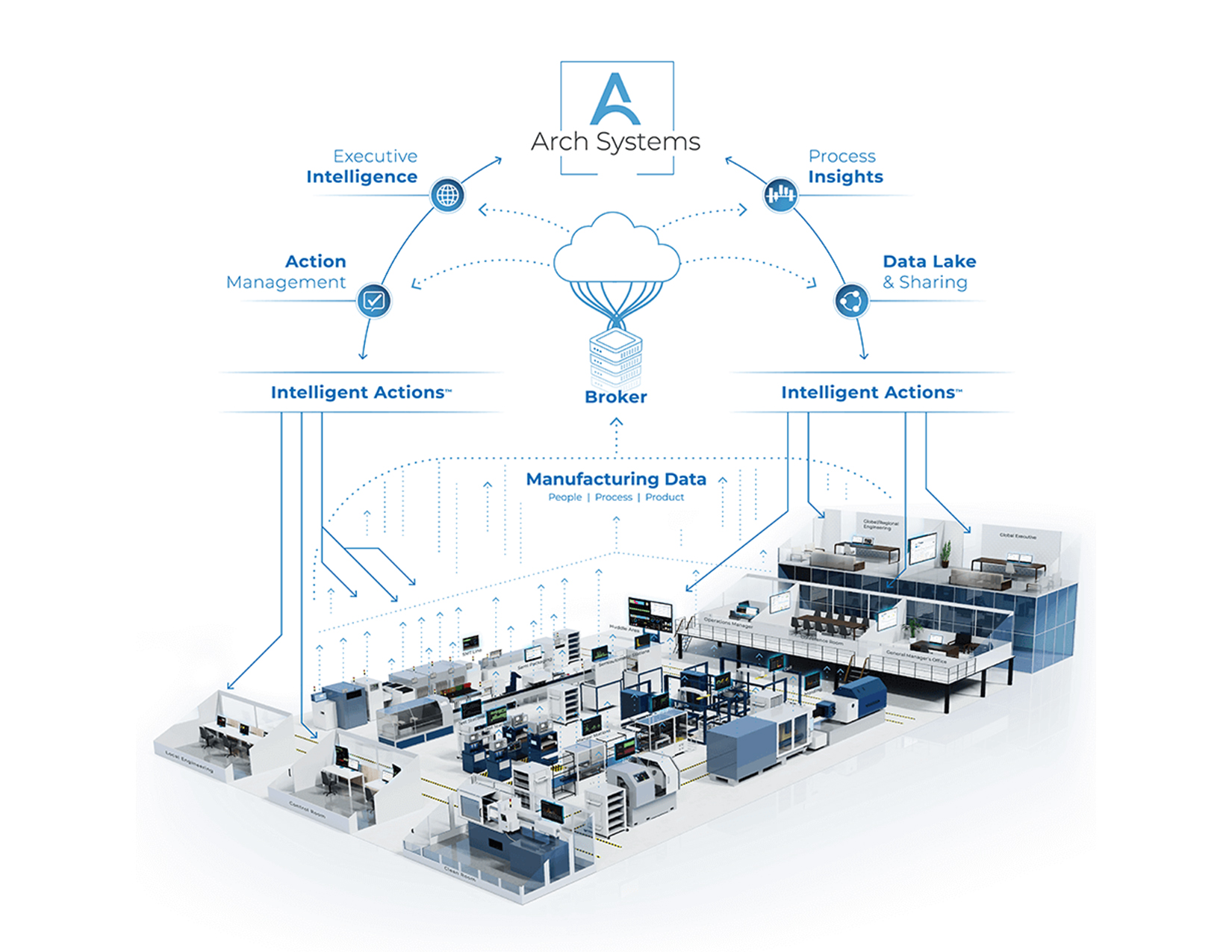

Value from Data Creating value from the varied data in manufacturing facilities can be an elusive goal. In our recent briefing with Arch Systems, we got an idea of how they convert massive quantities of data into intelligent actions for manufacturers. They do this for frontline workers, top-floor executives, and many in between. The premise…

- Executive Summary

- Evaluate the Opportunity

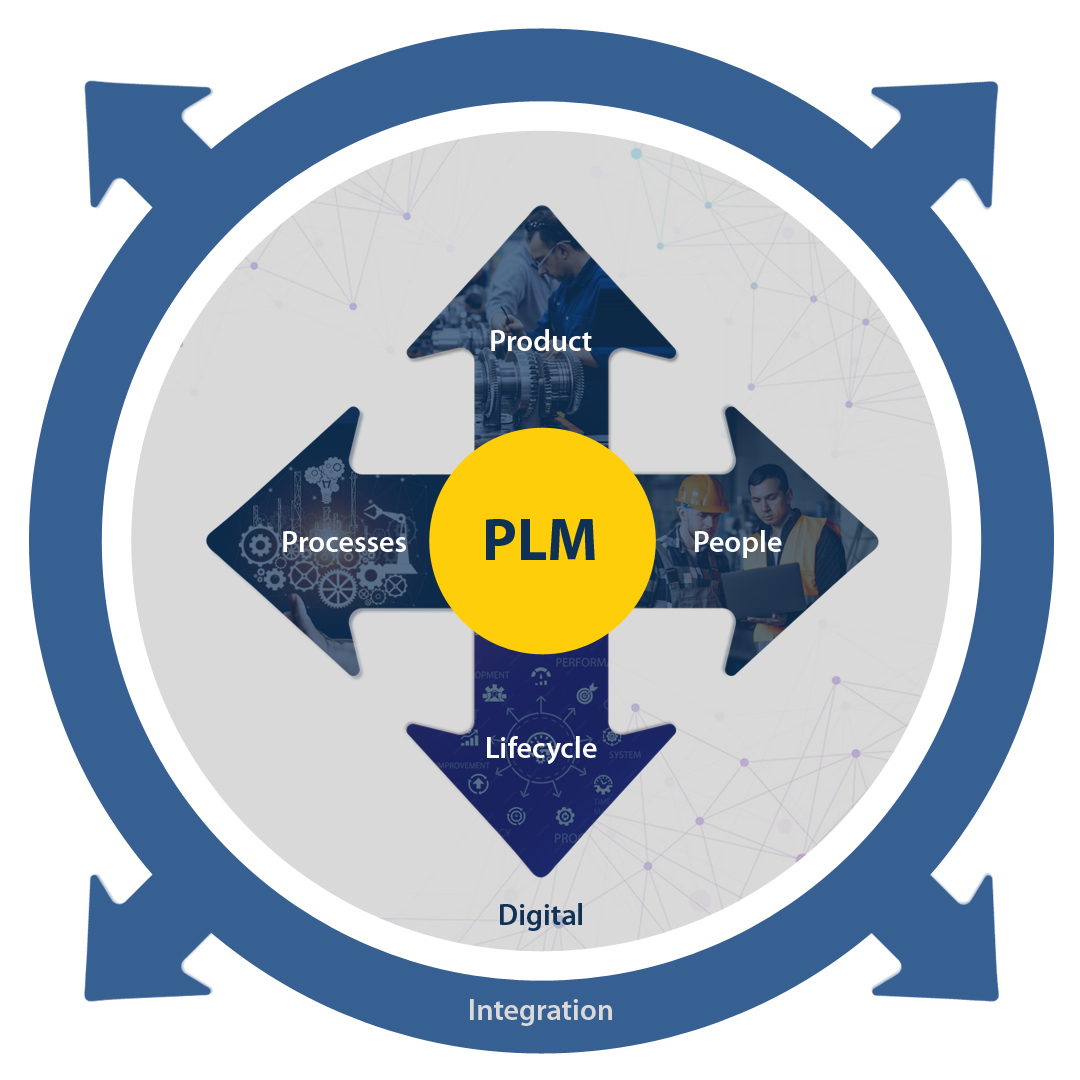

- Six Ways to Increase Business Value from PLM

- 1 - Expand the View of the Product

- 2 - Include More People / Roles

- 3 - Support More (and More Mature) Processes

- 4 - Expand to the Full Product Lifecycle

- 5 - Digitalize the Product Backbone

- 6 - Integrate Product Data and Processes

- Start Expanding PLM to Increase Business Value

- Acknowledgments

Leveling Up Your PLM Value

It’s Time to Drive Enterprise Level Value with PLM Our research shows that manufacturers achieve significant business value from PLM. The manufacturing industry benefits from new levels of efficiency and control from PLM and now recognizes it as a standard part of the engineering and product development toolkit. Many manufacturers started their PLM journey by getting CAD files under control. Then, they may have grown more mature and developed BOM and change management processes. They’re getting value but falling short of the full potential PLM has to offer. Times have changed. The world is now more digital, connected, and data-driven. The way companies use PLM must evolve to meet the needs of the modern manufacturer. Fortunately, our research shows that there is significant additional business value available from most current PLM implementations. Resetting the PLM Strategy for the Future But how do manufacturers choose the right opportunities to "level up" and dramatically extend their existing system's value? We used our Six Dimensions of PLM expansion as the basis for this guide to share six practical ways manufacturers can incrementally increase business value from PLM. Executive Summary

Executive Summary

PLM Drives Significant Business Value

Most manufacturers with PLM (product lifecycle management) recognize that it improves engineering efficiency and reduces errors and rework. Our research shows that PLM adoption helps grow the top line in addition to these essential bottom-line savings. For example, PLM can speed up time to market by cutting product development time by up to 50%. Beyond that, PLM acts as the digital product backbone, providing the trusted product data backbone to support strategic needs like improving sustainability, enabling advanced analytics, artificial intelligence (AI), and driving innovation.

Untapped Value of PLM

Despite the potential, many companies are only achieving a fraction of the available business value because they adopted PLM as more of a PDM (product data management) solution.

That leaves room to grow and tap into higher potential value to compete in today's market as companies digitally transform, become more connected across their value chain, and leverage data-centricity to get an edge on the competition.

Extend Value by Increasing Adoption and Maturity

Long-term success relies on trusted, current product data that is consumable across the enterprise. It depends on streamlined processes that connect across the business and the value chain. Many manufacturers already have the system they need to meet these requirements, but they must evolve their PLM implementation and adoption to broaden the scope of product data and support more people and processes.

Choose the Right Path to New Value

The end goal is mature, enterprise-level PLM adoption that serves as the digital product data backbone of the enterprise. But it can't happen overnight. It's essential to be realistic about your starting point and adopt what your company is ready for. Then, it's time to be agile, continuously improve, and drive additional top-line, bottom-line, and strategic benefits. We offer six ways companies can elevate PLM value to help guide the process.

Start Expanding PLM to Increase Business Value

Find Your PLM Expansion Opportunity The six dimensions of PLM expansion provide a wide variety of ways that manufacturers can get more out of their PLM system. PLM expansion should be considered a journey, not a destination. There is always room for improvement and added value. To expand value, manufacturers should:- Ensure they are getting value from PLM basics

- Understand the potential ways to expand PLM

- Focus improvement efforts on business strategy and business goals

- Take reasonable steps with clear operational and business value

- Take an agile approach to continuous improvement

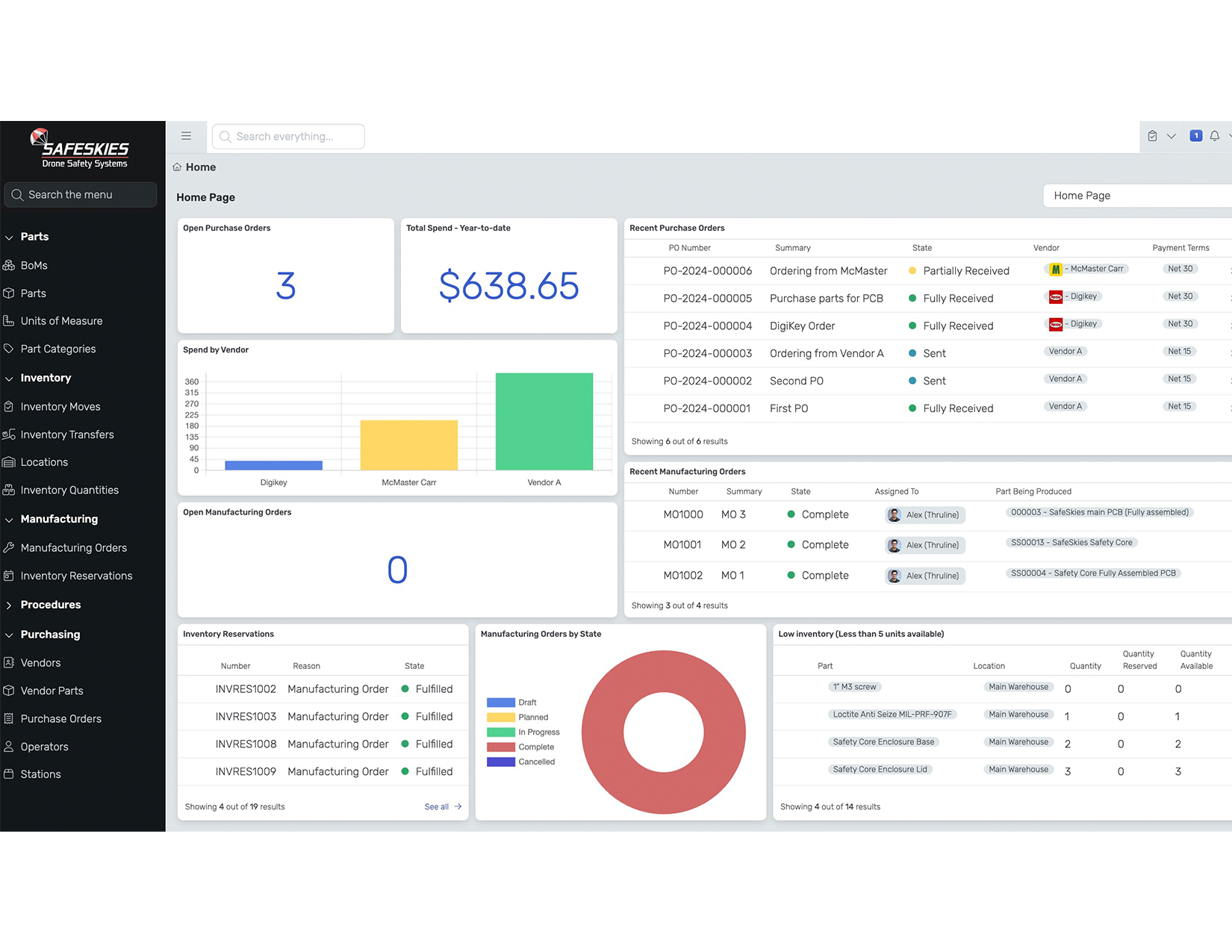

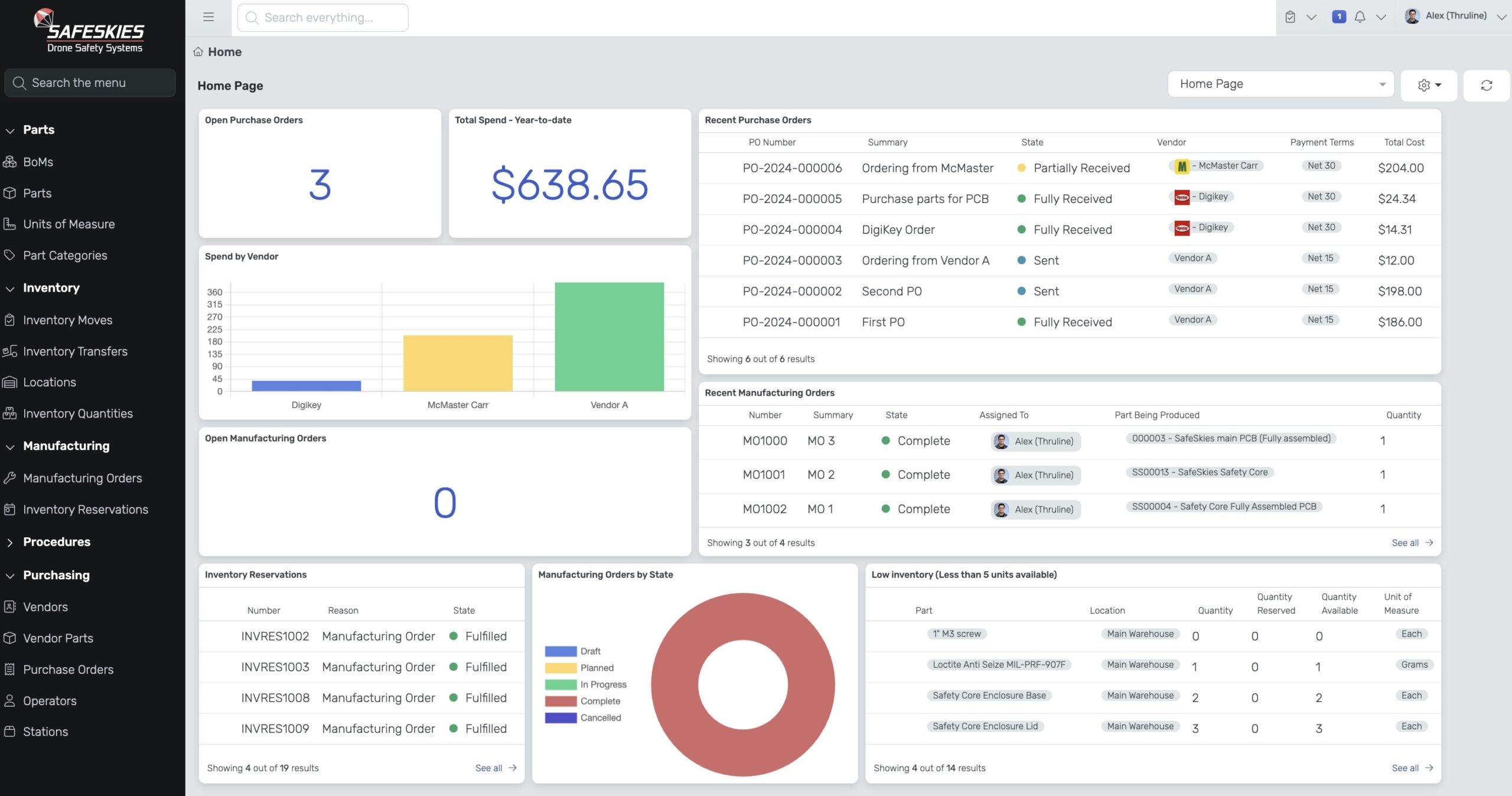

Better Software

What would make ERP and lab software better? Perhaps software that’s lean, flexible, cloud-based, low cost, easy to deploy… and yet highly capable with deep and configurable workflows between modules. Thruline’s founders have implemented and used software on either side of that ellipsis (…) and set out to create software that’s all of the above.

This venture-funded startup is out to improve the lives of those in manufacturing companies, including labs. They talk about building software that’s faster, cheaper, and ultra-flexible. It has a clean user interface, too. ERP was the original target, and they are building that out now. Thruline has modules for inventory (with units of measure), manufacturing, parts and BOM integration, procedures, runs, redlines, purchasing, and parts. Accounting is in the works, and integration to Quickbooks is already available.

LIMS and ELN are also available. These modules are designed for production company research and development staff, not academics. ELN ties in with ERP modules such as inventory management and manufacturing orders. This integration allows the company to track a BOM or recipe in the lab through manufacturing.

Integration at Core

They know companies have other software, so Thruline integrates with Odoo, NetSuite, MS Dynamics, and other ERPs. Other integrations include Calendly for scheduling, CRM, PLM, and Onshape for CAD. In addition, integration to Slack and several apps for eCommerce and Plaid for bank info, Stripe for payment processing. In the lab, Thruline has integrated with Quartzy for checkout and purchasing. Other integrations are in the works.

Modern Technology

Thruline does not have versions. Rather, they offer constant upgrades in a continuous deployment model. When something new comes out, they ask each customer if they want that. If they do, Thruline acts as admin and adds it into the customer’s version on their private instance of the SaaS software.

It is based on a low-code platform, but they don’t expect the small manufacturer to do the configuration and administration. They take the data analyst and software developer out of the equation by doing the admin for them. Support, configuration, and upgrades are part of the monthly subscription, not an add-ons.

Frustration Leads to Innovation

I won’t tell the entire backstory of Thruline, but suffice it to say the founders had some frustrating experiences working with software. Some lightweight ERPs do not support multi-module processes like costing and track and trace, and they cannot easily upgrade customized software. In small companies, they discovered how many things people do on spreadsheets that really should not be, as they need more coordination and assurance for multiple users.

Smaller companies are often surprised by what the software they buy does not do. Consultants often make money getting companies to basic functionality, but Thruline aims to eliminate that consulting time. However, they are having success working with consultants. In a single day on-site with a set of questions, a consulting partner assembled the workflow diagrams for a customer. The software was then up and running quickly with minimal additional consulting hours.

I can see how learning from challenges can lead people to create high-value, innovative software. Thank you, Derek Lam, for reaching out and to Alex Lazich, CEO, for taking the time to brief me about Thruline’s vision and new approach to getting growing companies there. I look forward to following your progress in the market!

[post_title] => Thruline Reimagines Manufacturing and Lab Software for Small Growing Companies

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => software-for-small-growing-manufacturers

[to_ping] =>

[pinged] =>

[post_modified] => 2024-08-13 22:33:11

[post_modified_gmt] => 2024-08-14 02:33:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20544

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 20547

[post_author] => 2

[post_date] => 2024-08-06 10:00:55

[post_date_gmt] => 2024-08-06 14:00:55

[post_content] =>

Better Software

What would make ERP and lab software better? Perhaps software that’s lean, flexible, cloud-based, low cost, easy to deploy… and yet highly capable with deep and configurable workflows between modules. Thruline’s founders have implemented and used software on either side of that ellipsis (…) and set out to create software that’s all of the above.

This venture-funded startup is out to improve the lives of those in manufacturing companies, including labs. They talk about building software that’s faster, cheaper, and ultra-flexible. It has a clean user interface, too. ERP was the original target, and they are building that out now. Thruline has modules for inventory (with units of measure), manufacturing, parts and BOM integration, procedures, runs, redlines, purchasing, and parts. Accounting is in the works, and integration to Quickbooks is already available.

LIMS and ELN are also available. These modules are designed for production company research and development staff, not academics. ELN ties in with ERP modules such as inventory management and manufacturing orders. This integration allows the company to track a BOM or recipe in the lab through manufacturing.

Integration at Core

They know companies have other software, so Thruline integrates with Odoo, NetSuite, MS Dynamics, and other ERPs. Other integrations include Calendly for scheduling, CRM, PLM, and Onshape for CAD. In addition, integration to Slack and several apps for eCommerce and Plaid for bank info, Stripe for payment processing. In the lab, Thruline has integrated with Quartzy for checkout and purchasing. Other integrations are in the works.

Modern Technology

Thruline does not have versions. Rather, they offer constant upgrades in a continuous deployment model. When something new comes out, they ask each customer if they want that. If they do, Thruline acts as admin and adds it into the customer’s version on their private instance of the SaaS software.

It is based on a low-code platform, but they don’t expect the small manufacturer to do the configuration and administration. They take the data analyst and software developer out of the equation by doing the admin for them. Support, configuration, and upgrades are part of the monthly subscription, not an add-ons.

Frustration Leads to Innovation

I won’t tell the entire backstory of Thruline, but suffice it to say the founders had some frustrating experiences working with software. Some lightweight ERPs do not support multi-module processes like costing and track and trace, and they cannot easily upgrade customized software. In small companies, they discovered how many things people do on spreadsheets that really should not be, as they need more coordination and assurance for multiple users.

Smaller companies are often surprised by what the software they buy does not do. Consultants often make money getting companies to basic functionality, but Thruline aims to eliminate that consulting time. However, they are having success working with consultants. In a single day on-site with a set of questions, a consulting partner assembled the workflow diagrams for a customer. The software was then up and running quickly with minimal additional consulting hours.

I can see how learning from challenges can lead people to create high-value, innovative software. Thank you, Derek Lam, for reaching out and to Alex Lazich, CEO, for taking the time to brief me about Thruline’s vision and new approach to getting growing companies there. I look forward to following your progress in the market!

[post_title] => Thruline Reimagines Manufacturing and Lab Software for Small Growing Companies

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => software-for-small-growing-manufacturers

[to_ping] =>

[pinged] =>

[post_modified] => 2024-08-13 22:33:11

[post_modified_gmt] => 2024-08-14 02:33:11

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20544

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[3] => WP_Post Object

(

[ID] => 20547

[post_author] => 2

[post_date] => 2024-08-06 10:00:55

[post_date_gmt] => 2024-08-06 14:00:55

[post_content] => I always look forward to briefings with the CoLab Software team. That’s partially because I think they’re doing something interesting and because I’m following a trend toward systems of engagementto see where it goes. It’s also because they have a dynamic team that is passionate about what they’re doing and has good perspectives to share on the industry.

The Basics

Here are some of the basics to the set the context from our recent briefing. You can also read our short writeup from last year if you’re interested. CoLab is a seven-year-old company, they are VC funded, and they are growing nicely. According to a press release from Insight Partners in May, CoLab has grown revenue nearly 10x in the last two years. We’ve been impressed that they are working with some very large companies including Ford, Komatsu, Polaris, Johnson Controls, and Schaeffler as well as government institutions.

The System of Engagement Trend

The System of Engagement Trend

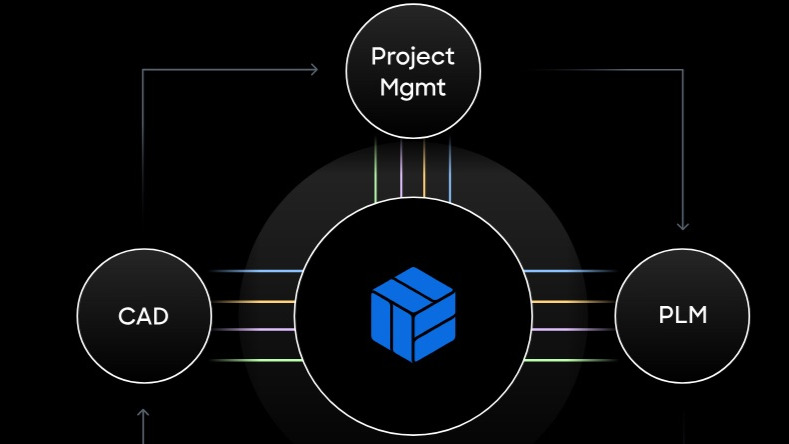

CoLab delivers a system of engagement (SOE) primarily focused on the tangible challenges engineering teams face with design review. I’m going to step back and talk about systems of engagement, feel free to skip ahead if you are on board. SOEs are becoming more popular as a way to differentiate a style of application and user experience that are typically more lightweight and agile than existing systems of record (SOR) that manage data. SOEs are filling an important systems ecosystem gap by enabling collaboration across one or more SORs such as PLM, ERP, or others.

The system of engagement concept is important given the fragmented nature of today’s systems, for example the variety of systems that contain a part of the product digital thread. Our research, in fact, shows that most manufacturers have more than one PLM system. The idea is to integrate across these systems to deliver processes / workflows that enable collaboration and allow people to take action based on contextual data about their current. It’s what I called “the potential second half of the PLM promise” in a previous post, if for no other reason because it acts beyond a single system.

As an aside, I’m starting to think of the need to differentiate “Industrial” SOEs that are based on the product / manufacturing data context, the digital thread, as opposed to general SOE platform without any industry specialization. But that’s for another time. I realize this is a lot to digest but I think the background is important and I tried to keep it short and simple.

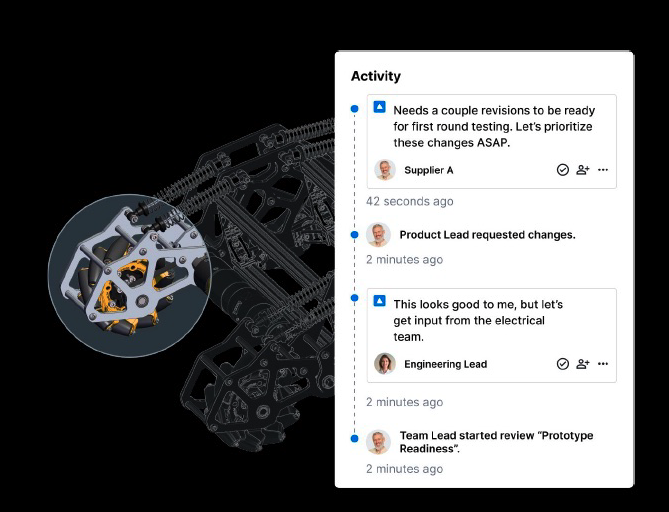

CoLab’s Design Engagement System

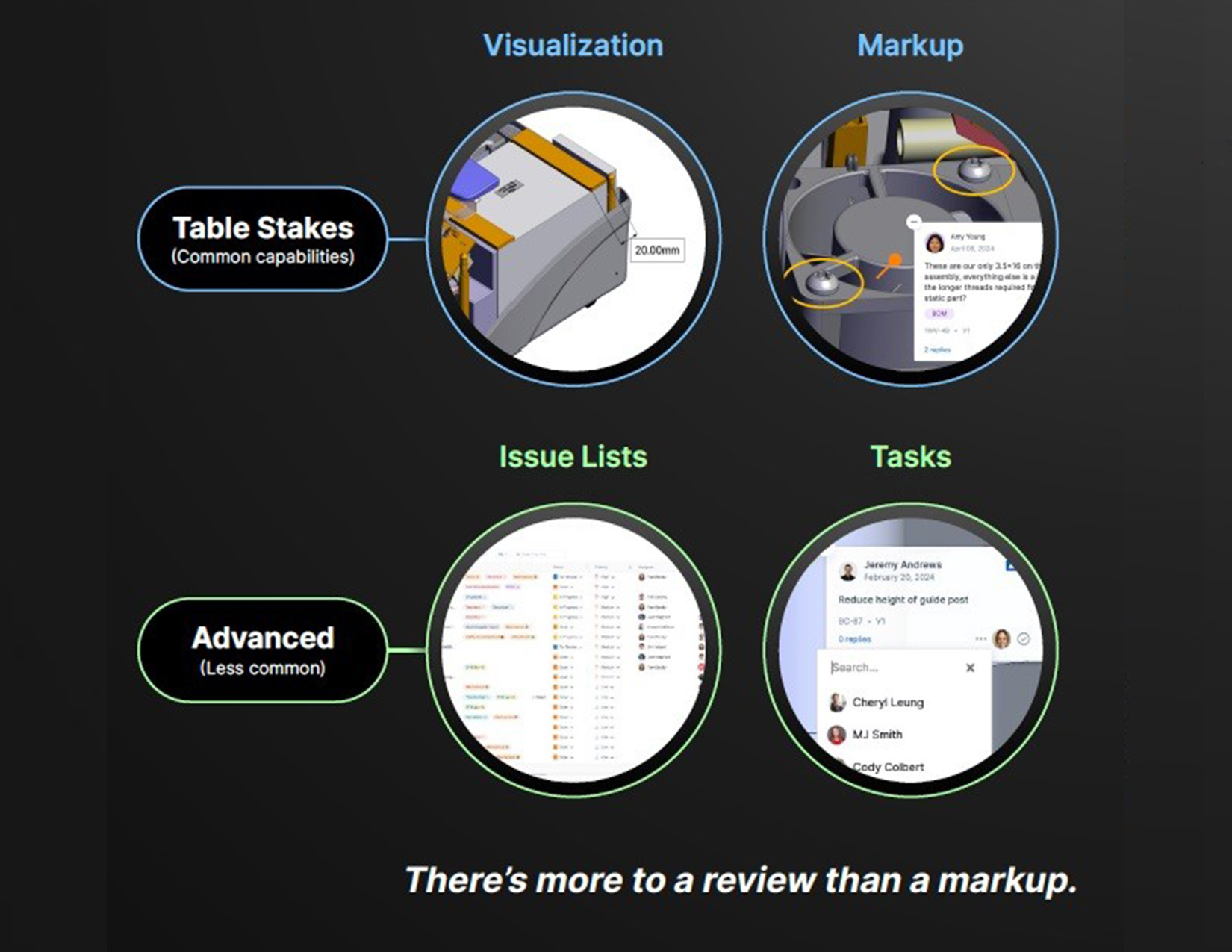

CoLab offers a very specialized SOE focused on design and engineering, the design engagement system (DES). In particular, they have drilled in very specifically on solving the inefficiencies manufacturers face with design review. This is an example of a company really focusing and going deep to solve a challenging problem. CoLab gives engineering teams the ability to share designs so others can review and leave detailed, contextual feedback on them. For example someone in manufacturing could add a comment or markup to a specific feature in a specific version of a CAD model. Their review provides contextual feedback to the design team so they can analyze and act on it. But differently than most third party collaboration or viewing tools, that feedback persists over time and stays associated with that particular revision. In this way, design review feedback is not a lost moment in time, it becomes a part of the product history and company knowledge.

There are other solutions that support design review, including those from PLM vendors themselves. But CoLab is going deep and creating an experience tailored specifically to the design review process. They have really focused on the user experience to make it efficient and effective, going so far as to make it “self-documenting” to prevent additional non-value-added work to capture feedback.

Their portals are a great example of how tailored their solution is. CoLab creates a workspace for the internal team and then allows them to create multiple, linked portals to securely share designs selectively with suppliers to gather feedback. What’s really interesting about the portals is that each one is not just a separate disconnected copy. Suppliers can’t see other’s feedback, but the design team can see consolidated feedback from all of the additional portals in their internal workspace. To me, this is a great example of building a tailored solution works in the real world instead of an idealized environment.

The Secret Sauce

Part of what makes CoLab effective is what they call “replacing the messy middle” between existing CAD, Project Management, and PLM systems. This is a big factor in allowing them to help design teams move away from informal, ad-hoc (and ineffective) tools like spreadsheets that are far too common in these processes. One of the key ways to support this effectively is by providing the reviewer the right context, the underlying CAD model for example, so they can act effectively. I like the way CoLab calls this “cutting down on the context gap” as they manage the relationships between visualization, markup, issue lists, and the tasks engineers and others are executing.

Looking Forward

CoLab’s system of engagement, or even more specifically their design engagement system, will not stop at design review. The collaborative capabilities are already being applied to help manufacturers with design review, supplier collaboration, and cost reduction programs. But they have lots of room to grow and some exciting plans for the future.

One example that caught my attention is that they have meaningful plans to incorporate AI. Everyone is talking about AI, but I believe CoLab is on to something important. If you think about the design review feedback they capture as company knowledge, the potential value of mining and learning from that information to improve future design review, or design in the first place, is intriguing. There will be more to come on that, we are following it closely.

Final Thoughts

CoLab is taking their DES / SOE role seriously. They are happy to sit outside of PLM and not get directly involved in managing CAD data. Instead, they access it from PLM and supply it in an accessible form to design review participants. They are partnering with PTC and have integrated with Windchill, a PTC Technology, and they are working toward other PLM systems including Siemens Teamcenter and Dassault Systèmes 3DEXPERIENCE platform. They will integrate beyond PLM as well.

We’re still watching to see how the system of engagement model as a separate platform plays out. You can clearly make an argument that a design execution system should be part of a broader product innovation platform. But CoLab is filling an important gap, and it’s becoming increasingly clear that there will not be one home to the product digital thread inside the enterprise let alone in the supply chain where design review must excel.

Thank you Adam Keating and MJ Smith for the update!

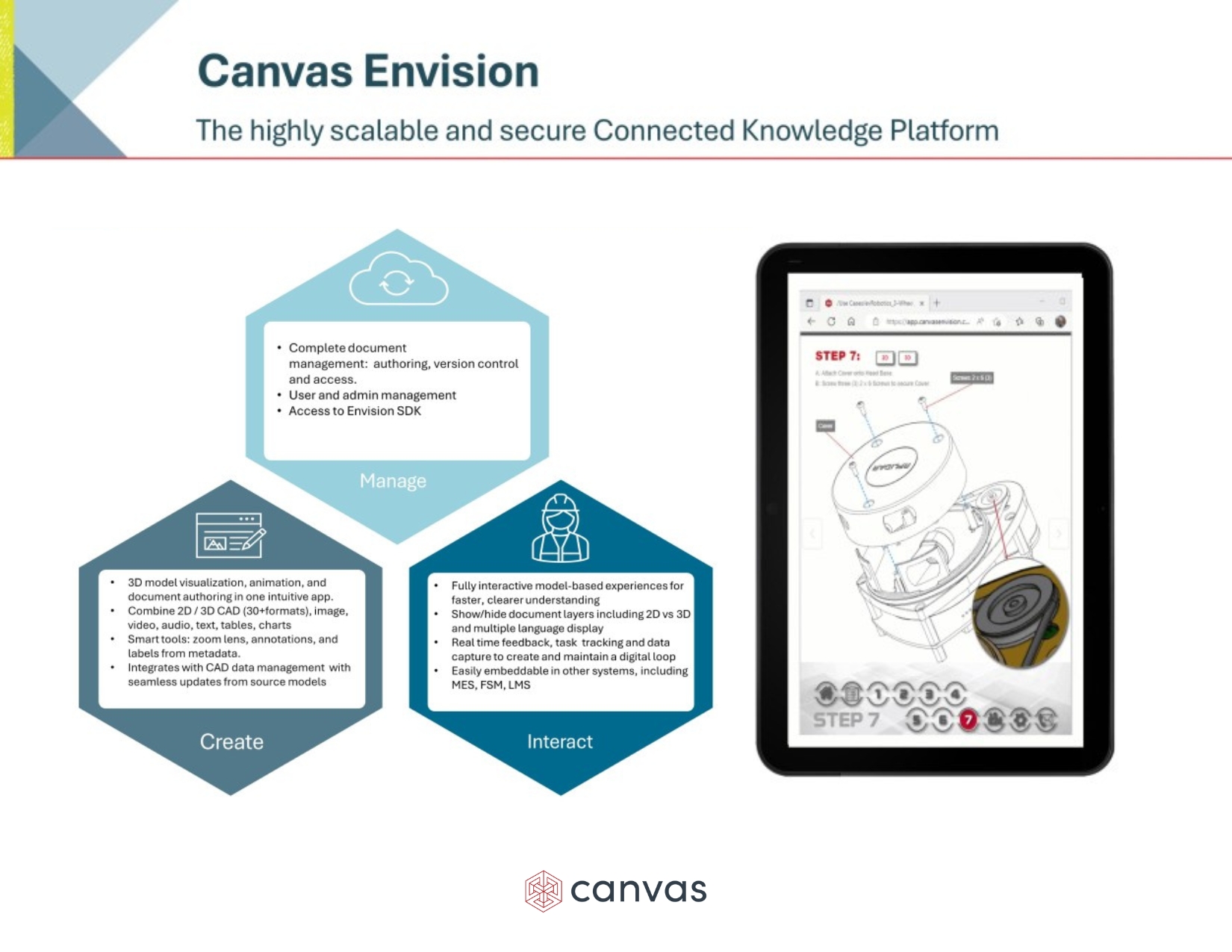

[post_title] => CoLab Continues to Deliver on Design Engagement System Promise [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => design-engagement-system [to_ping] => [pinged] => [post_modified] => 2024-08-13 22:03:06 [post_modified_gmt] => 2024-08-14 02:03:06 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20547 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [4] => WP_Post Object ( [ID] => 20514 [post_author] => 2574 [post_date] => 2024-07-25 10:00:06 [post_date_gmt] => 2024-07-25 14:00:06 [post_content] => In our update briefing with Canvas GFX, CEO Pat Hume said, “A lot has changed since a year ago.” Perhaps the most significant strategic shift is that they are now focusing Envision as a connected knowledge platform for midsize and larger enterprises. The concept is two-way knowledge sharing between product engineering and production frontline workers making and repairing those products.

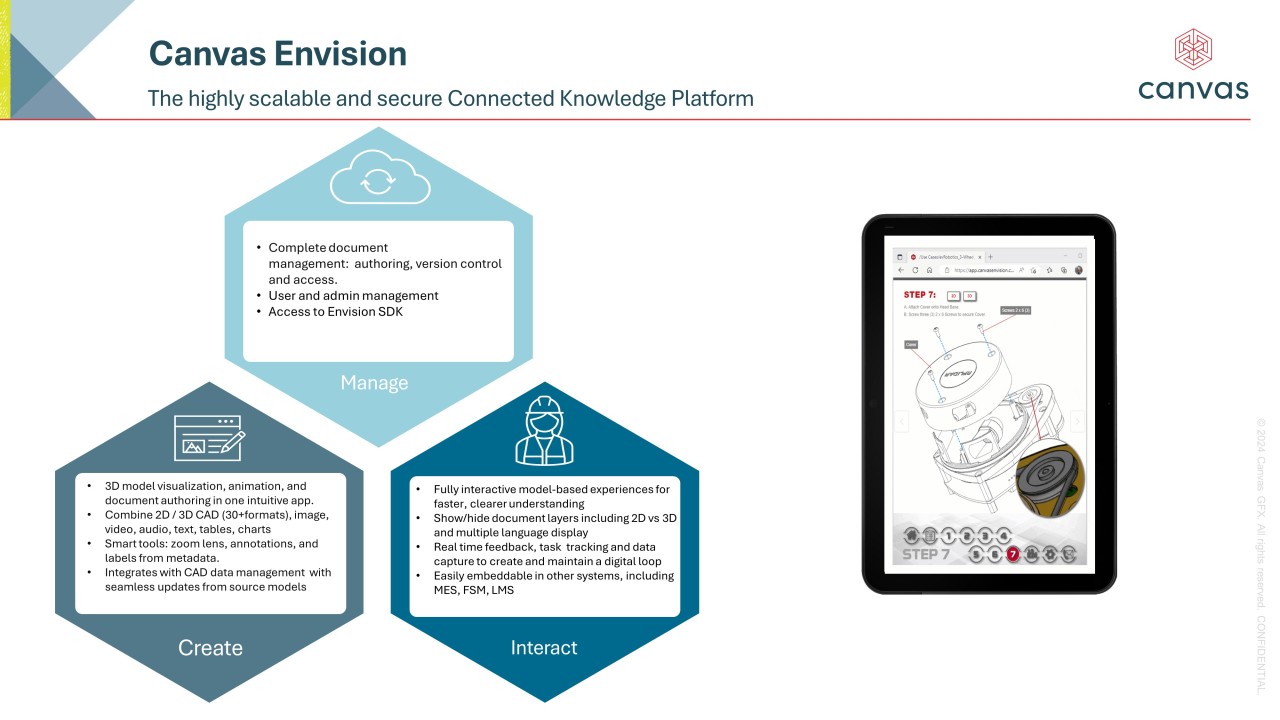

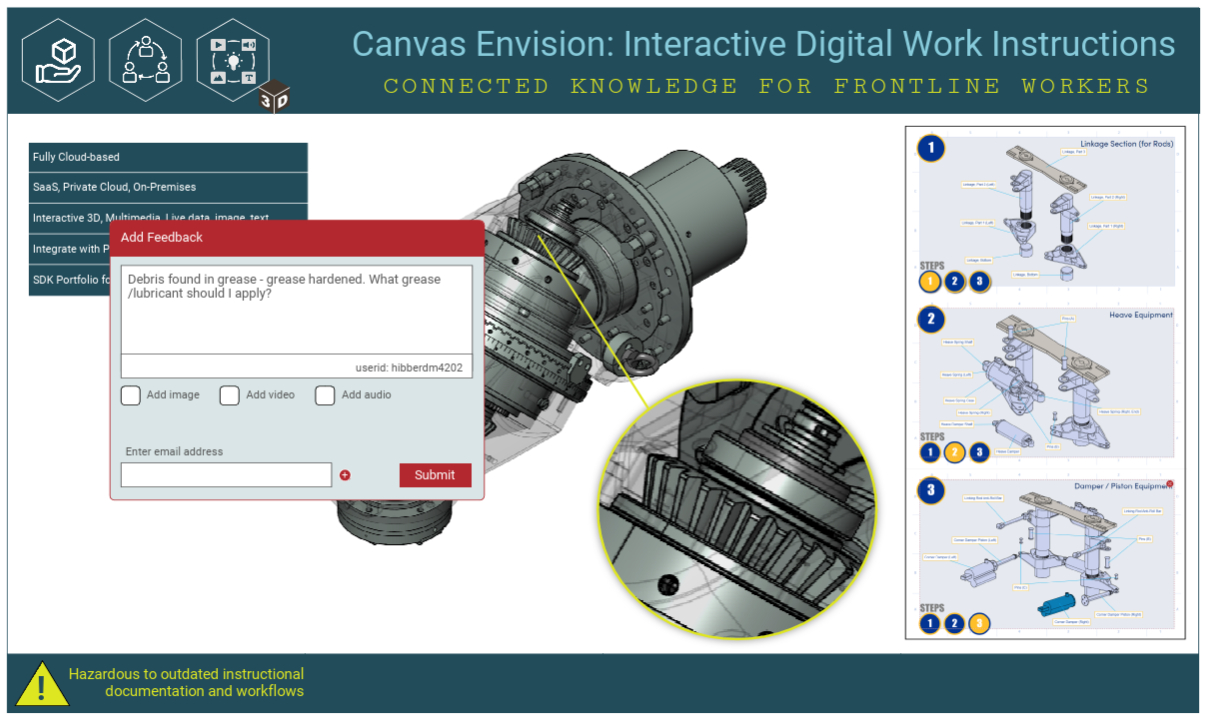

In our update briefing with Canvas GFX, CEO Pat Hume said, “A lot has changed since a year ago.” Perhaps the most significant strategic shift is that they are now focusing Envision as a connected knowledge platform for midsize and larger enterprises. The concept is two-way knowledge sharing between product engineering and production frontline workers making and repairing those products.

Product information is central to what frontline workers need to do, and Canvas GFX has long played a role in the 2D and 3D product info-sharing business. Canvas Envision is a SaaS platform for creating, managing, and interacting with model-based work instructions. Outdated, unclear, or hard-to-understand work instructions are a common cause of quality issues for manufacturers. Canvas GFX is looking to solve this challenge.

The platform can convert text-based work and maintenance instructions to easy-to-follow visual information linked to the CAD model. Based on the company’s heritage, using 3D CAD models as the single source of truth is a given. What’s novel is the company’s view that the frontline workers in production, quality, maintenance, and sustainment can use the Canvas Envision platform to deliver feedback to the product teams and each other. The platform enables workers to ask for help or support. For example, If the instructions don't seem to match the parts referenced in the CAD model, a maintenance worker who may work for a different company, such as an airline, can connect with the engineering team at the OEM for guidance.

To gain a foothold in the midmarket and enterprise, Canvas GFX knows they must be minimally disruptive and complement or enhance existing workflows. APIs to PLM, PDM, ERP, QMS, and MES are table stakes. Canvas GFX works with digital twins, animations, images, video, audio, text, live data feeds, and AR/VR to extend the value of the core CAD model.

Another fascinating direction is that Canvas GFX has established Envision partnerships with companies such as Aras and Rockwell Plex to embed Envision in the partner’s user experience. So, an Aras PLM user can author in Canvas Envision, launching it from their Aras Innovator interface. Similarly, a production worker on Plex can interact with their work instructions in Envision but see the familiar Plex UI. Other partners include SAIC for DoD, SSI for shipbuilding, Autodesk with the Vault PDM, Zebra for connected workers, and Microsoft for AI. Partners will be an increasing channel to market for Canvas Envision.

The Canvas Envision SDK is intended to allow customers to automate content creation and customize user experiences. Depending on the current technology stack, each company may want the system to do more or less for authoring and frontline worker support. The company’s AI roadmap, with products due out later this year, will enable greater automation.

Per the example above, Canvas GFX’s vision for Envision goes even beyond enterprise, out to customers, customer’s customers, and suppliers. Many very complex products, for which model-based work instructions are most important, have a set of sub-assemblies where product information is needed. Many of these complex products also have long lives in the field, where service or maintenance, repair, and overhaul operations (MRO) might also need detailed product knowledge and have valuable knowledge to share from later in the product lifecycle.

We are excited by the opportunities Canvas Envision offers to manufacturers to move toward a model-based enterprise (MBE) using CAD data for frontline workers. As the workforce challenges continue, supporting frontline workers and improving collaboration across many disciplines should improve employee satisfaction and productivity rates. Thank you, Patricia Hume and Becky Darsch, for taking the time to update us on Envision and your market strategy. We look forward to learning more and hearing about AI updates and additional partners and customers!

Thank you, Patricia Hume and Becky Darsch, for taking the time to update us on Envision and your market strategy. We look forward to learning more and hearing about AI updates and additional partners and customers!

How do you know if your CAD tool will keep you competitive?

CAD is a critical engineering tool, but if your CAD tool has not kept up with the latest technologies, your engineers could be at a disadvantage. As companies enjoy efficiencies gained through digital transformation, CAD tools have also evolved to support digital processes that can help you develop more competitive products in less time. Has yours?

This eBook reveals the results of a survey of product development professionals that examined what they look for in a CAD tool and the results they saw when they switched CAD tools. Further, the analysis of the survey results and practices of Top Performing companies, seven questions were identified to help you determine if you should consider evaluating other CAD tools.

Please enjoy the summary* below. For the full research, please visit our sponsor SOLIDWORKS (registration required).

How do you know if your CAD tool will keep you competitive?

CAD is a critical engineering tool, but if your CAD tool has not kept up with the latest technologies, your engineers could be at a disadvantage. As companies enjoy efficiencies gained through digital transformation, CAD tools have also evolved to support digital processes that can help you develop more competitive products in less time. Has yours?

This eBook reveals the results of a survey of product development professionals that examined what they look for in a CAD tool and the results they saw when they switched CAD tools. Further, the analysis of the survey results and practices of Top Performing companies, seven questions were identified to help you determine if you should consider evaluating other CAD tools.

Please enjoy the summary* below. For the full research, please visit our sponsor SOLIDWORKS (registration required).

Table of Contents

- Executive Summary

- Competitive PRoducts Require Exceptional Engineering

- Top Drivers to Switch CAD

- Identifying Top Performers

- Impact of Switching CAD

- 1. Can you CAD tool support good collaboration?

- 2. Does your CAD tool support the latest technology?

- 3. Is there a vision and current support for AI?

- 4. Is Engineering's personal productivity optimized?

- 5. Does a complementary portfolio extend value beyond design?

- 6. Does your CAD tool overcome process bottlenecks?

- 7. Does your CAD vendor meet your needs?

- Recommendations

- About the Research

- Acknowledgments

Executive Summary

Staying Competitive Engineers face a lot of pressure to develop competitive products as quickly as possible. The best CAD tools can help engineers work smarter and focus on innovation. However, achieving the desired efficiencies to remain competitive may require a change in CAD tools. In fact, over the last three years, digital transformation - a key enabler for greater efficiency - has been the top driver for making a switch.

You can extend a CAD model’s value with digital processes and new technologies, including complementary design portfolio offerings. Overall, 99% of study respondents believe using innovation-enabling technology with CAD will help them achieve their goals for more competitive products. These technologies include simulation, digital transformation, Artificial Intelligence (AI), generative design, and the cloud. As companies look at new technology, 95% believe that AI will improve product development; AI opportunities for improvement range from automating tedious repetitive work to detecting errors.

Impact of Changing CAD

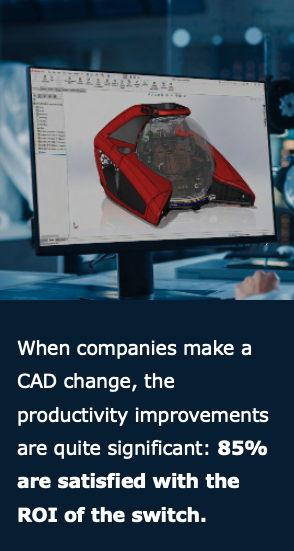

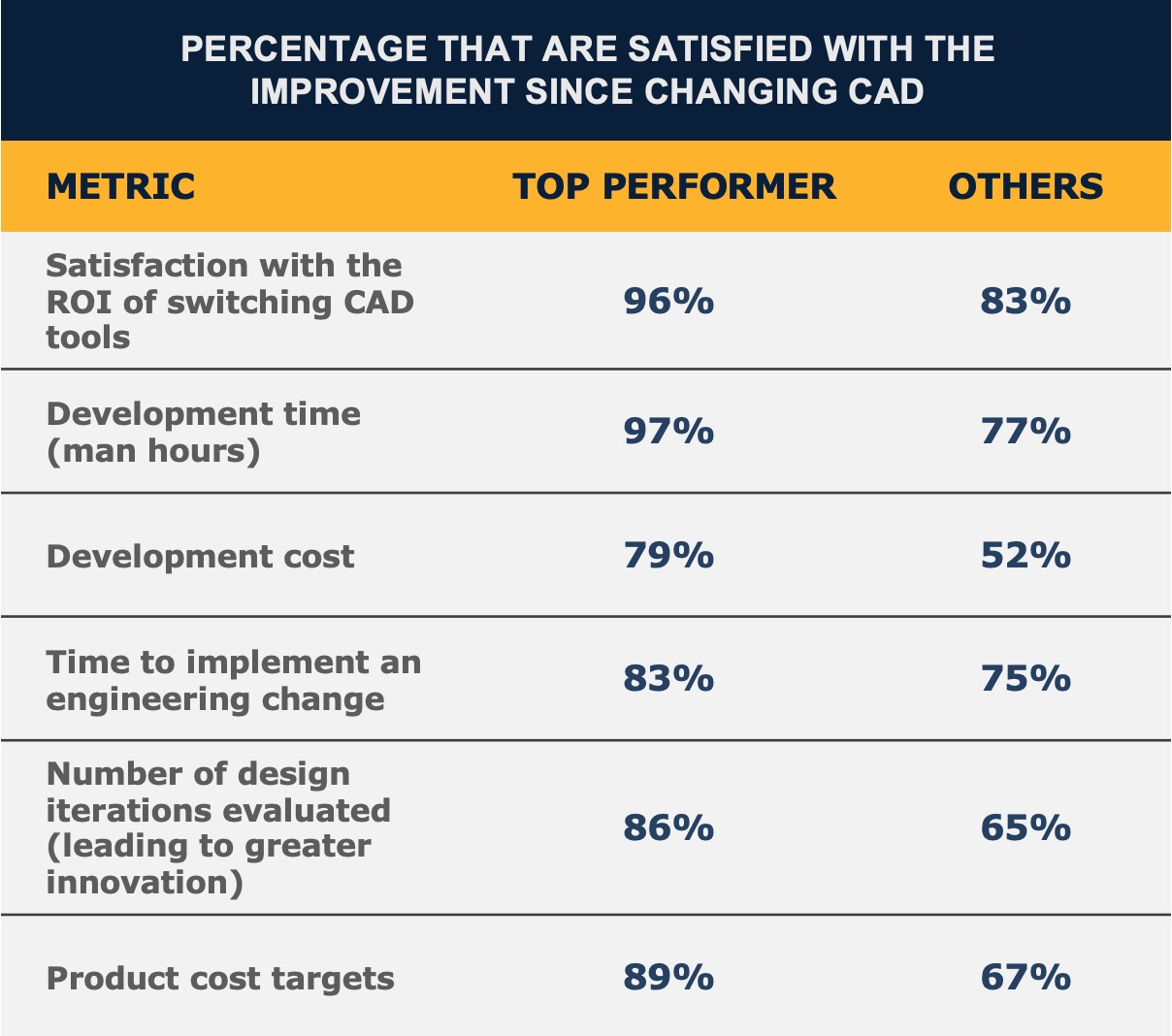

When companies make a CAD change, the productivity improvements are quite significant: 85% are satisfied with the ROI of the switch, with an even higher percentage (96%) of Top Performers satisfied. Top Performers’ higher level of satisfaction can be partly attributed to what they look for in a CAD solution.

Seven Questions

This research identified what Top Performing companies look for in a CAD tool. The findings revealed seven questions to help determine if you may benefit from switching CAD tools. Consider if a new solution may offer technological advancements that will support better engineering decisions and accelerate product development processes by asking these questions:

1. Can your CAD tool support good collaboration?

2. Does your CAD tool support the latest technology?

3. Is there a vision and current support for AI?

4. Is Engineering’s personal productivity optimized?

5. Does a complementary portfolio extend value beyond design?

6. Does your CAD tool overcome process bottlenecks?

7. Does your CAD vendor meet your needs?

Engineers face a lot of pressure to develop competitive products as quickly as possible. The best CAD tools can help engineers work smarter and focus on innovation. However, achieving the desired efficiencies to remain competitive may require a change in CAD tools. In fact, over the last three years, digital transformation - a key enabler for greater efficiency - has been the top driver for making a switch.

You can extend a CAD model’s value with digital processes and new technologies, including complementary design portfolio offerings. Overall, 99% of study respondents believe using innovation-enabling technology with CAD will help them achieve their goals for more competitive products. These technologies include simulation, digital transformation, Artificial Intelligence (AI), generative design, and the cloud. As companies look at new technology, 95% believe that AI will improve product development; AI opportunities for improvement range from automating tedious repetitive work to detecting errors.

Impact of Changing CAD

When companies make a CAD change, the productivity improvements are quite significant: 85% are satisfied with the ROI of the switch, with an even higher percentage (96%) of Top Performers satisfied. Top Performers’ higher level of satisfaction can be partly attributed to what they look for in a CAD solution.

Seven Questions

This research identified what Top Performing companies look for in a CAD tool. The findings revealed seven questions to help determine if you may benefit from switching CAD tools. Consider if a new solution may offer technological advancements that will support better engineering decisions and accelerate product development processes by asking these questions:

1. Can your CAD tool support good collaboration?

2. Does your CAD tool support the latest technology?

3. Is there a vision and current support for AI?

4. Is Engineering’s personal productivity optimized?

5. Does a complementary portfolio extend value beyond design?

6. Does your CAD tool overcome process bottlenecks?

7. Does your CAD vendor meet your needs?

Impact of Switching CAD

High Satisfaction When companies make a switch, 85% are satisfied with the switch’s return on investment (ROI), with an even higher percentage of Top Performers satisfied (96%). Those who have made the switch enjoy numerous improvements when they update their CAD tool to one that will better meet their needs (see table). Top Performers’ Advantage

Top Performers enjoy even more benefits when they make a change. Some of this is due to what they look for in a CAD tool. Overall, they look for a tool that improves engineering efficiency while also benefiting the larger enterprise beyond engineering.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor SOLIDWORKS (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Are You Using the Best CAD Tool?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => best-cad

[to_ping] =>

[pinged] =>

[post_modified] => 2024-07-17 11:52:49

[post_modified_gmt] => 2024-07-17 15:52:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20466

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 20454

[post_author] => 2574

[post_date] => 2024-07-11 10:00:51

[post_date_gmt] => 2024-07-11 14:00:51

[post_content] =>

Top Performers’ Advantage

Top Performers enjoy even more benefits when they make a change. Some of this is due to what they look for in a CAD tool. Overall, they look for a tool that improves engineering efficiency while also benefiting the larger enterprise beyond engineering.

*This summary is an abbreviated version of the research and does not contain the full content. For the full research, please visit our sponsor SOLIDWORKS (registration required).

If you have difficulty obtaining a copy of the report, please contact us.

[post_title] => Are You Using the Best CAD Tool?

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => best-cad

[to_ping] =>

[pinged] =>

[post_modified] => 2024-07-17 11:52:49

[post_modified_gmt] => 2024-07-17 15:52:49

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20466

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[6] => WP_Post Object

(

[ID] => 20454

[post_author] => 2574

[post_date] => 2024-07-11 10:00:51

[post_date_gmt] => 2024-07-11 14:00:51

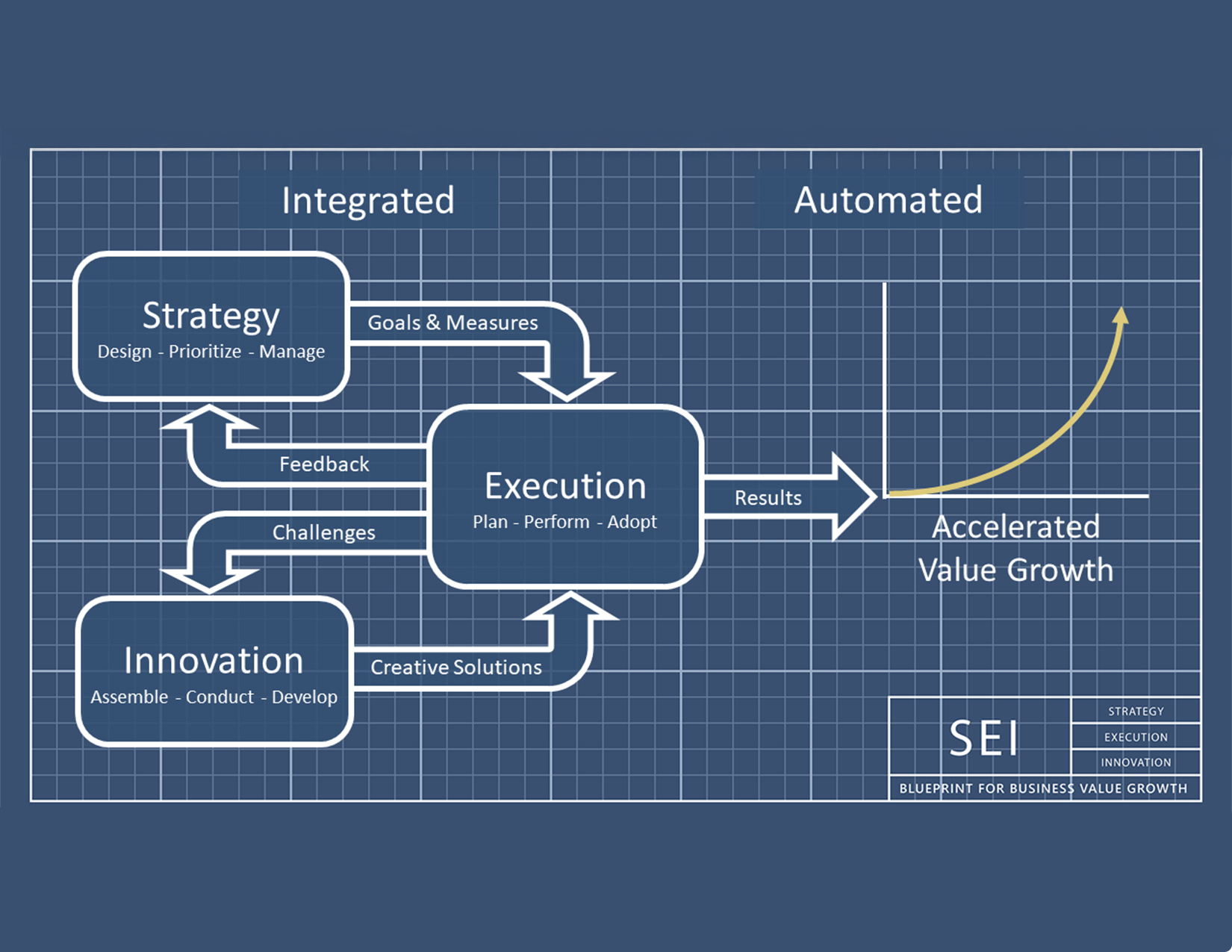

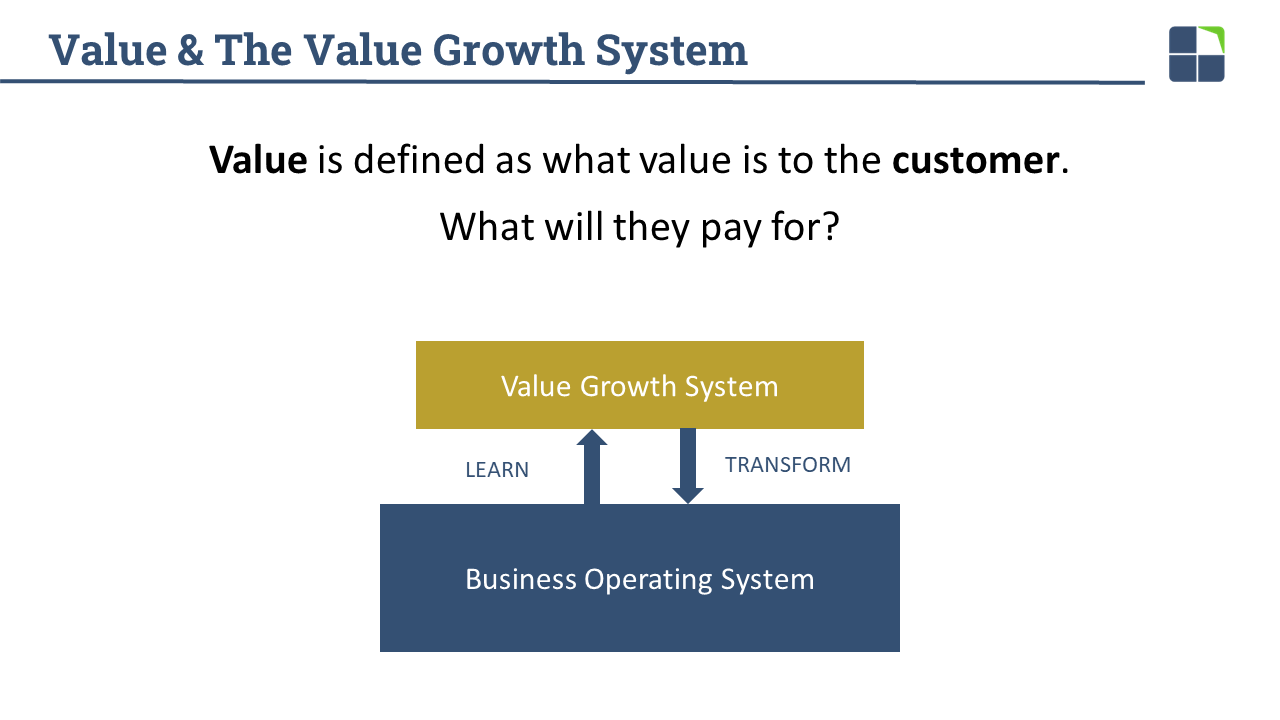

[post_content] =>  “Can an executive scientifically grow the value their company delivers to customers and thus company value?” It’s not often we encounter a solution provider aiming to answer a totally different question than others, but we just did. Pivotal Innovation has developed the Value Growth System, a combined SaaS software and services offering, to systemize value growth.

We are excited about the potential for this because business transformation has not been straightforward or reliably successful, and this begins to explain why. Also, the Value Growth System is both comprehensive and comprehensible. We believe visionary executives can benefit from even the fundamental concepts we learned in one call.

Pivotal Innovation, founded by serial entrepreneurs Kevin Fallon and Justin Griep, focuses on helping manufacturers go beyond a customer focus to grow customer value systematically. The company aims to help organizations make this transformation less costly and stressful. They call it “Growth as a Service.”

One big ‘aha’ here is that two connected but distinct systems make up a company. There is an operating system for delivering current value, which most companies have systematized well. There is also a value growth system for transformation that typically runs ad hoc (to the detriment of growth). Integrating these is crucial. Another big aha is that strategy is directional, not transformational. Transformation needs to incorporate execution and innovation as well as strategy.

“Can an executive scientifically grow the value their company delivers to customers and thus company value?” It’s not often we encounter a solution provider aiming to answer a totally different question than others, but we just did. Pivotal Innovation has developed the Value Growth System, a combined SaaS software and services offering, to systemize value growth.

We are excited about the potential for this because business transformation has not been straightforward or reliably successful, and this begins to explain why. Also, the Value Growth System is both comprehensive and comprehensible. We believe visionary executives can benefit from even the fundamental concepts we learned in one call.

Pivotal Innovation, founded by serial entrepreneurs Kevin Fallon and Justin Griep, focuses on helping manufacturers go beyond a customer focus to grow customer value systematically. The company aims to help organizations make this transformation less costly and stressful. They call it “Growth as a Service.”

One big ‘aha’ here is that two connected but distinct systems make up a company. There is an operating system for delivering current value, which most companies have systematized well. There is also a value growth system for transformation that typically runs ad hoc (to the detriment of growth). Integrating these is crucial. Another big aha is that strategy is directional, not transformational. Transformation needs to incorporate execution and innovation as well as strategy.

The Pivotal Innovator SaaS platform systematically ensures strategy, execution, and innovation work together. Most solution providers focus on just one element of this overall value growth system. Execution of current value is the most common focus for transactional and process software applications. Software such as ERP, PLM, SCM, and CRM aim to ensure things happen reliably in the current state. The Pivotal Innovator focuses on transforming to a desired future state, with closed-loop feedback among strategy, execution, and innovation.

Fallon claims they can change a company's culture in 30 days. The focus is on balancing transformation with current performance. The approach creates a common growth language across disciplines to help everyone focus on the growth gap, not just the current state. Because this is an enterprise-level transformation, no single discipline can “own” or manage growth.

Senior executives may relate to the consulting aspects of the offering and champion the software. They may also join mastermind groups to learn from each other. Pivotal Innovation is partnering with the Advanced Manufacturing Sciences Institute at Metropolitan State University of Denver to offer a 12-week educational program. By the third week, executives will have an executable strategy for the company based on priorities and will be accelerating growth and transforming culture.

The concepts of integrating and automating value growth came from Fallon’s years of research after a significant career in manufacturing automation and Lean supply chain solutions. They are not currently taught in most business schools. Yet, it appears this offering addresses the main stumbling blocks to value growth:

The Pivotal Innovator SaaS platform systematically ensures strategy, execution, and innovation work together. Most solution providers focus on just one element of this overall value growth system. Execution of current value is the most common focus for transactional and process software applications. Software such as ERP, PLM, SCM, and CRM aim to ensure things happen reliably in the current state. The Pivotal Innovator focuses on transforming to a desired future state, with closed-loop feedback among strategy, execution, and innovation.

Fallon claims they can change a company's culture in 30 days. The focus is on balancing transformation with current performance. The approach creates a common growth language across disciplines to help everyone focus on the growth gap, not just the current state. Because this is an enterprise-level transformation, no single discipline can “own” or manage growth.

Senior executives may relate to the consulting aspects of the offering and champion the software. They may also join mastermind groups to learn from each other. Pivotal Innovation is partnering with the Advanced Manufacturing Sciences Institute at Metropolitan State University of Denver to offer a 12-week educational program. By the third week, executives will have an executable strategy for the company based on priorities and will be accelerating growth and transforming culture.

The concepts of integrating and automating value growth came from Fallon’s years of research after a significant career in manufacturing automation and Lean supply chain solutions. They are not currently taught in most business schools. Yet, it appears this offering addresses the main stumbling blocks to value growth:

- Designing better strategy

- Achieving organizational alignment

- Balancing operating with transforming activity

- Engaging people

- Adding growth capability

- Executing successfully

We’re excited to kick off Propel Software's new “Office Hours” series of educational webinars. Our President, Jim Brown, will lead an interactive conversation with Zoetis Director of R&D, Greg Yow, and Propel VP, Tom Shoemaker. Together, they’ll discuss the state of the PLM market and the landscape for modern PLM solutions.

The webinar will look at the current state of the PLM market and then explore what companies should look for in a modern solution. Jim will share his research on the state of PLM including the benefits manufacturers can expect from PLM, what the current PLM implementation landscape looks like, the transition to the cloud, and requirements for supporting PLM processes well into the future. Greg will share his experience with global animal health company Zoetis and his broad design and PLM background. Tom will share his perspectives from his deep experience in the PLM industry and conversations with Propel customers.

Join this Propel-sponsored educational webinar on July 16 to join in the conversation and get your questions about the PLM market answered.

[post_title] => Evaluating Modern PLM Systems

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => modern-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2024-07-10 11:25:28

[post_modified_gmt] => 2024-07-10 15:25:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20439

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 20428

[post_author] => 2574

[post_date] => 2024-06-28 10:00:52

[post_date_gmt] => 2024-06-28 14:00:52

[post_content] =>

We’re excited to kick off Propel Software's new “Office Hours” series of educational webinars. Our President, Jim Brown, will lead an interactive conversation with Zoetis Director of R&D, Greg Yow, and Propel VP, Tom Shoemaker. Together, they’ll discuss the state of the PLM market and the landscape for modern PLM solutions.

The webinar will look at the current state of the PLM market and then explore what companies should look for in a modern solution. Jim will share his research on the state of PLM including the benefits manufacturers can expect from PLM, what the current PLM implementation landscape looks like, the transition to the cloud, and requirements for supporting PLM processes well into the future. Greg will share his experience with global animal health company Zoetis and his broad design and PLM background. Tom will share his perspectives from his deep experience in the PLM industry and conversations with Propel customers.

Join this Propel-sponsored educational webinar on July 16 to join in the conversation and get your questions about the PLM market answered.

[post_title] => Evaluating Modern PLM Systems

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => modern-plm

[to_ping] =>

[pinged] =>

[post_modified] => 2024-07-10 11:25:28

[post_modified_gmt] => 2024-07-10 15:25:28

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20439

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[8] => WP_Post Object

(

[ID] => 20428

[post_author] => 2574

[post_date] => 2024-06-28 10:00:52

[post_date_gmt] => 2024-06-28 14:00:52

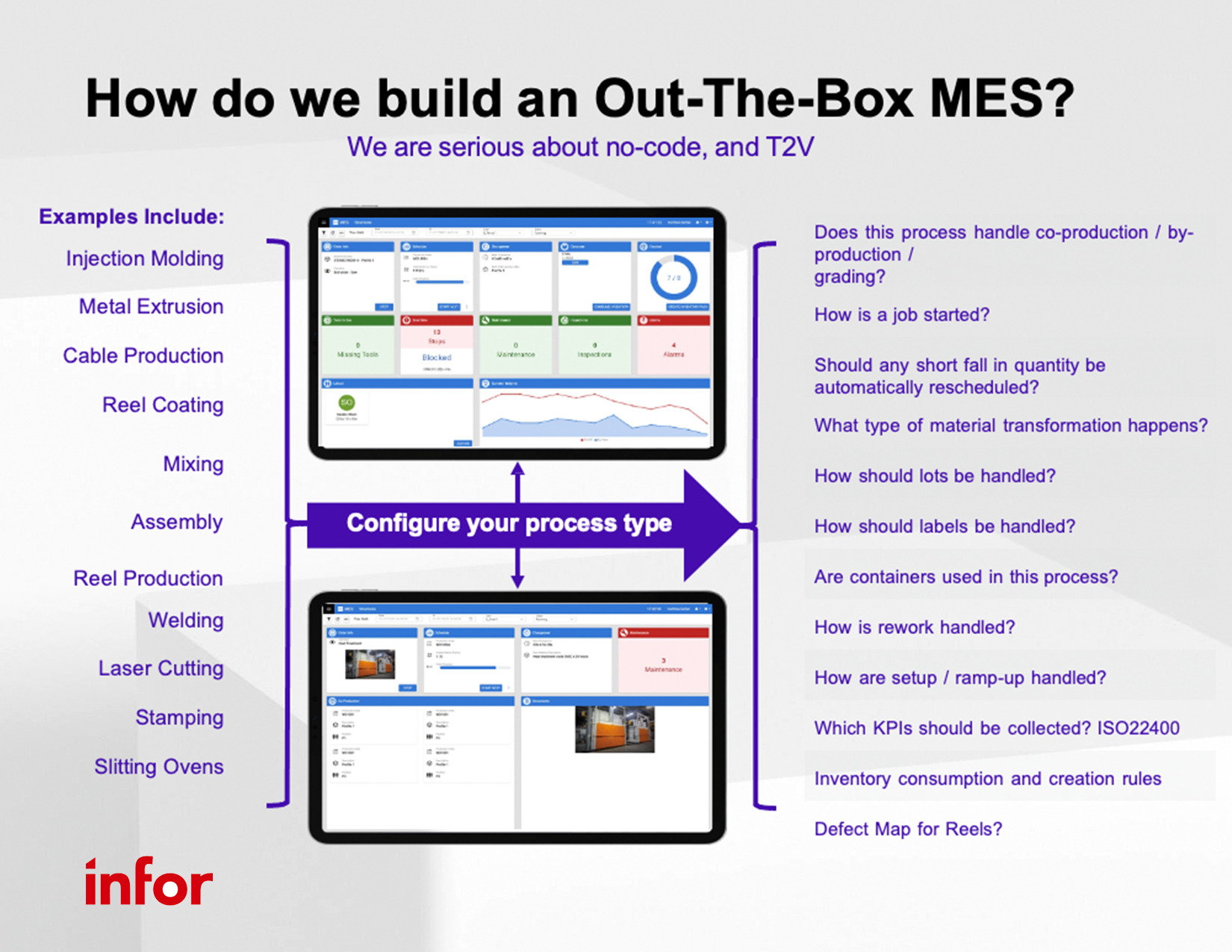

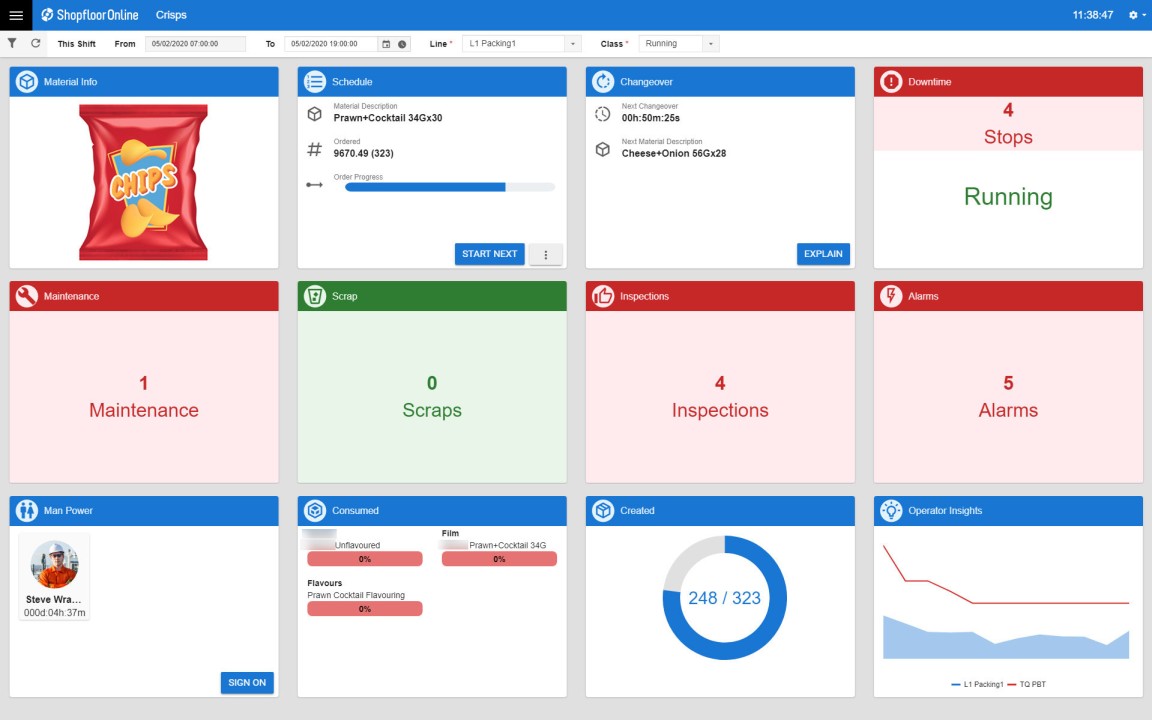

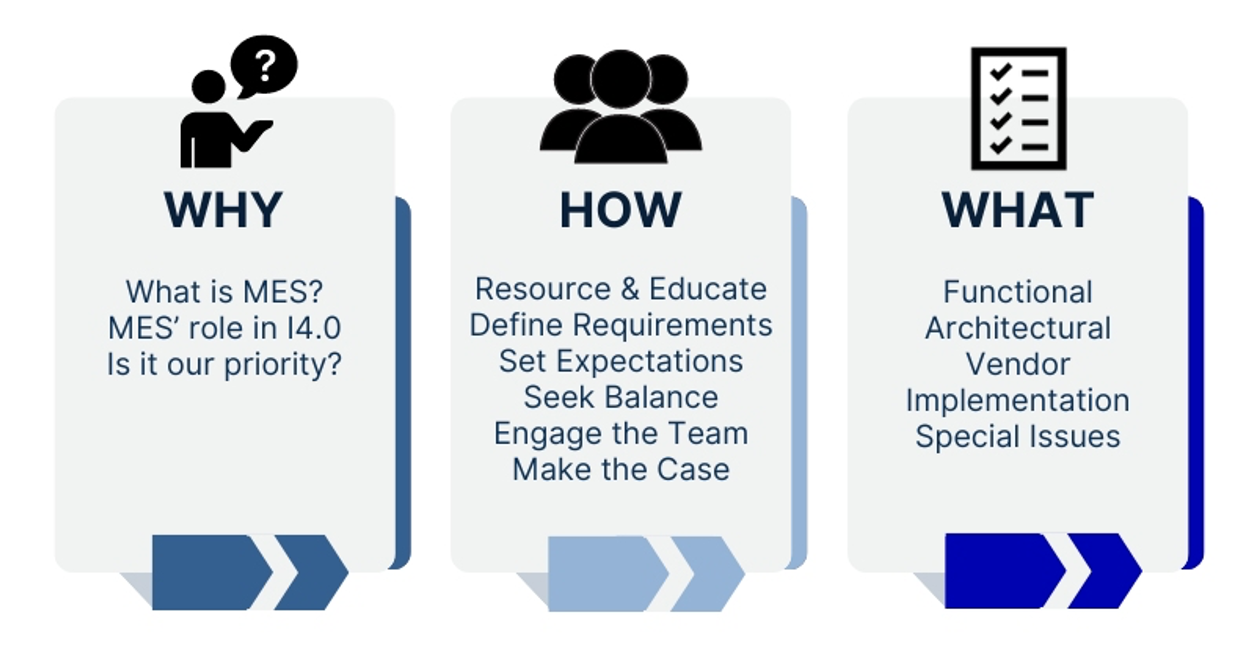

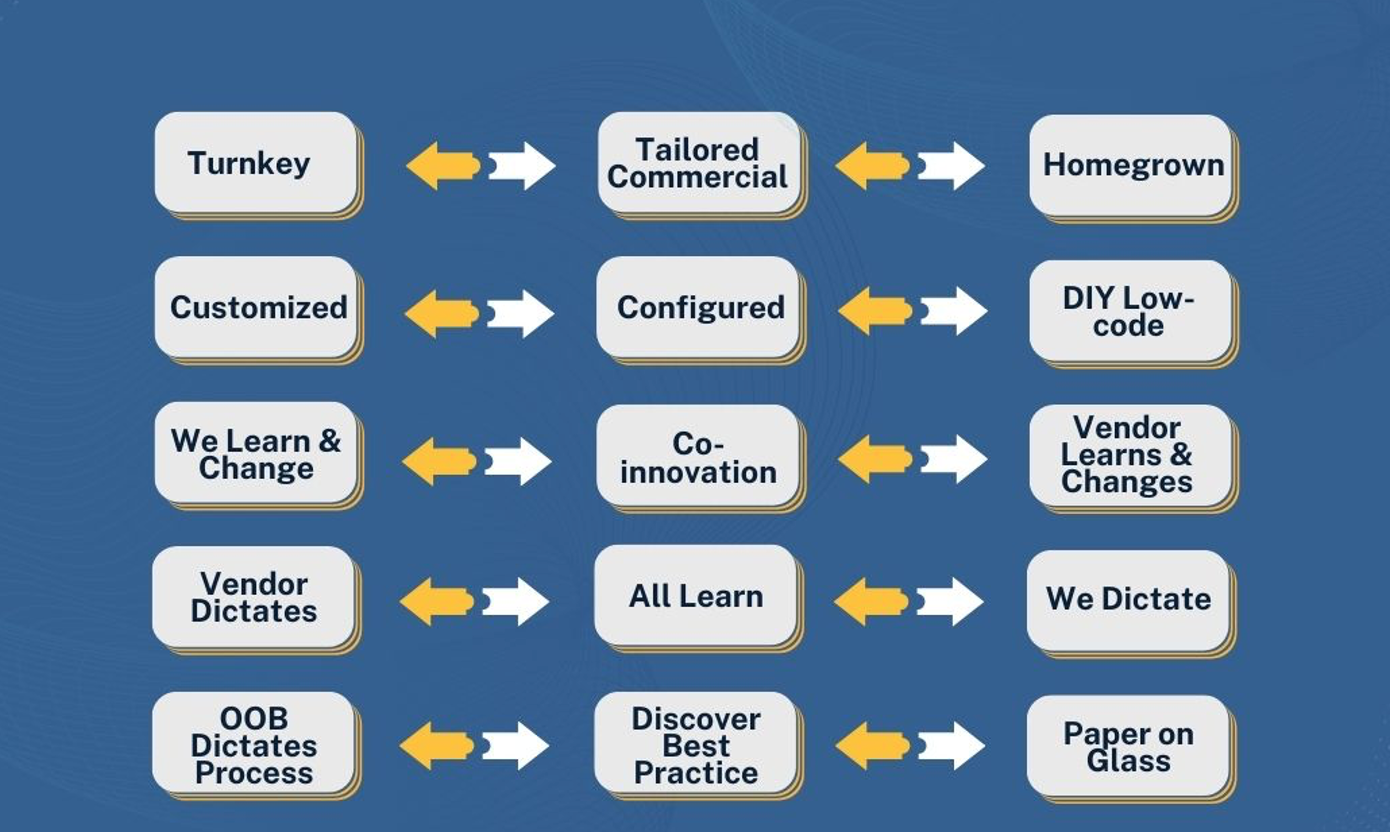

[post_content] =>  Can you shorten the time to value (T2V) for MES? In a recent briefing, Julie Fraser came to an understanding that Infor is working to do that with its no-code configuration approach. Infor MES comes from a heritage of encouraging customers to use the solution completely out of the box with no custom code. It may sound far-fetched, but they claim customers are doing that.

Can you shorten the time to value (T2V) for MES? In a recent briefing, Julie Fraser came to an understanding that Infor is working to do that with its no-code configuration approach. Infor MES comes from a heritage of encouraging customers to use the solution completely out of the box with no custom code. It may sound far-fetched, but they claim customers are doing that.

Infor MES’s approach is different, with many examples of “last mile” functionality plus built-in options that the manufacturer can select, rather than create. Newer examples of special functions using no-code include reel production including defect tracking and co-production variations for ovens, stamping, grading, reel slitting, and painting. Integrations and connections are also largely based on field- and expression-based mappings.

Infor’s MES covers all factory operations for a relatively wide variety of industries and production modes. Broad areas include production, quality, inventory, logistics, maintenance, tooling, and energy. This enables their ERP products to focus on their core functions and strengths, removing complexity from ERP and allowing MES to simplify operations.

The all-organically developed MES also supports frontline workers with a consistent look, feel, and view of everything in their production environment. The operator’s dashboard is built from pre-defined or user-configured “cards” with saved reports behind each. These reports can be combined for valuable views for each process, area, and role in the facility. Screens are built simply, knowing gloves and goggles are common for these users.

MES is integrated to many of the Infor ERP CloudSuites, but not tightly coupled. Standalone MES sales are still a substantial portion of the base. Yet, more complete integration is also boosting cross-selling to existing Infor ERP customers. Investment continues in Infor MES to solve more customer challenges.

MES is a differentiator for the Infor ERP suites. The ability to leverage the Infor OS Platform, which includes data lake, data fabric, robotic process automation, and Generative AI is a huge boost to the enterprise’s ability to make full use of MES data.

Infor MES is available with a choice of hosting options:

- Traditional on-premises.

- Enterprise - single tenant for global master data across multiple factories.

- Distributed Enterprise - central hosting of master data and reporting, but individual factory or regional instances for reliability, redundancy, and low latency.

Infor’s twice-a-year spring and fall product release cycle works for MES. The roadmap includes more configurability, extended mobility, and making the most of Infor innovations. The next release is scheduled to include integrations with Infor Document Management and new GenAI functionalities, for example.

Sometimes, a robust small software company’s acquisition by a much larger company works well for customers and employees. That appears to be the case with Infor’s MES, which was Lighthouse Systems (Shopfloor-Online) until late 2021. Infor has taken this product seriously. The company sees Infor MES adding substantial value to customers looking to achieve complete digital transformation of manufacturing operations.

Thank you, Jennifer Marzolf for arranging this briefing with MES mavens Matt Barber and Brandon Billingham. We look forward to following the MES and other Infor products' developments and successes in the market.

[post_title] => Infor Keeps Investing in Configurable Multi-Mode MES [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => infor-keeps-investing-in-mes [to_ping] => [pinged] => [post_modified] => 2024-07-01 15:31:36 [post_modified_gmt] => 2024-07-01 19:31:36 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20428 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [9] => WP_Post Object ( [ID] => 20388 [post_author] => 2574 [post_date] => 2024-06-20 10:00:44 [post_date_gmt] => 2024-06-20 14:00:44 [post_content] => How can smaller manufacturers chart effective automation strategies with their limited resources? That’s the topic of this Automation World article. In it, Tech-Clarity’s Julie Fraser and three other industry professionals offer suggestions for small manufacturers' automation approach to plan for and execute successful and cost-effective automation programs.

Automation World spoke with four industry experts: Jeff Payne, director of business development at AutomationDirect; Steve Bieszczat, CMO at DelmiaWorks; Caleb Funk, engagement engineer with ImaginIt Technologies; and Julie Fraser, vice president of research for operations and manufacturing at Tech-Clarity.

AW: How can smaller manufacturers identify specific challenges in their manufacturing processes to set achievable objectives for automation technology adoption?

Fraser: Most manufacturers have process experts who can identify the issues that are creating waste if you ask them the right questions. Asking the right questions often means challenging how things work. Typically, your most experienced people have created workarounds that enable the product to go through processes relatively smoothly and reliably, and they may no longer recognize the original issue. Once the issues to improve are identified, setting achievable objectives for automation may be obvious or may require an experienced automation engineer or system integrator to determine achievable objectives.

The article also covers how to:

How can smaller manufacturers chart effective automation strategies with their limited resources? That’s the topic of this Automation World article. In it, Tech-Clarity’s Julie Fraser and three other industry professionals offer suggestions for small manufacturers' automation approach to plan for and execute successful and cost-effective automation programs.

Automation World spoke with four industry experts: Jeff Payne, director of business development at AutomationDirect; Steve Bieszczat, CMO at DelmiaWorks; Caleb Funk, engagement engineer with ImaginIt Technologies; and Julie Fraser, vice president of research for operations and manufacturing at Tech-Clarity.

AW: How can smaller manufacturers identify specific challenges in their manufacturing processes to set achievable objectives for automation technology adoption?

Fraser: Most manufacturers have process experts who can identify the issues that are creating waste if you ask them the right questions. Asking the right questions often means challenging how things work. Typically, your most experienced people have created workarounds that enable the product to go through processes relatively smoothly and reliably, and they may no longer recognize the original issue. Once the issues to improve are identified, setting achievable objectives for automation may be obvious or may require an experienced automation engineer or system integrator to determine achievable objectives.

The article also covers how to:

- align technology goals and business strategies

- evaluate vendors

- estimate project costs

- create a timeline with realistic milestones

- prepare for challenges and setbacks

Tech-Clarity’s Julie Fraser was on the analyst panel of the Manufacturing Leadership Council’s (MLC’s) 20th anniversary Rethink conference. The panel looked back 20 years and forward 20 years in the journey to digital manufacturing. Julie’s perspective is that some things that seem new are not – like AI, which she wrote a report about in about 1990. That shows how many things must be in place technologically and in our mindset and culture.

Tech-Clarity’s Julie Fraser was on the analyst panel of the Manufacturing Leadership Council’s (MLC’s) 20th anniversary Rethink conference. The panel looked back 20 years and forward 20 years in the journey to digital manufacturing. Julie’s perspective is that some things that seem new are not – like AI, which she wrote a report about in about 1990. That shows how many things must be in place technologically and in our mindset and culture.

The digital transformation will also require a personal transformation. The key is to go after Smart with Heart. She also believes there is a “pot of gold” at the end of this journey. Like a leprechaun, rather than only seeing the material wealth there, we’ll want to ensure we do the manufacturing dance to celebrate.

Technology and Buzzing People

The panel – and the entire conference - touched on technology, including networking, materials handling, enterprise and plant software, AI, and Generative AI. Every presentation also emphasized innovation, processes, workforce engagement, and leadership skills. The more new technologies we employ in manufacturing, the more conversation it generates around human beings. People are, and it seems will continue to be, at the center of manufacturing – even as it is increasingly automated and autonomous.

One of the notable features of this conference was the level of engagement in the MLC community. These leaders and their teams eagerly and openly engaged with each other and with the technology and services providers. It was rare to find someone standing alone for even a short time—we were all sharing and learning with each other.

The MLC is part of the National Association of Manufacturers - NAM (NAM), but people from around the world were there, sharing their stories and competing for awards. This conference has cleverly incorporated an awards gala to ensure that leaders and their teams who are nominated come, share their stories, and learn from one another. When one company shared information, you could see groups from other companies discussing it with each other.

Manufacturer Examples

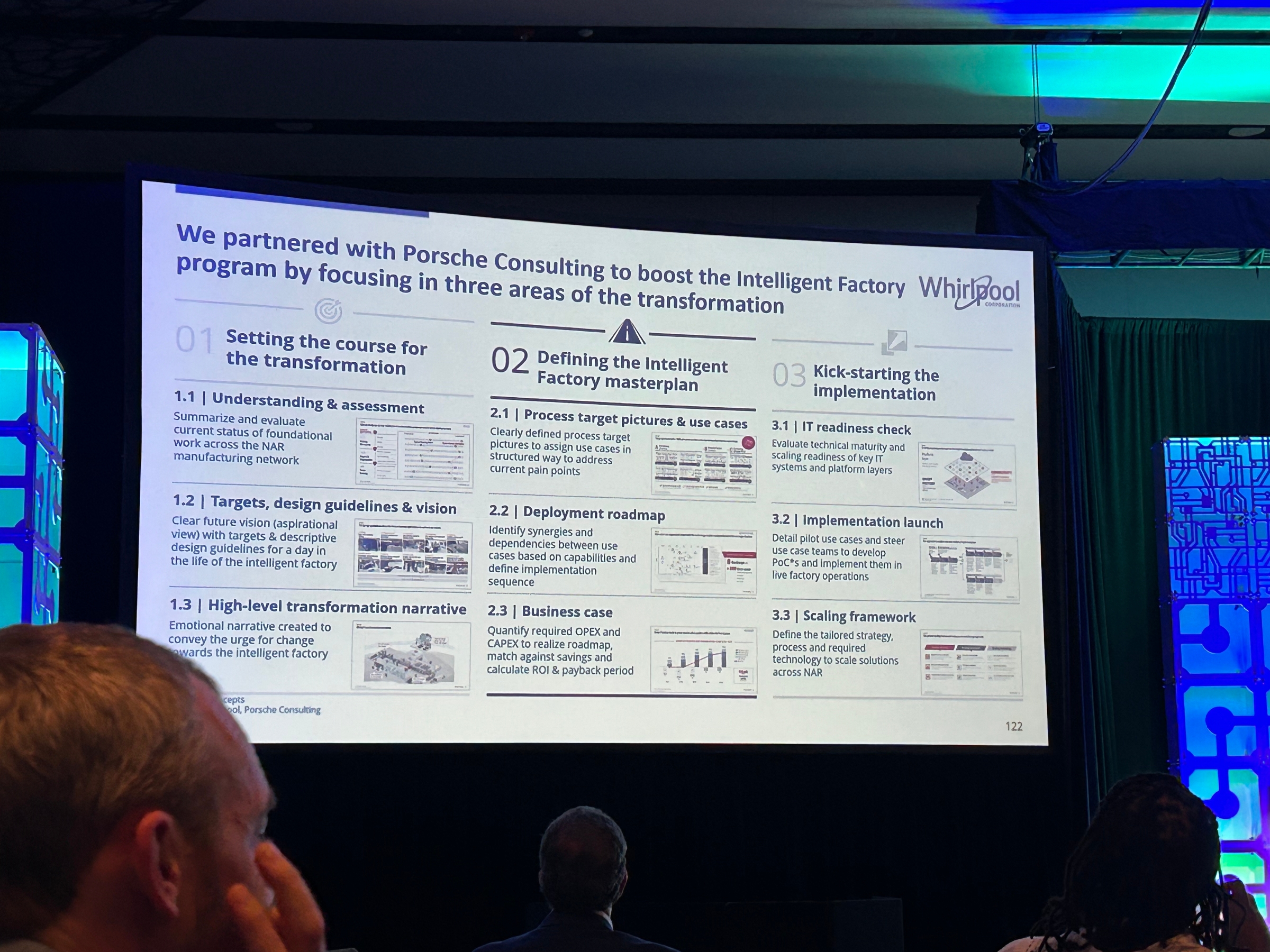

Some award nominees and speakers, like Matthew Herman of Whirlpool, are turning the corner in understanding how to gain benefits while building toward scalability and enterprise-wide rollout. This scaling seems to often involve changes to the organizational structure and staffing.

Becky Sidelinger of Flex shared the journey to extreme contract manufacturing flexibility in their production operations to match product innovation. They use digital twins of their end-to-end manufacturing lines, machine learning, and AR/VR goggles to guide work. Beyond that, she discussed effectively bringing suppliers into the sustainability frame. A key takeaway was to “be generous with your time” as a leader.

J. Kirby Best of Bespoke talked about his startup custom clothing company, Bespoke. Here, autonomous robots work with people, and real-time location tracking and AI are used to gain productivity at the point of activity. This truly innovative approach to garment manufacturing is based on “getting out of your mind how anything was done before.” The result is essentially infinite selection in zero time.

Craig Stephen Slavtcheff of Campbell’s focused on their agile approach. It is not just meeting hygiene, and not just in R&D, but a deep approach to agile in food and its supply chain. Modifying existing unit operations to live up to the design brief has been crucial. Deep change management plays into ensuring data is considered an essential part of every job.

Prasad Rajiv of forklift maker Hyster-Yale talked about making great strides toward smart and autonomous products. The ability to use 5G communications and interact effectively with WMS, MES, people, and manual operations such as picking. Bringing decisions closer to the action was part of it, zero emissions another.

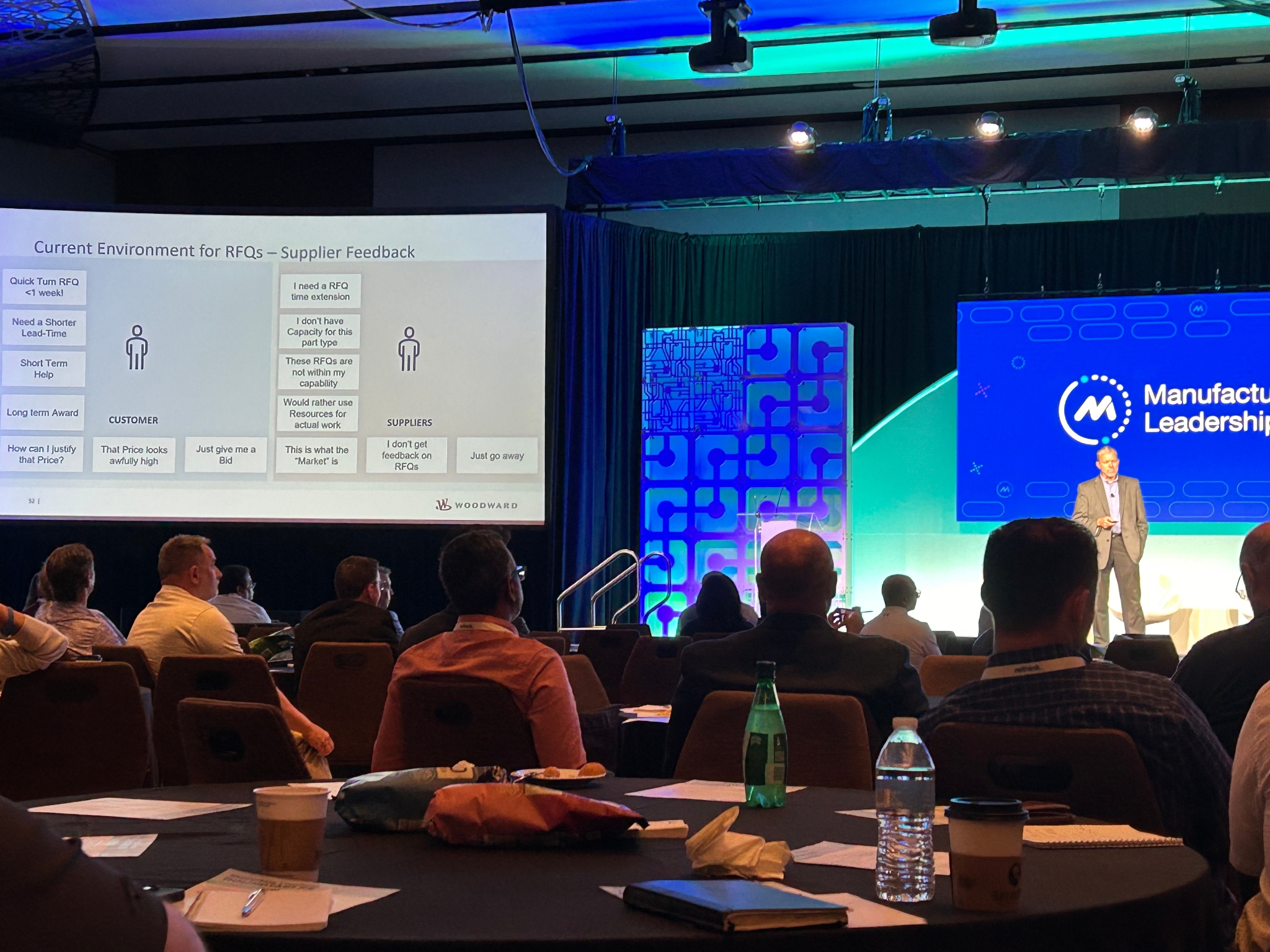

Chris Platz of Woodward talked about their journey to transform supplier collaboration, even with their many small suppliers. They have built a digital twin of suppliers’ capability and capacity to show what to send where and when. In about a week, they can set up a digital twin of a supplier factory and begin working with the simulation-selected best partner on a 1:1 basis based on pre-negotiated pricing.

The next-generation leaders panel dispelled misunderstandings. Megan McCarthy of General Motors discussed two-way feedback and GM’s commitment to electric vehicles. Jonathan Miller from St. Gobain Life Sciences saw that machine connectivity foundations were a tough sell, but they delivered benefits and removed drudge work once in place. His advice was, “Make everyone comfortable failing.” Angela Accurso, MPA of MdX talked about mentorship and sponsorship, and Marlon Alberto Gonzalez Martinez of IBM pushed for “giving a voice to young people and their ideas.”

Takeaways

Takeaways

Here are some of Julie’s takeaways and highlights from the two days she attended the conference.

- Working with consultants and system integrators, manufacturers are already gaining significant benefits from AI and Generative AI. Knowledge management and retention is a good application. Yet they are not the right fit for every problem.

- Scalability continues to be daunting, and while some leaders feel they are now on a good path, this path typically involves failures and learning from shortcomings.

- Technical debt is an important issue for companies to consider regarding their legacy systems and how best to avoid it with new investments.

- IT and OT are learning to work together in the most successful companies –the results can be more autonomous operations and more effective people.

- All five generations of current workers have valuable contributions—the company culture and its leaders must encourage those ideas so all can support each other.

- New technology, processes, and thinking are improving quality, efficiency, cost, and success both inside companies and across their ecosystems.

It is truly an exciting time to be in manufacturing. The transformation is underway, and while there are some challenges, the gains are tremendous. Thank you, Manufacturing Leadership Council and David R. Brousell, for hosting us there!

[post_title] => New Thinking from MLC Rethink 2024 [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => new-mlc-rethink-2024 [to_ping] => [pinged] => [post_modified] => 2024-09-20 13:05:33 [post_modified_gmt] => 2024-09-20 17:05:33 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20402 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [11] => WP_Post Object ( [ID] => 20327 [post_author] => 2 [post_date] => 2024-06-11 09:00:24 [post_date_gmt] => 2024-06-11 13:00:24 [post_content] => How can manufacturers leverage search-powered GenAI to connect their digital thread to improve engineering and service performance? Join our webinar on as we discuss how to get more value from enterprise systems like PLM by tapping into the data that already exists.

Rapid product development and fast service response are critical to profitability in the manufacturing industry. Engineers, product developers, and technicians need fast access to accurate information to develop and support today’s complex products. But today’s product digital thread data is hard to access, creating inefficiencies, rework, and errors across the product lifecycle.

The systems that make up the product digital thread, which often include one or more PLM systems, are complex and typically disconnected. How can advanced technologies like Search-powered GenAI help manufacturers tap into the product and service intelligence they need to get products to market fast and support them efficiently?

Join Jim Brown, President of Digital Innovation Research at Tech-Clarity, and Jeff Evernham, Chief Technology Evangelist at Sinequa, to learn:

How can manufacturers leverage search-powered GenAI to connect their digital thread to improve engineering and service performance? Join our webinar on as we discuss how to get more value from enterprise systems like PLM by tapping into the data that already exists.

Rapid product development and fast service response are critical to profitability in the manufacturing industry. Engineers, product developers, and technicians need fast access to accurate information to develop and support today’s complex products. But today’s product digital thread data is hard to access, creating inefficiencies, rework, and errors across the product lifecycle.

The systems that make up the product digital thread, which often include one or more PLM systems, are complex and typically disconnected. How can advanced technologies like Search-powered GenAI help manufacturers tap into the product and service intelligence they need to get products to market fast and support them efficiently?

Join Jim Brown, President of Digital Innovation Research at Tech-Clarity, and Jeff Evernham, Chief Technology Evangelist at Sinequa, to learn:

- How much time is wasted searching for product data and preparing data for others to do their jobs.

- Why it’s hard to access digital thread data from today’s multiple Enterprise applications.

- How GenAI and enterprise search can reduce product development times and improve time to market.

- How these advanced technologies can unlock service intelligence to improve MRO performance and profitability.

Will connected medical devices make the Star Trek medical tricorders a reality in healthcare?

A few decades ago, Star Trek’s tricorders were complete science fiction – only in the imagination could a device perform a simple scan and offer a full medical diagnosis of any ailment. While we may not be quite there yet, today’s connected medical devices are getting close to making that a reality and, in some cases, have already delivered. In fact, connected medical devices have come so far, they can provide medical treatments, diagnostics, and real-time monitoring that would have been considered science fiction not too long ago. Connected medical devices will revolutionize healthcare by advancing the quality of patient care, lowering healthcare costs, and improving people's lives.

To learn more, read our guest post that:

Will connected medical devices make the Star Trek medical tricorders a reality in healthcare?

A few decades ago, Star Trek’s tricorders were complete science fiction – only in the imagination could a device perform a simple scan and offer a full medical diagnosis of any ailment. While we may not be quite there yet, today’s connected medical devices are getting close to making that a reality and, in some cases, have already delivered. In fact, connected medical devices have come so far, they can provide medical treatments, diagnostics, and real-time monitoring that would have been considered science fiction not too long ago. Connected medical devices will revolutionize healthcare by advancing the quality of patient care, lowering healthcare costs, and improving people's lives.

To learn more, read our guest post that:

- Defines connected medical devices and shares examples

- Explains how they improve the quality of healthcare

- Discusses the future of connected medical devices

- Includes video snip-its explaining how connected medical devices have helped Fresenius improve patient outcomes

[post_title] => How Connected Medical Devices Will Revolutionize Healthcare

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => connected-medical-devices

[to_ping] =>

[pinged] =>

[post_modified] => 2024-06-12 15:09:21

[post_modified_gmt] => 2024-06-12 19:09:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20351

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 20325

[post_author] => 2574

[post_date] => 2024-06-07 10:00:24

[post_date_gmt] => 2024-06-07 14:00:24

[post_content] =>

[post_title] => How Connected Medical Devices Will Revolutionize Healthcare

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => connected-medical-devices

[to_ping] =>

[pinged] =>

[post_modified] => 2024-06-12 15:09:21

[post_modified_gmt] => 2024-06-12 19:09:21

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20351

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[13] => WP_Post Object

(

[ID] => 20325

[post_author] => 2574

[post_date] => 2024-06-07 10:00:24

[post_date_gmt] => 2024-06-07 14:00:24

[post_content] =>  What steps is your company taking to make your supply chain more sustainable? Join our community discussion on Wednesday, June 12 from 11AM-12PM EST hear Julie Fraser facilitate this conversation and learn from each other.

Nearly every company has sustainability initiatives now. The era of greenwashing is fading away. So what can you do, and how will it impact your business? The pressures and expectations vary by industry and company. Please come to share; what you’ve done already may help to inform others and accelerate our entire manufacturing economy toward greater sustainability success.

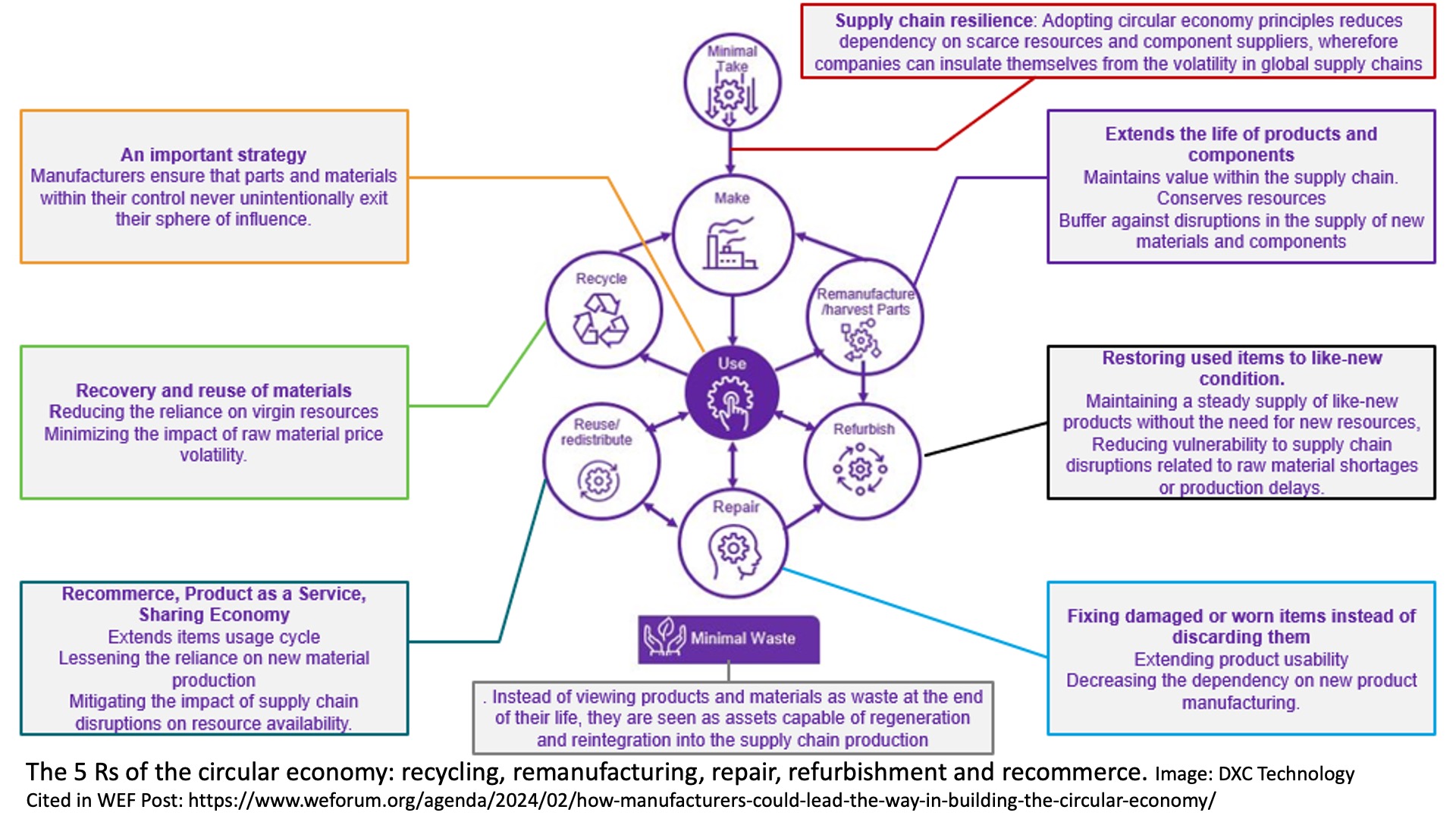

The World Economic Forum claims that the circular economy will be good for your supply chain, and lower the risk. Are you finding that? Are you seeing benefits? Are your suppliers ready to step into this arena with you? How do you measure environmental impact, and where do you start?

Consumers and customers are seeking suppliers who support their environmental sustainability policies. Yet, as a manufacturer, that means taking both internal and partner measures. In emissions terms, we can consider 1 (direct), 2 (directly used such as from the local power plants fueling factories and distribution centers), and 3 (in our value network).

Join us to discuss your experiences and questions such as:

What steps is your company taking to make your supply chain more sustainable? Join our community discussion on Wednesday, June 12 from 11AM-12PM EST hear Julie Fraser facilitate this conversation and learn from each other.

Nearly every company has sustainability initiatives now. The era of greenwashing is fading away. So what can you do, and how will it impact your business? The pressures and expectations vary by industry and company. Please come to share; what you’ve done already may help to inform others and accelerate our entire manufacturing economy toward greater sustainability success.

The World Economic Forum claims that the circular economy will be good for your supply chain, and lower the risk. Are you finding that? Are you seeing benefits? Are your suppliers ready to step into this arena with you? How do you measure environmental impact, and where do you start?

Consumers and customers are seeking suppliers who support their environmental sustainability policies. Yet, as a manufacturer, that means taking both internal and partner measures. In emissions terms, we can consider 1 (direct), 2 (directly used such as from the local power plants fueling factories and distribution centers), and 3 (in our value network).

Join us to discuss your experiences and questions such as:

- How are you moving to greener practices?

- What areas have you found easiest to improve? Energy, materials, emissions, supply routes, etc.?

- Are you working to participate in the circular economy with recycled materials, re-use, return, and recycling programs for your products?

- How are you measuring your environmental impact? That of your suppliers, logistics partners, and distributors or retail partners?

- What criteria come into prioritizing sustainability projects?

- What is working to ensure partners actually live up to your requests and expectations?

- Is sustainability part of your business and operating KPI set? Your Continuous Improvement programs?

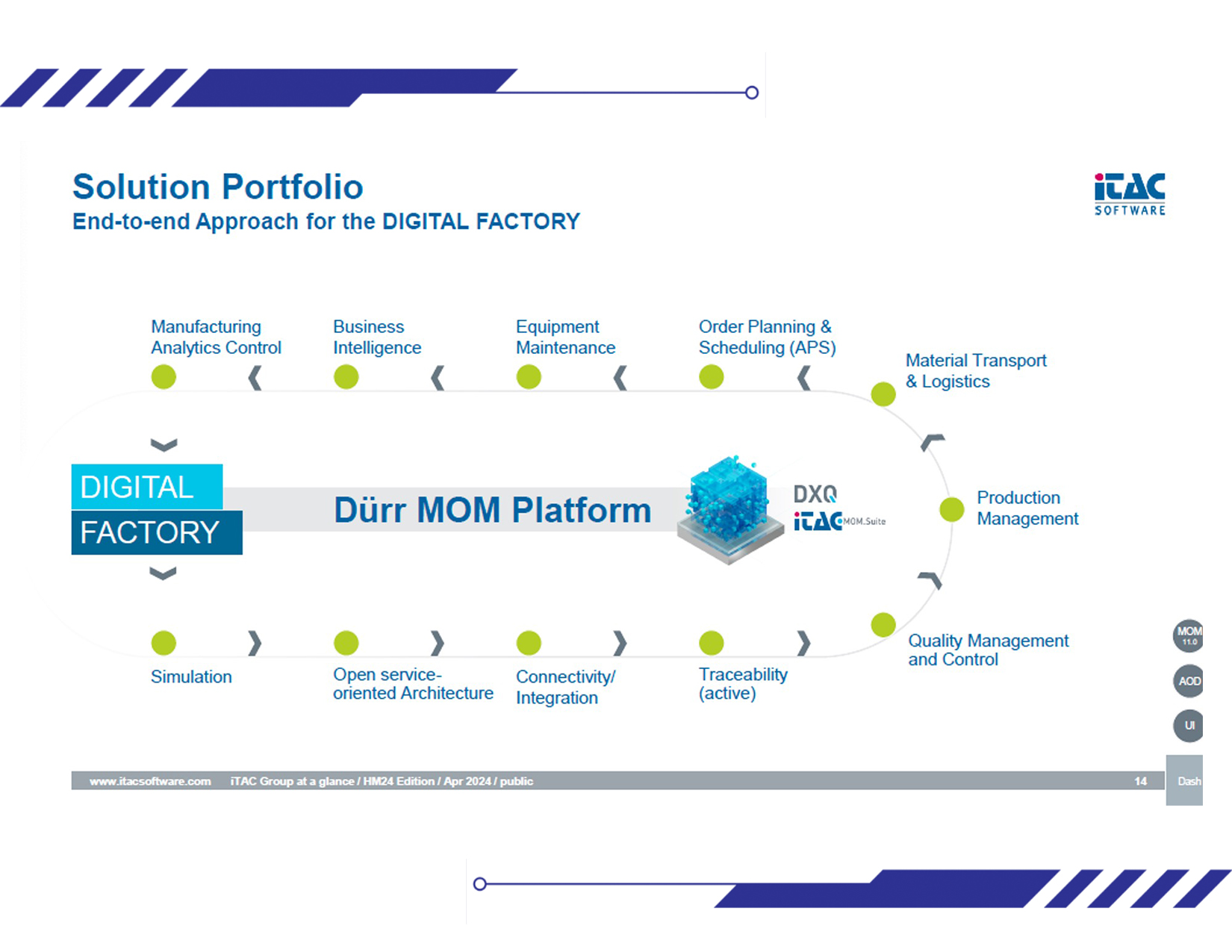

Based on our recent update briefing with iTAC board member Martin Heinz, we have an exhilarating view of how high and low an MES player can reach. With an offering that includes strong integration to sensors and IIoT, controls, SCADA, and ISA 95 Level 3 MES/MOM, iTAC shares this depth with only a few other players in the market. They talk about an end-to-end approach for the digital factory.

iTAC has long been a leading MES/MOM provider, and they continue to upgrade the MOM Suite, with Version 11 due out in the 2nd Quarter 2024. Beyond the original product, this release adds to both the platform and the application suite. It moves analytics forward and allows customers to choose from hosting options: on-premise, cloud, or hybrid.

iTAC built in low code for extensions a few years ago. Now, beyond the standard client and customer-specific clients, they offer a client framework. With the framework, the standard client can get a customer-dedicated plug-in. This becomes a single client for customization that can also upgrade with new releases. The company has also added a ChatGPT-based product, Ask Our Doc, to make their technical documentation easier to use.

And so much more. iTAC can now claim it goes from level 0 to level 3 of the ISA 95 model. This claim holds water even beyond Cogiscan factory connectivity to nearly anything. Newer integration with DXQ SCADA from Dürr deepen the level 1 and 0 story. They can also begin to address process industries through new Dürr acquisition ANT Solution. While some companies get buried or neglected in larger organizations, iTAC has gained significant advantages from being part of Dürr.

Machine integration and bi-directional communication is through an API layer. The combination of these features and Dürr-family products enables iTAC customers to integrate to machines, IIoT, and other enterprise software as well as define workflows and create custom-specific clients. With Dürr, MANZ and GROB, iTAC also supports closed loop continuous improvement (CI) processes for battery production.

Despite the richness and equipment connectivity, iTAC fosters customer enablement for independence. For example, one major customer who started over 20 years ago now implements the systems by themselves, which for many MES customers with automation has been a difficult dream to fulfill. At the same time, iTAC has expanded its professional services, enabling it to better serve customers globally.

We’re looking forward to following iTAC’s progress in the market, bolstered by the entire iTAC Software AG and Dürr Group portfolio. Thank you, Martin Heinz, for keeping us updated even though we could not be at Hannover Messe to see it all.

[post_title] => iTAC Reaches to New Heights and Depths [post_excerpt] => [post_status] => publish [comment_status] => open [ping_status] => open [post_password] => [post_name] => itac-reaches-new-heights [to_ping] => [pinged] => [post_modified] => 2024-06-06 19:30:16 [post_modified_gmt] => 2024-06-06 23:30:16 [post_content_filtered] => [post_parent] => 0 [guid] => https://tech-clarity.com/?p=20312 [menu_order] => 0 [post_type] => post [post_mime_type] => [comment_count] => 0 [filter] => raw ) [15] => WP_Post Object ( [ID] => 20294 [post_author] => 2 [post_date] => 2024-06-04 10:00:47 [post_date_gmt] => 2024-06-04 14:00:47 [post_content] => The integration of advanced digital technologies and data-driven approaches in the laboratory provides greater efficiency and improved accuracy in scientific research. Innovative technologies are enabling scientists to capture and extract novel insights from their experiments, optimize experiment design, and identify important patterns in their data. Implementing digital technologies in the lab requires proper planning and a strategic approach to maximize the benefits.

In this Genetic Engineering and Biotechnology News webinar, industry experts Jim Brown, Kirsten Gesenberg, and Stephen Hayward provide a comprehensive approach to digitally transforming the lab. During the webinar, you’ll learn how to enhance lab operations with streamlined workflows and improved data management, how to boost overall business performance through increased efficiency and productivity, and how to navigate the digital transformation journey with confidence.

Key topics covered in the webinar include:

The integration of advanced digital technologies and data-driven approaches in the laboratory provides greater efficiency and improved accuracy in scientific research. Innovative technologies are enabling scientists to capture and extract novel insights from their experiments, optimize experiment design, and identify important patterns in their data. Implementing digital technologies in the lab requires proper planning and a strategic approach to maximize the benefits.

In this Genetic Engineering and Biotechnology News webinar, industry experts Jim Brown, Kirsten Gesenberg, and Stephen Hayward provide a comprehensive approach to digitally transforming the lab. During the webinar, you’ll learn how to enhance lab operations with streamlined workflows and improved data management, how to boost overall business performance through increased efficiency and productivity, and how to navigate the digital transformation journey with confidence.

Key topics covered in the webinar include:

- Five key areas that impact lab integration success.

- How to optimize people, processes, and technology for peak performance.

- Understanding the importance of a common data model for seamless information flow.

[post_title] => Unlock Efficiency with 5 Dimensions of Lab Digital Transformation

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => lab-digital-transformation-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2024-06-06 19:25:41

[post_modified_gmt] => 2024-06-06 23:25:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20294

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 20268

[post_author] => 2574

[post_date] => 2024-05-31 10:00:44

[post_date_gmt] => 2024-05-31 14:00:44

[post_content] =>

[post_title] => Unlock Efficiency with 5 Dimensions of Lab Digital Transformation

[post_excerpt] =>

[post_status] => publish

[comment_status] => open

[ping_status] => open

[post_password] =>

[post_name] => lab-digital-transformation-webinar

[to_ping] =>

[pinged] =>

[post_modified] => 2024-06-06 19:25:41

[post_modified_gmt] => 2024-06-06 23:25:41

[post_content_filtered] =>

[post_parent] => 0

[guid] => https://tech-clarity.com/?p=20294

[menu_order] => 0

[post_type] => post

[post_mime_type] =>

[comment_count] => 0

[filter] => raw

)

[16] => WP_Post Object

(

[ID] => 20268

[post_author] => 2574

[post_date] => 2024-05-31 10:00:44

[post_date_gmt] => 2024-05-31 14:00:44

[post_content] =>  Can manufacturers use existing data to instantly improve profitability and customer satisfaction? Join the webinar on June 12 to hear experts from Magic Software FactoryEye and their partner Sugar CRM along with Tech-Clarity’s Julie Fraser discuss whether this is a pipe dream or reality. Learn what it takes to have this data-based lever for business results at your decision-makers’ fingertips.

Our panel of experienced manufacturing software industry veterans will discuss:

Can manufacturers use existing data to instantly improve profitability and customer satisfaction? Join the webinar on June 12 to hear experts from Magic Software FactoryEye and their partner Sugar CRM along with Tech-Clarity’s Julie Fraser discuss whether this is a pipe dream or reality. Learn what it takes to have this data-based lever for business results at your decision-makers’ fingertips.

Our panel of experienced manufacturing software industry veterans will discuss: