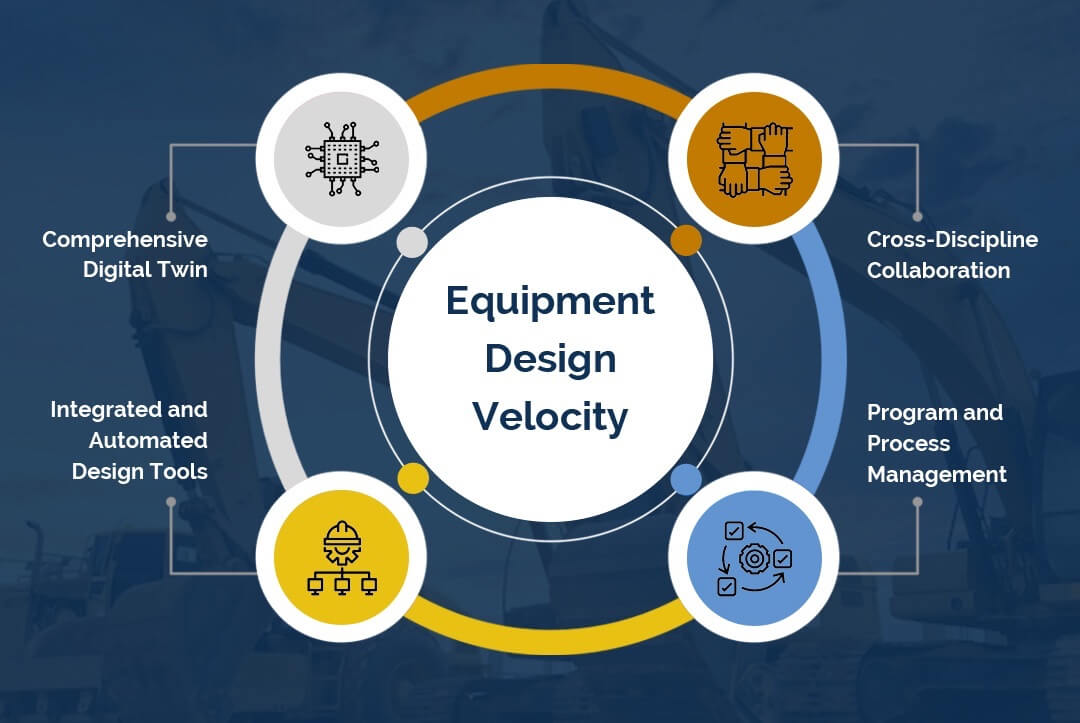

How can manufacturers accelerate equipment quotes, design, and delivery without sacrificing performance and quality? What four disciplines do they need to digitally transform their design processes to move faster and get designs right the first time despite increasing complexity?

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

For related research, register for the upcoming live webinar: Accelerate equipment design using product design software.

How can manufacturers accelerate equipment quotes, design, and delivery without sacrificing performance and quality? What four disciplines do they need to digitally transform their design processes to move faster and get designs right the first time despite increasing complexity?

Please enjoy the summary* below. For the full research, please visit our sponsor Siemens (registration required).

For related research, register for the upcoming live webinar: Accelerate equipment design using product design software.

Table of Contents

- Innovation Introduces Complexity

- Embrace Complexity without Compromises

- Adopt a Comprehensive Digital Twin

- Integrate and Streamline Design

- Enable Cross-Discipline Collaboration

- Operationalize Program and Process Management

- Move Faster with a Comprehensive Digital Twin and Digital Continuity

- Acknowledgments

Rapidly Developing Complex Equipment

Accelerate Equipment Design to Drive Profits Speed is the key to top-line business performance. Equipment manufacturers must rapidly quote, design, and deliver machines to satisfy customers and drive revenue. But speed can’t come at the expense of performance, quality, and cost. Sacrificing product fundamentals leads to poor bottom-line profitability regardless of top-line growth. In addition, trading off quality, cost, and performance to meet due dates damages customer relationships and brand reputation. It’s time for equipment manufacturers to digitally transform equipment design and development so they can accelerate equipment design and get designs right the first time.Embrace Complexity without Compromises

Adopt a Better Design Process Despite the challenges, complexity isn’t an inherently bad thing. Manufacturers can embrace complexity to further technology advances like autonomous operations and connected work environments that allow them to bring new capabilities to market. In addition, they can differentiate by increasing configurability to better allow customers to tailor equipment more exactly to their needs. Mastering complexity lets manufacturers help their customers dramatically improve efficiency and productivity. Digitally Transform

To compete in this complex environment, however, equipment manufacturers must digitally transform their product design and development processes to be as efficient, agile, and adaptable as possible. They have to be able to design more quickly without compromising quality, reliability, or performance. Accelerating design requires a better way of doing things, a collaborative, systems-oriented product development process based on digital data and process continuity. This process should allow them to iterate and innovate without fear, with the comfort that their design and engineering processes are under control.

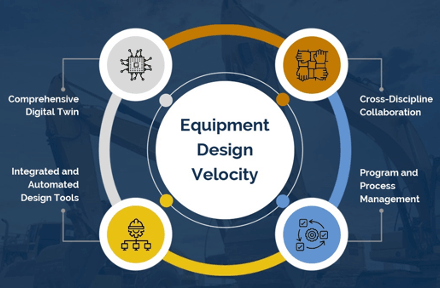

Improve Four Disciplines to Drive Speed with Quality

Mastering the design of complex products is an opportunity to rise above the crowd. It’s time to digitally transform equipment design and development to raise the bar on the competition through rapid, accurate product design. To support this, we’ve identified four key disciplines to drive speed while accommodating complexity:

Digitally Transform

To compete in this complex environment, however, equipment manufacturers must digitally transform their product design and development processes to be as efficient, agile, and adaptable as possible. They have to be able to design more quickly without compromising quality, reliability, or performance. Accelerating design requires a better way of doing things, a collaborative, systems-oriented product development process based on digital data and process continuity. This process should allow them to iterate and innovate without fear, with the comfort that their design and engineering processes are under control.

Improve Four Disciplines to Drive Speed with Quality

Mastering the design of complex products is an opportunity to rise above the crowd. It’s time to digitally transform equipment design and development to raise the bar on the competition through rapid, accurate product design. To support this, we’ve identified four key disciplines to drive speed while accommodating complexity:

- Comprehensive Digital Twin

- Integrated and Automated Design Tools

- Cross-Discipline Collaboration

- Program and Process Management

Move Faster with a Comprehensive Digital Twin and Digital Continuity

Improve Processes Complex equipment manufacturers must reduce the time it takes to quote and deliver configured equipment to meet customer needs. Today’s markets are competitive and time is the key to winning business. However, companies can’t afford to increase design speed at the expense of performance, quality, or cost. Instead, manufacturers have to accelerate equipment design while getting things right the first time. Embrace Complexity Companies shouldn’t trade off complexity for speed, either. Equipment manufacturers have an opportunity to raise the bar on their competitors by not only managing the current complexity of mechatronic equipment but taking it to the next level. With process improvement, manufacturers can innovate with the confidence to incorporate new features and technologies including more electrified, connected equipment. Improve Enabling Technology Manufacturers can accelerate design without making compromises by adopting the following four key disciplines:- Comprehensive Digital Twin

- Integrated and Automated Design Tools

- Cross-Discipline Collaboration

- Program and Process Management

What strategies are companies adopting to ensure long-term business success and profitability as they experience constant business disruptions like COVID, supply chain instability, and now armed conflict in Ukraine? What impacts do these events, coupled with increased environmental, social, and governance (ESG) pressure, have on their business? How are they transforming to overcome growing risk? Read our 4th annual survey for insights.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

For related research, please read our prior survey results: Business Sustainability and Transformation Strategies 2021, Business Sustainability and Survival 2020, and Executive Strategies for Long-Term Business Success 2019.

What strategies are companies adopting to ensure long-term business success and profitability as they experience constant business disruptions like COVID, supply chain instability, and now armed conflict in Ukraine? What impacts do these events, coupled with increased environmental, social, and governance (ESG) pressure, have on their business? How are they transforming to overcome growing risk? Read our 4th annual survey for insights.

Please enjoy the summary* below. For the full research, please visit our sponsor Dassault Systèmes (registration required).

For related research, please read our prior survey results: Business Sustainability and Transformation Strategies 2021, Business Sustainability and Survival 2020, and Executive Strategies for Long-Term Business Success 2019.

Table of Contents

- Business Risks and Disruption are Expanding

- European Conflict Adds to Existing Challenges*

- Fundamentals and Strategy Drivers Largely Unchanged*

- Focus on Long-Term Business Sustainability

- Increased Attention to ESG*

- Drivers of Increased ESG Focus*

- Companies Report Ambitious ESG Plans

- Companies Report Putting ESG Plans into Action*

- Adopting Technologies to Support the Pillars*

- Conclusions and Recommendations

- About the Research*

- Acknowledgments*

Risk and Disruption Persist, ESG Pressure Grows

Business Risk and Disruption Continue to Climb “Business is all about risk taking and managing uncertainties and turbulence,” said billionaire industrialist Gautam Adani. Managing disruption may never have been more important than over the last decade. Starting in 2019, our research series, Executive Strategies for Long-Term Business Success, reported significant growth in business risk and disruption. The survey series then tracked related business trends, as companies shifting focus to survive the COVID-19 pandemic in 2020. Then, in 2021, companies leveraged digital technologies to emerge more agile and resilient to disruption. This year finds business risk and disruption increasing again, highlighted by supply chain disruption, energy shortages, and labor shortfalls. In addition, the conflict in Ukraine is creating extensive global market impacts. Increasing Urgency on Sustainability Issues Beyond these disruptions, the 2022 survey finds increasing business pressure related to environmental, social, and governance (ESG) concerns. Environmental compliance and social responsibility have always been pillars of long-term business sustainability. Now, they have become more urgent as climate change advances, financial markets pay more attention, and governments adopt specific dates to achieve goals such as net zero carbon. Our survey of 183 companies now finds that ESG is a more urgent part of a comprehensive business sustainability strategy that includes digital transformation, product/service innovation, developing/retaining the future, and capturing knowledge/IP. What are companies doing to ensure long-term business success in these turbulent times? How can they leverage the pillars of long-term business sustainability to succeed?Focus on Long-term Business Sustainability

Focus on the Pillars of Business Sustainability Our executive survey series tracks a collection of areas companies must address to survive and thrive despite persistent risk and disruption. These pillars have evolved with our research and include:- Digital Transformation / Adopting New Technology

- Product / Service Innovation and Agility

- Workforce Development

- Environmental and Social Sustainability

- Adopting New Business Models

Companies Report Ambitious ESG Plans

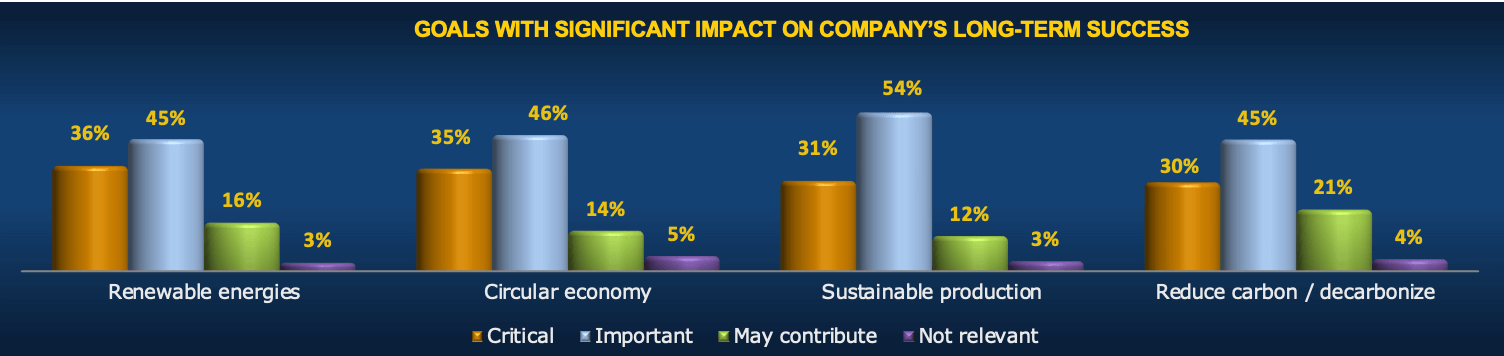

Companies Recognize Business Impact of ESG Initiatives Drilling down into sustainability plans, researchers investigated which goals companies believe will significantly impact their company’s long-term success. More than three-quarters of companies viewed all of the ESG initiatives investigated as either critical or important to their success. This perspective confirms that all of these initiatives; shifting to renewable energies, adopting circular economy principles, pursuing sustainable production, and reducing carbon, are business necessities. Fortunately, these initiatives are interrelated, and pursuing any of them may help reach the objectives of others. For example, renewable energies can help reduce carbon emissions. Going Beyond the Minimum ESG needs are essential to business success and becoming higher priorities due to customer and market demands. So how are companies reacting to requirements? In prior studies and experience, we’ve encountered many companies doing the least they could do, typically to avoid regulatory action. In this study, we asked respondents to share both the timing and the scope of their company’s plans to meet environmental and social responsibility requirements. The majority of responding companies focus on meeting all customer / government requirements for scope and timing. Conversely, very few companies only plan to meet either “some or very few” or only address requirements that are most actively enforced or expected to be enforced. In fact, about one-third of companies plan to exceed expectations. Of course, stating these as objectives is not as easy as attaining these goals, but it's a positive sign that companies are taking a more proactive stance on ESG.Conclusions and Recommendations

Take a Balanced Approach to Business Sustainability Companies will have to continue to deal with business risk and disruption. It is the status quo. Although companies are moving away from the crisis response to COVID, they are still dealing with supply chain, energy, workforce, and financial market issues that are getting worse due to factors like the conflict in Europe. Companies must focus on business fundamentals and be agile to adapt to changing circumstances so they can drive long-term business success. They need to take a balanced approach to address all of the pillars of business sustainability, including:- Digital Transformation / Adopting New Technology

- Product / Service Innovation and Agility

- Workforce Development

- Environmental and Social Sustainability

- Adopting New Business Models

The most surprising finding in this year’s study is a significant rise in focus on ESG. Survey results show an increased recognition of ESG’s role in maintaining success and profitably over the long term. Customers and markets are now demanding social and environmental sustainability.

Although prior surveys showed an awareness of these needs, there was a significant disconnect between awareness and action. The most dramatic change in the data is that companies report that they are taking action. Respondents report that they are actively pursuing ESG goals, including:

The most surprising finding in this year’s study is a significant rise in focus on ESG. Survey results show an increased recognition of ESG’s role in maintaining success and profitably over the long term. Customers and markets are now demanding social and environmental sustainability.

Although prior surveys showed an awareness of these needs, there was a significant disconnect between awareness and action. The most dramatic change in the data is that companies report that they are taking action. Respondents report that they are actively pursuing ESG goals, including:

- Renewable energies

- Circular economy

- Sustainable production

- Decarbonization / reducing carbon

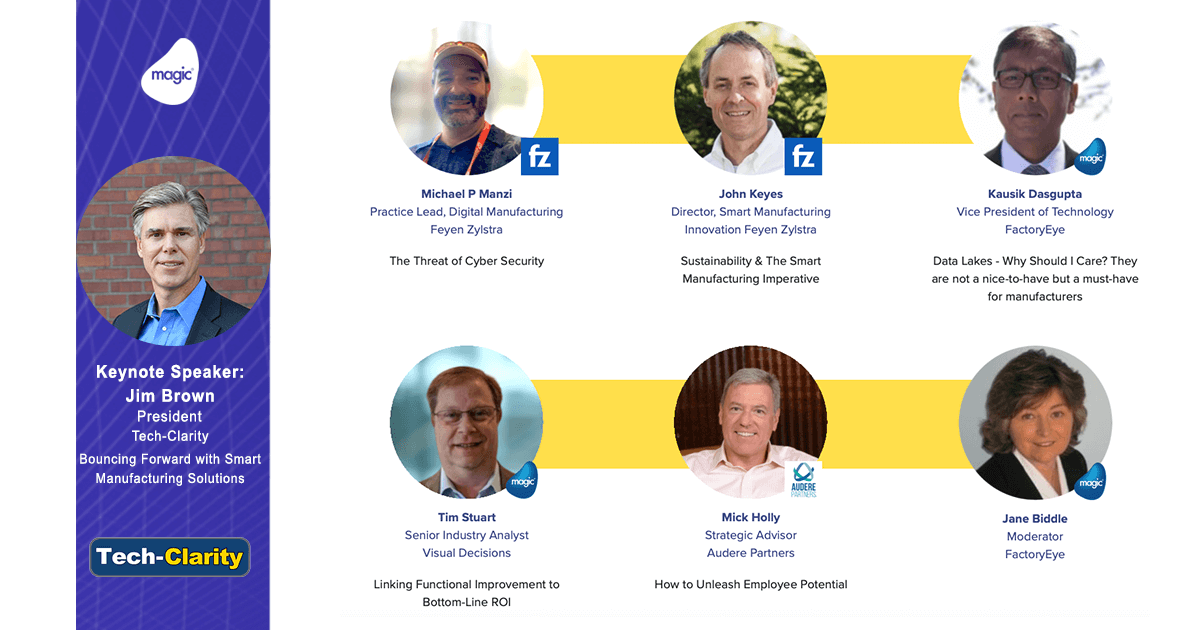

What do industry experts and your manufacturing peers have to say about Industry 4.0 and smart manufacturing initiatives? Join this free live event on October 6th in Charlotte, North Carolina to learn and share your experience.

Our own Jim Brown will keynote the conference. He will share his research on how manufacturers can “bounce forward” from recent disruptions with smart manufacturing. Then you’ll hear from a host of knowledgeable speakers and have the opportunity to join in the roundtable discussion to learn from the presenters, panelists, and peers alike. And you can stay for the happy hour to continue the conversations or just enjoy the experience at The Barrel Room at Trip C Brewing Co.

What do industry experts and your manufacturing peers have to say about Industry 4.0 and smart manufacturing initiatives? Join this free live event on October 6th in Charlotte, North Carolina to learn and share your experience.

Our own Jim Brown will keynote the conference. He will share his research on how manufacturers can “bounce forward” from recent disruptions with smart manufacturing. Then you’ll hear from a host of knowledgeable speakers and have the opportunity to join in the roundtable discussion to learn from the presenters, panelists, and peers alike. And you can stay for the happy hour to continue the conversations or just enjoy the experience at The Barrel Room at Trip C Brewing Co.

List of speakers:

List of speakers:

- Jim Brown (keynote) – President and Founder, Tech-Clarity

- Bouncing Forward with Smart Manufacturing Solutions

- Michael P Manzi - Practice Lead, Digital Manufacturing, Feyen Zylstra

- The Threat of Cyber Security

- John Keyes - Director, Smart Manufacturing Innovation, Feyen Zylstra

- Sustainability & The Smart Manufacturing Imperative

- Kausik Dasgupta - Vice President of Technology, FactoryEye

- Data Lakes - Why Should I Care? They are not a nice-to-have but a must-have for manufacturers

- Tim Stuart - Senior Industry Analyst Visual Decisions, Visual Decisions

- Linking Functional Improvement to Bottom-Line ROI

- Mick Holly - Strategic Advisor, Audere Partners

- How to Unleash Employee Potential

- Jane Biddle, Moderator, FactorEye

How can heavy equipment manufacturers accelerate how they quote, build, and deliver equipment to grow revenue without forfeiting profits by sacrificing quality and performance? This webinar shares four disciplines that equipment producers can adopt to implement a world-class design process based on a comprehensive digital twin and digital continuity.

Register for this live webinar sponsored by Siemens on September 28th to hear Jim Brown share the results of his recent research, Increasing Equipment Design Velocity.

For related research, watch the Improving Performance Engineering webinar to learn how companies can increase performance engineering maturity to develop more innovative, high-performance equipment with fewer prototypes and lower costs.

[post_title] => Four Disciplines to Accelerate Heavy Equipment Design

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => heavy-equipment-design-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 16:26:32

[post_modified_gmt] => 2023-12-15 21:26:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11835

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 11810

[post_author] => 2572

[post_date] => 2022-09-13 09:00:50

[post_date_gmt] => 2022-09-13 13:00:50

[post_content] =>

How can heavy equipment manufacturers accelerate how they quote, build, and deliver equipment to grow revenue without forfeiting profits by sacrificing quality and performance? This webinar shares four disciplines that equipment producers can adopt to implement a world-class design process based on a comprehensive digital twin and digital continuity.

Register for this live webinar sponsored by Siemens on September 28th to hear Jim Brown share the results of his recent research, Increasing Equipment Design Velocity.

For related research, watch the Improving Performance Engineering webinar to learn how companies can increase performance engineering maturity to develop more innovative, high-performance equipment with fewer prototypes and lower costs.

[post_title] => Four Disciplines to Accelerate Heavy Equipment Design

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => heavy-equipment-design-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2023-12-15 16:26:32

[post_modified_gmt] => 2023-12-15 21:26:32

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=11835

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[17] => WP_Post Object

(

[ID] => 11810

[post_author] => 2572

[post_date] => 2022-09-13 09:00:50

[post_date_gmt] => 2022-09-13 13:00:50

[post_content] =>  How do Top Performing companies get better results with their multi-disciplinary development projects?

Projects involving multiple engineering disciplines such as mechanical, electrical, and software can be incredibly complex. How much time do team members waste searching for information, investigating and fixing errors, dealing with integration issues, working around poor architecture design choices, and redoing work due to miscommunications? How much better could products be if more of that time went to innovation and improving designs? How do Top Performing companies deal with this?

How to Improve Multi-Disciplinary Project Performance with Model-Based Systems Engineering (MBSE), a research study based on a survey of 193 companies, examines the practices of those involved with multi-disciplinary development projects. The study looks at what Top Performing companies do to achieve better results than their peers and identifies how any company can improve efficiency, lower cost, and increase quality.

Please enjoy the summary* below. For the full research, please visit our sponsor IBM (registration required).

How do Top Performing companies get better results with their multi-disciplinary development projects?

Projects involving multiple engineering disciplines such as mechanical, electrical, and software can be incredibly complex. How much time do team members waste searching for information, investigating and fixing errors, dealing with integration issues, working around poor architecture design choices, and redoing work due to miscommunications? How much better could products be if more of that time went to innovation and improving designs? How do Top Performing companies deal with this?

How to Improve Multi-Disciplinary Project Performance with Model-Based Systems Engineering (MBSE), a research study based on a survey of 193 companies, examines the practices of those involved with multi-disciplinary development projects. The study looks at what Top Performing companies do to achieve better results than their peers and identifies how any company can improve efficiency, lower cost, and increase quality.

Please enjoy the summary* below. For the full research, please visit our sponsor IBM (registration required).

Table of Contents

- Executive Summary

- Importance of Systems Engineering Best Practices

- Business Impact of System Challenges

- Identifying Top Performers

- Top Performers' Strategies

- Model-Based Systems Engineering (MBSE)

- What to Look for in an MBSE Solution

- How Top Performers Use MBSE

- Preparing Staff to Support MBSE

- Drivers to Adopt MBSE

- MBSE Results

- Recommendations

- About the Research

- Acknowledgments

Executive Summary

Today's Modern Products Many of today’s products have evolved into complex systems of mechanical components, electronics, and software. Consequently, systems engineering best practices have become essential as demand for integrated systems has continued to increase. These practices have become instrumental to product development in many industries, especially aerospace and defense, automotive, industrial machinery, medical devices, consumer electronics, and others. The Cost of Suboptimal Processes While companies continue to release products, most struggle with increasing complexity, more requirements, late discovery of problems, and poor collaboration. Unfortunately, these challenges add significant cost and hurt profitability. While these costs may not be easy to quantify, do not underestimate their impact as product complexity grows. Those who do not look for better ways to manage these challenges risk falling behind their competition and suffering significant profitability hits. This research explores the plans Top Performers have for the next 12 months, revealing insights companies can use to improve their development processes. Top Performers plan to embrace digitalization further, invest in solutions that better integrate engineering disciplines, adopt systems engineering best practices, and transition from a document-based approach to a model-based one. A finding that stood out is that Model-Based Systems Engineering (MBSE) is becoming a crucial enabler. MBSE An overwhelming 97% of Top Performing companies have adopted MBSE or plan to adopt it. Companies that have already adopted MBSE report benefits such as a single source of truth, improved traceability, and a common visual reference. As a result, their teams are more productive and produce higher-quality products. While 99% of all companies that have deployed MBSE report benefits, Top Performers experience even more value due to how they adopt and use the solution. Further, many companies that have adopted MBSE report even more benefits than anticipated by their own estimations. This Research Report This research report reveals:- Why you should consider adopting MBSE

- How to get even more value from MBSE

- Benefits you can expect to realize with MBSE

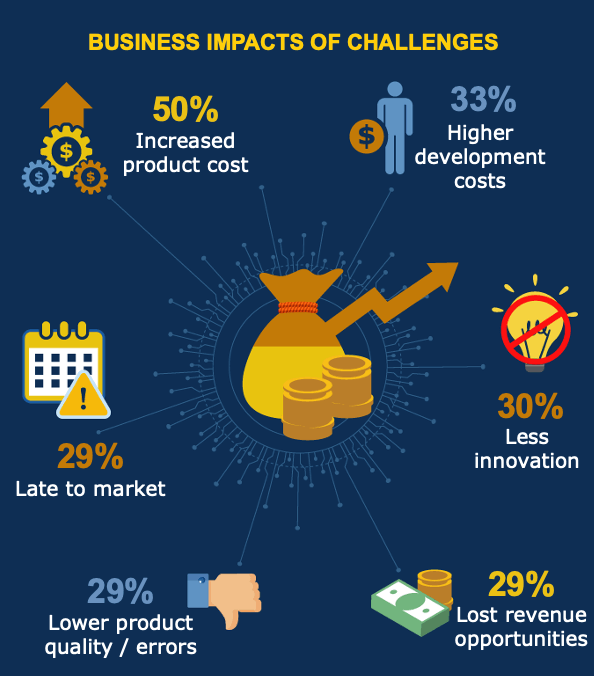

Business Impact of System Challenges

Business Impact of System Challenges

Business Impacts

While products still get released, ignoring the top challenges of system design comes at a high cost. The graph reveals the top business impacts of the challenges associated with designing multi-disciplinary systems.

Higher Cost

Without suitable methods for managing system complexity, mistakes are hard to avoid. It’s also harder to catch errors early and identify all the impacts, especially considering interdependencies across components and subsystems. Finding problems late can result in rework, hours or even days of wasted effort, and scrap, increasing costs. Plus, late discovered problems take longer to correct, which means longer development times and delays, further increasing development costs. Then when you consider the impact across all system variants, costs grow exponentially.

The lack of good ways to plan and visualize complex systems can compromise optimal decisions around system architecture. This can lead to higher product costs and more brittle systems that make changes even more expensive and time-consuming.

Less Innovation and Revenue

Innovation sets your products apart, excites customers, and drives revenue opportunities. If your development teams cannot deliver on innovation, your company will miss out on future revenue streams and lose market share to more innovative competitors.

Innovation requires dedicated effort. However, engineers report they waste over half their time on system integration, which consumes their bandwidth to innovate.

Without suitable methods for managing system complexity, mistakes are hard to avoid. It’s also harder to catch errors early and identify all the impacts, especially considering interdependencies across components and subsystems. Finding problems late can result in rework, hours or even days of wasted effort, and scrap, increasing costs. Plus, late discovered problems take longer to correct, which means longer development times and delays, further increasing development costs. Then when you consider the impact across all system variants, costs grow exponentially.

The lack of good ways to plan and visualize complex systems can compromise optimal decisions around system architecture. This can lead to higher product costs and more brittle systems that make changes even more expensive and time-consuming.

Less Innovation and Revenue

Innovation sets your products apart, excites customers, and drives revenue opportunities. If your development teams cannot deliver on innovation, your company will miss out on future revenue streams and lose market share to more innovative competitors.

Innovation requires dedicated effort. However, engineers report they waste over half their time on system integration, which consumes their bandwidth to innovate.

Recommendations

Recommendations and Next Steps Developing multi-disciplinary systems is inherently complex. Suboptimal processes can result in higher costs, less innovation, lost revenue, and poor quality. However, companies can enjoy a competitive advantage by improving profitability with the right practices and technology. MBSE can be particularly useful. Based on industry experience and research for this report, Tech-Clarity offers the following recommendations to improve the development of multi-disciplinary systems:- Transition from a document-centric approach to a model-based one to enjoy the benefits of digitalization and greater automation of development processes.

- Invest in solutions that will integrate content across engineering disciplines to support better collaboration across the development team, throughout the lifecycle.

- Think about software development early in the lifecycle. Developing optimized complex products may require rethinking traditional hardware approaches, starting with a system-level approach that considers software from the start.

- Consider adopting MBSE as part of recommended systems engineering best practices.

- Leverage MBSE throughout the entire development lifecycle, not just as an upfront tool for initial definitions, but also use it for simulating and prototyping to verify and validate the system.

- Think through how to best support your staff to overcome cultural resistance so that they are more open to MBSE adoption.

What does the future of PLM look like in the CPG industry? Watch this webcast to gain insights into the value of PLM, its importance to broader supply chain and digital thread processes, and its ability to help CPG companies innovate smarter and faster than ever before.

Jim shares the findings from his survey on the future of PLM in CPG and engages an industry expert panel including:

What does the future of PLM look like in the CPG industry? Watch this webcast to gain insights into the value of PLM, its importance to broader supply chain and digital thread processes, and its ability to help CPG companies innovate smarter and faster than ever before.

Jim shares the findings from his survey on the future of PLM in CPG and engages an industry expert panel including:

- Sachin Misra, Principal and Global Lead Life Sciences at Kalypso

- John Kelley, VP of Product Strategy at Oracle

- Jim Brown, President of Digital Innovation at Tech-Clarity

How do digital twins improve the way companies design, engineer, and operate today’s products and buildings? Register for this webinar as Jim Brown hosts a panel of experts to discuss how gaming engines can be applied to improve the business value of digital twins. The speakers will discuss:

How do digital twins improve the way companies design, engineer, and operate today’s products and buildings? Register for this webinar as Jim Brown hosts a panel of experts to discuss how gaming engines can be applied to improve the business value of digital twins. The speakers will discuss:

- How companies use digital twins to improve the way they design, engineer, create, and operate today’s products and built structures

- The business case for immersive, interactive, high-fidelity visualizations and how game engines can help deliver them

- Why game engines are different than existing 3D technologies

- David Craig Weir-McCall, Industry Marketing Manager - Architecture, Epic Games

- Erin Khan, National Director of Construction Solutions, Suffolk Construction

- Elizabeth Baron, Enterprise Solutions Executive, Unity Technologies

- Igor Tsinman, Co-Founder and President, AMC Bridge

- How Software Enables Industrial Additive Manufacturing

- Embracing Cloud Engineering Software and Data

- Digital Twin - Bridging the Gap Between Vision and Reality

- The Role of Simulation Technology in Digital Twins

[post_title] => Update on Product Mining Company Soley (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => product-mining-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2022-12-12 12:19:10

[post_modified_gmt] => 2022-12-12 17:19:10

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17656

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => c1061e2f5fd28b786718aac4db04c83c

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:892654e108e985d3b0a2823232b12f20:0.72213600 17690394950.73187200 1769039495

)

[post_title] => Update on Product Mining Company Soley (Insight)

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => product-mining-insight

[to_ping] =>

[pinged] =>

[post_modified] => 2022-12-12 12:19:10

[post_modified_gmt] => 2022-12-12 17:19:10

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=17656

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[comment_count] => 0

[current_comment] => -1

[found_posts] => 876

[max_num_pages] => 44

[max_num_comment_pages] => 0

[is_single] =>

[is_preview] =>

[is_page] =>

[is_archive] =>

[is_date] =>

[is_year] =>

[is_month] =>

[is_day] =>

[is_time] =>

[is_author] =>

[is_category] =>

[is_tag] =>

[is_tax] =>

[is_search] =>

[is_feed] =>

[is_comment_feed] =>

[is_trackback] =>

[is_home] => 1

[is_privacy_policy] =>

[is_404] =>

[is_embed] =>

[is_paged] =>

[is_admin] =>

[is_attachment] =>

[is_singular] =>

[is_robots] =>

[is_favicon] =>

[is_posts_page] =>

[is_post_type_archive] =>

[query_vars_hash:WP_Query:private] => c1061e2f5fd28b786718aac4db04c83c

[query_vars_changed:WP_Query:private] => 1

[thumbnails_cached] =>

[allow_query_attachment_by_filename:protected] =>

[stopwords:WP_Query:private] =>

[compat_fields:WP_Query:private] => Array

(

[0] => query_vars_hash

[1] => query_vars_changed

)

[compat_methods:WP_Query:private] => Array

(

[0] => init_query_flags

[1] => parse_tax_query

)

[query_cache_key:WP_Query:private] => wp_query:892654e108e985d3b0a2823232b12f20:0.72213600 17690394950.73187200 1769039495

)

All Results for "All"

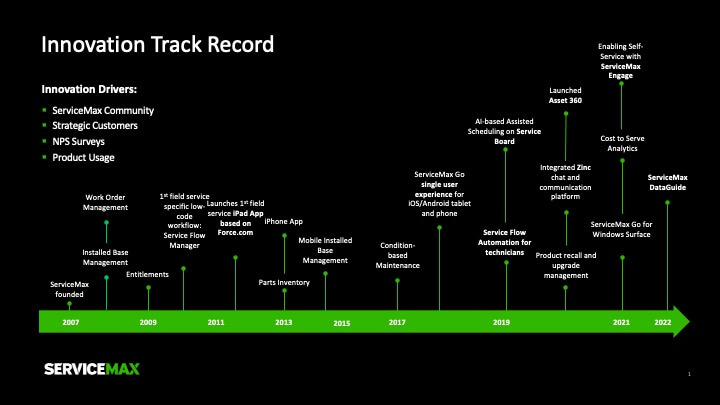

ServiceMax Pre-PTC Highlights (Insight)

We are excited about prospects for continued service transformation for complex equipment after hearing the latest updates from ServiceMax. We know a new chapter will unfold as the PTC acquisition takes hold. Yet even before that, ServiceMax’s traction in field service management is impressive, with all of its primary product suites scoring new wins to…

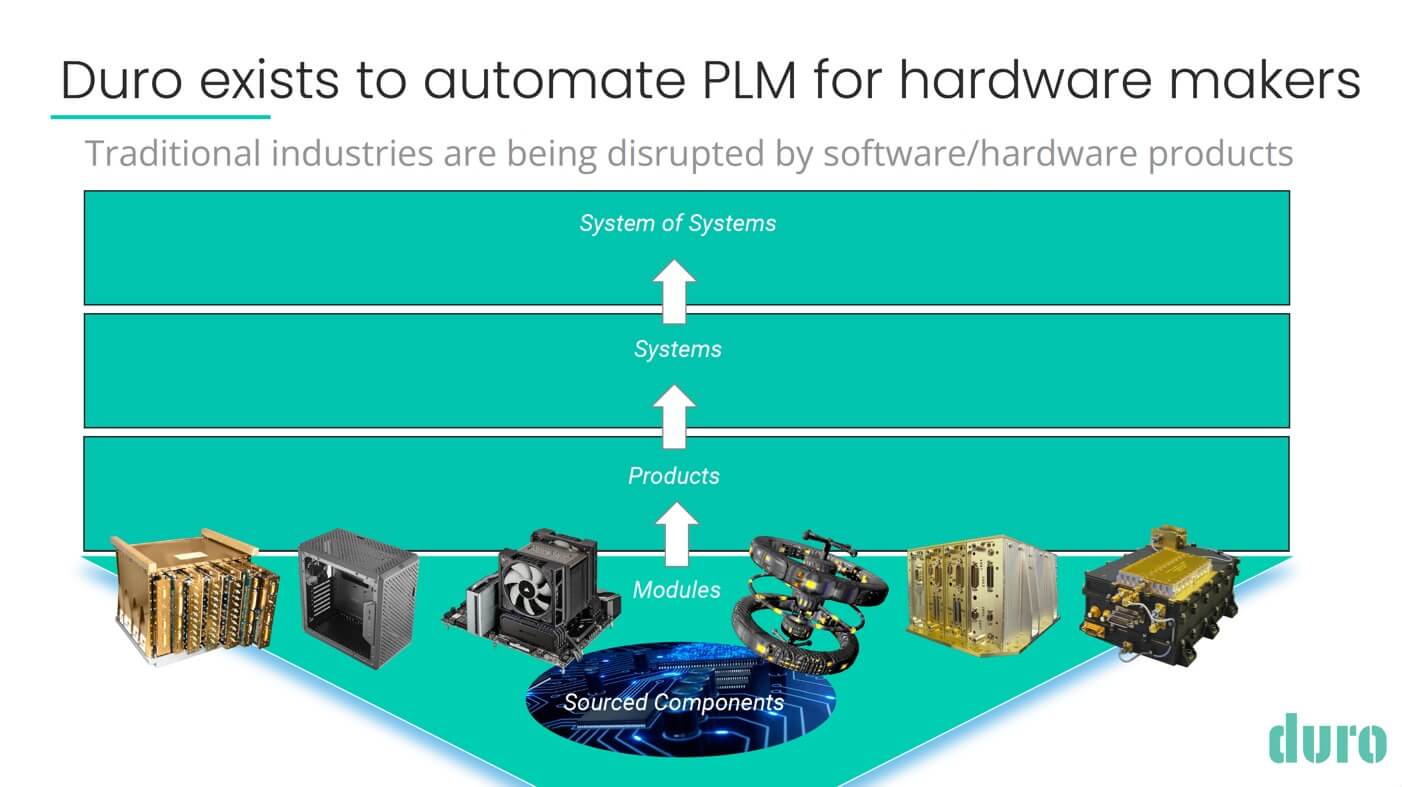

Duro Makes Progress in Agile PLM for Hardware (Insight)

I had the opportunity to meet with the Duro team to get an update on their progress. We’re paying attention to Duro because they’re applying agile paradigms created for software development and making them applicable to companies that develop hardware. This is a novel approach that’s proving promising for software-intensive products like those in space, industrial…

Arcstone: MES to Feed Supply Chain Compliance and Sustainability

I am giddy with optimism after a briefing with Arcstone. Finally, end-to-end supply chain visibility for compliance and sustainability assurance appears possible. This Singapore-based company recognized that a crucial missing piece for supply chain operations is accurate information from the plant floors of everyone in that ecosystem. They also address a way to share that…

Bouncing Forward with Digital Transformation and Analytics

Business risk continues to grow and disrupt businesses, markets, and supply chains. Companies struggle to just bounce back from each disruption. But how can they do more, using digital transformation and analytics to bounce forward to take advantage of the opportunities that disruption presents? In this webinar, Jim Brown will share how companies have accelerated…

Path to Digital Twins – Hype vs Reality

Jim Brown will host a panel discussion focusing on what it takes to deliver on the promise of the digital twin. The webinar will focus on what’s currently achievable and what results companies can reasonably expect from today’s commercially available solutions. We’ll compare the pros and cons of buying, building, and assembling digital twins and…

The How-to Guide for Changing CAD Tools: What You Should Know

To keep pace with your competition, is it time to upgrade your CAD tool? Tech-Clarity’s How-to Guide for Changing CAD Tools takes a look at this question and investigates what’s involved. Standing out in today’s global economy is not an easy task, so there is the constant quest for innovation. To innovate, many companies are…

PLM for Operational Excellence

How can PLM, traditionally an engineering-centric solution, drive innovation, agility, and operational excellence throughout the entire product lifecycle? Attend this webinar to learn how the right PLM can help manufacturers focus on the big picture, not just engineering, to develop profitable products. Hear from: Jim Brown, President of Tech-Clarity, reviewing findings from his recent research…